ASTM B803/B803M-22

(Specification)Standard Specification for High-Strength Zinc–5 % Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Use in Overhead Electrical Conductors

Standard Specification for High-Strength Zinc–5 % Aluminum-Mischmetal Alloy-Coated Steel Core Wire for Use in Overhead Electrical Conductors

ABSTRACT

This specification covers round, high-strength, zinc-aluminum-mischmetal (Zn-5Al-MM) alloy-coated, steel core wire with Class A Zn-5Al-MM alloy coating used for mechanical reinforcement in the manufacture of special aluminum and aluminum-alloy conductors, steel reinforced. The base metal shall be steel produced by the open-hearth, electric furnace, or basic oxygen process. The wire shall be cold drawn and coated with Zn-5Al-MM alloy to produce the desired properties. Chemical requirements of the steel, such as carbon, manganese, phosphorus, sulfur, and silicon shall meet the requirements prescribed in this specification. The Zn-5Al-MM-coated steel core wire shall conform to the tensile and elongation requirements. Test methods for tensile, wrap, coating and adherence shall be also be performed.

SCOPE

1.1 This specification covers round, high strength, zinc–5 % aluminum-mischmetal (Zn–5Al–MM) alloy-coated, steel core wire with one class of Zn–5Al–MM coating (MA3) for use in overhead electrical conductors.

1.2 This specification covers wire of diameter from 0.0500 in. to 0.1900 in. inclusive or 1.27 mm to 4.82 mm inclusive.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B803/B803M −22

Standard Specification for

High-Strength Zinc–5% Aluminum-Mischmetal Alloy-Coated

1

Steel Core Wire for Use in Overhead Electrical Conductors

This standard is issued under the fixed designation B803/B803M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

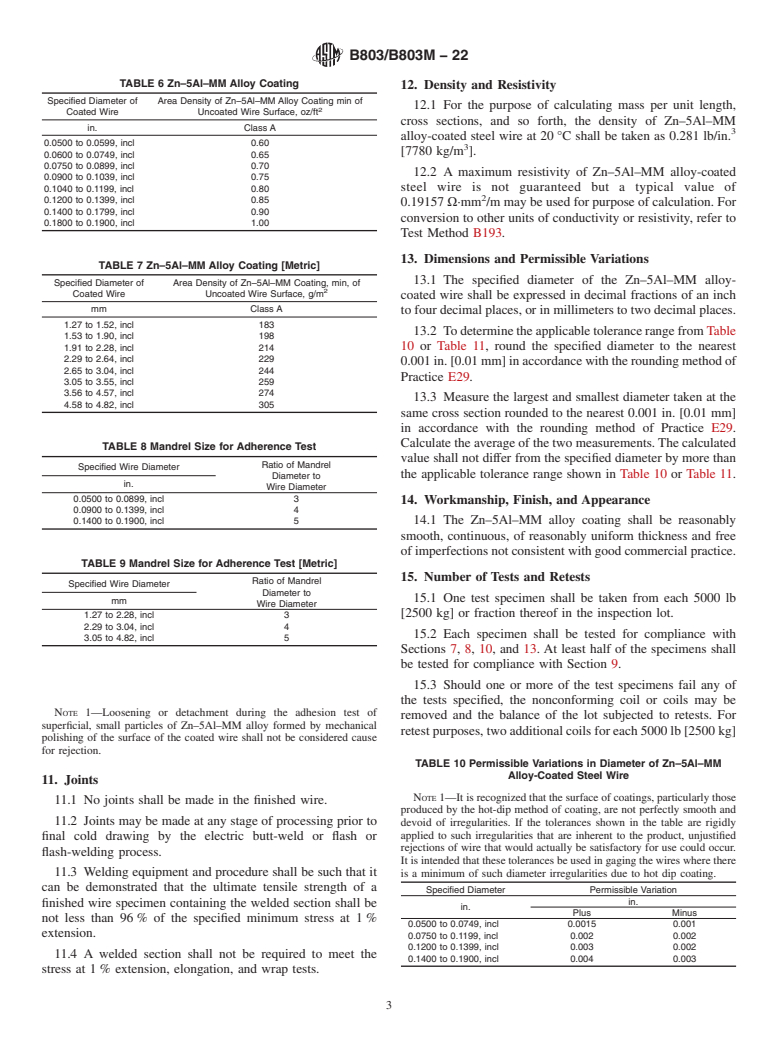

1. Scope B193 Test Method for Resistivity of Electrical Conductor

Materials

1.1 This specification covers round, high strength, zinc–5 %

B750 Specification for GALFAN (Zinc-5 % Aluminum-

aluminum-mischmetal (Zn–5Al–MM) alloy-coated, steel core

Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

wire with one class of Zn–5Al–MM coating (MA3) for use in

E47 Test Methods for Chemical Analysis of Zinc Die-

overhead electrical conductors.

