ASTM B770-96

(Specification)Standard Specification for Copper-Beryllium Alloy Sand Castings for General Applications

Standard Specification for Copper-Beryllium Alloy Sand Castings for General Applications

SCOPE

1.1 This specification establishes requirements for copper-beryllium alloy sand castings for general applications and nominal compositions alloys defined by this specification are shown in Table 1.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only.

1.3 The following safety hazard caveat pertains only to the test methods described in this specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 770 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Copper-Beryllium Alloy Sand Castings for General

Applications

This standard is issued under the fixed designation B 770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * 3.1.5 Chemical analysis of residual elements, if specified in

the purchase order (Specification B 824),

1.1 This specification establishes requirements for copper-

3.1.6 Mechanical requirements, if specified in the purchase

beryllium alloy sand castings for general applications. Nominal

order (Section 6),

compositions of the alloys defined by this specification are

3.1.7 Pressure test requirements, if specified in the purchase

shown in Table 1.

order (Specification B 824),

1.2 The values stated in inch-pound units are to be regarded

3.1.8 Soundness requirements, if specified in the purchase

as the standard. Metric values in parentheses are for informa-

order (Specification B 824),

tion only.

3.1.9 Repair of castings (Section 8),

2. Referenced Documents 3.1.10 Certification, if specified in the purchase order

(Specification B 824),

2.1 The following documents in effect on date of material

3.1.11 Foundry test report, if specified in the purchase order

purchase form a part of this specification to the extent

(Specification B 824),

referenced herein:

3.1.12 Witness inspection, if specified in the purchase order

2.2 ASTM Standards:

(Specification B 824), and

B 30 Specification for Copper-Base Alloys in Ingot Form

3.1.13 Product marking, if specified in the purchase order

B 208 Practice for Preparing Tension Test Specimens for

(Specification B 824).

Copper-Base Alloys for Sand, Permanent Mold, Centrifu-

3.2 When material is purchased for agencies of the U.S.

gal and Continuous Castings

Government, the Supplementary Requirements of Specifica-

B 601 Practice for Temper Designations for Copper and

tion B 824 may be specified.

Copper Alloys—Wrought and Cast

B 824 Specification for General Requirements for Copper

4. Chemical Composition

Alloy Castings

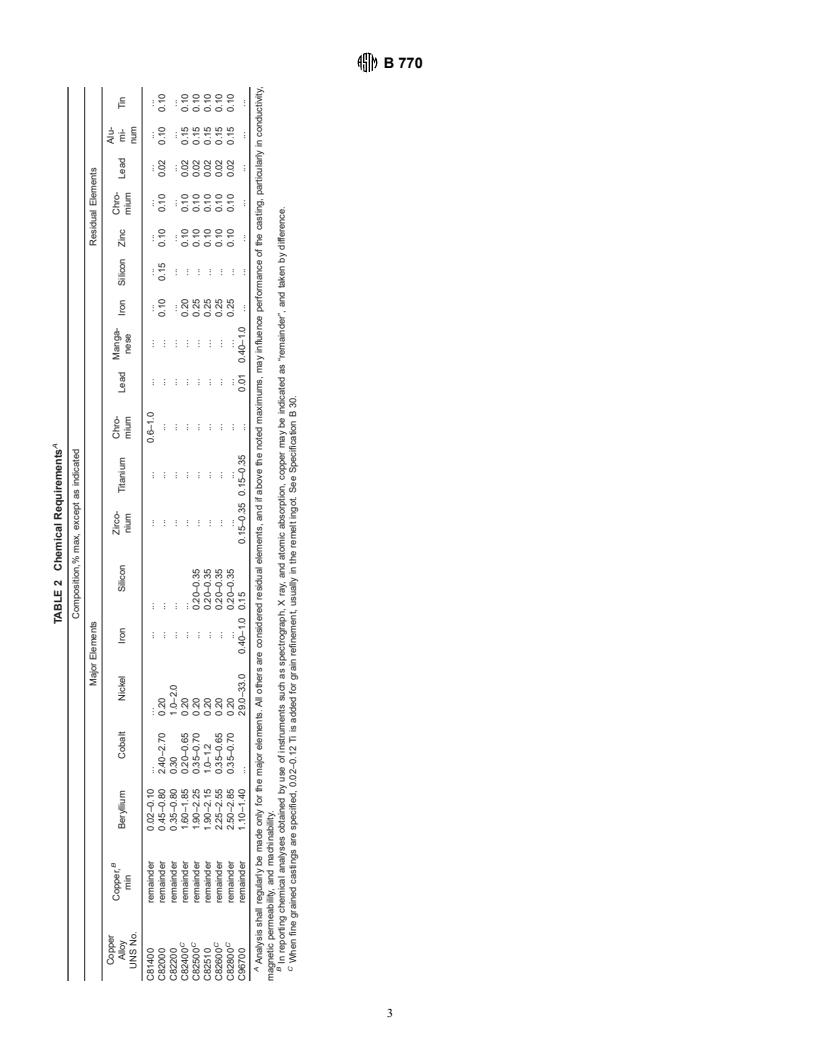

4.1 The castings shall conform to the requirements shown in

E 527 Practice for Numbering Metals and Alloys (UNS)

Table 2.

