ASTM C1254-99

(Test Method)Standard Test Method for Determination of Uranium in Mineral Acids by X-Ray Fluorescence

Standard Test Method for Determination of Uranium in Mineral Acids by X-Ray Fluorescence

SCOPE

1.1 This test method covers the steps necessary for the preparation and analysis by X-ray fluorescence (XRF) of mineral acid solutions containing uranium.

1.2 This test method is valid for those solutions containing 2 to 20 g uranium/L as presented to the spectrometer. Higher concentrations may be covered by appropriate dilutions.

1.3 This test method requires the use of an appropriate internal standard. Care must be taken to ascertain that samples analyzed by this test method do not contain the internal standard element or that this contamination has been corrected for mathematically whenever present. Such corrections are not addressed in this test method. Care must also be taken that the choice of internal standard and sample medium are compatible; that is, do not use yttrium with solutions containing HF or strontium with those having H 2 SO 4 . Alternatively a scatter line may be used as internal standard.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 8 and Note 1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1254–99

Standard Test Method for

Determination of Uranium in Mineral Acids by X-Ray

Fluorescence

This standard is issued under the fixed designation C 1254; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 135 Terminology Relating to Analytical Chemistry for

Metals, Ores, and Related Materials

1.1 This test method covers the steps necessary for the

2.2 Other Document:

preparation and analysis by X-ray fluorescence (XRF) of

NBS Handbook 111, Radiation Safety for X-Ray Diffraction

mineral acid solutions containing uranium.

and X-Ray Fluorescence Analysis Equipment

1.2 This test method is valid for those solutions containing

0.05 to 20 g uranium/L as presented to the spectrometer.

3. Terminology

Higher concentrations may be covered by appropriate dilu-

3.1 Definitions:

tions.

3.1.1 See Terminology E 135 for definitions of terms appli-

1.3 This test method requires the use of an appropriate

cable to this test method.

internal standard. Care must be taken to ascertain that samples

analyzed by this test method do not contain the internal

4. Summary of Test Method

standard element or that this contamination has been corrected

4.1 Solution standards containing 0.025 g/L uranium to 20

for mathematically whenever present. Such corrections are not

g/L uranium and an appropriate internal standard (usually

addressed in this test method. Care must also be taken that the

eitheryttriumorstrontium)areplacedinaliquidsampleholder

choiceofinternalstandardandsamplemediumarecompatible;

of an X-ray spectrometer and exposed to an X-ray beam

that is, do not use yttrium with solutions containing HF or

capable of exciting the uranium L-alpha emission line and the

strontium with those having H SO .Alternatively a scatter line

2 4

2 appropriate emission line for the internal standard (usually the

may be used as internal standard.

K-alpha line). The intensities generated are measured by an

1.4 The values stated in SI units are to be regarded as the

appropriate detector. The intensity ratio values obtained from

standard.

this data are used to calibrate the X-ray analyzer.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 This test method is applicable to aqueous solutions of

priate safety and health practices and determine the applica-

uranium containing 0.05 to 20 g uranium per litre of solution

bility of regulatory limitations prior to use. Specific precau-

presented to the spectrometer.

tionary statements are given in Section 8 and Note 1.

5.2 Either wavelength-dispersive or energy-dispersive

X-ray fluorescence systems may be used provided the software

2. Referenced Documents

accompanying the system is able to accommodate the use of

2.1 ASTM Standards:

internal standards.

C 982 Guide for Selecting Components for Energy Disper-

sive X-Ray Fluorescence (XRF) Systems

6. Apparatus

C 1118 Guide for Selecting Components for Wavelength-

6.1 X-Ray Spectrometer—See Guide C 982 or Guide

Dispersive X-Ray Fluorescence (XRF) Systems

4 C 1118 for the selection of the X-ray spectrometer. This test

D 1193 Specification for Reagent Water

method is valid for either energy-dispersive or wavelength-

dispersive systems.

