ASTM F877-11

(Specification)Standard Specification for Crosslinked Polyethylene (PEX) Hot- and Cold-Water Distribution Systems

Standard Specification for Crosslinked Polyethylene (PEX) Hot- and Cold-Water Distribution Systems

ABSTRACT

This specification covers requirements, test methods, and methods of marking for crosslinked polyethylene plastic hot- and cold-water distribution systems components made in one standard dimension ratio. Components are comprised of tubing and fittings intended for use in residential and commercial, hot and cold, potable water distribution systems as well as sealed central heating, including under-floor heating systems. Requirements and test methods are included for materials, workmanship, dimensions and tolerances, burst pressure, sustained pressure, excessive temperature and pressure, temperature cycling tests, and bend strength. Also included are tests related to system malfunctions.

SCOPE

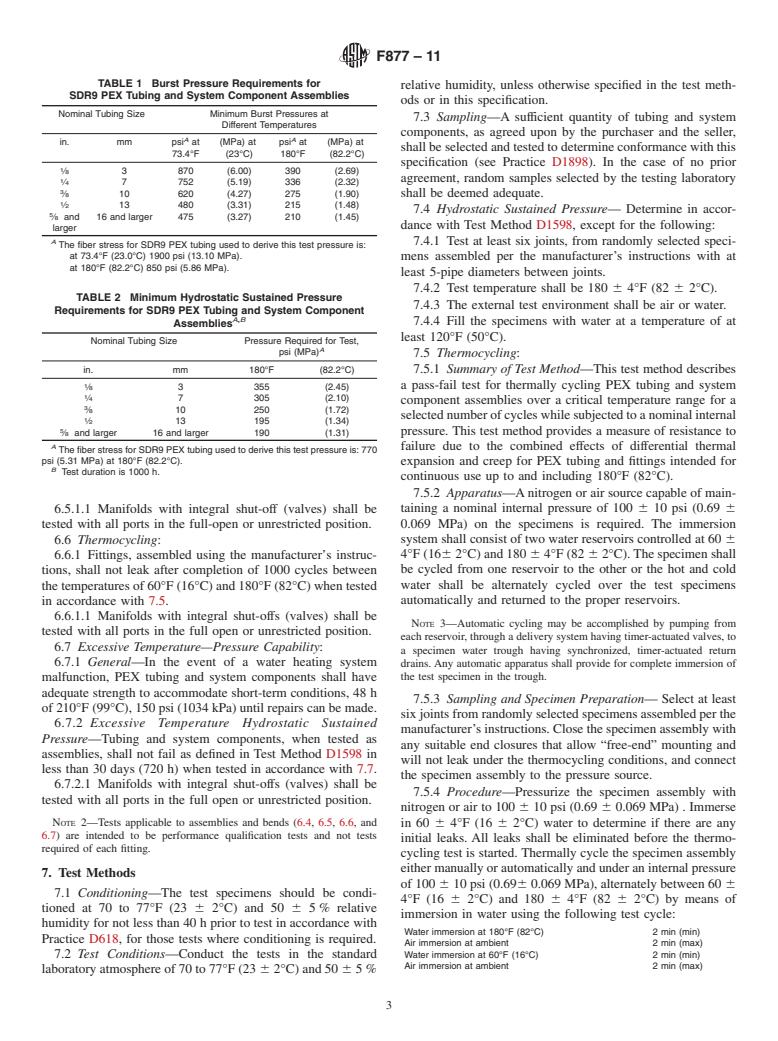

1.1 This specification covers requirements, test methods, and marking requirements for system components when tested with nominal SDR9 crosslinked polyethylene tubing as a system. Systems are intended for 100 psi (0.69 MPa) water service up to and including a maximum working temperature of 180°F (82°C). Requirements and test methods are included for materials, workmanship, dimensions and tolerances, burst pressure, sustained pressure, excessive temperature and pressure, and thermo-cycling tests. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems or other applications such as municipal water service lines, radiant panel heating systems, hydronic baseboard heating systems, snow and ice melting systems, and building services pipe.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are provided for information only.

Note 1—Suggested hydrostatic design stresses and hydrostatic pressure ratings for tubing and fittings are listed in Appendix X1. Design, assembly, and installation considerations are discussed in Appendix X2. An optional performance qualification and an in-plant quality control program are recommended in Appendix X3.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F877 – 11

Standard Specification for

Crosslinked Polyethylene (PEX) Hot- and Cold-Water

1

Distribution Systems

ThisstandardisissuedunderthefixeddesignationF877;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers requirements, test methods, 2.1 ASTM Standards:

and marking requirements for system components when tested D618 Practice for Conditioning Plastics for Testing

with nominal SDR9 crosslinked polyethylene tubing as a D1598 Test Method for Time-to-Failure of Plastic Pipe

system. Systems are intended for 100 psi (0.69 MPa) water Under Constant Internal Pressure

service up to and including a maximum working temperature D1599 TestMethodforResistancetoShort-TimeHydraulic

of 180°F (82°C). Requirements and test methods are included Pressure of Plastic Pipe, Tubing, and Fittings

for materials, workmanship, dimensions and tolerances, burst D1600 Terminology for Abbreviated Terms Relating to

pressure, sustained pressure, excessive temperature and pres- Plastics

3

sure, and thermo-cycling tests. The components covered by D1898 Practice for Sampling of Plastics

this specification are intended for use in residential and D2749 Symbols for Dimensions of Plastic Pipe Fittings

commercial,hotandcold,potablewaterdistributionsystemsor D2837 TestMethodforObtainingHydrostaticDesignBasis

other applications such as municipal water service lines, forThermoplastic Pipe Materials or Pressure Design Basis

radiant panel heating systems, hydronic baseboard heating for Thermoplastic Pipe Products

