ASTM C1582/C1582M-04

(Specification)Standard Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete

Standard Specification for Admixtures to Inhibit Chloride-Induced Corrosion of Reinforcing Steel in Concrete

ABSTRACT

This specification covers material for use as chloride-corrosion-inhibiting admixtures for concrete. Concrete must meet the physical requirements such as compressive strength and flexural strength. The test admixture must show corrosion-inhibiting performance with the required mean integrated macrocell current of test beams and mean corroded area of test beams as a fraction of control. At the completion of testing, the mean chloride-ion content of the test beams must be greater than or equal to the critical chloride-ion content. Two types of concrete are used to make test specimens. One, the control concrete, is made without the chloride-corrosion-inhibiting admixture. The other concrete, the test concrete, is made with the chloride-corrosion-inhibiting admixture. Tests of freshly mixed concrete include slump test, air content test, and time of setting test. Test of hardened concrete include compressive strength test, flexural strength test, resistance to freezing and thawing test, and length change test. Corrosion testing shall also be done.

SCOPE

1.1 This specification covers material for use as chloride-corrosion-inhibiting admixtures for concrete.

1.2 Results of the tests conducted to meet this specification are not to be used to rank the expected field performance of various chloride-corrosion-inhibiting admixtures.

1.3 The values stated in either inch-pound or SI units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other without combining values in any way.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use. (Warning-Fresh hydraulic cementitious mixtures are caustic and may cause chemical burns to skin and tissue upon prolonged exposure.)

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1582/C1582M – 04

Standard Specification for

Admixtures to Inhibit Chloride-Induced Corrosion of

Reinforcing Steel in Concrete

This standard is issued under the fixed designation C1582/C1582M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C231 Test Method for Air Content of Freshly Mixed Con-

crete by the Pressure Method

1.1 This specification covers material for use as chloride-

C260 Specification for Air-Entraining Admixtures for Con-

corrosion-inhibiting admixtures for concrete.

crete

1.2 Results of the tests conducted to meet this specification

C403/C403M Test Method for Time of Setting of Concrete

are not to be used to rank the expected field performance of

Mixtures by Penetration Resistance

various chloride-corrosion-inhibiting admixtures.

C494/C494M Specification for Chemical Admixtures for

1.3 The values stated in either inch-pound or SI units shall

Concrete

be regarded separately as standard. The values stated in each

C666/C666M Test Method for Resistance of Concrete to

system may not be exact equivalents; therefore, each system

Rapid Freezing and Thawing

must be used independently of the other without combining

C1152/C1152M Test Method for Acid-Soluble Chloride in

values in any way.

Mortar and Concrete

1.4 This standard does not purport to address all of the

G15 Terminology Relating to Corrosion and Corrosion

safety concerns, if any, associated with its use. It is the

Testing

responsibility of the user of this standard to establish appro-

G109 Test Method for Determining Effects of Chemical

priate safety and health practices and determine the applica-

Admixtures on Corrosion of Embedded Steel Reinforce-

bility of regulatory requirements prior to use. (Warning—

ment in Concrete Exposed to Chloride Environments

Fresh hydraulic cementitious mixtures are caustic and may

2.2 American Concrete Institute Standard:

cause chemical burns to skin and tissue upon prolonged

ACI 211.1 Practice for Selecting Proportions of Normal,

exposure. )

Heavyweight, and Mass Concrete

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions—Refer to Terminologies C125 and G15 for

C39/C39M Test Method for Compressive Strength of Cy-

definitions of terms used in this specification.

lindrical Concrete Specimens

3.2 Definitions of Terms Specific to This Standard:

C78 Test Method for Flexural Strength of Concrete (Using

3.2.1 chloride-ion content—the acid-soluble chloride-ion

Simple Beam with Third-Point Loading)

content, measured according to Test Method C1152/C1152M,

C125 Terminology Relating to Concrete and Concrete Ag-

of a powder sample taken at a depth equal to the depth of

gregates

reinforcement.

C143/C143M Test Method for Slump of Hydraulic-Cement

3.2.2 completion of testing—when the following conditions

Concrete

are satisfied: (1) the mean integrated macrocell current in the

C150 Specification for Portland Cement

controlbeamsisgreaterthanorequalto150coulombs(C);and

C157/C157M Test Method for Length Change of Hardened

(2) the mean chloride-ion content of the test beams is greater

Hydraulic-Cement Mortar and Concrete

than or equal to the critical chloride-ion content.

