ASTM C1725-17(2022)

(Guide)Standard Guide for Hot Cell Specialized Support Equipment and Tools

Standard Guide for Hot Cell Specialized Support Equipment and Tools

SIGNIFICANCE AND USE

4.1 This guide is relevant to the design of specialized support equipment and tools that are remotely operated, maintained, or viewed through shielding windows, or combinations thereof, or by other remote viewing systems.

4.2 Hot cells contain substances and processes that may be extremely hazardous to personnel or the external environment, or both. Process safety and reliability are improved with successful design, installation, and operation of specialized mechanical and support equipment.

4.3 Use of this guide in the design of specialized mechanical and support equipment can reduce costs, improve productivity, reduce failed hardware replacement time, and provide a standardized design approach.

SCOPE

1.1 Intent:

1.1.1 This guide presents practices and guidelines for the design and implementation of equipment and tools to assist assembly, disassembly, alignment, fastening, maintenance, or general handling of equipment in a hot cell. Operating in a remote hot cell environment significantly increases the difficulty and time required to perform a task compared to completing a similar task directly by hand. Successful specialized support equipment and tools minimize the required effort, reduce risks, and increase operating efficiencies.

1.2 Applicability:

1.2.1 This guide may apply to the design of specialized support equipment and tools anywhere it is remotely operated, maintained, and viewed through shielding windows or by other remote viewing systems.

1.2.2 Consideration should be given to the need for specialized support equipment and tools early in the design process.

1.2.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 Caveats:

1.3.1 This guide is generic in nature and addresses a wide range of remote working configurations. Other acceptable and proven international configurations exist and provide options for engineer and designer consideration. Specific designs are not a substitute for applied engineering skills, proven practices, or experience gained in any specific situation.

1.3.2 This guide does not supersede federal or state regulations, or both, or codes applicable to equipment under any conditions.

1.3.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: C1725 − 17 (Reapproved 2022)

Standard Guide for

Hot Cell Specialized Support Equipment and Tools

This standard is issued under the fixed designation C1725; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 Intent:

ization established in the Decision on Principles for the

1.1.1 This guide presents practices and guidelines for the

Development of International Standards, Guides and Recom-

design and implementation of equipment and tools to assist

mendations issued by the World Trade Organization Technical

assembly, disassembly, alignment, fastening, maintenance, or

Barriers to Trade (TBT) Committee.

general handling of equipment in a hot cell. Operating in a

remote hot cell environment significantly increases the diffi-

2. Referenced Documents

culty and time required to perform a task compared to

2.1 ASTM Standards:

completing a similar task directly by hand. Successful special-

A193/A193M Specification for Alloy-Steel and Stainless

ized support equipment and tools minimize the required effort,

Steel Bolting for High Temperature or High Pressure

reduce risks, and increase operating efficiencies.

Service and Other Special Purpose Applications

1.2 Applicability:

A354 Specification for Quenched and TemperedAlloy Steel

1.2.1 This guide may apply to the design of specialized

Bolts, Studs, and Other Externally Threaded Fasteners

support equipment and tools anywhere it is remotely operated,

A453/A453M Specification for High-Temperature Bolting,

maintained, and viewed through shielding windows or by other

with Expansion Coefficients Comparable to Austenitic

remote viewing systems.

Stainless Steels

1.2.2 Consideration should be given to the need for special-

A962/A962M Specification for Common Requirements for

ized support equipment and tools early in the design process.

Bolting Intended for Use at Any Temperature from Cryo-

1.2.3 The values stated in inch-pound units are to be

genic to the Creep Range

regarded as standard. The values given in parentheses are

C859 Terminology Relating to Nuclear Materials

mathematical conversions to SI units that are provided for

C1217 Guide for Design of Equipment for Processing

information only and are not considered standard.

Nuclear and Radioactive Materials

1.3 Caveats:

C1533 Guide for General Design Considerations for Hot

1.3.1 This guide is generic in nature and addresses a wide Cell Equipment

range of remote working configurations. Other acceptable and

C1554 Guide for Materials Handling Equipment for Hot

proven international configurations exist and provide options Cells

for engineer and designer consideration. Specific designs are

C1615 Guide for Mechanical Drive Systems for Remote

not a substitute for applied engineering skills, proven practices, Operation in Hot Cell Facilities

or experience gained in any specific situation.

C1661 Guide for Viewing Systems for Remotely Operated

1.3.2 This guide does not supersede federal or state Facilities

regulations, or both, or codes applicable to equipment under

SI10-02 IEEE/ASTM SI 10 American National Standard for

any conditions. Use of the International System of Units (SI):The Modern

1.3.3 This standard does not purport to address all of the

Metric System

safety concerns, if any, associated with its use. It is the

2.2 Federal Regulations:

responsibility of the user of this standard to establish appro-

10 CFR 830.120 Subpart A, Nuclear Safety Management,

priate safety, health, and environmental practices and deter-

Quality Assurance Requirements

mine the applicability of regulatory limitations prior to use.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

This guide is under the jurisdiction ofASTM Committee C26 on Nuclear Fuel Standards volume information, refer to the standard’s Document Summary page on

Cycle and is the direct responsibility of Subcommittee C26.14 on Remote Systems. the ASTM website.

