ASTM F3007-13

(Test Method)Standard Test Method for Ball Drop Impact Resistance of Laminated Architectural Flat Glass

Standard Test Method for Ball Drop Impact Resistance of Laminated Architectural Flat Glass

SIGNIFICANCE AND USE

5.1 The impact performance of laminated glass varies with the glass ply thickness, type, and kind as well as the thickness and type of interlayer used in the overall configuration.

5.2 Specific safety properties are required for laminated glass to meet the safety glazing requirements of ANSI Z97.1 and CPSC 16 CFR 1201. Compliance with the minimum quality requirements of Specification C1172 does not constitute compliance or assure compliance with the referenced safety glazing standards.

5.3 While this test method does not replace the test requirements of ANSI Z97.1 or CPSC 16 CFR 1201 safety glazing standards addressed above, destructive ball drop impact testing does provide a method of expeditious in-plant evaluation of laminated glass products being fabricated.

5.4 Impact procedures for testing in accordance with safety glazing standards ANSI Z97.1 and CPSC 16 CFR 1201 differ from this ball drop test method; however, the penetration resistance of a single laminated lite can be determined and used for quality control purposes.

SCOPE

1.1 This test method covers the destructive ball drop testing of laminated flat glass products intended for use in architectural glazing applications.

1.2 This test method is intended for use as an in-plant quality control test to evaluate the impact performance of laminated flat glass when a 2.3 kg, 83 mm diameter smooth solid steel ball is dropped from a user selected height.

1.3 This test method is not a substitute for safety glazing test requirements of ANSI Z97.1 or CPSC 16 CFR 1201.

1.4 This test method is applicable to symmetrical and asymmetrical annealed, heat-strengthened, chemically strengthened, fully tempered laminated architectural flat glass including but not limited to: float, patterned, sheet, sand-blasted, grooved, and fritted.

1.5 The values stated in SI units are to be regarded as standard. No other units of measure are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Some specific hazards statements are given in Section 7 on Hazards.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3007 − 13 An American National Standard

Standard Test Method for

Ball Drop Impact Resistance of Laminated Architectural Flat

1

Glass

This standard is issued under the fixed designation F3007; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C1422 Specification for Chemically Strengthened Flat Glass

3

2.2 ANSI Standards:

1.1 This test method covers the destructive ball drop testing

Z26.1 American National Standard for Safety Glazing Ma-

oflaminatedflatglassproductsintendedforuseinarchitectural

terials for Glazing Motor Vehicles and Motor Vehicle

glazing applications.

Equipment Operating on Land Highways—Safety Stan-

1.2 This test method is intended for use as an in-plant

dard

quality control test to evaluate the impact performance of

Z97.1 American National Standard for Safety Glazing Ma-

laminated flat glass when a 2.3 kg, 83 mm diameter smooth

terials Used in Buildings—Safety Performance Specifica-

solid steel ball is dropped from a user selected height.

tion and Methods of Test

4

2.3 CPSC Standards:

1.3 Thistestmethodisnotasubstituteforsafetyglazingtest

requirements of ANSI Z97.1 or CPSC 16 CFR 1201. CPSC 16 CFR 1201 Safety Standard forArchitectural Glaz-

ing Materials

1.4 This test method is applicable to symmetrical and

asymmetrical annealed, heat-strengthened, chemically

3. Terminology

strengthened, fully tempered laminated architectural flat glass

3.1 Definitions:

including but not limited to: float, patterned, sheet, sand-

3.1.1 For definitions of terms used in this test method, refer

blasted, grooved, and fritted.

to Terminology C162.

1.5 The values stated in SI units are to be regarded as

4. Summary of Test Method

standard. No other units of measure are included in this

standard.

