ASTM C1206-02(2010)

(Test Method)Standard Test Method for Plutonium by Iron (II)/Chromium (VI) Amperometric Titration (Withdrawn 2015)

Standard Test Method for Plutonium by Iron (II)/Chromium (VI) Amperometric Titration (Withdrawn 2015)

SIGNIFICANCE AND USE

All plutonium materials covered in this test method are used in the preparation of nuclear-reactor fuels. In order to be suitable for this purpose, the materials must meet specified criteria for plutonium content. This test method is used to verify the plutonium content.

A primary standard dichromate such as that available from National Institute of Standards and Technology (NIST) or a dichromate traceable to a primary standard such as New Brunswick Laboratory (NBL) plutonium standard, is required for this technique.

SCOPE

1.1 This test method covers the determination of plutonium in unirradiated nuclear-grade plutonium dioxide, uranium-plutonium mixed oxides with uranium (U)/plutonium (Pu) ratios up to 21, plutonium metal, and plutonium nitrate solutions. Optimum quantities of plutonium to measure are 7 to 15 mg.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covered the determination of plutonium in unirradiated nuclear-grade plutonium dioxide, uranium-plutonium mixed oxides with uranium (U)/plutonium (Pu) ratios up to 21, plutonium metal, and plutonium nitrate solutions. Optimum quantities of plutonium to measure are 7 to 15 mg.

Formerly under the jurisdiction of Committee C26 on Nuclear Fuel Cycle, this test method was withdrawn in June 2015. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1206 − 02 (Reapproved2010)

Standard Test Method for

Plutonium by Iron (II)/Chromium (VI) Amperometric

Titration

This standard is issued under the fixed designation C1206; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope testmethoddoesnotautomaticallyguaranteeregulatoryaccep-

tance of the resulting safeguards measurements. It remains the

1.1 This test method covers the determination of plutonium

sole responsibility of the user of this test method to ensure that

in unirradiated nuclear-grade plutonium dioxide, uranium-

its application to safeguards has the approval of the proper

plutonium mixed oxides with uranium (U)/plutonium (Pu)

regulatory authorities.

ratios up to 21, plutonium metal, and plutonium nitrate

solutions.Optimumquantitiesofplutoniumtomeasureare7to

4. Summary of Test Method

15 mg.

4.1 Amperometric titrations are based on the measured

1.2 The values stated in SI units are to be regarded as

change in the current flow between two electrodes, held at

standard. No other units of measurement are included in this

constant potential, when a titrant is added. The plutonium is

standard.

first oxidized to the +6 oxidation state in a dilute sulfuric acid

1.3 This standard does not purport to address all of the

solution with argentic oxide. The excess oxidant is destroyed

safety concerns, if any, associated with its use. It is the

by heating, and the Pu(VI) is then reduced to Pu(IV) by excess

responsibility of the user of this standard to establish appro-

Fe(II) during the titration. The excess Fe(II) is titrated by

priate safety and health practices and determine the applica-

Cr(VI), and the Pu determined by difference from the quanti-

bility of regulatory limitations prior to use.

ties of the two titrants.

4.2 Oxide and metal samples are prepared to produce final

2. Referenced Documents

solutions as a soluble sulfate. Plutonium-nitrate solutions can

2.1 ASTM Standards:

beintroduceddirectlyatthebeginningoftheprocedureandare

C1168 PracticeforPreparationandDissolutionofPlutonium

later diluted with sulfuric acid. Chlorides must be removed.

Materials for Analysis

5. Significance and Use

3. Committee C-26 Safeguards Statement

5.1 All plutonium materials covered in this test method are

3.1 The materials [nuclear-grade mixed oxides (U, Pu)O

used in the preparation of nuclear-reactor fuels. In order to be

powders,pellets,Pumetal,Puoxides,andPunitrates]towhich

suitable for this purpose, the materials must meet specified

this test method applies, are subject to nuclear safeguards

criteria for plutonium content. This test method is used to

regulations governing their possession and use. This analytical

verify the plutonium content.