6.2 Sample Cups:

ThistestmethodisunderthejurisdictionofASTMCommitteeC-26onNuclear

6.2.1 Prepare liquid sample cups for the X-ray spectrometer

Fuel Cycle and is the direct responsibility of Subcommittee C26.05 on Methods of

as described by the manufacturer. Vented, disposable sample

Tests.

Current edition approved Jan. 10, 1999. Published February 1999. Originally

published as C 1254–93. Last previous edition C 1254–93.

Andermann,George,andKemp,J.W.,“ScatteredX-RaysasInternalStandards

in X-ray Spectroscopy,” Analytical Chemistry, Vol 20(8), 1958. Annual Book of ASTM Standards, Vol 03.05.

3 6

Annual Book of ASTM Standards, Vol 12.01. Available as a photocopy from the U.S. Department of Commerce, National

Annual Book of ASTM Standards, Vol 11.01. Institute of Standards and Technology, Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1254

cups with snap-on caps are satisfactory for most such analyses; detrimental to the spectrometer chamber. It is desirable to flush

such cups decrease the likelihood of contamination between this chamber with an inert gas (usually helium) before and

samples. during analysis. Some X-ray spectrometers control the change

6.2.2 Polyester, polyethylene, and polypropylene films have of sample chamber atmosphere (air, vacuum, helium) auto-

been used successfully as the film window for such cups. Tests matically through the software; in others, it must be done

should be performed to determine the serviceability of any film manually. Follow the instrument manufacturer’s recommenda-

chosen before insertion into the instrument. tions to achieve the inert gas environment.

6.3 Solution Dispenser—Thedispenserfortheinternalstan-

NOTE 1—Caution: Allow sufficient stabilization time before analysis.

dard solution should be capable of reproducibly dispensing the

Care must be taken to ensure that a vacuum environment is not chosen

internal standard to a level of 0.5 % relative standard deviation

with liquid samples.

of the volume dispensed.

9.2 X-Ray Power Supply—If the power to the X-ray tube is

not controlled by the instrument software, set the proper

7. Reagents and Materials

combination of voltage and current for the instrument in use.

7.1 Purity of Reagents—Reagent grade chemicals shall be

These settings must be determined by the user for his instru-

used in all tests. Unless otherwise indicated, it is intended that

ment and choice of X-ray tube. Allow sufficient stabilization

all reagents conform to the specifications of the Committee of

time prior to analysis.

Analytical Reagents of the American Chemical Society where

such specifications are available. Other grades may be used

10. Calibration and Standardization

provided it is first ascertained that the reagent is of sufficiently

10.1 Internal Standard Solution (25.0 g/L):

high purity to permit its use without lessening the accuracy of

10.1.1 Weigh 25 g of the chosen internal standard com-

the determination.

pound into an 800-mL beaker. Cover with water. Add concen-

7.2 Purity of Water—Unless otherwise indicated, references

trated nitric acid slowly. For yttrium oxide the reaction will be

to water shall mean reagent water conforming to Specification

slow and may require heating. For strontium carbonate, the

D 1193.

reaction will be vigorous.

7.3 Ferric Nitrate, Fe(NO ) ·9H O.

3 3 2

10.1.2 Heat on a hot plate if necessary to complete the

7.4 Nitric Acid, HNO , concentrated (70 %).

dissolution.

7.5 Strontium Carbonate, SrCO .

10.1.3 Cool the solution to room temperature, and transfer

7.6 Uranium Oxide,U O , NBLCRM-129 (or equivalent).

3 8

to a 1000-mL volumetric flask. (Filter the solution if neces-

7.7 Yttrium Oxide,Y O .

2 3

sary.) Dilute to volume with water and mix thoroughly.

10.2 Impurity Stock Solution (Optional):

8. Technical Precautions

10.2.1 Weigh 50 g of reagent grade ferric nitrate,

8.1 XRF equipment analyzes by the interaction of ionizing

Fe(NO ) ·9H O, into a 600-mL beaker.

