ASTM D3754-96

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer and Industrial Pressure Pipe

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Sewer and Industrial Pressure Pipe

SCOPE

1.1 This specification covers machine-made fiberglass pipe, 8 in. (200 mm) through 144 in. (3700 mm), for use in pressure systems for conveying sanitary sewage, storm water, and many industrial wastes, and corrosive fluids. Both glass-fiber-reinforced thermosetting-resin pipe (RTRP) and glass-fiber-reinforced polymer mortar pipe (RPMP) are fiberglass pipes. This standard is suited primarily for pipes to be installed in buried applications, although it may be used to the extent applicable for other installations such as, but not limited to, sliplining and rehabilitation of existing pipelines. Pipe covered by this specification is intended to operate at internal gage pressures of 250 psi (1.72 MPa) or less.

Note 1—For the purposes of this standard, polymer does not include natural polymers.

1.2 The values given in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

Note 2—There is no similar or equivalent ISO standard.

1.3 The following precautionary caveat pertains only to the test method portion, Section 8 , of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3754 – 96

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

1,2

Sewer and Industrial Pressure Pipe

This standard is issued under the fixed designation D 3754; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 695 Test Method for Compressive Properties of Rigid

Plastics

1.1 This specification covers machine-made fiberglass pipe,

D 790 Test Methods for Flexural Properties of Unreinforced

8 in. (200 mm) through 144 in. (3700 mm), for use in pressure

and Reinforced Plastics and Electrical Insulating Materi-

systems for conveying sanitary sewage, storm water, and many

als

industrial wastes, and corrosive fluids. Both glass-fiber-

D 883 Terminology Relating to Plastics

reinforced thermosetting-resin pipe (RTRP) and glass-fiber-

D 1600 Terminology for Abbreviated Terms Relating to

reinforced plastic mortar pipe (RPMP) are fiberglass pipes.

Plastics

This standard is suited primarily for pipes to be installed in

D 2290 Test Method for Apparent Tensile Strength of Ring

buried applications, although it may be used to the extent

or Tubular Plastics and Reinforced Plastics by Split Disk

applicable for other installations such as, but not limited to,

Method

sliplining and rehabilitation of existing pipelines. Pipe covered

D 2412 Test Method for Determination of External Loading

by this specification is intended to operate at internal gage

Characteristics of Plastic Pipe by Parallel-Plate Loading

pressures of 250 psi (1.72 MPa) or less.

D 2584 Test Method for Ignition Loss of Cured Reinforced

1.2 The values given in inch-pound units are to be regarded

Resins

as the standard. The values given in parentheses are provided

D 2992 Practice for Obtaining Hydrostatic or Pressure De-

for information purposes only.

sign Basis for “Fiberglass’’ (Glass-Fiber-Reinforced

NOTE 1—There is no similar or equivalent ISO standard. 4

Thermosetting-Resin) Pipe and Fittings

1.3 The following precautionary caveat pertains only to the D 3567 Practice for Determining Dimensions of “Fiber-

test method portion, Section 8, of this specification: This glass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

standard does not purport to address all of the safety concerns, and Fittings

if any, associated with its use. It is the responsibility of the user D 3681 Test Method for Chemical Resistance of “Fiber-

of this standard to establish appropriate safety and health glass” (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

practices and determine the applicability of regulatory limita- in a Deflected Condition

tions prior to use. D 3892 Practice for Packaging/Packing of Plastics

D 4161 Specification for “Fiberglass” (Glass-Fiber-

2. Referenced Documents

Reinforced Thermosetting-Resin) Pipe Joints Using Flex-

2.1 ASTM Standards: ible Elastomeric Seals

C 33 Specification for Concrete Aggregates F 412 Terminology Relating to Plastic Piping Systems

C 581 Practice for Determining Chemical Resistance of

F 477 Specification for Elastomeric Seals (Gaskets) for

Thermosetting Resins Used in Glass-Fiber-Reinforced Joining Plastic Pipe

Structures Intended for Liquid Service

2.2 ISO Standard:

D 638 Test Method for Tensile Properties of Plastics ISO 1172 Textile Glass Reinforced Plastics—Determination

of Loss on Ignition

2.3 AWWA Standard:

This specification is under the jurisdiction of ASTM Committee D-20 on

AWWA C-950 Glass-Fiber Reinforced Thermosetting Resin

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced 10

Pressure Pipe

Plastic Piping Systems and Chemical Equipment.

