ASTM B101-12(2019)

(Specification)Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

ABSTRACT

This specification covers ounce-weight thick lead-coated copper sheets and strips in flat lengths or in coils. These materials are recommended for use in roofing, flashing, gutters, downspouts and general sheet metalwork in building constructions but not for electrical applications. This standard contains information on acceptable chemical compositions and mechanical properties of the copper sheets or strips and the lead coating deposited by hot dipping.

SCOPE

1.1 This specification establishes the requirements for lead-coated copper sheet and strip in flat lengths (or in coils) in ounce-weight thicknesses for roofing, flashing, gutters, downspouts, and for the general sheet metalwork in building construction. The lead coating is applied by hot dipping.

1.2 Products produced to this specification are not intended for electrical applications.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 1: A companion specification for copper sheet and strip for building construction is Specification B370.

1.4 The following hazard caveat pertains to the test method portion, Section 17, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B101 −12 (Reapproved 2019)

Standard Specification for

Lead-Coated Copper Sheet and Strip for Building

1

Construction

This standard is issued under the fixed designation B101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* B248 Specification for General Requirements for Wrought

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

1.1 This specification establishes the requirements for lead-

Bar

coated copper sheet and strip in flat lengths (or in coils) in

B370 Specification for Copper Sheet and Strip for Building

ounce-weight thicknesses for roofing, flashing, gutters,

Construction

downspouts, and for the general sheet metalwork in building

B846 Terminology for Copper and Copper Alloys

construction. The lead coating is applied by hot dipping.

B950 Guide for Editorial Procedures and Form of Product

1.2 Products produced to this specification are not intended

Specifications for Copper and Copper Alloys

for electrical applications.

E8/E8M Test Methods for Tension Testing of Metallic Ma-

terials

1.3 Units—The values stated in inch-pound units are to be

regarded as standard. The values given in parentheses are E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

mathematical conversions to SI units that are provided for

information only and are not considered standard. E37 Test Methods for Chemical Analysis of Pig Lead

E46 Test Methods for Chemical Analysis of Lead- and

NOTE 1—A companion specification for copper sheet and strip for

3

Tin-Base Solder (Withdrawn 1994)

building construction is Specification B370.

E62 Test Methods for Chemical Analysis of Copper and

1.4 The following hazard caveat pertains to the test method

3

CopperAlloys (Photometric Methods)(Withdrawn 2010)

portion, Section 17, of this specification. This standard does

E112 Test Methods for Determining Average Grain Size

not purport to address all of the safety concerns, if any,

E478 Test Methods for ChemicalAnalysis of CopperAlloys

associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety, health, and environ-

3. General Requirements

mental practices and determine the applicability of regulatory

3.1 The following sections of Specification B248 constitute

limitations prior to use.

a part of this specification:

1.5 This international standard was developed in accor-

3.1.1 Significance of numerical limits,

dance with internationally recognized principles on standard-

3.1.2 Inspection,

ization established in the Decision on Principles for the

3.1.3 Rejection and rehearing,

Development of International Standards, Guides and Recom-

3.1.4 Certification,

mendations issued by the World Trade Organization Technical

3.1.5 Mill test reports, and

Barriers to Trade (TBT) Committee.

3.1.6 Packaging and package marking.

2. Referenced Documents

3.2 In addition, when a section with a title identical to that

2

referenced in 3.1, above, appears in this specification, it

2.1 ASTM Standards:

contains additional requirements that supplement those appear-

ing in Specification B248.

1

This specification is under the jurisdiction of Committee B05 on Copper and

Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

4. Terminology

Sheet, and Strip.

Current edition approved Oct. 1, 2019. Published October 2019. Originally

4.1 For definitions of terms related to copper and copper

approved in 1935. Last previous edition approved in 2012 as B101–12. DOI:

alloys, refer to Terminology B846.

