ASTM D5852-95

(Test Method)Standard Test Method for Erodibility Determination of Soil in the Field or in the Laboratory by the Jet Index Method

Standard Test Method for Erodibility Determination of Soil in the Field or in the Laboratory by the Jet Index Method

SCOPE

1.1 This test method covers the estimation of erodibility of a soil by a jet index method. This test method involves either preparing a field site or obtaining a relatively undisturbed soil sample and the subsequent activities for the determination of the erodibility of soil. This test method also may be run on compacted samples in the laboratory.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5852 – 95

Standard Test Method for

Erodibility Determination of Soil in the Field or in the

Laboratory by the Jet Index Method

This standard is issued under the fixed designation D 5852; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope performance and prediction relationships.

3.2 The jet index test is not suited for determining erodibil-

1.1 This test method covers the estimation of erodibility of

ity of soils that have structure characteristics larger than the

a soil by a jet index method. This test method involves either

scale of the jet testing device. For example, the erodibility of

preparing a field site or obtaining a relatively undisturbed soil

soil that has a dominant soil structure of 7 to 8 cm or larger

sample and the subsequent activities for the determination of

(that is, aggregate, clod, or particle size), that might play a key

the erodibility of soil. This test method also may be run on

role in the detachment process, should not be estimated with

compacted samples in the laboratory.

the jet index test. Care should be taken that the test sample and

1.2 The values stated in SI units are to be regarded as the

test is representative of expected conditions at the site under

standard. The values given in parentheses are for information

investigation. If it is known in advance that the soil will be

only.

saturated prior to an erosion event, then the soil should be

1.3 This standard does not purport to address all of the

tested in that condition. At present, the effects of water

safety concerns, if any, associated with its use. It is the

chemistry on detachment rate are unknown. Therefore, water

responsibility of the user of this standard to establish appro-

quality during testing should be simulated as close as possible

priate safety and health practices and determine the applica-

to the water quality anticipated during actual erosion.

bility of regulatory limitations prior to use.

4. Apparatus

2. Referenced Documents

4.1 Field Testing:

2.1 ASTM Standards:

4.1.1 Vertical Submerged Jet Device— An apparatus that

D 420 Guide to Site Characterization for Engineering, De-

can be taken to the field to index soil erodibility (see Fig. 1).

sign, and Construction Purposes

The device is mounted on a base ring with a sealing ring to

D 2216 Test Method for Laboratory Determination of Water

prevent leakage and piping. A cylindrical tank is attached to the

(Moisture) Content of Soil and Rock

base ring to act as a weir while maintaining the water level

D 2488 Practice for Description and Identification of Soils

required to submerge the jet. The soil surface inside the device

(Visual-Manual Procedure)

is 0.44 m in diameter. Attached to the tank is an inner

D 4220 Practice for Preserving and Transporting Soil

cylindrical liner that acts as a baffle to minimize return

Samples

turbulence to the jet. The jet and pin profiler (see Fig. 2 and

D 4753 Specification for Evaluating, Selecting, and Speci-

Fig. 3) are interchangeable and are mounted to the upper

fying Balances and Scales for Use in Testing Soil, Rock,

surface of this liner. A 51-mm diameter clear acrylic tube, the

and Related Construction Materials

lower end of which is fitted with a 13-mm diameter nozzle, is

3. Significance and Use

mounted in a hanger that can be set on the inner cylindrical

liner.

3.1 Water flow in nature exerts a force on soils that results

in erosion. Erosion potential of a soil is of concern in vegetated

NOTE 1—Detailed drawings of the apparatus and supporting equipment

channels, road embankments, dams, levees, spillways, con-

are available from ASTM Headquarters.

struction sites, etc. The jet index method is intended to provide

4.1.2 Pin Profiler, used to determine the maximum depth of

a standard method of expressing erosion resistance; to assist

material removed during testing.

those who work with different soils and soil conditions to

4.1.3 Water Delivery System, required to run the jet test.

measure erosion resistance for design purposes; and to provide

Water delivery may be accomplished by pumping directly from

a common system of characterizing soil properties to develop

a body of water at the site, from a storage tank delivered to the

site, or from a city water supply system if available.

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

4.1.4 Differential Pressure Device, necessary in order to

and Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and

determine the mean velocity at the jet nozzle. This may be

Related Field Testing for Soil Evaluations.

accomplished by manometers, differential pressure gage, or

Current edition approved Oct. 10, 1995. Published December 1995.

Annual Book of ASTM Standards, Vol 04.08. pressure transducer.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