Current edition approved April 10, 1996. Published June 1996. Originally

published as D 3754 – 79. Last previous edition D 3754 – 91. This specification

replaces Specification D 4162. Annual Book of ASTM Standards, Vol 15.03.

2 7

This revision includes renumbering existing Note 1 through 13 to be Note 2 Annual Book of ASTM Standards, Vol 08.02.

through 14. Also changed are 8.7.2, Table 3, Note 10 (old 9). Note 1 (ISO Annual Book of ASTM Standards, Vol 08.03.

equivalency), 6.6.1, and 6.6.2 were added. Available from American National Standards Institute (ANSI), 11 West 42nd

Annual Book of ASTM Standards, Vol 04.02. Street, 13th Floor, New York, NY 10036.

4 10

Annual Book of ASTM Standards, Vol 08.04. Available from the American Water Works Association, 6666 West Quincey

Annual Book of ASTM Standards, Vol 08.01. Ave., Denver, CO 80235.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3754

to be used under the installation and operating conditions that will exist for

3. Terminology

the project in which the pipe is to be used.

3.1 Definitions:

4.2 Designation Requirements—The pipe materials desig-

3.1.1 General—Definitions are in accordance with Termi-

nation code shall consist of the standard designation, ASTM

nology D 883 or Terminology F 412 and abbreviations with

D 3754, followed by type, liner, and grade in arabic numerals,

Terminology D 1600, unless otherwise indicated.

class by the letter C with two or three arabic numerals, and pipe

3.2 Definitions of Terms Specific to This Standard:

stiffness by a capital letter. Table 1 presents a summary of the

3.2.1 fiberglass pipe—a tubular product containing glass

designation requirements. Thus a complete material code shall

fiber reinforcements embedded in or surrounded by cured

consist of ASTM D 3754, three numerals, C.and two or three

thermosetting resin. The composite structure may contain

numerals, and a capital letter.

aggregate, granular or platelet fillers, thixotropic agents, pig-

ments, or dyes. Thermoplastic or thermosetting liners or

NOTE 3—Examples of the designation codes are as follows: (1) ASTM

coatings may be included.

D 3754-1-1-3-C50-A for glass-fiber-reinforced aggregate and polyester

3.2.2 reinforced thermosetting resin pipe—a fiberglass pipe

resin mortar pipe with a reinforced thermoset liner and an unreinforced

polyester resin and sand surface layer, for operation at 50 psi (345 kPa),

without aggregate.

and having a minimum pipe stiffness of 9 psi (62 kPa). (2) ASTM

3.2.3 reinforced plastic mortar pipe—a fiberglass pipe with

D 3754-4-2-6-C200-C for glass-fiber-reinforced epoxy resin pipe with an

aggregate.

unreinforced thermoset liner, no surface layer, for operation at 200 psi

3.2.4 industrial pipe—pipe designed for internal, or external

(1380 kPa) and having a minimum pipe stiffness of 36 psi (248 kPa).

environments, or both, commonly encountered in industrial

NOTE 4—Although the “Form and Style for ASTM Standards” manual

piping systems used for many process solutions or effluents.

requires that the type classification be roman numerals, it is recognized

3.2.5 qualification test—one or more tests used to prove the

that few companies have stencil-cutting equipment for this style of type,

and it is therefore acceptable to mark the product type in arabic numbers.

design of a product. Not a routine quality control test.

3.2.6 liner—a resin layer, with or without filler or reinforce-

5. Materials and Manufacture

ment, or both, forming the interior surface of the pipe.

5.1 General—The resins, reinforcements, colorants, fillers,

3.2.7 surface layer—a resin layer, with or without filler or

and other materials, when combined as a composite structure,

reinforcement, or both, applied to the exterior surface of the

shall produce a pipe that shall meet the performance require-

pipe structural wall.

ments of this specification.

4. Classification

5.2 Wall Composition—The basic structural wall composi-

tion shall consist of a thermosetting resin, glass-fiber reinforce-

4.1 General—This specification covers fiberglass sewer and

ment, and, if used, an aggregate filler.

industrial pressure pipe defined by raw materials in the

5.2.1 Resin—A thermosetting polyester or epoxy resin, with

structural wall (type) and liner, surface layer material (grade),

or without filler.

operating pressure (class), and pipe stiffness. Table 1 lists the

5.2.2 Aggregate—A siliceous sand conforming to the re-

types, liners, grades, classes, and stiffnesses that are covered.

quirements of Specification C 33, except that the requirements

NOTE 2—All possible combinations of types, liners, grades, classes,

for gradation shall not apply.

