ASTM E881-92(2003)

(Practice)Standard Practice for Exposure of Solar Collector Cover Materials to Natural Weathering Under Conditions Simulating Stagnation Mode

Standard Practice for Exposure of Solar Collector Cover Materials to Natural Weathering Under Conditions Simulating Stagnation Mode

SIGNIFICANCE AND USE

This practice describes a weathering box test fixture and establishes limits for the heat loss coefficients. Uniform exposure guidelines are provided to minimize the variables encountered during outdoor exposure testing.

Since the combination of elevated temperature and solar radiation may cause some solar collector cover materials to degrade more rapidly than either exposure alone, a weathering box that elevates the temperature of the cover materials is used.

This practice may be used to assist in the evaluation of solar collector cover materials in the stagnation mode. No single temperature or procedure can duplicate the range of temperatures and environmental conditions to which cover materials may be exposed during stagnation conditions. To assist in evaluation of solar collector cover materials in the operational mode, Practice E 782 should be used. Insufficient data exist to obtain exact correlation between the behavior of materials exposed in accordance with this practice and actual in-service performance.

This practice may also be useful in comparing the performance of different materials at one site or the performance of the same material at different sites, or both.

Means of evaluating the effects of weathering are provided in Practice E 765, and in other ASTM test methods that evaluate material properties.

Exposures of the type described in this practice may be used to evaluate the stability of solar collector cover materials when exposed outdoors to the varied influences that comprise weather. Exposure conditions are complex and changeable. Important factors are material temperature, climate, time of year, presence of industrial pollution, etc. Generally, because it is difficult to define or measure precisely the factors influencing degradation due to weathering, results of outdoor exposure tests must be taken as indicative only. Repeated exposure testing at different seasons over a period of more than one year is required to confirm exposure t...

SCOPE

1.1 This practice covers a procedure for the exposure of solar collector cover materials to the natural weather environment at elevated temperatures that approximate stagnation conditions in solar collectors having a combined back and edge loss coefficient of less than 1.5 W/(m2 C).

1.2 This practice is suitable for exposure of both glass and plastic solar collector cover materials. Provisions are made for exposure of single and double cover assemblies to accommodate the need for exposure of both inner and outer solar collector cover materials.

1.3 This practice does not apply to cover materials for evacuated collectors, photovoltaic cells, flat-plate collectors having a combined back and edge loss coefficient greater than 1.5 W/(m2 C), or flat-plate collectors whose design incorporates means for limiting temperatures during stagnation.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 881 – 92 (Reapproved 2003)

Standard Practice for

Exposure of Solar Collector Cover Materials to Natural

Weathering Under Conditions Simulating Stagnation Mode

This standard is issued under the fixed designation E881; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope FederalSpecificationHH-I-558B, Amendment3,Insulation

Blocks,Boards,Felts,Sleeving(PipeandTubeCovering),

1.1 This practice covers a procedure for the exposure of

and Pipe Fitting CoveringThermal (Mineral Fiber, Indus-

solar collector cover materials to the natural weather environ-

trial Type) August 1976

ment at elevated temperatures that approximate stagnation

conditionsinsolarcollectorshavingacombinedbackandedge

3. Terminology

loss coefficient of less than 1.5 W/(m · °C).

3.1 Definitions—For definitions of terms used in this

1.2 This practice is suitable for exposure of both glass and

practice, refer to Terminology E772.

plastic solar collector cover materials. Provisions are made for

exposure of single and double cover assemblies to accommo-

4. Significance and Use

date the need for exposure of both inner and outer solar

4.1 Thispracticedescribesaweatheringboxtestfixtureand

collector cover materials.

establishes limits for the heat loss coefficients. Uniform expo-

1.3 This practice does not apply to cover materials for

sureguidelinesareprovidedtominimizethevariablesencoun-

evacuated collectors, photovoltaic cells, flat-plate collectors

tered during outdoor exposure testing.

having a combined back and edge loss coefficient greater than

4.2 Sincethecombinationofelevatedtemperatureandsolar

1.5 W/(m ·° C), or flat-plate collectors whose design incorpo-

radiation may cause some solar collector cover materials to

rates means for limiting temperatures during stagnation.

degrade more rapidly than either exposure alone, a weathering

1.4 This standard does not purport to address all of the

boxthatelevatesthetemperatureofthecovermaterialsisused.

safety concerns, if any, associated with its use. It is the

4.3 This practice may be used to assist in the evaluation of

responsibility of the user of this standard to establish appro-

solar collector cover materials in the stagnation mode. No

priate safety and health practices and determine the applica-

single temperature or procedure can duplicate the range of

bility of regulatory limitations prior to use.

temperatures and environmental conditions to which cover

materials may be exposed during stagnation conditions. To

2. Referenced Documents

assist in evaluation of solar collector cover materials in the

2.1 ASTM Standards:

2 operational mode, Practice E782 should be used. Insufficient

D1435 Practice for Outdoor Weathering of Plastics

data exist to obtain exact correlation between the behavior of

E765 Practice for Evaluation of Cover Materials for Flat

3 materials exposed in accordance with this practice and actual

Plate Solar Collectors

3 in-service performance.