10.1520/B0101–12R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B101−12 (2019)

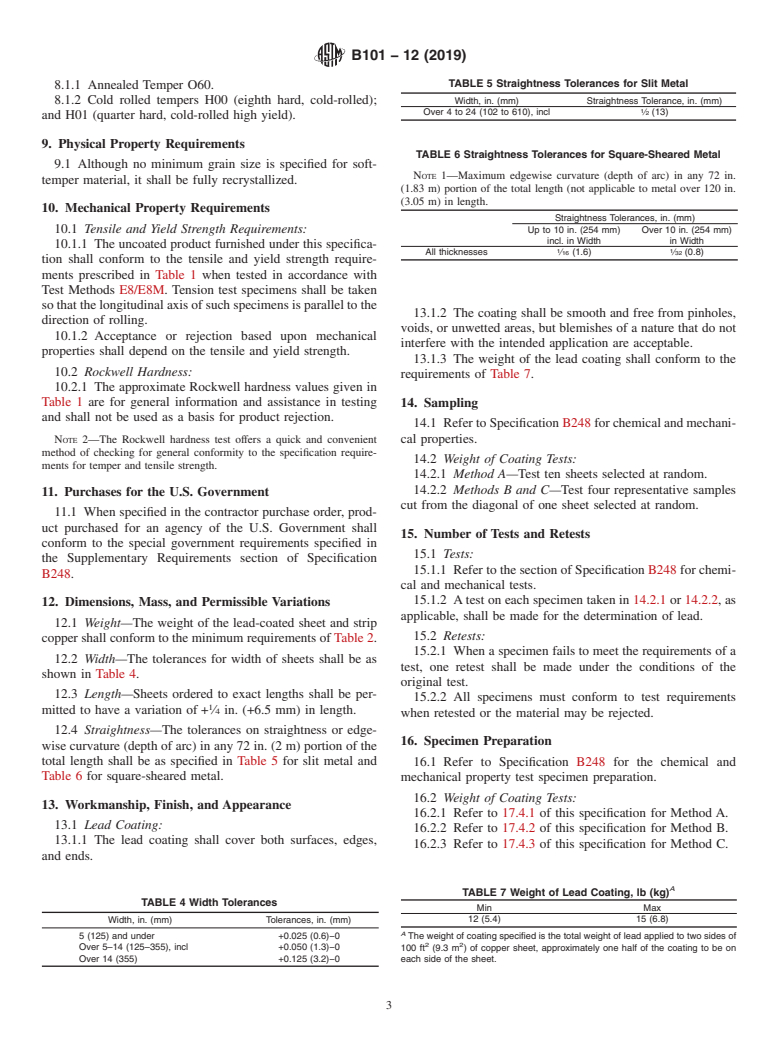

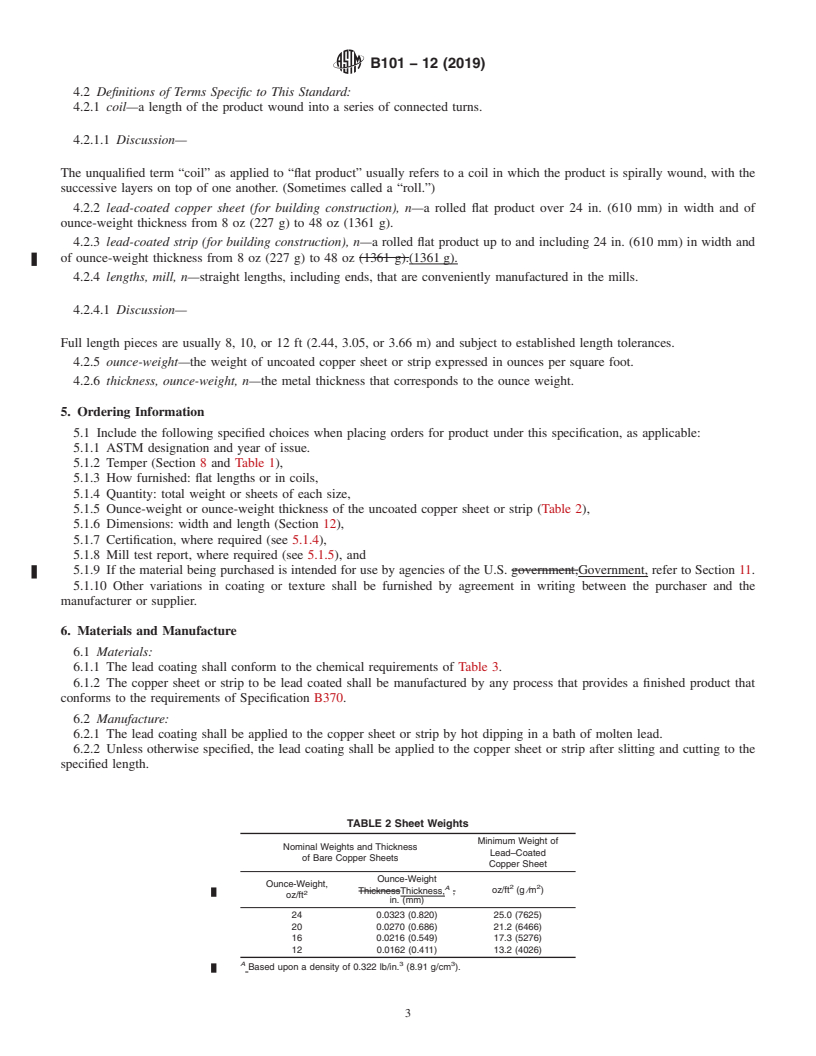

TABLE 1 Mechanical Properties of Uncoated Sheet

B

Yield Strength, at Approximate Rockwell Hardness

A

Temper Designation Tensile Strength, ksi (MPa)

(for Information Only)

0.5 % Extension

F Scale Superficial 30 T

Under Load, min,

Standard Former Min Max

ksi (MPa) Min Max Min Max

O60 soft 30 (205) 38 (260) . . 65 . 31

H00 cold-rolled 32 (220) 40 (275) 20 (140) 54 82 15

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B101 − 12 B101 − 12 (Reapproved 2019)

Standard Specification for

Lead-Coated Copper Sheet and Strip for Building

1

Construction

This standard is issued under the fixed designation B101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification establishes the requirements for lead-coated copper sheet and strip in flat lengths (or in coils) in

ounce-weight thicknesses for roofing, flashing, gutters, downspouts, and for the general sheet metalwork in building construction.

The lead coating is applied by hot dipping.

1.2 Products produced to this specification are not intended for electrical applications.

1.3 Units—Values The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are

mathematical conversions to SI units, whichunits that are provided for information only and are not considered standard.

NOTE 1—A companion specification for copper sheet and strip for building construction is Specification B370.

1.4 The following hazard caveat pertains to the test method portion, Section 17, of this specification. This This standard does

not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard

to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