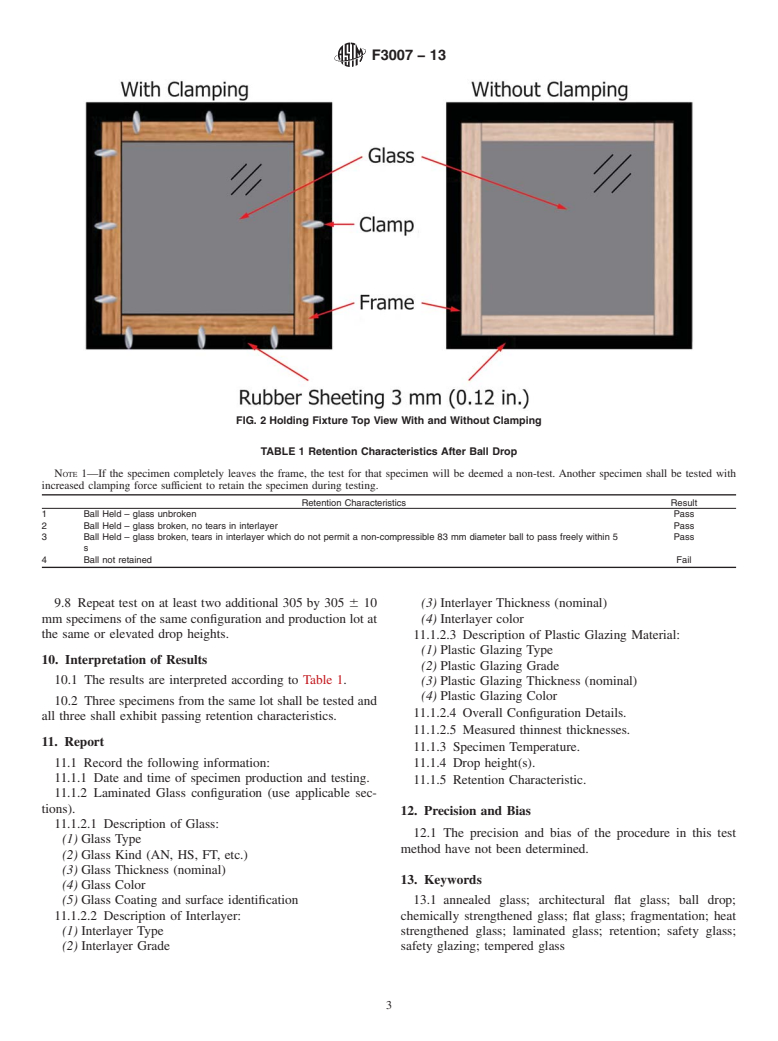

4.1 In this test method, a single lite of laminated glass

1.6 This standard does not purport to address all of the (eithermadetosizeorcuttosize)thathasbeenfabricatedfrom

safety concerns, if any, associated with its use. It is the glass meeting the specification of Specifications C1036 or

responsibility of the user of this standard to establish appro-

C1048, or both, and quality parameters of Specification C1172

priate safety and health practices and determine the applica- is removed from the production process and subjected to

bility of regulatory limitations prior to use. Some specific

destructive ball drop testing. After impact, the retention per-

hazards statements are given in Section 7 on Hazards. formance of the laminate is recorded and achieved drop height

documented.

2. Referenced Documents

5. Significance and Use

2

2.1 ASTM Standards:

5.1 The impact performance of laminated glass varies with

C162 Terminology of Glass and Glass Products

the glass ply thickness, type, and kind as well as the thickness

C1036 Specification for Flat Glass

and type of interlayer used in the overall configuration.

C1048 Specification for Heat-Strengthened and Fully Tem-

pered Flat Glass

5.2 Specific safety properties are required for laminated

C1172 Specification for Laminated Architectural Flat Glass

glass to meet the safety glazing requirements of ANSI Z97.1

and CPSC 16 CFR 1201. Compliance with the minimum

quality requirements of Specification C1172 does not consti-

1

This test method is under the jurisdiction ofASTM Committee F12 on Security

tute compliance or assure compliance with the referenced

Systems and Equipment and is the direct responsibility of Subcommittee F12.10 on

Systems Products and Services.

safety glazing standards.

Current edition approved Aug. 1, 2013. Published August 2013. DOI: 10.1520/

F3007-13.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from U.S. Consumer Product Safety Commission (CPSC), 4330 East

the ASTM website. West Hwy., Bethesda, MD 20814, http://www.cpsc.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3007 − 13

5.3 While this test method does not replace the test require- 9. Procedure

ments of ANSI Z97.1 or CPSC 16 CFR 1201 safety glazing

9.1 Record the minimum thickness of the specimen.

standards addressed above, destructive ball drop impact testing

NOTE 1—The thickness of the specimen shall be measured at the

does provide a method of exp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.