and stiffness may not be commercially available. Additional types, liners,

5.2.3 Reinforcement—A commercial grade of glass fiber

grades, and stiffnesses may be added as they become commercially

with a sizing compatible with the resin used.

available. The purchaser should determine for himself or consult with the

manufacturer for the proper class, type, liner, grade, and stiffness of pipe 5.3 Liner and Surface Layers—A liner or surface layer, or

TABLE 1 General Designation Requirements for Fiberglass Pressure Pipe

Desig- Prop-

A

Cell Limits

nation erty

1 Type 1 2 3 4

glass-fiber-reinforced glass-fiber-reinforced glass-fiber-reinforced glass-fiber-reinforced

B B

thermosetting polyester resin thermosetting polyester resin thermosetting epoxy resin thermosetting epoxy resin

B B

mortar (RPMP polyester) (RTRP polyester) mortar (RPMP epoxy) (RTRP epoxy)

2 Liner 1 2 3 4

reinforced thermoset liner non-reinforced thermoset liner thermoplastic liner no liner

3 Grade 1 2 3 4 5 6

B B

Polyester resin polyester resin polyester resin and epoxy resin epoxy resin No surface

surface layer— surface layer— sand surface layer surface layer— surface layer— layer

B B

reinforced nonreinforced nonreinforced reinforced nonreinforced

C

4 Class C50 C75 C100 C125 C150 C175 C200 C225 C250

5 Pipe Stiffness A B C D

ABC

psi (kPa) 9 (62) 18 (124) 36 (248) 72 (496)

A

The cell-type format provides the means of identification and specification of piping materials. This cell-type format, however, is subject to misapplication since

unobtainable property combinations can be selected if the user is not familiar with commercially available products. The manufacturer should be consulted.

B

For the purposes of this standard, polyester includes vinyl ester resin.

C

Based on operating pressure in psig (numerals).

D 3754

both, when incorporated into or onto the pipe shall meet the 18.29 m). The actual laying length shall be the nominal length

chemical and structural requirements of this specification. 62 in. (651 mm), when measured in accordance with 8.1.2. At

5.4 Joints—The pipe shall have a joining system that shall least 90 % of the total footage of any one size and class,

provide for fluid tightness for the intended service condition. excluding special-order lengths, shall be furnished in the

5.4.1 Unrestrained—Pipe joints capable of withstanding nominal lengths specified by the purchaser. Random lengths, if

internal pressure but not longitudinal forces. furnished, shall not vary from the nominal lengths by more