3.2.2.1 Discussion—Refer to the Appendix for additional

This specification is under the jurisdiction of ASTM Committee C09 on

explanation of the methodology used to evaluate the perfor-

Concrete and ConcreteAggregates and is the direct responsibility of Subcommittee

mance of a chloride-corrosion-inhibiting admixture.

C09.23 on Chemical Admixtures.

3.2.3 control beams—beams subjected to the treatment in

Current edition approved Aug. 1, 2004. Published September 2004. DOI:

10.1520/C1582_C1582M-04.

Test Method G109 that are made from concrete without the

Section on Safety Precautions, Manual of Aggregate and Concrete Testing,

chloride-corrosion-inhibiting admixture.

Annual Book of ASTM Standards, Vol 04.02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from the American Concrete Institute, P.O. Box 9094, Farmington

the ASTM website. Hills, MI 48333-9094.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1582/C1582M – 04

3.2.4 critical chloride-ion content—the mean chloride-ion 4.2.2 The performance property retesting shall consist of

content in the unreinforced control beams at t plus the time of setting and compressive strength at 3, 7, and 28 days.

standard deviation. Purchasers having special requirements are allowed to require

3.2.5 reinforced beams—beams used to measure macrocell additional tests currently in this standard.

corrosion current according to Test Method G109. 4.3 At the request of the purchaser, the manufacturer shall

3.2.6 t —time when the mean integrated macrocell current state in writing that the admixture supplied for use in the

of the control beams reaches 50 C. project is identical in all essential respects, including concen-

3.2.7 t —time when the mean integrated macrocell cur- tration, to the admixture tested under this specification and

rent of the control beams reaches 150 C. found to comply therewith.

3.2.8 test beams—beams subjected to the treatment in Test 4.4 Tests for uniformity and equivalence shall be made on

Method G109 that are made from concrete with the chloride- the initial sample in accordance with Specification C494/

corrosion-inhibiting admixture. C494M, and the results retained for reference and comparison

3.2.9 unreinforced beams—beams without reinforcement withtheresultsoftestsofsamplestakenfromelsewherewithin

that are subjected to the cyclic ponding and drying treatment in the lot or subsequent lots of admixture supplied for use in the

Test Method G109 and used to determine chloride-ion content. project.

5. Corrosion-Inhibiting Performance

4. General Requirements

5.1 In addition to producing concrete that meets the require-

4.1 For initial compliance with this specification, test-

ments in Table 1, the test admixture must show corrosion-

concrete made with the chloride-corrosion-inhibiting admix-

inhibiting performance as summarized in Table 2 when tested

ture shall conform to the requirements prescribed in Table 1.

in accordance with Test Method G109 with reinforcing bar

4.2 Thepurchaserisallowedtorequirealimitedretestingto

depths and mixture proportions as specified in Sections 10 and

confirm current compliance of the admixture to specification

11 of this specification. The following requirements must be

requirements.The limited retesting covers physical and chemi-

attained.

cal properties and performance of the admixture.

5.2 At completion of testing (see 3.2.2), the mean integrated

4.2.1 The physical properties retesting shall consist of

macrocell current of the test beams must be less than or equal

uniformity and equivalence tests for infrared analysis, residue

to 50 C.

by oven drying, and specific gravity as described in Specifica-

5.3 At completion of testing, the mean corroded area of the

tion C494/C494M.

top reinforcing steel in the test beams must be less than or

equal to ⁄3 of the mean corroded area of the top steel in the

control beams.