Current edition approved July 1, 2022. Published July 2022. Originally approved AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

in 2010. Last previous edition approved in 2017 as C1725 – 17. DOI: 10.1520/ 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

C1725-17R22. www.access.gpo.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1725 − 17 (2022)

2.3 Other Standards: reduce failed hardware replacement time, and provide a stan-

ANSI/ASME NQA-1 Quality Assurance Requirements for dardized design approach.

Nuclear Facility Applications

5. Design Requirements

ANSI/ISO/ASQ 9001 Quality Management Standard Re-

5.1 The complexity, performance, reliability, and life expec-

quirements

tancy of support equipment will be determined by the facility

3. Terminology

purpose, configuration, and radiation levels. A production

facility may require robust designs intended to be extensively

3.1 The terminology employed in this guide conforms to

used for the life of the facility. In contrast, equipment for a

industry practice insofar as practicable.

research or analytical facility may be intended only for limited

3.2 For definitions of general terms used to describe nuclear

short-term experiments.

materials, hot cells, and hot cell equipment, refer to Terminol-

5.2 Present and future radiation levels, chemical exposures,

ogy C859.

and other severe environmental conditions should be well

3.3 Definitions of Terms Specific to This Standard:

understood for their impact on material performance, life

3.3.1 acorn-head (cone-head) fastener—a bolt or screw

expectancy, and disposal.

witharoundedsphericalheadtaperingintoastandardhexhead

5.3 Limitations of the facility handling equipment should be

resembling the shape of the bottom portion of an acorn (or

identified and possible constraints imposed on support equip-

cone), the purpose of which is used to guide and align a tool

ment and tools understood. Applicable inputs include lift

onto the bolt head.

capacities,rangeofmotion,forcelimits,andareasofcoverage.

3.3.2 alignment (guide) pin—a pin used to align two mating

A specific example is to use the repeatable minimum incre-

components by mating a pin mounted in one component with

mental movement of the handling equipment to size features

a precisely sized and positioned hole in the mating part.

for easy alignment with appropriate tool.

Multiple pins are typically required for proper alignment

depending on the configuration and orientation of the mating 5.4 Operator interfaces with handling equipment should

also be identified to understand how the operator verifies

surfaces.

successful task completion or recognizes when a problem

3.3.3 captive fastener—a bolt or screw physically retained

occurs. Refer to Guides C1217, C1533, C1554, C1615, and

on a component that remains attached when mating parts are

C1661 for additional descriptions of hot cell equipment design

separated. Using captive fasteners eliminates the risk of drop-

requirements.

ping the fastener and helps to maintain the fastener in a ready

to use position. It can also apply to nuts when mating

6. Quality Assurance, Qualification and Acceptance

components are too thin for threading.

6.1 Facility owners and program managers should establish

3.3.4 grapple—a removable tool that attached by means of

a quality assurance program to assure proper equipment

a non-threaded connection to equipment and interfaces with an

operation and reliability consistent with that required for

overhead crane or electro-mechanical manipulator to lift and

facility operations as outlined by law or the agency of

move the equipment.

jurisdiction. Quality assurance programs may be required to

3.3.5 lifting bail—lifting handle, hook, or cable generally

comply with 10 CFR830.120, ANSI/ASME NQA-1, or ANSI/

attached over the center of gravity of the equipment to aid

ISO/ASQ 9001.

remote handling.

6.2 Qualityassurancespecificationsshouldbeestablishedto

3.3.6 power manipulator—manipulator controlled by an

ensure all procurement and fabrication meets the design

operator outside of the hot cell with the in-cell slave-arm

specifications. The level of complexity and risk consequences

powered by electric, pneumatic, or hydraulic actuators.

should be used to determine the level of required certification

documentation and the degree of inspection.