3

Casting Alloys (Withdrawn 1997)

1.2 This specification covers wire of diameter from

E1277 Test Method for Analysis of Zinc-5 % Aluminum-

0.0500 in. to 0.1900 in. inclusive or 1.27 mm to 4.82 mm

Mischmetal Alloys by ICP Emission Spectrometry

inclusive.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

1.3 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in 2.3 Other Standard:

each system may not be exact equivalents; therefore, each GF-1 Standard Practice for Determination of Cerium and

system shall be used independently of the other. Combining Lanthanum Compositions in GalfanAlloy (5 %Al-0.04 %

4

values from the two systems may result in non-conformance La-0.04 % Ce-Bal SHG Zn)

with the standard.

3. Terminology

1.4 This international standard was developed in accor-

3.1 Abbreviations:

dance with internationally recognized principles on standard-

3.1.1 MM—mischmetal

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

3.1.2 Zn–5Al–MM—zinc–5 % aluminum mischmetal alloy

mendations issued by the World Trade Organization Technical

3.2 Definitions:

Barriers to Trade (TBT) Committee.

3.2.1 lot—unless otherwise specified in the contract or

order, a lot shall consist of all coils of wire of the same

2. Referenced Documents

diameter and unit lengths submitted for inspection at the same

2.1 The following documents of the issue in effect on date

time.

of material purchase form a part of this specification to the

3.2.2 product code—defines product coating type, coating

extent referenced herein.

class and strength grade; this specification covers only High

2

2.2 ASTM Standards:

StrengthClassA Zn–5Al–MMcoatedproductsandidentifiedas

A90/A90M Test Method for Weight [Mass] of Coating on

product code MA3.

Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A370 Test Methods and Definitions for Mechanical Testing

4. Ordering Information

of Steel Products

4.1 Orders for material under this specification shall include

A751 Test Methods and Practices for Chemical Analysis of

the following information:

Steel Products

4.1.1 Quantity of each size,

4.1.2 Wire diameter in inches or millimeters (Section 13),

1

This specification is under the jurisdiction of ASTM Committee B01 on

4.1.3 Certification, if required (Section 18),

Electrical Conductors and is the direct responsibility of Subcommittee B01.05 on

4.1.4 Test report, if required (Section 18),

Conductors of Ferrous Metals.

4.1.5 Package size (Section 19), and

Current edition approved Oct. 1, 2022. Published October 2022. Originally

approved in 1989. Last previous edition approved in 2019 as B803/B803M – 19.

DOI: 10.1520/B0803_B0803M-22.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from International Lead Zinc Research Organization (ILZRO), 1822

the ASTM website. NC Highway 54 East, Suite 120, Durham, NC 27713, http://www.ilzro.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B803/B803M−22