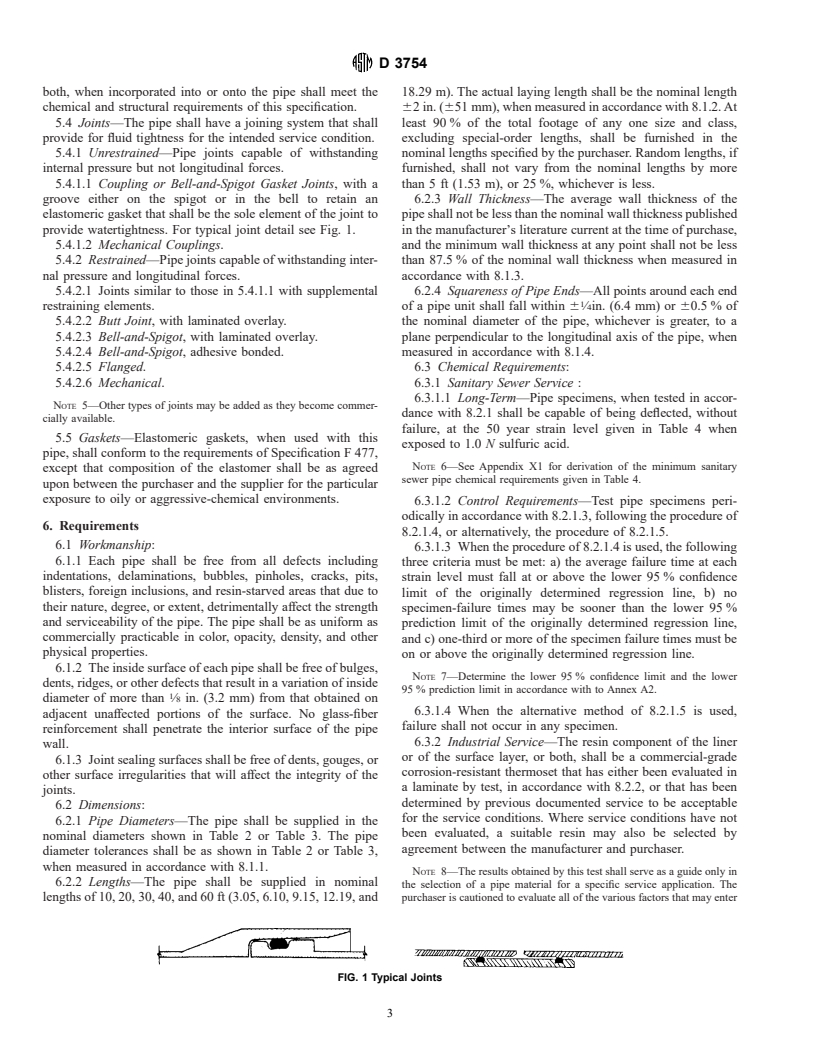

5.4.1.1 Coupling or Bell-and-Spigot Gasket Joints, with a than 5 ft (1.53 m), or 25 %, whichever is less.

groove either on the spigot or in the bell to retain an 6.2.3 Wall Thickness—The average wall thickness of the

elastomeric gasket that shall be the sole element of the joint to pipe shall not be less than the nominal wall thickness published

provide watertightness. For typical joint detail see Fig. 1. in the manufacturer’s literature current at the time of purchase,

5.4.1.2 Mechanical Couplings. and the minimum wall thickness at any point shall not be less

5.4.2 Restrained—Pipe joints capable of withstanding inter- than 87.5 % of the nominal wall thickness when measured in

nal pressure and longitudinal forces. accordance with 8.1.3.

5.4.2.1 Joints similar to those in 5.4.1.1 with supplemental 6.2.4 Squareness of Pipe Ends—All points around each end

restraining elements. of a pipe unit shall fall within 6 ⁄4in. (6.4 mm) or 60.5 % of

5.4.2.2 Butt Joint, with laminated overlay. the nominal diameter of the pipe, whichever is greater, to a

5.4.2.3 Bell-and-Spigot, with laminated overlay. plane perpendicular to the longitudinal axis of the pipe, when

5.4.2.4 Bell-and-Spigot, adhesive bonded. measured in accordance with 8.1.4.

5.4.2.5 Flanged. 6.3 Chemical Requirements:

5.4.2.6 Mechanical. 6.3.1 Sanitary Sewer Service :

6.3.1.1 Long-Term—Pipe specimens, when tested in accor-

NOTE 5—Other types of joints may be added as they become commer-

dance with 8.2.1 shall be capable of being deflected, without

cially available.

failure, at the 50 year strain level given in Table 4 when

5.5 Gaskets—Elastomeric gaskets, when used with this

exposed to 1.0 N sulfuric acid.

pipe, shall conform to the requirements of Specification F 477,

NOTE 6—See Appendix X1 for derivation of the minimum sanitary

except that composition of the elastomer shall be as agreed

sewer pipe chemical requirements given in Table 4.

upon between the purchaser and the supplier for the particular

exposure to oily or aggressive-chemical environments.

6.3.1.2 Control Requirements—Test pipe specimens peri-

odically in accordance with 8.2.1.3, following the procedure of

6. Requirements

8.2.1.4, or alternatively, the procedure of 8.2.1.5.

6.1 Workmanship:

6.3.1.3 When the procedure of 8.2.1.4 is used, the following

6.1.1 Each pipe shall be free from all defects including

three criteria must be met: a) the average failure time at each

indentations, delaminations, bubbles, pinholes, cracks, pits,

strain level must fall at or above the lower 95 % confidence

blisters, foreign inclusions, and resin-starved areas that due to

limit of the originally determined regression line, b) no

their nature, degree, or extent, detrimentally affect the strength

specimen-failure times may be sooner than the lower 95 %

and serviceability of the pipe. The pipe shall be as uniform as

prediction limit of the originally determined regression line,

commercially practicable in color, opacity, density, and other

and c) one-third or more of the specimen failure times must be

physical properties.

on or above the originally determined regression line.

6.1.2 The inside surface of each pipe shall be free of bulges,

NOTE 7—Determine the lower 95 % confidence limit and the lower

dents, ridges, or other defects that result in a variation of inside

95 % prediction limit in accordance with to Annex A2.

diameter of more than ⁄8 in. (3.2 mm) from that obtained on

6.3.1.4 When the alternative method of 8.2.1.5 is used,

adjacent unaffected portions of the surface. No glass-fiber

failure shall not occur in any specimen.

reinforcement shall penetrate the interior surface of the pipe

6.3.2 Industrial Service—The resin compon

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.