test method has been designated as technically acceptable for

5.2 A primary standard dichromate such as that available

generating safeguards accountability measurement data for

fromNationalInstituteofStandardsandTechnology(NIST)or

plutonium.

a dichromate traceable to a primary standard such as New

3.2 When used in conjunction with appropriate standard

Brunswick Laboratory (NBL) plutonium standard, is required

referencematerialthistestmethodcandemonstratetraceability

for this technique.

to the national measurement base. However, adherence to this

6. Interferences

This test method is under the jurisdiction ofASTM Committee C26 on Nuclear

6.1 Interference is caused by ions that are oxidized by

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of

argentic oxide and reduced by ferrous ion in sulfuric-acid

Test.

solution. Elements that may be present in plutonium materials

Current edition approved Jan. 1, 2010. Published February 2010. Originally

and that will produce quantitative positive errors include

approved in 1991. Last previous edition approved in 2002 as C1206 – 02. DOI:

10.1520/C1206-02R10.

vanadium (V), chromium (Cr), and manganese (Mn). Correc-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tion can be made for these elements by calculation when they

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

do not individually exceed 200 µg impurity elements per gram

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. of plutonium.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1206 − 02 (2010)

6.2 Other elements that will cause positive errors include

cerium (Ce), ruthenium (Ru), gold (Au), rhodium (Rh), plati-

num (Pt), lead (Pb), and neptunium (Np). Americium (Am)

does not interfere because it is not oxidized to higher valency

states during the argentic oxidation.

6.3 Thallium (Tl), selenium (Se), calcium (Ca), and barium

(Ba) give low results.

7. Apparatus

7.1 Weighing Burets, polyethylene drop-dispenser bottles

with polypropylene dropping closure and cap, 30 and 60-mL

sizes. Squeeze deliveries are made with these burets.They are

placed in a secondary, cut-off, slightly larger diameter polyeth-

ylene bottle to prevent mass changes from contact with the

hands. Burets are transferred to and from the balance using

forceps.

7.2 Digital Voltmeter, d-c precision, readable to 0.2 mv.

7.3 Microelectrode, rotating platinum.

7.4 Reference Mercury Electrode, saturated mercurous sul-

fate.