3 3 2

radiation with the sample. Applicable safety regulations and

10.2.2 Dissolve the crystals in 200 mL of water and 50 mL

standard operating procedures must be reviewed prior to the

of concentrated nitric acid.

use of such equipment. All modern XRF spectrometers are

10.2.3 When cool, transfer the solution to a 1000-mL

equipped with safety interlocks to prevent accidental penetra-

volumetric flask and dilute to volume with water.

tion of the X-ray beam by the user. Do NOT override these

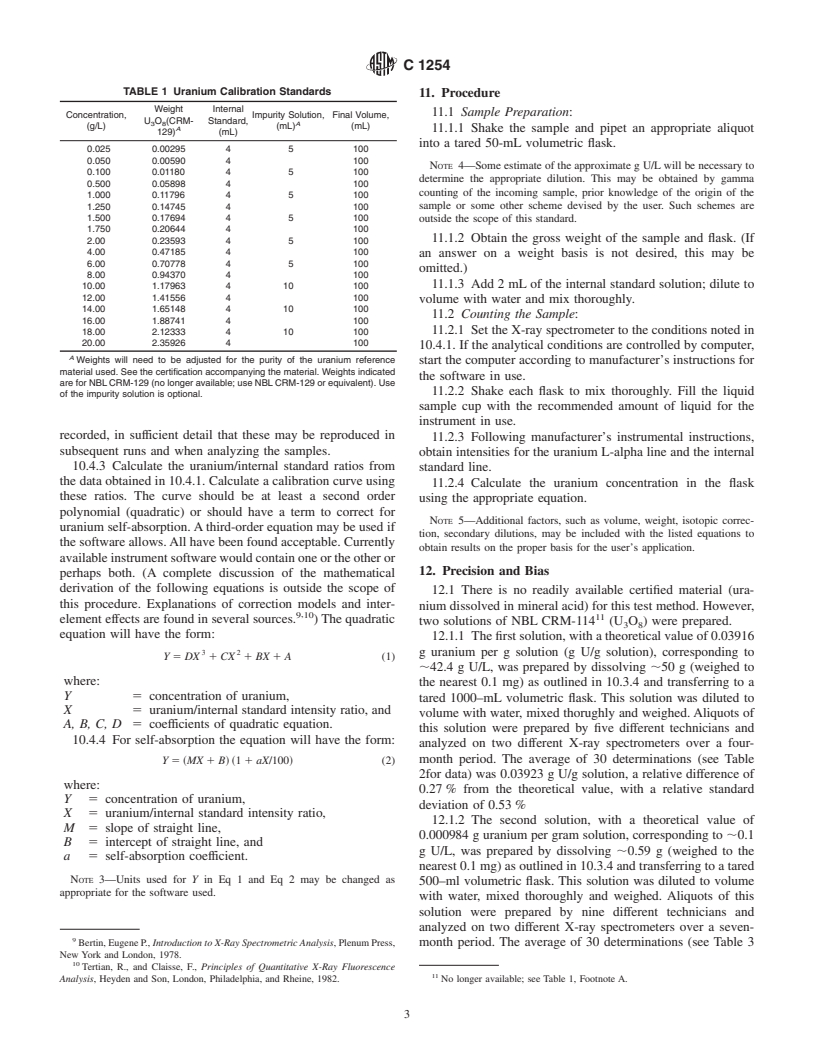

10.3 Uranium Calibration Standards:

interlocks without proper training, or a second knowledgeable

10.3.1 Prepare a uranium standard for each concentration

person present during such operation. (See NBS Handbook

level by weighing into a 150-mL beaker the amounts of

111.)

uranium oxide given in Table 1.

8.2 Instrument performance may be influenced by environ-

10.3.2 Dissolve the oxide in 25 mL of water and 25 mL

mental factors such as heat, vibration, humidity, dust, stray

concentrated nitric acid. Heat on a hot plate, if necessary to

electronic noise, and line voltage stability. These factors and

complete the dissolution.

performance characteristics should be reviewed prior to use of

10.3.3 When cool, transfer each solution to a properly

this standard.

labeled 100-mL vo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.