E772 Terminology Relating to Solar Energy Conversion

4.4 This practice may also be useful in comparing the

E782 Practice for Exposure of Cover Materials for Solar

performance of different materials at one site or the perfor-

Collectors to Natural Weathering Under Conditions Simu-

3 mance of the same material at different sites, or both.

lating Operational Mode

4.5 Means of evaluating the effects of weathering are

G7 Practice for Atmospheric Environmental Exposure

4 provided in Practice E765, and in other ASTM test methods

Testing of Nonmetallic Materials

that evaluate material properties.

2.2 Other Documents:

4.6 Exposures of the type described in this practice may be

used to evaluate the stability of solar collector cover materials

when exposed outdoors to the varied influences that comprise

These test methods are under the jurisdiction of ASTM Committee E44 on

weather. Exposure conditions are complex and changeable.

Solar, Geothermal, and Other Alternative Energy Sources and is the direct

responsibility of Subcommittee E44.05 on Solar Heating and Cooling Subsystems Important factors are material temperature, climate, time of

and Systems.

year,presenceofindustrialpollution,etc.Generally,becauseit

Current edition approved Sept. 15, 1992. Published March 1993. Originally

approved in 1982. Last previous edition approved in 1996 as E881-92(1996).

Annual Book of ASTM Standards, Vol 08.01.

3 5

Annual Book of ASTM Standards, Vol 12.02. Available from the General Services Administration (3 FRI), Building 197,

Annual Book of ASTM Standards, Vol 14.02. Navy Yard Annex, Washington, DC 20407.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 881 – 92 (2003)

NOTE 2—It is desirable that the box and box top be made of a material

isdifficulttodefineormeasurepreciselythefactorsinfluencing

that will be unaffected by the exposure environment.Ametal resistant to

degradation due to weathering, results of outdoor exposure

corrosion encountered in the environment would be suitable. If wood is

tests must be taken as indicative only. Repeated exposure

used, it should be painted or treated on the exterior to make it resistant to

testingatdifferentseasonsoveraperiodofmorethanoneyear

moisture. In certain climates only rot-resistant wood should be used to

is required to confirm exposure tests at any one location.

minimize deterioration during exposure.

Control samples must always be used in weathering tests for

5.2.2 The insulation shall be a material suitable for use at a

comparative analysis.

high temperature (for example, 150°C (302°F)).

5. Weathering Box Test Fixture

NOTE 3—Insulation materials having resins or binders should not be

5.1 Test Fixture Requirements:

used because elevated temperatures may cause the resin or binder to

5.1.1 The weathering box test fixture shall be constructed deteriorate and outgas. Outgassing products condense on the cover

material causing changes in the solar transmittance of the solar collector

such that the combined back and edge loss coefficient is less

2 2

cover material.

than 1.5 W/(m · °C) (0.264 Btu/(ft · h ·° F)) (Note 1). (The

methodfordeterminingthiscoefficientisoutlinedinAppendix

5.2.3 The absorber shall be of an adequate size to cover the

X1ofthispractice.)Thedistancebetweentheabsorberandthe

interior surface of the weathering box aperture. The absorber

closestcoverplateshallbebetween13and38mm(0.5and1.5

shall have a flat black nonselective coating having an absorp-

in.). For a double-cover exposure the separation between the

tance not less than 0.90 after exposure.

inner and outer cover shall be between 13 and 38 mm (0.5 and

5.2.4 Theboxtopshallbeofanadequatesizetofitoverthe

1.5in.).Notmorethan10%oftheabsorberplateareashallbe

box.

shadedwhenthesunisata30°anglewiththeplaneofthefront

NOTE 4—The box top is intended to protect the edges of the test

surface of the exposure box.

specimen in contact with the box from reaching excessively high

NOTE 1—A good flat-plate solar collector has a combined back and

temperatures, to minimize exposure of the adhesive tape to sunlight, and

2 2

edge loss coefficient of less than about 1.5 W/(m · °C) (0.264 Btu/(ft ·

to minimize moisture penetration into the exposure test fixture.

h·°F).