4. Significance and Use

6.3 Components should be tested in a simulated operating

4.1 This guide is relevant to the design of specialized

environment (mockup) before in-cell installation or use to

support equipment and tools that are remotely operated,

verify remote operability, maintainability, and to reduce the

maintained, or viewed through shielding windows, or combi-

risk of unexpected problems. The level of complexity and risk

nations thereof, or by other remote viewing systems.

consequences should be used to determine the degree of

4.2 Hot cells contain substances and processes that may be

simulation required to test designs before remote implementa-

extremely hazardous to personnel or the external environment,

tion.

or both. Process safety and reliability are improved with

6.4 Equipment to be used in nuclear or other regulatory

successful design, installation, and operation of specialized

controlled facilities may be required to meet specific qualifi-

mechanical and support equipment.

cation requirements and documentation by the regulatory

4.3 Useofthisguideinthedesignofspecializedmechanical

agency prior to installation or use.

and support equipment can reduce costs, improve productivity,

7. Remote Handling Features

7.1 Manipulator Finger Guides—Guides for the fingers on

Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

4th Floor, New York, NY 10036, http://www.ansi.org. the in-cell portion of the manipulators provide positive grips

C1725 − 17 (2022)

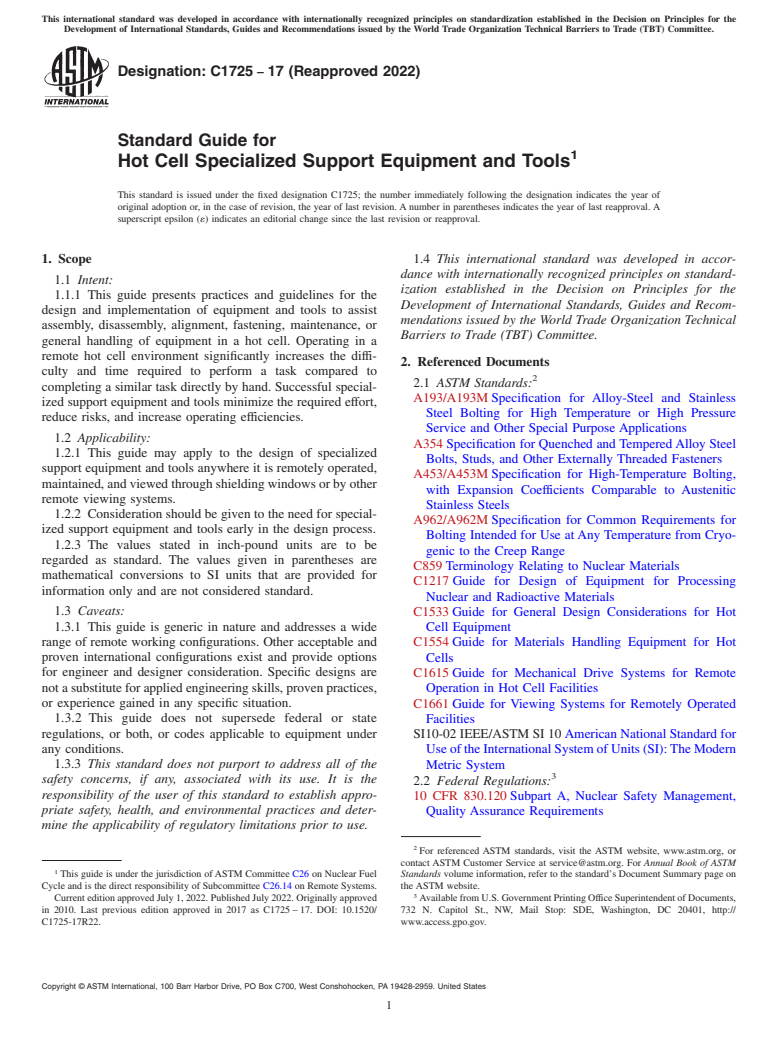

when handling items and prevent unnecessary damage and

delays resulting from dropped items. Fig. 1 is an example of

finger grips fabricated from sheet metal and attached to a tool.