3

systems, snow and ice melting systems, and building services D3140 Practice For Flaring Polyolefin Pipe And Tubing

pipe. F412 Terminology Relating to Plastic Piping Systems

1.2 The text of this specification references notes, footnotes, F876 Specification for Crosslinked Polyethylene (PEX)

and appendixes which provide explanatory material. These Tubing

notesandfootnotes(excludingthoseintablesandfigures)shall F1960 Specification for Cold Expansion Fittings with PEX

not be considered as requirements of the specification. Reinforcing Rings for Use with Cross-linked Polyethylene

1.3 The values stated in inch-pound units are to be regarded (PEX) Tubing

as the standard. The values stated in parentheses are provided F1961 Specification for Metal Mechanical Cold Flare Com-

for information only. pression Fittings with Disc Spring for Crosslinked Poly-

ethylene (PEX) Tubing

NOTE 1—Suggested hydrostatic design stresses and hydrostatic pres-

F1807 Specification for Metal Insert Fittings Utilizing a

sure ratings for tubing and fittings are listed in Appendix X1. Design,

Copper Crimp Ring for SDR9 Cross-linked Polyethylene

assembly, and installation considerations are discussed in Appendix X2.

(PEX)Tubing and SDR9 Polyethylene of RaisedTempera-

An optional performance qualification and an in-plant quality control

program are recommended in Appendix X3.

ture (PE-RT) Tubing

F1865 Specification for Mechanical Cold Expansion Insert

1.4 The following safety hazards caveat pertains only to the

FittingWithCompressionSleeveforCross-linkedPolyeth-

test method portion, Section 7, of this specification: This

ylene (PEX) Tubing

standard does not purport to address all of the safety concerns,

F2080 Specification for Cold-Expansion Fittings With

if any, associated with its use. It is the responsibility of the user

Metal Compression-Sleeves for Cross-Linked Polyethyl-

of this standard to establish appropriate safety and health

ene (PEX) Pipe

practices and determine the applicability of regulatory limita-

tions prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic Standards volume information, refer to the standard’s Document Summary page on

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. the ASTM website.

3

CurrenteditionapprovedJune1,2011.PublishedJuly2011.Originallyapproved Withdrawn. The last approved version of this historical standard is referenced

in 1984. Last previous approved 2007 as F877 – 07. DOI: 10.1520/F0877-11. on www.astm.org.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F877 – 11

F2159 Specification for Plastic Insert Fittings Utilizing a 4. Materials

Copper

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F877–07 Designation: F877 – 11

Standard Specification for

Crosslinked Polyethylene (PEX) Plastic Hot- and Cold-Water

1

Distribution Systems

ThisstandardisissuedunderthefixeddesignationF877;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1This specification covers requirements, test methods, and methods of marking for crosslinked polyethylene plastic hot- and

cold-water distribution systems components made in one standard dimension ratio and intended for 100 psi (0.69 MPa) water

service up to and including a maximum working temperature of 180°F (82°C). Components are comprised of tubing and fittings.

Requirements and test methods are included for materials, workmanship, dimensions and tolerances, burst pressure, sustained

pressure,excessivetemperatureandpressure,temperaturecyclingtests,andbendstrength.Alsoincludedaretestsrelatedtosystem

malfunctions. The components covered by this specification are intended for use in residential and commercial, hot and cold,

potable water distribution systems as well as sealed central heating, including under-floor heating systems. Scope*

1.1 This specification covers requirements, test methods, and marking requirements for system components when tested with

nominal SDR9 crosslinked polyethylene tubing as a system. Systems are intended for 100 psi (0.69 MPa) water service up to and

including a maximum working temperature of 180°F (82°C). Requirements and test methods are included for materials,

workmanship, dimensions and tolerances, burst pressure, sustained pressure, excessive temperature and pressure, and thermo-

cycling tests. The components covered by this specification are intended for use in residential and commercial, hot and cold,

potable water distribution systems or other applications such as municipal water service lines, radiant panel heating systems,

hydronic baseboard heating systems, snow and ice melting systems, and building services pipe.

1.2 The text of this specification references notes, footnotes, and appendixes which provide explanatory material. These notes

and footnotes (excluding those in tables and figures) shall not be considered as requirements of the specification.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values stated in parentheses are provided for

information only.

NOTE 1—Suggested hydrostatic design stresses and hydrostatic pressure ratings for tubing and fittings are listed in Appendix X1. Design, assembly,

and installation considerations are discussed in Appendix X2. An optional performance qualification and an in-plant quality control program are

recommended in Appendix X3.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification: This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D618 Practice for Conditioning Plastics for Testing

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

3

D1898 Practice for Sampling of Plastics

D2749 Symbols for Dimensions of Plastic Pipe Fittings

D2837 Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for

Thermoplastic Pipe Products

3

D3140 Practice forFor Flaring Polyolefin Pipe andAnd Tubing

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

Current edition approved Feb. 1, 2007. Published February 2007. Originally approved in 1984. Last previous approved 2005 as F877–05. DOI: 10.1520/F0877-07.

Current edition approved June 1, 2011. Published July 2011. Originally approved in 1984. Last previous approved 2007 as F877 – 07. DOI: 10.1520/F0877-11.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.