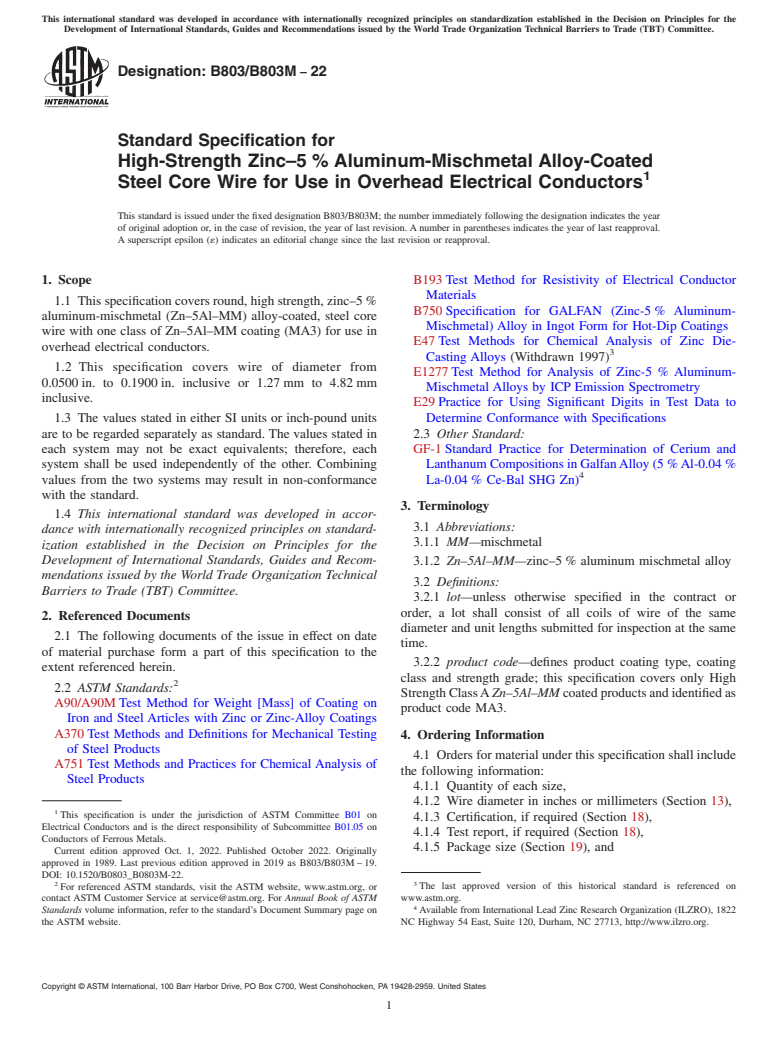

TABLE 2 Tensile Requirements

4.1.6 Product code (Paragraph 3.2.2).

4.1.7 Order Example—Five multiple lengths of 12 000 ft Stress at 1 % Ultimate Tensile Elongation in 10

Specified Diameter

Extension, min Strength, min in., min %

each, 0.1327 in. MA3 wir

...

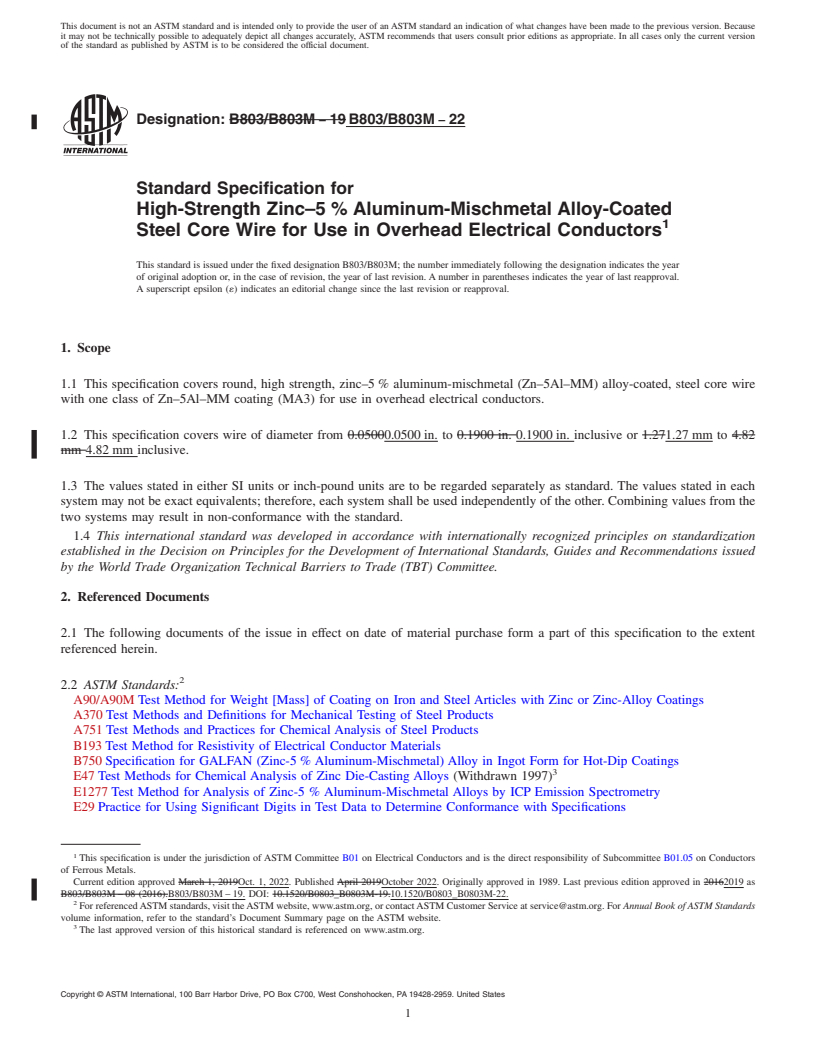

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B803/B803M − 19 B803/B803M − 22

Standard Specification for

High-Strength Zinc–5 % Aluminum-Mischmetal Alloy-Coated

1

Steel Core Wire for Use in Overhead Electrical Conductors

This standard is issued under the fixed designation B803/B803M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers round, high strength, zinc–5 % aluminum-mischmetal (Zn–5Al–MM) alloy-coated, steel core wire

with one class of Zn–5Al–MM coating (MA3) for use in overhead electrical conductors.

1.2 This specification covers wire of diameter from 0.05000.0500 in. to 0.1900 in. 0.1900 in. inclusive or 1.271.27 mm to 4.82

mm 4.82 mm inclusive.

