ASTM B750-03

(Specification)Standard Specification for GALFAN (Zinc-5 % Aluminum-Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

Standard Specification for GALFAN (Zinc-5 % Aluminum-Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

SCOPE

1.1 This specification covers GALFAN, zinc-5 % aluminum-mischmetal (Zn-5Al-MM) alloy (UNS Z38510) in ingot form for remelting for use in the production of hot-dip coatings on steel. Alloy composition is specified in Table 1.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 750 – 03

Standard Specification for

1

GALFAN (Zinc-5 % Aluminum-Mischmetal) Alloy in Ingot

2

Form for Hot-Dip Coatings

This standard is issued under the fixed designation B 750; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

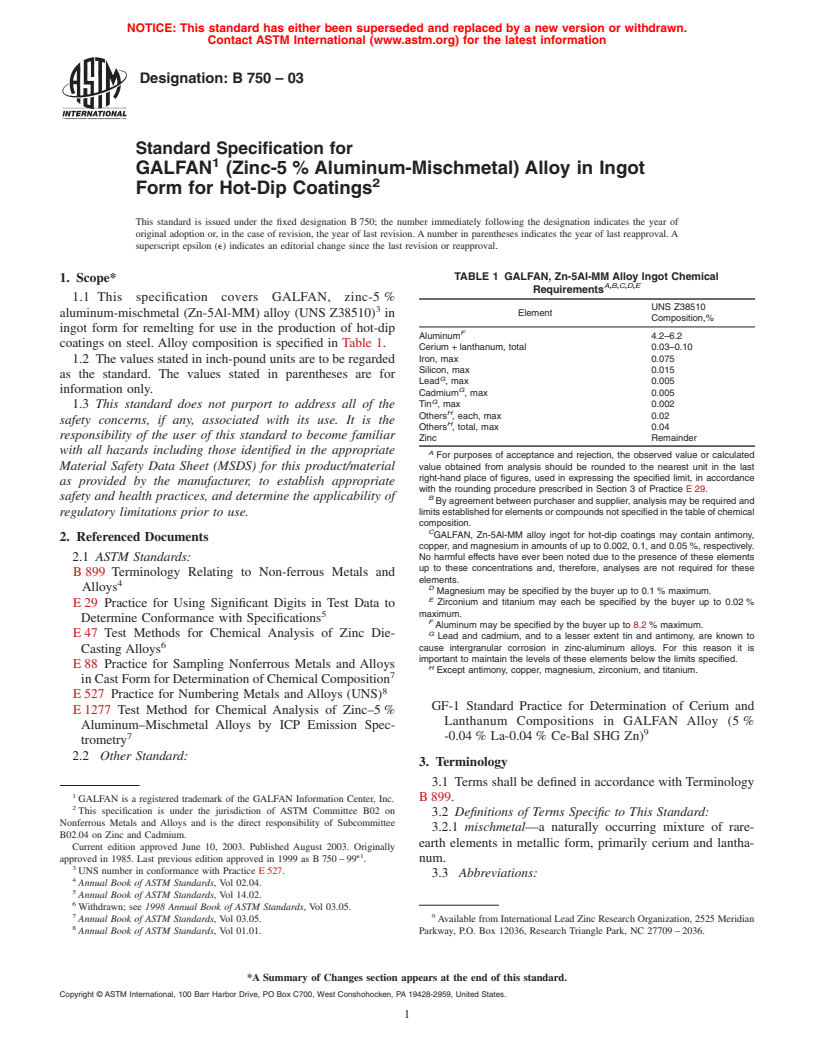

TABLE 1 GALFAN, Zn-5Al-MM Alloy Ingot Chemical

1. Scope*

A,B,C,D,E

Requirements

1.1 This specification covers GALFAN, zinc-5 %

UNS Z38510

3

Element

aluminum-mischmetal (Zn-5Al-MM) alloy (UNS Z38510) in

Composition,%

ingot form for remelting for use in the production of hot-dip

F

Aluminum 4.2–6.2

coatings on steel. Alloy composition is specified in Table 1.