5.2.5 The glazing frame is intended to hold the cover plate

5.1.2 Boxes that meet the requirements of 5.1.1 are de-

material. The glazing frame shall have dimensions similar to

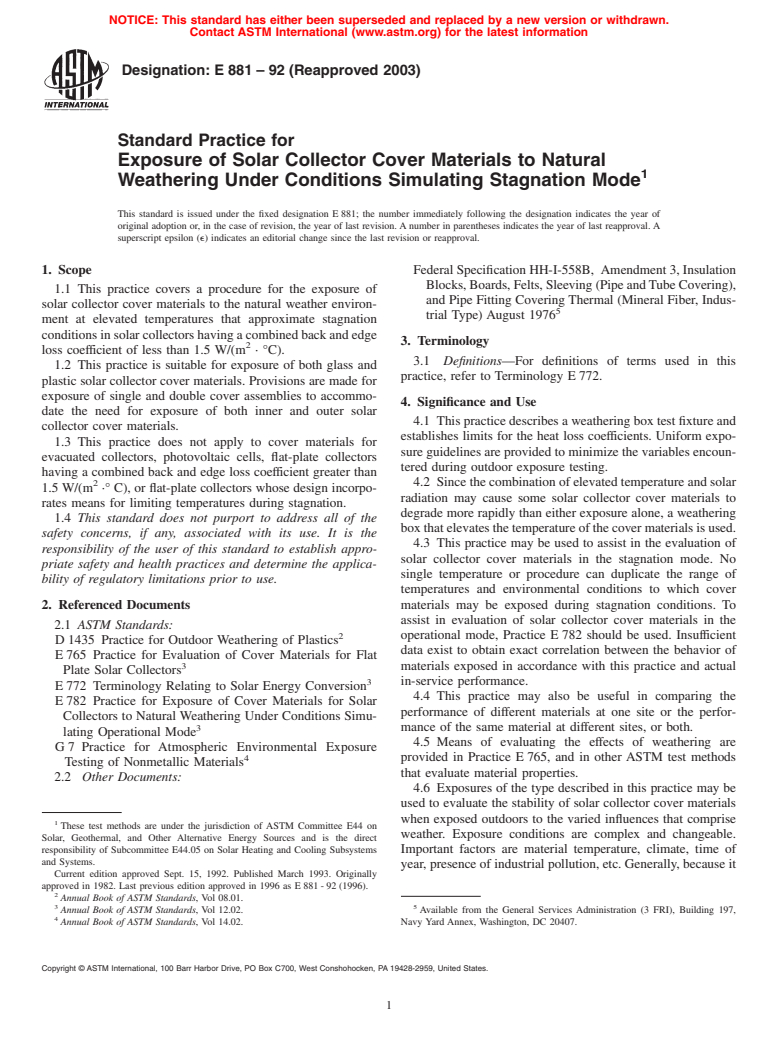

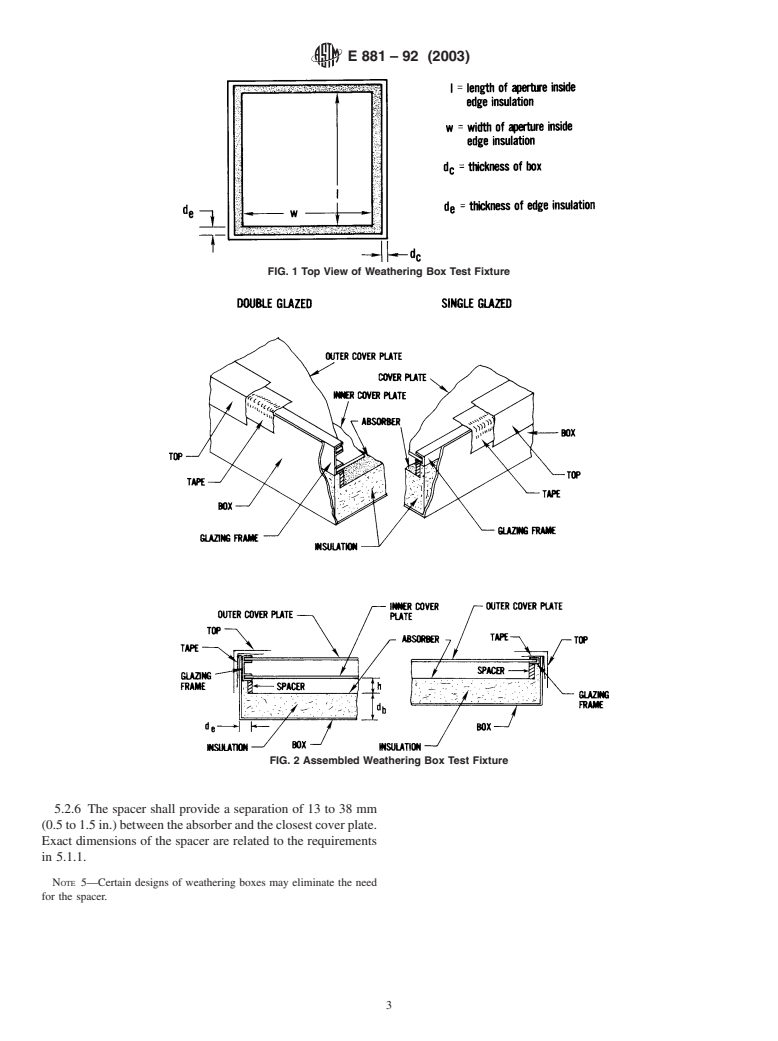

scribed in Table 1. Fig. 1 and Fig. 2 illustrate the weathering

the perimeter of the box. For a double-cover exposure the

box test fixtures. Although Fig. 1 shows a square box, any

frame shall provide a separation between the two cover plates

shape is permitted if the requirements in 5.1.1 are met.

ofnotlessthan13mm(0.5in.)orgreaterthan38mm(1.5in.).

Appendix X1 of this practice describes the method for deter-

Exact dimensions of the frame are related to the requirements

mining the combined back and edge loss coefficient.

in 5.1.1. A vent hole may be drilled at one end of the glazing

5.2 Contents of the Weathering Box Test Fixture: (1) a box,

frame to provide drainage and to minimize moisture accumu-

( 2) insulation, (3) absorber, ( 4) box top, (5) spacer, ( 6)

lation.

glazing frame, and (7) adhesive tapes.

5.2.1 Theboxmayhaveanydimensionsandbemadeofany

material as long as the requirements in 5.1.1 are met. A weep

hole shall be drilled at the lower end of the bottom of the box

Federal Specification HH-I-558B has several classes of insulation material

to provide drainage and to minimize moisture accumulation. intended for high-temperature use.

TABLE 1 Examples of Weathering Box Test Fixtures with Combined Heat Loss Coefficient for Back and Edge Losses Less than

2 2

1.5 W/(m ·°C) (0.264 Btu/(ft ·h·°F))

