ASTM C1725-17

(Guide)Standard Guide for Hot Cell Specialized Support Equipment and Tools

Standard Guide for Hot Cell Specialized Support Equipment and Tools

SIGNIFICANCE AND USE

4.1 This guide is relevant to the design of specialized support equipment and tools that are remotely operated, maintained, or viewed through shielding windows, or combinations thereof, or by other remote viewing systems.

4.2 Hot cells contain substances and processes that may be extremely hazardous to personnel or the external environment, or both. Process safety and reliability are improved with successful design, installation, and operation of specialized mechanical and support equipment.

4.3 Use of this guide in the design of specialized mechanical and support equipment can reduce costs, improve productivity, reduce failed hardware replacement time, and provide a standardized design approach.

SCOPE

1.1 Intent:

1.1.1 This guide presents practices and guidelines for the design and implementation of equipment and tools to assist assembly, disassembly, alignment, fastening, maintenance, or general handling of equipment in a hot cell. Operating in a remote hot cell environment significantly increases the difficulty and time required to perform a task compared to completing a similar task directly by hand. Successful specialized support equipment and tools minimize the required effort, reduce risks, and increase operating efficiencies.

1.2 Applicability:

1.2.1 This guide may apply to the design of specialized support equipment and tools anywhere it is remotely operated, maintained, and viewed through shielding windows or by other remote viewing systems.

1.2.2 Consideration should be given to the need for specialized support equipment and tools early in the design process.

1.2.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Caveats:

1.3.1 This guide is generic in nature and addresses a wide range of remote working configurations. Other acceptable and proven international configurations exist and provide options for engineer and designer consideration. Specific designs are not a substitute for applied engineering skills, proven practices, or experience gained in any specific situation.

1.3.2 This guide does not supersede federal or state regulations, or both, or codes applicable to equipment under any conditions.

1.3.3 This guide does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1725 − 17

Standard Guide for

1

Hot Cell Specialized Support Equipment and Tools

This standard is issued under the fixed designation C1725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 Intent:

ization established in the Decision on Principles for the

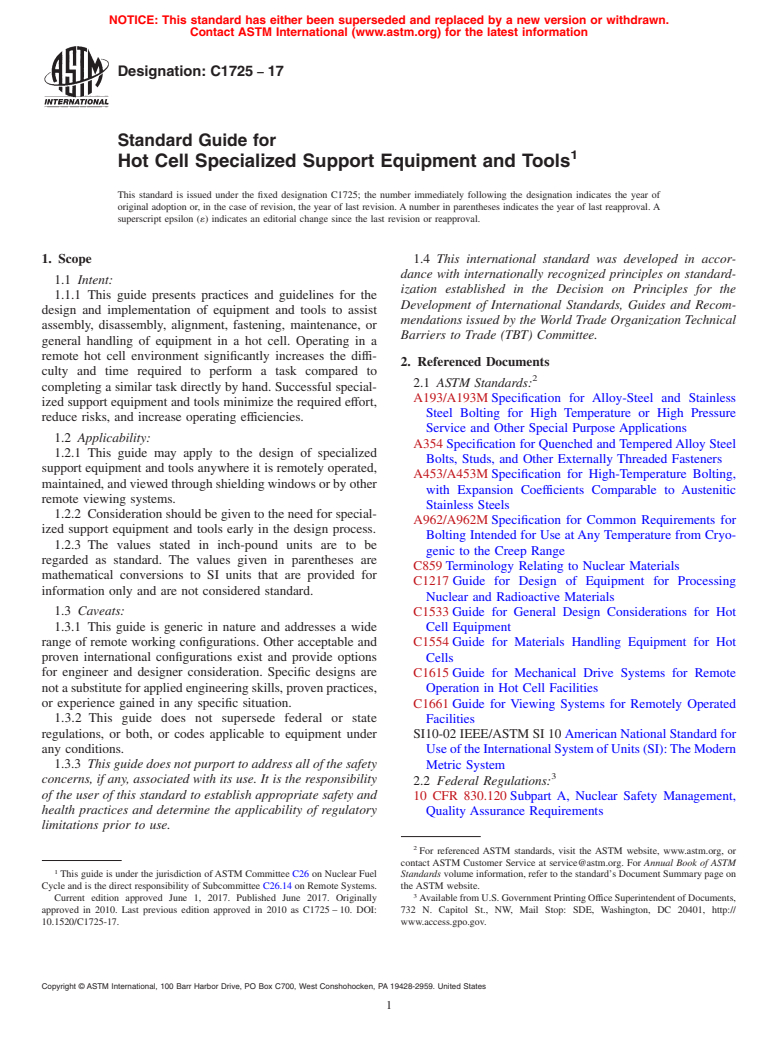

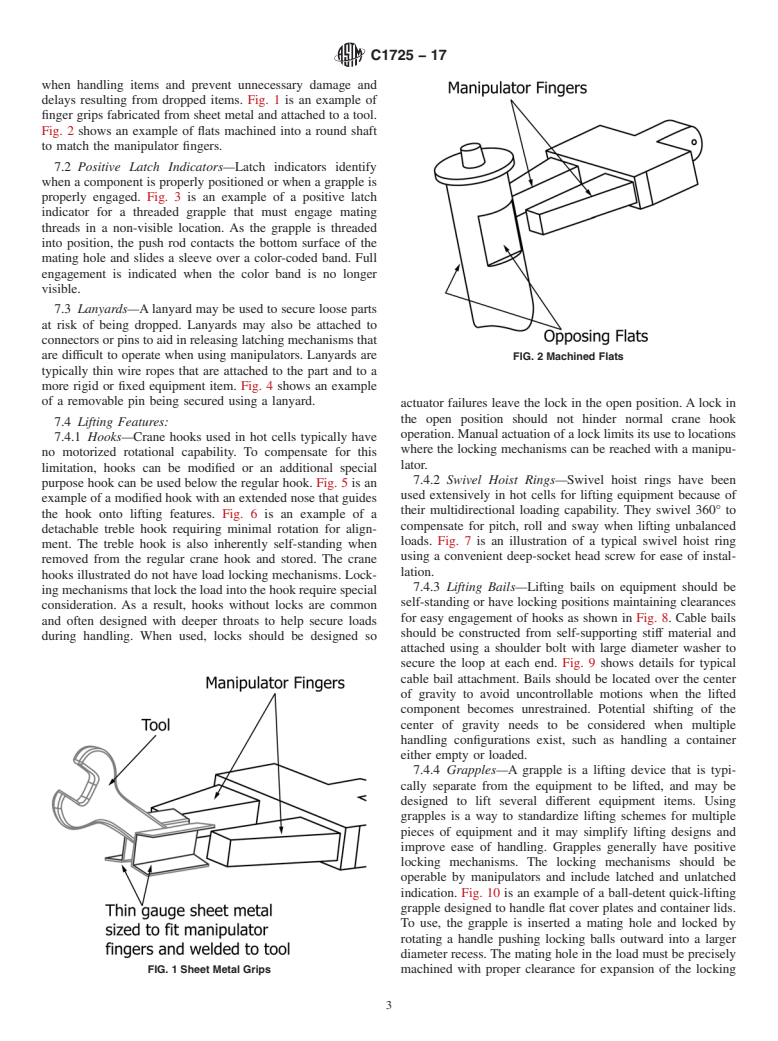

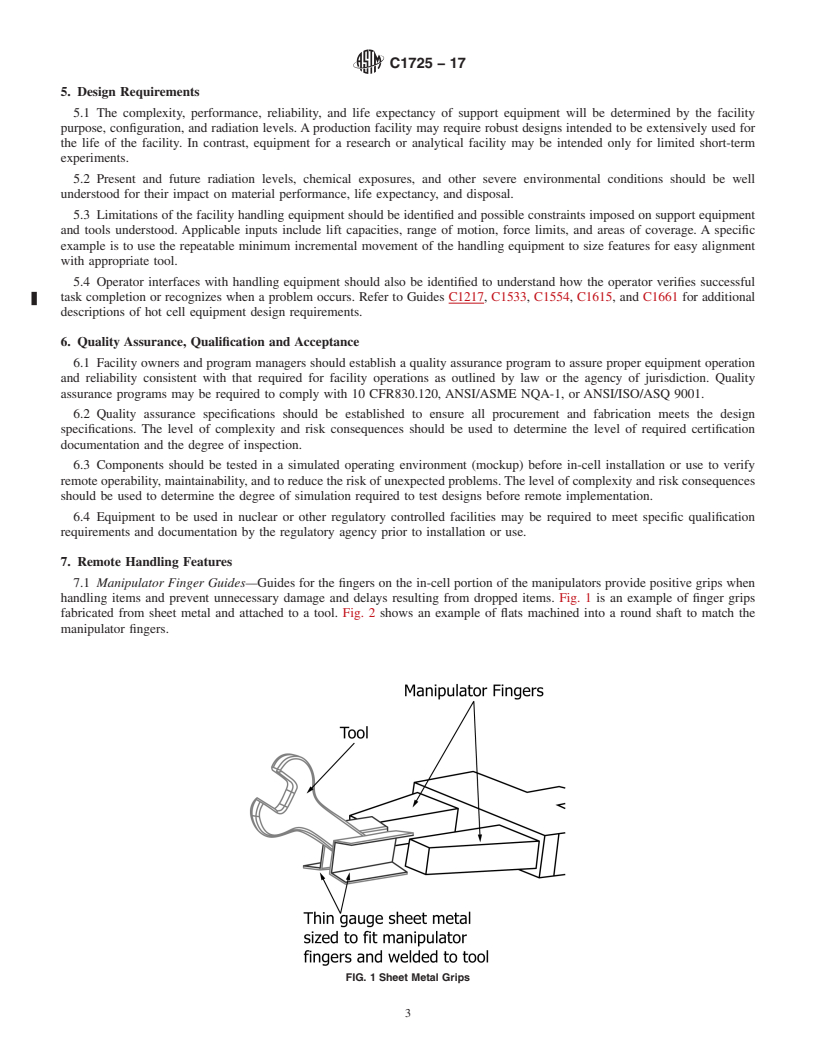

1.1.1 This guide presents practices and guidelines for the

Development of International Standards, Guides and Recom-

design and implementation of equipment and tools to assist

mendations issued by the World Trade Organization Technical

assembly, disassembly, alignment, fastening, maintenance, or

Barriers to Trade (TBT) Committee.

general handling of equipment in a hot cell. Operating in a

remote hot cell environment significantly increases the diffi-

2. Referenced Documents

culty and time required to perform a task compared to

2

2.1 ASTM Standards:

completing a similar task directly by hand. Successful special-

A193/A193M Specification for Alloy-Steel and Stainless

ized support equipment and tools minimize the required effort,

Steel Bolting for High Temperature or High Pressure

reduce risks, and increase operating efficiencies.

Service and Other Special Purpose Applications

1.2 Applicability:

A354 Specification for Quenched and TemperedAlloy Steel

1.2.1 This guide may apply to the design of specialized

Bolts, Studs, and Other Externally Threaded Fasteners

support equipment and tools anywhere it is remotely operated,

A453/A453M Specification for High-Temperature Bolting,

maintained, and viewed through shielding windows or by other

with Expansion Coefficients Comparable to Austenitic

remote viewing systems.

Stainless Steels

1.2.2 Consideration should be given to the need for special-

A962/A962M Specification for Common Requirements for

ized support equipment and tools early in the design process.

Bolting Intended for Use at Any Temperature from Cryo-

1.2.3 The values stated in inch-pound units are to be

genic to the Creep Range

regarded as standard. The values given in parentheses are

C859 Terminology Relating to Nuclear Materials

mathematical conversions to SI units that are provided for

C1217 Guide for Design of Equipment for Processing

information only and are not considered standard.