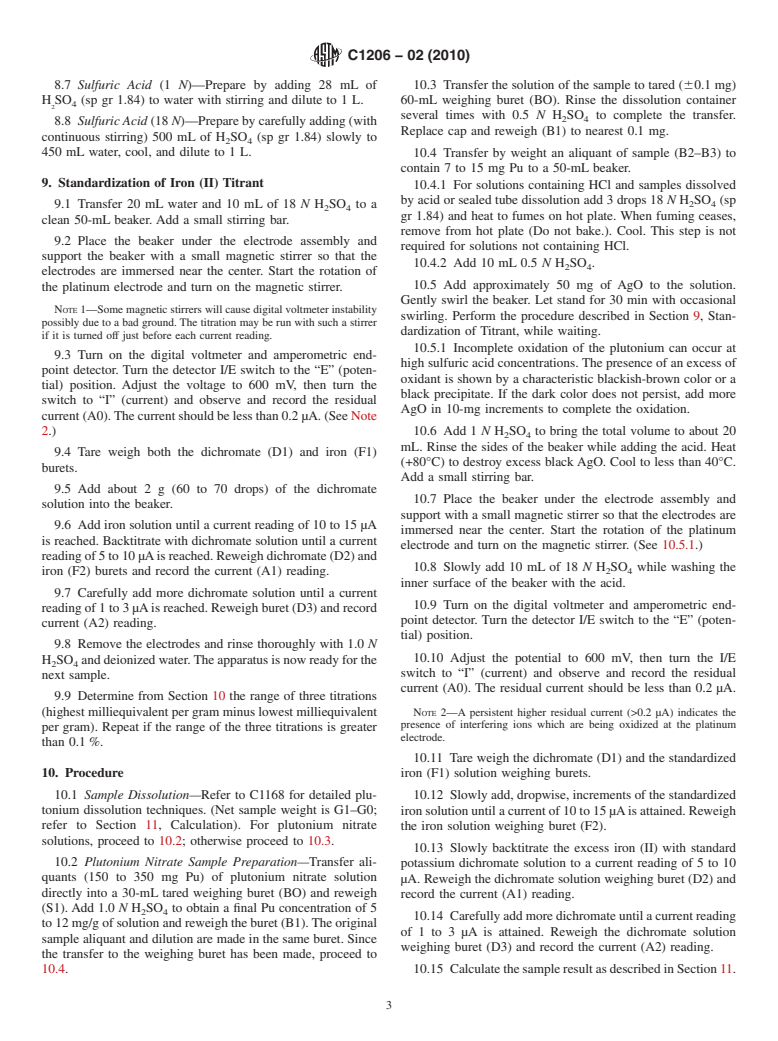

7.5 Titrator/Detector, amperometric (see Fig. 1).

8. Reagents

8.1 Purity of Reagents—Reagent grade chemicals shall be

FIG. 1 Amperometric Detector Circuit

used in all tests. Unless otherwise indicated, it is intended that

all reagents conform to the specifications of the Committee on

Analytical Reagents of the American Chemical Society where

8.4 Ferrous Ammonium Sulfate Solution, Iron (II) Titrant—

such specifications are available. Other grades may be used,

Dissolve 19.6 g of Fe(NH ) (SO ) ·6 H O in 500 mL of cold

4 2 4 2 2

provided it is first ascertained that the reagent is of sufficient

1 N H SO and dilute to 1 L with 1 N H SO . The solution is

2 4 2 4

high purity to permit its use without lessening the accuracy of

standardized daily or before beginning a series of plutonium

the determination.

standard and sample titrations, or both.

8.2 Purity of Water—Unless otherwise indicated, references

8.5 Potassium Dichromate Solution—UseNISTSRM136e

to water shall be understood to mean deionized or distilled

or equivalent. Weigh approximately 4.9 g to nearest 0.0001 g

water.

of potassium dichromate (K Cr O ) and dissolve in water.

2 2 7

Transfer to a tared 2-Lvolumetric flask. Dilute to volume with

8.3 Argentic Oxide (AgO).

water. Weigh the flask and contents. Make the buoyancy

correction and determine the mass of the solution. Express the

Nalgene drop-dispenser bottles, Nos. 2411-0030 and 2411-0060 have been

oxidizing strength as milliequivalents per gram of solution

found satisfactory. If you are aware of alternative suppliers, please provide this

(C1).

information to ASTM International Headquarters. Your comments will receive

careful consideration at a meeting of the responsible technical committee, which

K 3 P 3 B

you may attend.

C1 5 (1)

4 E 3 S

Both Ealing Pye Scalamp Microammeter No. 29-222 and Keithley Model 197

Digital Multimeter have been found satisfactory. If you are aware of alternative

where:

suppliers, please provide this information to ASTM International Headquarters.

Your comments will receive careful consideration at a meeting of the responsible

C1=K Cr O concentration, milliequivalents per gram,

2 2 7

technical committee, which you may attend.

K = weight, mg, K Cr O ,

2 2 7

Both Sargent & Co. No. S-30420 with No. S-76485 synchronous rotator and

P = purity of K Cr O ,

2 2 7

Brinkmann Model 2.628.0010 (628-10, 68-50) have been found satisfactory. If you

B = buoyancy correction for K Cr O , 1.00031 (use only if

are aware of alternative suppliers, please provide this information to ASTM 2 2 7

International Headquarters. Your comments will receive careful consideration at a

significant),

meeting of the responsible technical committee, which you may attend.

E = equivalent weight of K Cr O , 49.0320, and

2 2 7

Brinkmann Model EA 406 has been found satisfactory. If you are aware of

S = weight of solution, g.

alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the

8.6 Sulfuric Acid (0.5 N)—Prepare by adding 14 mL of

responsible technical committee, which you may attend.

sulfuric acid (H SO , sp gr 1.84) to water with stirring and

7 2 4

Reagent Chemicals, American Chemical Society Specifications, American

dilute to 1 L.

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, Available from National Institute of Standards and Technology (NIST), 100

MD. Bur

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.