Example 1 Example 2

Box material steel aluminum

Insulation material glass fiber glass fiber

l, length of aperture inside edge insulation 0.25 m (9.8 in.) 0.61 m (24 in.)

w, width of aperture inside edge insulation 0.13 m (5.2 in.) 0.61 m (24 in.)

h, distance from top of absorber to bottom of cover 0.013 m (0.5 in.) 0.038 m (1.5 in.)

plate

2 2 2 2

A , area of aperture of test fixture A =(l 3 w) 0.033 m (51 in. ) 0.372 m (576 in. )

a a

2 2 2 2

A , area of back insulation A =(l 3 w) 0.033 m (51 in. ) 0.372 m (576 in. )

b b

2 2 2 2

A , area of edge insulation A =2(l + w)h 0.01 m (15 in. ) 0.093 m (144 in. )

e e

d , thickness of back insulation 0.077 m (3 in.) 0.05 m (2 in.)

b

d , thickness of box 0.001 m (0.04 in.) 0.002 m (0.08 in.)

c

d , thickness of edge insulation 0.013 m (0.5 in.) 0.025 m (1 in.)

e

2 2

K , conductivity of back insulation 0.038 W/(m·°C) (0.22 Btu/(ft ·h·°F)) 0.038 W/(m·°C) (0.022 Btu/(ft ·h·°F))

b

2 2

K , conductivity of box 43 W/(m·°C) (24.9 Btu/(ft ·h·°F) 204 W/(m·°C) (118 Btu/(ft ·h·°F))

c

2 2

K , conductivity of edge insulation 0.038 W/(m·°C) (0.022 Btu/(ft ·h·°F)) 0.038 W/(m·°C) (0.022 Btu/(ft ·h·°F))

e

A /A 11

b a

A /A 0.305 0.25

e a

2 2 2 2

d /K 2.03 m ·°C/W (11.4 (ft ·h·°F)/Btu) 1.32 m ·°C/W (7.5 (ft ·h·°F)/Btu)

b b

−5 2 −4 2 −6 2 −5 2

d /K 2.33 3 10 m ·°C/W (1.32 3 10 (ft ·h·°F)/Btu) 9.8 3 10 m ·°C/W (5.6 3 10 (ft ·h·°F)/Btu)

c c

2 2 2 2

d /K 0.342 m ·°C/W (1.94 (ft ·h·°F)/Btu) 0.658 m ·°C/W (3.74 (ft ·h·°F)/Btu)

e e

2 2 2 2

U , back + U , edge 1.38 W/(m ·°C) (0.243 Btu/(ft ·h·°F)) 1.14 W/(m ·°C) (0.201 Btu/(ft ·h·°F))