1.3 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2

2.2 ASTM Standards:

A90/A90M Test Method for Weight [Mass] of Coating on Iron and Steel Articles with Zinc or Zinc-Alloy Coatings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A751 Test Methods and Practices for Chemical Analysis of Steel Products

B193 Test Method for Resistivity of Electrical Conductor Materials

B750 Specification for GALFAN (Zinc-5 % Aluminum-Mischmetal) Alloy in Ingot Form for Hot-Dip Coatings

3

E47 Test Methods for Chemical Analysis of Zinc Die-Casting Alloys (Withdrawn 1997)

E1277 Test Method for Analysis of Zinc-5 % Aluminum-Mischmetal Alloys by ICP Emission Spectrometry

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.05 on Conductors

of Ferrous Metals.

Current edition approved March 1, 2019Oct. 1, 2022. Published April 2019October 2022. Originally approved in 1989. Last previous edition approved in 20162019 as

B803/B803M – 08 (2016).B803/B803M – 19. DOI: 10.1520/B0803_B0803M-19.10.1520/B0803_B0803M-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

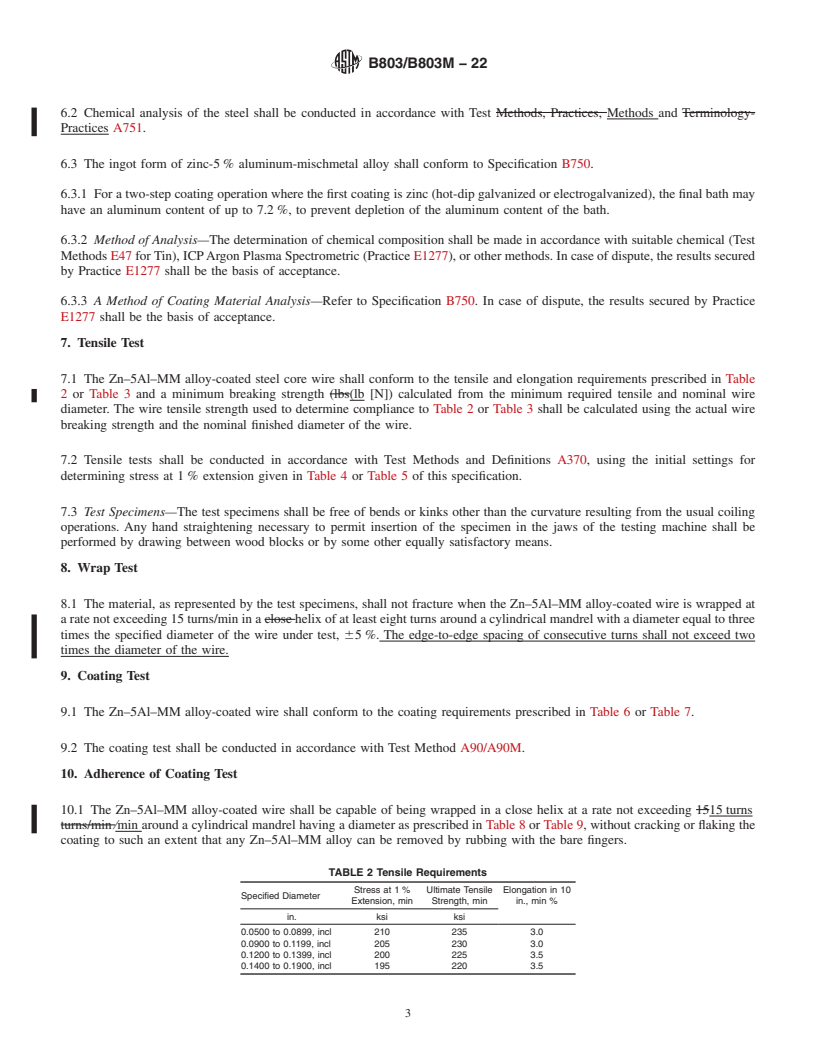

B803/B803M − 22

2.3 Other Standard:

GF-1 Standard Practice for Determination of Cerium and Lanthanum Compositions in Galfan Alloy (5 % Al-0.04 % La-0.04 %

4

Ce-Bal SHG Zn)

3. Terminology

3.1 Abbreviations:

3.1.1 MM—mischmetal

3.1.2 Zn–5Al–MM—zinc–5 % aluminum mischmetal alloy

3.2 Definitions:

3.2.1 lot—unless otherwise specified in the contract or order, a lot shall consist of all coils of wire of the same diameter and unit

lengths submitted for inspection at the same time.

3.2.2 product code—Definesdefines product coating type, coating class and strength grade. Thisgrade; this specification covers

only High Strength Class A Zn–5Al–MM coated products and identified as product code MA3.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

4.1.2 Wire diameter in inches or millimeters (Section 13),

4.1.3 Certification, if required (Section 18),

4.1.4 Test report, if required (Section 18), and

4.1.5 Package Sizesize (Section 19).), and

4.1.6 Product Codecode (Paragraph 3.2.2).

4.1.7 Order Example—Order Example: five Five multiple lengths of 12 000 ft.ft each, 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.