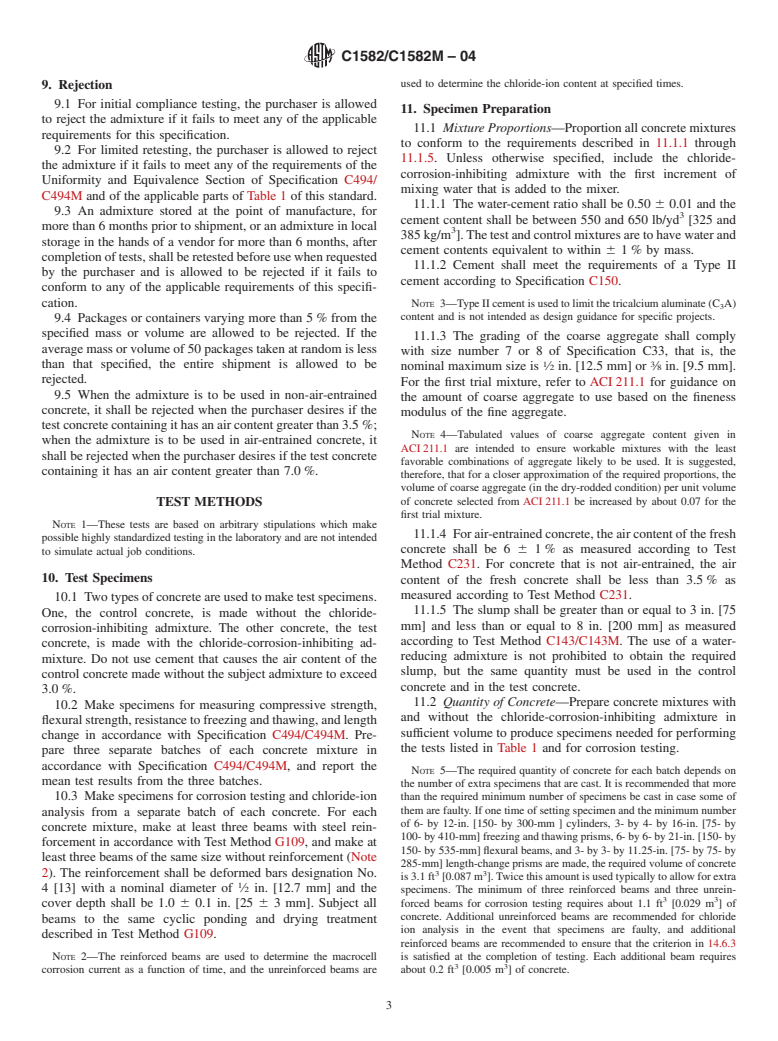

TABLE 1 Physical Requirements of Concrete Containing a

Chloride-Corrosion-Inhibiting Admixture

5.4 At the completion of testing, the mean chloride-ion

Time of setting, allowable deviation from control, h:min content of the test beams must be greater than or equal to the

Initial: not more than 3:30 earlier or later

critical chloride-ion content.

Final: not more than 3:30 earlier or later

6. Packaging and Package Marking

Strength:

Age Compressive strength, Flexural strength,

6.1 When the admixture is delivered in packages or con-

A,B A,B

min. % of control: min. % of control:

tainers, the proprietary name of the admixture and the net mass

3 days 80 80

7 days 80 80

orvolumeshallbeplainlymarkedthereon.Similarinformation

28 days 80 80

shall be provided in the shipping information accompanying

6 months 80

packaged or bulk shipments of admixtures.

1 year 80

C

Length change, max. shrinkage (alternative requirements)

7. Storage

Percent of control: 135

Increase over control, percentage points: 0.010

7.1 Store the admixture so as to permit easy access for

proper inspection and identification of each shipment, and in a

Relative durability factor, minimum %: 80

suitable weather-tight building that will protect the admixture

A

The values in the table include allowance for normal variation in test results.

from dampness and freezing.

The objective of the 80 % relative strength is to require a level of performance

comparable to that of the control concrete. Reinforced concrete, subjected to

brackish water, salt spray and/or deicers, requires a water-cement ratio of 0.40 or

8. Sampling and Inspection

less for long-term durability. This durability requirement results typically in com-

pressive strengths in excess of what is required structurally. If high-strength 8.1 Sampling and inspection shall be in accordance with

concrete is needed for structural purposes, mixture proportions may need to be

Specification C494/C494M.

adjusted when using a chloride-corrosion-inhibiting admixture.

B

The compressive and flexural strength of the concrete containing the admix-

ture under test at any test age shall not be less than 90 % of that attained at any

previous test age. The objective of this limit is to require that the compressive or TABLE 2 Corrosion Inhibiting Requirements

flexural strength of the concrete containing the admixture under test shall not

A

Mean integrated macrocell current of test beams, C # 50

decrease with age.