L L

E 881 – 92 (2003)

FIG. 1 Top View of Weathering Box Test Fixture

FIG. 2 Assembled Weathering Box Test Fixture

5.2.6 The spacer shall provide a separation of 13 to 38 mm

(0.5to1.5in.)betweentheabsorberandtheclosestcoverplate.

Exact dimensions of the spacer are related to the requirements

in 5.1.1.

NOTE 5—Certain designs of weathering boxes may eliminate the need

for the spacer.

E 881 – 92 (2003)

5.2.7 The adhesive tapes shall be stable when exposed to such as those described in Practice D1435. The racks shall be

moisture and elevated temperatures. They shall be compatible capable of having the angles adjusted and have their axis of

with the specific materials from which the box, glazing frame, rotation on an east-west line.

box top, and cover plate are made. 6.2 Use a variable angle exposure to maximize solar radia-

5.2.8 Organic materials are potential sources of outgassing tion incident upon the weathering box. Adjust the racks

andshallbeeliminatedfromtheinterioroftheweatheringbox accordingtotheschedulegiveninTable2.Positiverackangles

where possible. For example, metallic parts shall be cleaned to face south. Choose the angles so that the weathering boxes are

remove traces of grease or other foreign matter. Other possible never closer to the horizontal than by 5°. Other variable

sources of outgassing include coatings and sealants. Test exposure schedules requiring more than four adjustments per

fixture components containing organic materials (for example, year may be used. The method for determining the variable

absorber coatings or insulation) shall be heated in an oven at angle exposure schedule is described in Appendix X2 of this

150°C (302°F) for 24 h before the test fixture is assembled. practice.

Thisshouldminimizeoutgassingthatresultsfromdeterioration 6.3 When a number of weathering boxes are exposed

of the organic components exposed to elevated temperatures. simultaneously,mounttheboxessidebysidewiththesidesnot

5.3 Test Specimen: touching.

5.3.1 Thetestspecimenshallbeofanadequatesizetocover 6.4 Do not clean the solar collector cover materials during

the aperture of the box or glazing frame and to permit suitable exposure.

attachment. 6.5 Visually inspect the test specimens at intervals of not

more than one month. Record all changes in appearance.

NOTE 6—Adequate allowances should be made for materials that will

undergo dimensional changes due to temperature.

7. Report

5.3.2 The test specimen identification marks shall not inter-

7.1 The report shall include the following:

fere with either the exposure or the subsequent testing.

7.1.1 Description of the weathering box test fixture and its

5.4 Sample Mounting:

calculated combined back and edge loss coefficient,

5.4.1 Rigid and Semirigid Glazings:

7.1.2 Whether the solar collector cover materials are ex-

5.4.1.1 Lay the test specimen for single cover exposure

posed as a single- or double-cover configuration and whether

directly on either the spacer or the glazing frames. If used, the

the test specimen was the inner or outer cover,

frame is then placed on the spacer in the weathering box (see

7.1.3 Complete identification of the solar collector outer

Fig. 2).

cover material(s),

5.4.1.2 Lay the test specimen for inner cover exposure of a

7.1.4 Complete identification of the solar collector inner

double cover assembly on the spacer or attach it to the glazing

cover material(s) (if any),

framebeforetheglazingframeisplacedinthebox(seeFig.2).

7.1.5 A description of the test specimen attachment and

5.4.1.3 Lay the test specimen for outer cover exposure of a

mounting procedures,

doublecoverassemblyonthetopoftheglazingframe(seeFig.

7.1.6 Latitude,longitude,altitude,andaddressofthetesting

2).

site including a description of the type of climate,

5.4.2 Films—Placefilmtestspecimensontheglazingframe

NOTE 7—Types of climate are described in Practice G7.

usingadhesivetransfertapetoholdthetestspecimentaut.Itis

essential that uniform tensioning be obtained prior to applying 7.1.7 Exposure data:

7.1.7.1 Calendar dates of exposure and

the tape. Then place the frame in the box similar to 5.4.1.1,

5.4.1.2, and 5.4.1.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.