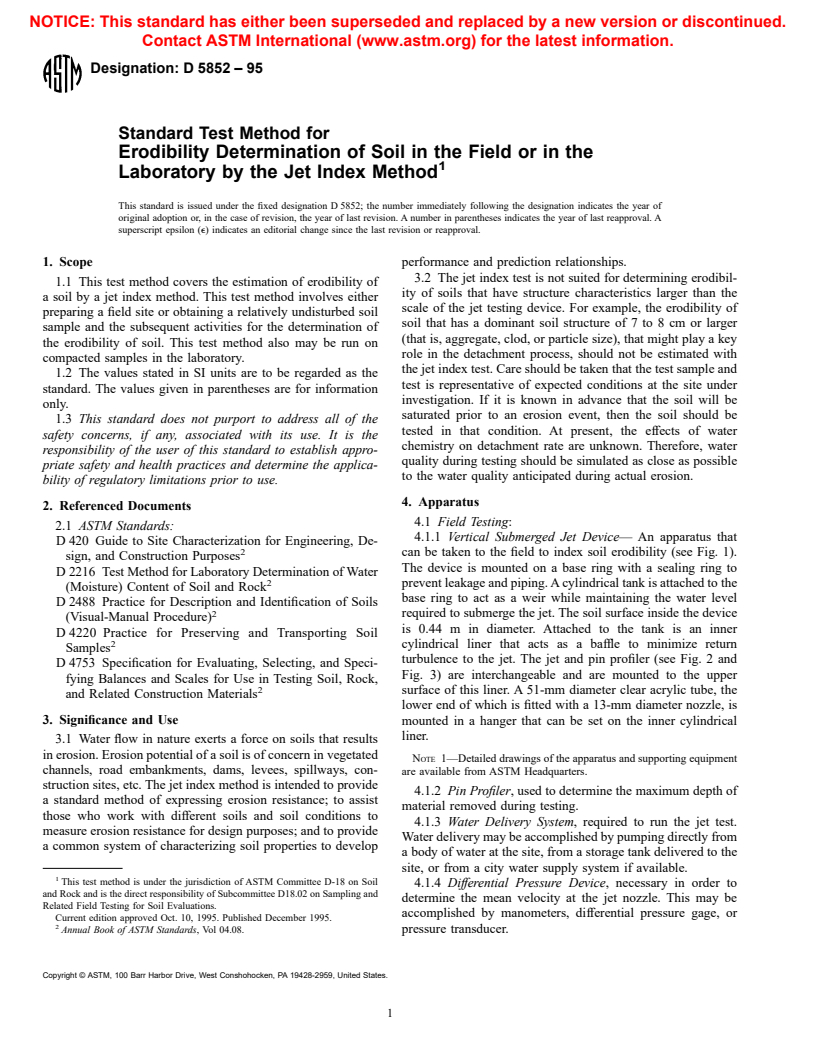

D 5852

FIG. 1 Submerged Jet Apparatus for Field Testing

FIG. 3 Pin Profile Following a Time Sequence

FIG. 2 Jet Apparatus in Operation

4.1.5 Pressure Control, necessary to maintain a constant to prevent leakage during testing. The sample is loaded into the

velocity at the jet nozzle. This may be accomplished by a lower tank and slid under the upper tank. The upper tank acts

constant head tank or a valve. as a weir while maintaining the water level required to

4.1.6 Level—A carpenters level is necessary to level the submerge the jet. The soil samples are contained in pvc molds

foundation ring and inner liner of the tank. with an inner diameter of 0.44 m and a height of 0.18 m.

4.1.7 Shovel—A flat-nosed shovel is useful in preparing the Attached to the tank is an inner cylindrical liner that acts as a

site for testing. baffle to minimize return turbulence to the jet. The jet and pin

4.1.8 Ruler—A ruler is required to set the jet nozzle at a profiler are interchangeable, mounted to the upper surface of

height of 0.22 m above the unscoured soil surface. this liner. A 51-mm diameter clear acrylic tube, the lower end

of which is fitted with a 13-mm diameter nozzle, is mounted in

4.1.9 Miscellaneous Equipment—A 10 to 13 cm diameter

flat disk, sledgehammer, wrenches, plastic bags and other soil a hanger that can be set on the inner cylindrical liner.

4.2.2 Mold—A large mold is required for obtaining rela-

sampling equipment for other soil tests of interest.

4.2 Laboratory Testing: tively undisturbed samples from the field. Due to the size of the

4.2.1 Vertical Submerged Jet Device— An apparatus that samples required, it is recommended that pvc molds be used to

can be used in the laboratory to determine soil erodibility (see minimize the mass of the sample. The mold size recommended

Fig. 4). The device consists of a lower cylindrical tank that consists of 0.44 m inner diameter and 0.18 m height. Once a

slides under a fixed upper cylindrical tank. The upper and mold sample is obtained in the field, it should be immediately

lower cylindrical tanks are sealed together with an inflated tube covered at both ends with stiff plastic disks held firmly with a

D 5852

FIG. 4 Submerged Jet Apparatus for Laboratory Testing

framing system. Sampling and preserving/transporting soils in accordance with Test Method D 2216.

samples will be done in accordance with Guide D 420 and 4.2.8 Water Delivery System, Differential Pressure Device,

Practice 4220 respectively. and Pressure Control—Equipment necessary for water deliv-

4.2.3 Cutting Head—A cutting head is essential for taking ery, differential pressure control and measurement are neces-

samples this size in the field. The cutting head should be sary for both the laboratory device and for the field testing

mounted to the front end of the mold and driven in or pushed device.

in advance of the mold. The procedure for obtaining a sample 4.2.9 Miscellaneous Equipment—A 10 to 13 cm diameter

is to advance the mold and cutting head 5 to 8 cm at a time, flat disk, sledgehammer, plastic bags, cans, gloves, wrenches

remove the material around the outside of the mold and repeat and ruler.

the process until the mold is to the desired depth.

5. Procedure

4.2.4 Straight Edge—A straight edge is necessary to trim

5.1 Field Testing:

both ends of the sample flush with the mold.

4.2.5 Shovel—Any one of several types of shovels or spades 5.1.1 Prepare the surface at the test location so that it is

is satisfactory for shallow sampling when digging around the reasonably level and void of vegetation. When the site is ready

mold. for testing, push the base ring into the soil. This may require

4.2.6 Balances—All balances must meet the requir

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.