A

Mean corroded area of test beams, fraction of control # ⁄3

C

For the alternative requirements (see Specification C494/C494M), the percent

A

of control limit applies when length change of the control concrete is 0.030 % or At completion of testing using Test Method G109 and based on a minimum of

greater, and the increase over control limit applies when length change of the three specimens of control and test concrete, and discarded specimens are not

control concrete is less than 0.030 %. included.

C1582/C1582M – 04

used to determine the chloride-ion content at specified times.

9. Rejection

9.1 For initial compliance testing, the purchaser is allowed

11. Specimen Preparation

to reject the admixture if it fails to meet any of the applicable

11.1 Mixture Proportions—Proportion all concrete mixtures

requirements for this specification.

to conform to the requirements described in 11.1.1 through

9.2 For limited retesting, the purchaser is allowed to reject

11.1.5. Unless otherwise specified, include the chloride-

the admixture if it fails to meet any of the requirements of the

corrosion-inhibiting admixture with the first increment of

Uniformity and Equivalence Section of Specification C494/

mixing water that is added to the mixer.

C494M and of the applicable parts of Table 1 of this standard.

11.1.1 The water-cement ratio shall be 0.50 6 0.01 and the

9.3 An admixture stored at the point of manufacture, for

cement content shall be between 550 and 650 lb/yd [325 and

more than 6 months prior to shipment, or an admixture in local

385kg/m ].Thetestandcontrolmixturesaretohavewaterand

storage in the hands of a vendor for more than 6 months, after

cement contents equivalent to within 6 1 % by mass.

completionoftests,shallberetestedbeforeusewhenrequested

11.1.2 Cement shall meet the requirements of a Type II

by the purchaser and is allowed to be rejected if it fails to

cement according to Specification C150.

conform to any of the applicable requirements of this specifi-

cation. NOTE 3—TypeIIcementisusedtolimitthetricalciumaluminate(C A)

content and is not intended as design guidance for specific projects.

9.4 Packages or containers varying more than 5 % from the

specified mass or volume are allowed to be rejected. If the

11.1.3 The grading of the coarse aggregate shall comply

average mass or volume of 50 packages taken at random is less

with size number 7 or 8 of Specification C33, that is, the

1 3

than that specified, the entire shipment is allowed to be

nominal maximum size is ⁄2 in. [12.5 mm] or ⁄8 in. [9.5 mm].

rejected.

For the first trial mixture, refer to ACI 211.1 for guidance on

9.5 When the admixture is to be used in non-air-entrained

the amount of coarse aggregate to use based on the fineness

concrete, it shall be rejected when the purchaser desires if the

modulus of the fine aggregate.

testconcretecontainingithasanaircontentgreaterthan3.5 %;

NOTE 4—Tabulated values of coarse aggregate content given in

when the admixture is to be used in air-entrained concrete, it

ACI 211.1 are intended to ensure workable mixtures with the least

shall be rejected when the purchaser desires if the test concrete

favorable combinations of aggregate likely to be used. It is suggested,

containing it has an air content greater than 7.0 %.

therefore, that for a closer approximation of the required proportions, the

volume of coarse aggregate (in the dry-rodded condition) per unit volume

of concrete selected from ACI 211.1 be increased by about 0.07 for the

TEST METHODS

first trial mixture.

NOTE 1—These tests are based on arbitrary stipulations which make

11.1.4 For air-entrained concrete, the air content of the fresh

possible highly standardized testing in the laboratory and are not intended

concrete shall be 6 6 1 % as measured according to Test

to simulate actual job conditions.

Method C231. For concrete that is not air-entrained, the air

10. Test Specimens

content of the fresh concrete shall be less than 3.5 % as

measured according to Test Method C231.

10.1 Twotypesofconcreteareusedtomaketestspecimens.

11.1.5 The slump shall be greater than or equal to 3 in. [75

One, the control concrete, is made without the chloride-

mm] and less than or equal to 8 in. [200 mm] as measured

corrosion-inhibiting admixture. The other concrete, the test

according to Test Method C143/C143M. The use of a water-

concrete, is made with the chloride-corrosion-inhibiting ad-

reducing admixture is not prohibited to obtain the required

mixture. Do not use cement that causes the air content of the

slump, but the same quantity must be used in the control

control concrete made without the subject admixture to exceed

concrete and in the test concrete.

3.0 %.

11.2 Quantity of Concrete—Prepare concrete mixtures with

10.2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.