3. Ordering Information 4.2 These specification limits do not preclude the presence

of other elements. Limits may be established for unnamed

3.1 Orders for castings under this specification shall include

elements by agreement between manufacturer or supplier and

the following information:

purchaser. Copper may be given as remainder and may be

3.1.1 Quantity of castings required,

taken as the difference between the sum of all elements

3.1.2 Copper alloy UNS number (Table 2) and temper

analyzed and 100 %. When all elements in Table 2 are

(as-cast, heat treated, etc.) (Section 5),

analyzed, their sum shall be 99.5 % minimum.

3.1.3 Specification number, title, and year of issue,

4.3 It is recognized that residual elements may be present in

3.1.4 Pattern or drawing number, and condition (cast, ma-

cast copper-base alloys. Analysis shall be made for residual

chined, etc.),

elements only when specified in the purchase order (Specifi-

cation B 824).

This practice is under the jurisdiction of ASTM Committee B-5 on Copper and

Copper Alloys and is the direct responsibility of Subcommittee B05.05 on Castings

5. Temper

and Ingots for Remelting.

Current edition approved Sept. 10, 1996. Published November 1996. Originally

5.1 The standard tempers are listed as follows:

published as B 770 – 87. Last previous edition B 770 – 93.

5.1.1 TF00—Cast, solution heat treated and precipitation

The UNS system for copper and copper alloys (see Practice E 527) is a simple

heat treated.

expansion of the former standard designation system accomplished by the addition

of a prefix “C” and a suffix “00”. The suffix can be used to accommodate 5.1.2 M01—As sand cast.

composition variations of the base alloy.

5.1.3 Special or non-standard tempers are subject to nego-

Annual Book of ASTM Standards, Vol 02.01.

tiation between the supplier and purchaser. Standard temper

Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

B 770

TABLE 1 Nominal Compositions

Copper Alloy Previous

Copper Nickel Silicon Beryllium Cobalt Chromium Iron Zirconium Tin Manganese

UNS No. Designation

C81400 70C 99.1 . . 0.06 . 0.8 . . . .

C82000 10C 97 . . 0.5 2.5 . . . . .

C82200 3C, 14C 98 1.5 . 0.5 . . . . . .

A A

C82400 165C, 165CT 97.8 . . 1.7 0.5 . . . . .

A A

C82500 20C, 20CT 97.2 . 0.3 2.0 0.5 . . . . .

C82510 21C 96.6 . 0.3 2.0 1.1 . . . . .

A A

C82600 245C, 245CT 96.8 . 0.3 2.4 0.5 . . . . .

A A

C82800 275C, 275CT 96.6 . 0.3 2.6 0.5 . . . . .

C96700 72C 67.2 31.0 . 1.2 . . 0.6 0.3 0.3 0.6

A

When fine-grained castings are specified, 0.02 to 0.12 Ti is added for grain refinement, usually in the remelt ingot. See Specification B 30.

designations are in accordance with Practice B 601. of the purchaser (3.1.8).

8.2 The castings shall not be impregnated without approval

6. Mechanical Properties

of the purchaser (3.1.8).

6.1 Material furnished under this specification is not nor-

mally sold with mechanical requirements.

9. General Requirements

6.2 When tension tests are required, separately cast test bar

9.1 Material furnished under this specification shall con-

castings shall be used to determine mechanical properties, and

form to the applicable requirements of Specification B 824.

shall meet the requirements shown in Table 3 in the as cast, or

solution heat-treated and precipitation heat-treated condition.

10. Sampling

7. Precipitation Heat Treatment

10.1 Lot Size:

7.1 For the purpose of determining conformance to the

10.1.1 A lot shall consist of all castings produced from one

appropriate requirement in Table 3, the castings and test

furnace melt or crucible melt.

specimens shall be precipitation heat treated at a uniform

10.1.2 When two or more furnace melts or crucible melts, or

temperature from the solution heat treated condition. Solution

bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.