Nuclear and Radioactive Materials

1.3 Caveats:

C1533 Guide for General Design Considerations for Hot

1.3.1 This guide is generic in nature and addresses a wide Cell Equipment

range of remote working configurations. Other acceptable and

C1554 Guide for Materials Handling Equipment for Hot

proven international configurations exist and provide options Cells

for engineer and designer consideration. Specific designs are

C1615 Guide for Mechanical Drive Systems for Remote

not a substitute for applied engineering skills, proven practices, Operation in Hot Cell Facilities

or experience gained in any specific situation.

C1661 Guide for Viewing Systems for Remotely Operated

1.3.2 This guide does not supersede federal or state Facilities

regulations, or both, or codes applicable to equipment under

SI10-02 IEEE/ASTM SI 10 American National Standard for

any conditions. Use of the International System of Units (SI):The Modern

1.3.3 This guide does not purport to address all of the safety

Metric System

3

concerns, if any, associated with its use. It is the responsibility

2.2 Federal Regulations:

of the user of this standard to establish appropriate safety and

10 CFR 830.120 Subpart A, Nuclear Safety Management,

health practices and determine the applicability of regulatory

Quality Assurance Requirements

limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

1

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel Standards volume information, refer to the standard’s Document Summary page on

Cycle and is the direct responsibility of Subcommittee C26.14 on Remote Systems. the ASTM website.

3

Current edition approved June 1, 2017. Published June 2017. Originally AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

approved in 2010. Last previous edition approved in 2010 as C1725 – 10. DOI: 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

10.1520/C1725-17. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1725 − 17

4

2.3 Other Standards:

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1725 − 10 C1725 − 17

Standard Guide for

1

Hot Cell Specialized Support Equipment and Tools

This standard is issued under the fixed designation C1725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 Intent:

1.1.1 This guide presents practices and guidelines for the design and implementation of equipment and tools to assist assembly,

disassembly, alignment, fastening, maintenance, or general handling of equipment in a hot cell. Operating in a remote hot cell

environment significantly increases the difficulty and time required to perform a task compared to completing a similar task directly

by hand. Successful specialized support equipment and tools minimize the required effort, reduce risks, and increase operating

efficiencies.

1.2 Applicability:

1.2.1 This guide may apply to the design of specialized support equipment and tools anywhere it is remotely operated,

maintained, and viewed through shielding windows or by other remote viewing systems.

1.2.2 Consideration should be given to the need for specialized support equipment and tools early in the design process.

1.2.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 Caveats:

1.3.1 This guide is generic in nature and addresses a wide range of remote working configurations. Other acceptable and proven

international configurations exist and provide options for engineer and designer consideration. Specific designs are not a substitute

for applied engineering skills, proven practices, or experience gained in any specific situation.

1.3.2 This guide does not supersede federal or state regulations, or both, or codes applicable to equipment under any conditions.

1.3.3 This guide does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A193/A193M Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other

Special Purpose Applications

A354 Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners

A453/A453M Specification for High-Temperature Bolting, with Expansion Coefficients Comparable to Austenitic Stainless

Steels

A962/A962M Specification for Common Requirements for Bolting Intended for Use at Any Temperature from Cryogenic to the

Creep Range

C859 Terminology Relating to Nuclear Materials

C1217 Guide for Design of Equipment for Processing Nuclear and Radioactive Materials

C1533 Guide for General Design Considerations for Hot Cell Equipment

C1554 Guide for Materials Handling Equipment for Hot Cells

1

This guide is under the jurisdiction of ASTM Committee C26 on Nuclear Fuel Cycle and is the direct responsibility of Subcommittee C26.14 on Remote Systems.

Current edition approved June 15, 2010June 1, 2017. Published August 2010June 2017. Originally approved in 2010. Last previous edition approved in 2010 as

C1725 – 10. DOI: 10.1520/C1725–10.10.1520/C1725-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1725 − 17

C1615 Guide for Mechanical Drive Systems for Remote Operation in Hot Cell Facilities

C1661 Guide for Viewing Systems for Remotely Operated Facilities

SI10-02 IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI):

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.