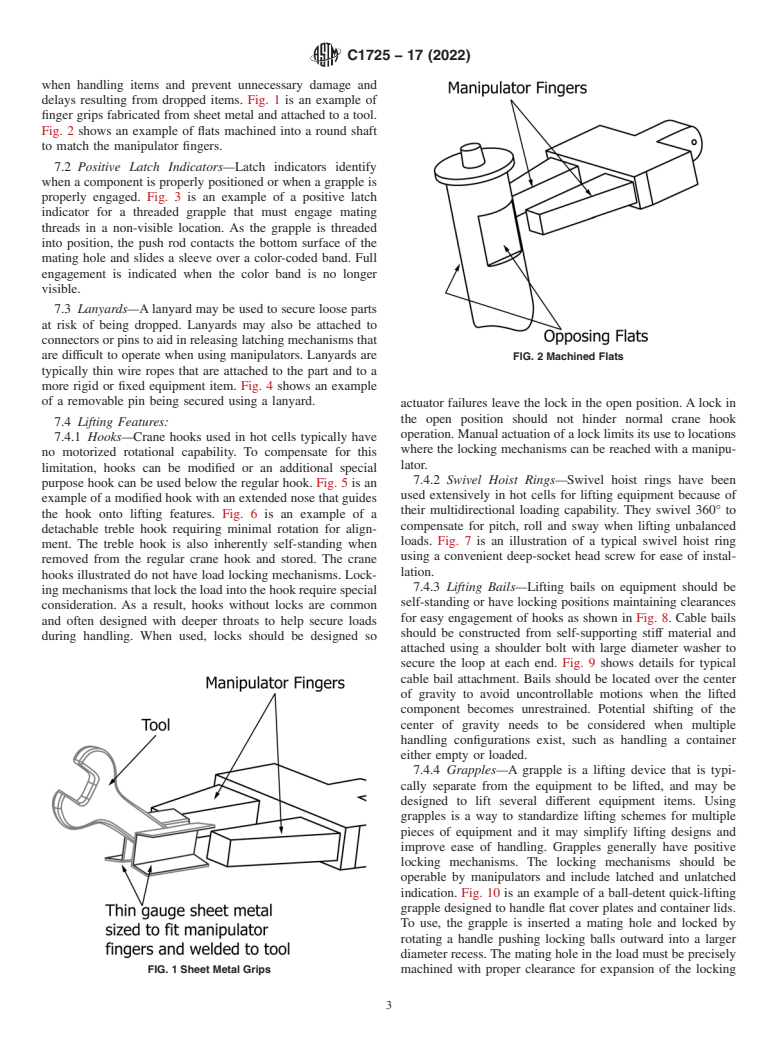

Fig. 2 shows an example of flats machined into a round shaft

to match the manipulator fingers.

7.2 Positive Latch Indicators—Latch indicators identify

when a component is properly positioned or when a grapple is

properly engaged. Fig. 3 is an example of a positive latch

indicator for a threaded grapple that must engage mating

threads in a non-visible location. As the grapple is threaded

into position, the push rod contacts the bottom surface of the

mating hole and slides a sleeve over a color-coded band. Full

engagement is indicated when the color band is no longer

visible.

7.3 Lanyards—A lanyard may be used to secure loose parts

at risk of being dropped. Lanyards may also be attached to

connectors or pins to aid in releasing latching mechanisms that

are difficult to operate when using manipulators. Lanyards are

FIG. 2 Machined Flats

typically thin wire ropes that are attached to the part and to a

more rigid or fixed equipment item. Fig. 4 shows an example

of a removable pin being secured using a lanyard.

actuator failures leave the lock in the open position. A lock in

the open position should not hinder normal crane hook

7.4 Lifting Features:

operation. Manual actuation of a lock limits its use to locations

7.4.1 Hooks—Crane hooks used in hot cells typically have

where the locking mechanisms can be reached with a manipu-

no motorized rotational capability. To compensate for this

lator.

limitation, hooks can be modified or an additional special

7.4.2 Swivel Hoist Rings—Swivel hoist rings have been

purpose hook can be used below the regular hook. Fig. 5 is an

used extensively in hot cells for lifting equipment because of

example of a modified hook with an extended nose that guides

their multidirectional loading capability. They swivel 360° to

the hook onto lifting features. Fig. 6 is an example of a

compensate for pitch, roll and sway when lifting unbalanced

detachable treble hook requiring minimal rotation for align-

loads. Fig. 7 is an illustration of a typical swivel hoist ring

ment. The treble hook is also inherently self-standing when

using a convenient deep-socket head screw for ease of instal-

removed from the regular crane hook and stored. The crane

lation.

hooks illustrated do not have load locking mechanisms. Lock-

7.4.3 Lifting Bails—Lifting bails on equipment should be

ing mechanisms that lock the load into the hook require special

self-standing or have locking positions maintaining clearances

consideration. As a result, hooks without locks are common

for easy engagement of hooks as shown in Fig. 8. Cable bails

and often designed with deeper throats to help secure loads

should be constructed from self-supporting stiff material and

during handling. When used, locks should be designed so

attached using a shoulder bolt with large diameter washer to

secure the loop at each end. Fig. 9 shows details for typical

cable bail attachment. Bails should be located over the center

of gravity to avoid uncontrollable motions when the lifted

component becomes unrestrained. Potential shifting of the

center of gravity needs to be considered when multiple

handling configurations exist, such as handling a container

either empty or loaded.

7.4.4 Grapples—A grapple is a lifting device that is typi-

cally separate from the equipment to be lifted, and may be

designed to lift several different equipment items. Using

grapples is a way to standardize lifting schemes for multiple

pieces of equipment and it may simplify lifting designs and

improve ease of handling. Grapples generally have positive

locking mechanisms. The locking mechanisms should be

operable by manipulators and include latched and unlatched

indication. Fig. 10 is an example of a ball-detent quick-lifting

grapple designed to handle flat cover plates and container lids.

To use, the grapple is inserted a mating hole and locked by

rotating a handle pushing locking balls outward into a larger

diameter recess. The mating hole in the load must be precisely

FIG. 1 Sheet Metal Grips machined with proper clearance for expansion of the locking

C1725

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.