B248 Specification for General Requirements for Wrought Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled Bar

B370 Specification for Copper Sheet and Strip for Building Construction

B846 Terminology for Copper and Copper Alloys

B950 Guide for Editorial Procedures and Form of Product Specifications for Copper and Copper Alloys

E8/E8M Test Methods for Tension Testing of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E37 Test Methods for Chemical Analysis of Pig Lead

33

E46 Test Methods for Chemical Analysis of Lead- and Tin-Base SoldersSolder (Withdrawn 1994)

3

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Methods) (Withdrawn 2010)

E112 Test Methods for Determining Average Grain Size

E478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 The following sections of Specification B248 constitute a part of this specification:

3.1.1 Significance of numerical limits,

1

This specification is under the jurisdiction of Committee B05 on Copper and Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate, Sheet, and

Strip.

Current edition approved April 1, 2012Oct. 1, 2019. Published April 2012October 2019. Originally approved in 1935. Last previous edition approved in 20072012 as

B101 – 07.B101–12. DOI: 10.1520/B0101-12.10.1520/B0101–12R19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B101 − 12 (2019)

3.1.2 Inspection,

3.1.3 Rejection and rehearing,

3.1.4 Certification,

3.1.5 Mill test reports, and

3.1.6 Packaging and package marking.

3.2 In addition, when a section with a title identical to that referenced in 3.1, above, appears in this specification, it contains

additional requirements that supplement those appearing in Specification B248.

4. Terminology

4.1 For definitions of terms related to copper and copper alloys, refer to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.