Cerium + lanthanum, total 0.03–0.10

1.2 The values stated in inch-pound units are to be regarded Iron, max 0.075

Silicon, max 0.015

as the standard. The values stated in parentheses are for

G

Lead , max 0.005

information only. G

Cadmium , max 0.005

G

Tin , max 0.002

1.3 This standard does not purport to address all of the

H

Others , each, max 0.02

safety concerns, if any, associated with its use. It is the

H

Others , total, max 0.04

responsibility of the user of this standard to become familiar

Zinc Remainder

with all hazards including those identified in the appropriate

A

For purposes of acceptance and rejection, the observed value or calculated

Material Safety Data Sheet (MSDS) for this product/material value obtained from analysis should be rounded to the nearest unit in the last

right-hand place of figures, used in expressing the specified limit, in accordance

as provided by the manufacturer, to establish appropriate

with the rounding procedure prescribed in Section 3 of Practice E29.

B

safety and health practices, and determine the applicability of

By agreement between purchaser and supplier, analysis may be required and

regulatory limitations prior to use. limits established for elements or compounds not specified in the table of chemical

composition.

C

GALFAN, Zn-5Al-MM alloy ingot for hot-dip coatings may contain antimony,

2. Referenced Documents

copper, and magnesium in amounts of up to 0.002, 0.1, and 0.05 %, respectively.

2.1 ASTM Standards: No harmful effects have ever been noted due to the presence of these elements

up to these concentrations and, therefore, analyses are not required for these

B 899 Terminology Relating to Non-ferrous Metals and

elements.

4

D

Alloys

Magnesium may be specified by the buyer up to 0.1 % maximum.

E

E29 Practice for Using Significant Digits in Test Data to Zirconium and titanium may each be specified by the buyer up to 0.02 %

5 maximum.

Determine Conformance with Specifications

F

Aluminum may be specified by the buyer up to 8.2 % maximum.

G

E47 Test Methods for Chemical Analysis of Zinc Die-

Lead and cadmium, and to a lesser extent tin and antimony, are known to

6

cause intergranular corrosion in zinc-aluminum alloys. For this reason it is

Casting Alloys

important to maintain the levels of these elements below the limits specified.

E88 Practice for Sampling Nonferrous Metals and Alloys

H

Except antimony, copper, magnesium, zirconium, and titanium.

7

in Cast Form for Determination of Chemical Composition

8

E 527 Practice for Numbering Metals and Alloys (UNS)

GF-1 Standard Practice for Determination of Cerium and

E 1277 Test Method for Chemical Analysis of Zinc–5 %

Lanthanum Compositions in GALFAN Alloy (5 %

Aluminum–Mischmetal Alloys by ICP Emission Spec-

9

7

-0.04 % La-0.04 % Ce-Bal SHG Zn)

trometry

2.2 Other Standard:

3. Terminology

3.1 Terms shall be defined in accordance with Terminology

1

B 899.

GALFAN is a registered trademark of the GALFAN Information Center, Inc.

2

This specification is under the jurisdiction of ASTM Committee B02 on

3.2 Definitions of Terms Specific to This Standard:

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

3.2.1 mischmetal—a naturally occurring mixture of rare-

B02.04 on Zinc and Cadmium.

earth elements in metallic form, primarily cerium and lantha-

Current edition approved June 10, 2003. Published August 2003. Originally

e1

approved in 1985. Last previous edition approved in 1999 as B 750 – 99 . num.

3

UNS number in conformance with Practice E 527.

3.3 Abbreviations:

4

Annual Book of ASTM Standards, Vol 02.04.

5

Annual Book of ASTM Standards, Vol 14.02.

6

Withdrawn; see 1998 Annual Book of ASTM Standards, Vol 03.05.

7 9

Annual Book of ASTM Standards, Vol 03.05. Available from International Lead Zinc Research Organization, 2525 Meridian

8

Annual Book of ASTM Standards, Vol 01.01. Parkway, P.O. Box 12036, Research Triangle Park, NC 27709 – 2036.

*A Summary of Changes section appears at the end of this standard.

Copyright © A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.