ASTM A813/A813M-95e2

(Specification)Standard Specification for Single- or Double-Welded Austenitic Stainless Steel Pipe

Standard Specification for Single- or Double-Welded Austenitic Stainless Steel Pipe

General Information

Standards Content (Sample)

e2

Designation: A 813/A 813M – 95 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Single- or Double-Welded Austenitic Stainless Steel Pipe

This standard is issued under the fixed designation A 813/A 813M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—The Celsius conversion in 5.2.4 was added editorially in May 1996.

2

e NOTE—The UNS designation N08367 was added to 5.2.1 in July 1996.

1. Scope 1.6 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

1.1 This specification covers two classes of fit-up and

SI units are shown in brackets. The values stated in each

alignment quality straight-seam single- or double-welded aus-

system are not exact equivalents; therefore, each system must

tenitic steel pipe intended for high-temperature and general

be used independently of the other. Combining values from the

corrosive service.

two systems may result in nonconformance with the specifi-

NOTE 1—When the impact test criterion for a low-temperature service

cation. The inch-pound units shall apply unless the “M”

would be 15 ft·lbf [20 J] energy absorption or 15 mils [0.38 mm] lateral

designation of this specification is specified in the order.

expansion, some of the austenitic stainless steel grades covered by this

specification are accepted by certain pressure vessel or piping codes

2. Referenced Documents

without the necessity of making the actual test. For example, Grades 304,

304L, and 347 are accepted by the ASME Pressure Vessel Code, Section

2.1 ASTM Standards:

VIII Division 1, and by the Chemical Plant and Refinery Piping Code,

A 262 Practices for Detecting Susceptibility to Intergranu-

ANSI B31.3 for service at temperatures as low as −425°F [−250°C]

2

lar Attack in Austenitic Stainless Steels

without qualification by impact tests. Other AISI stainless steel grades are

A 370 Test Methods and Definitions for Mechanical Testing

usually accepted for service temperatures as low as −325°F [−200°C]

2

of Steel Products

without impact testing. Impact testing may, under certain circumstances,

A 530/A 530M Specification for General Requirements for

be required. For example, materials with chromium or nickel content

3

outside the AISI ranges, and for material with carbon content exceeding Specialized Carbon and Alloy Steel Pipe

0.10 %, are required to be impact tested under the rules of ASME Section

A 751 Test Methods, Practices, and Terminology for

2,3

VIII Division 1 when service temperatures are lower than −50°F [−45°C]

Chemical Analysis of Steel Products

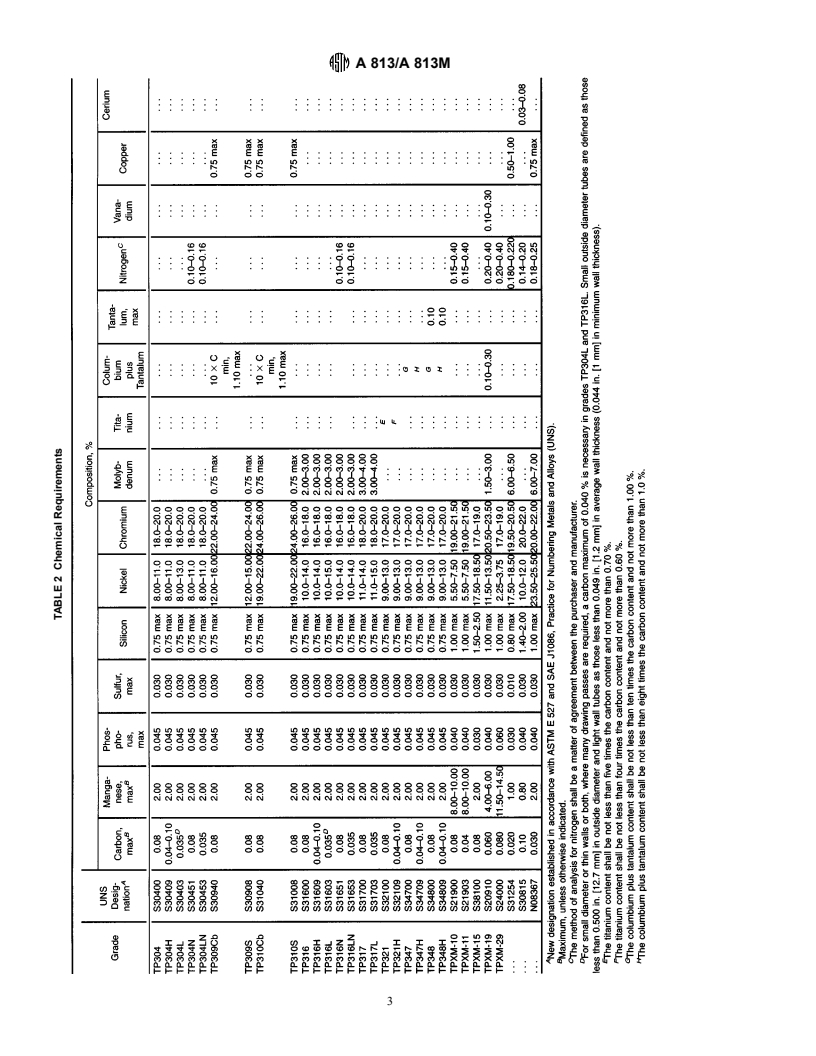

1.2 Grades TP304H, TP304N, TP316H, TP316N, TP321H, E 381 Method of Macroetch Testing, Inspection, and Rating

Steel Products, Comprising Bars, Billets, Blooms, and

TP347H, and TP348H are modifications of Grades TP304,

4

TP316, TP321, TP347, and TP348, and are intended for Forgings

3

E 527 Practice for Numbering Metals and Alloys (UNS)

high-temperature service.

1.3 Two classes of pipe are covered as follows: 2.2 ANSI Standards:

5

B1.20.1 Pipe Threads, General Purpose

1.3.1 Class SW—Pipe, single-welded with no addition of

5

filler metal and B36.10 Welded and Seamless Wrought Steel Pipe

5

1.3.2 Class DW—Pipe, double-welded with no addition of

B36.19 Stainless Steel Pipe

filler metal. 2.3 ASME Boiler and Pressure Vessel Code:

6

1.4 Optional supplementary requirements are provided for

Section VIII Division 1, Pressure Vessels

pipe where a greater degree of testing is desired. These

supplementary requirements call for additional tests to be made 3. Ordering Information

and, when desired, one or more of these may be specified in the

3.1 Orders for material under this specification should

order.

include the following as required, to describe the desired

1.5 Table 1 lists the dimensions of welded stainless steel

material adequately:

pipe as shown in ANSI B36.19. Pipe having other dimensions

3.1.1 Quantity (feet, centimetres, or number of lengths),

may be furnished provided such pipe complies with all other

requirements of this specification.

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 01.01.

1 4

This specification is under the jurisdiction of ASTM Committee A-1 on Steel, Annual Book of ASTM Standards, Vol 03.03.

5

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee Available from American National Standards Institute, 11 West 42nd St., 13th

A01.10 on Steel Tubing. Floor, New York, NY 10036.

6

Current edition approved Nov. 10, 1995. Published February 1996. Originally Available from American Society of Mechanical Engineers, 345 E. 47th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.