ASTM B798-95(2005)

(Test Method)Standard Test Method for Porosity in Gold or Palladium Coatings on Metal Substrates by Gel-Bulk Electrography

Standard Test Method for Porosity in Gold or Palladium Coatings on Metal Substrates by Gel-Bulk Electrography

SCOPE

1.1 This test method covers equipment and techniques for determining porosity in noble metal coatings, particularly electrodeposits and clad metals used on electrical contacts.

1.2 The test method is designed to show whether the porosity level is less or greater than some value which by experience is considered by the user to be acceptable for the intended application.

1.3 Other porosity testing methods are outlined in Guide B765. Detailed critical reviews of porosity testing are also available. Other porosity test methods are B735, B741, B799, and B809.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 7 and 8.

1.5 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B798–95(Reapproved2005)

Standard Test Method for

Porosity in Gold or Palladium Coatings on Metal Substrates

by Gel-Bulk Electrography

This standard is issued under the fixed designation B 798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope B 741 Test Method for Porosity In Gold Coatings On Metal

Substrates By Paper Electrography

1.1 This test method covers equipment and techniques for

B 765 Guide for Selection of Porosity and Gross Defect

determining porosity in noble metal coatings, particularly

Tests for Electrodeposits and Related Metallic Coatings

electrodeposits and clad metals used on electrical contacts.

B 799 Test Method for Porosity in Gold and Palladium

1.2 The test method is designed to show whether the

Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

porosity level is less or greater than some value which by

B 809 Test Method for Porosity in Metallic Coatings by

experience is considered by the user to be acceptable for the

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

intended application.

1.3 Other porosity testing methods are outlined in Guide

3. Terminology

B 765. Detailed critical reviews of porosity testing are also

2 3.1 Definitions—Many terms used in this test method are

available. Other porosity test methods are B 735, B 741,

defined in Terminology B 542 and terms relating to metallic

B 799, and B 809.

coatings are defined in Terminology B 374.

1.4 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.2.1 decorations, n—those reaction products emanating

responsibility of the user of this standard to become familiar

from the pores that provide visual contrast with the gel

with all hazards including those identified in the appropriate

medium.

Material Safety Data Sheet (MSDS) for this product/material

3.2.2 measurement area (or “significant surface”), n—the

as provided by the manufacturer, to establish appropriate

surface that is examined for the presence of porosity. The

safety and health practices, and determine the applicability of

significant surfaces or measurement areas of the part to be

regulatory limitations prior to use. For specific hazard state-

tested shall be indicated on the drawing of the part or by

ments, see Sections 7 and 8.

provision of suitably marked samples.

1.5 The values stated in SI units are to be regarded as

3.2.2.1 Discussion—For specification purposes, the signifi-

standard. The values in parentheses are for information only.

cant surfaces or measurement areas are often defined as those

2. Referenced Documents portions of the surface that are essential to the serviceability or

3 functionofthepart,suchasitscontactproperties,orwhichcan

2.1 ASTM Standards:

be the source of corrosion products or tarnish films that

B 374 Terminology Relating to Electroplating

interfere with the function of the part.

B 542 Terminology Relating to Electrical Contacts and

3.2.3 metallic coatings, n—include platings, claddings, or

Their Use

other metallic layers applied to the substrate. The coatings can

B 735 Test Method for Porosity in Gold Coatings on Metal

comprise a single metallic layer or a combination of metallic

Substrates by Nitric Acid Vapor

layers.

3.2.4 porosity, n—the presence of any discontinuity, crack,

1 or hole in the coating that exposes a different underlying metal.

This test method is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee 3.2.5 underplate, n—a metallic coating layer between the

B02.11 on Electrical Contact Test Methods.

substrate and the topmost layer or layers. The thickness of an

Current edition approved Nov. 1, 2005. Published February 2006. Originally

underplate is usually greater that 0.8 µm (30 µin.).

approved in 1988. Last previous edition approved in 2000 as B 798 – 95 (2000).

Nobel, F. J., Ostrow, B. D., and Thompson, D. W., “Porosity Testing of Gold

4. Summary of Test Method

Deposity,” Plating, Vol 52, 1965, p. 1001, and Krumbein S. J., “Porosity Testing of

Contact Platings,” Proceedings, Connectors and Interconnection Technology Sym-

4.1 This test method is an electrographic technique, “gel-

posium, October 1987, p. 47.

bulk electrography.” The specimen is made the anode in a cell

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B798–95 (2005)

containing a solid or semisolid electrolyte of gelatin, conduct- 5.5 This test method is capable of detecting porosity or

ing salts, and an indicator. Application of current to this cell other defects in gold or palladium coatings that could partici-

results in the migration of base medal ions through continuous pate in substrate corrosion reactions. In addition, it can be used

pores. Reaction of cations with an indicator gives rise to on contacts having complex geometry such as pin-socket

colored reaction products at pore sites which may be counted contacts (although difficulty may be experienced in inspecting

through the clear gel. Individual spots are counted with the aid deep recesses).

of a loupe or low power stereomicroscope.

4.2 This test method is suitable for coatings containing 6. Limitations

75 % or more of gold on substrates of silver, nickel, copper,

6.1 This test is considered destructive in that it reveals the

and its alloys, which are commonly used in electrical contacts.

presence of porosity by contaminating the surface with corro-

This test method is also suitable for coatings of 95 % or more

sion products and by under-cutting the corrodible metal at pore

of palladium on nickel, copper and its alloys.

sites and at unplated areas. In addition, the surface is coated

4.3 These porosity tests involve corrosion reactions in

with a corrosive gel mixture which is difficult to remove

which the products delineate defect sites in coatings. Since the

completely. Any parts exposed to the gel test shall not be

chemistry and properties of these products do not resemble

placed in service.

those found in natural or service environments, these tests are

6.2 The gel-bulk procedure is not as sensitive to small pores

not recommended for prediction of the electrical performance

and is more complex than porosity tests involving gaseous

of contacts unless correlation is first established with service 5

corrodants (see Test Methods B 735 and B 799). It also

experience.

involves more chemicals, preparation, and auxiliary equip-

ment.

5. Significance and Use

6.3 This test is intended to be used for quantitative descrip-

5.1 Noblemetalcoatings,particularlygoldorpalladium,are

tions of porosity (such as number of pores per unit area or per

often specified for the contacts of separable electrical connec-

contact) only on measurement areas where coatings have pore

tors and other devices. Electrodeposits are the form of gold or

densities that are sufficiently low so that the corrosion sites are

palladium which is most used on contacts, although gold and

well separated and can be readily resolved. As a general

palladium are also employed as clad metal and as weldments

guideline this can be achieved for pore densities up to about

on the contact surface. The intrinsic nobility of gold and to a

25/cm .

certainextentpalladiumenablesthemtoresisttheformationof

6.4 For this purpose, the measurement area, or “significant

insulating films that could interfere with reliable contact

surface,’’ shall be defined as those portions of the surface that

operation.

are essential to the serviceability or function of the part, such

5.2 In order that the nobility of gold be assured, porosity,

as its contact properties, or which can be the source of

cracks, and other defects in the coating that expose base metal

corrosion products or tarnish films that interfere with the

substrates and underplates must be minimal or absent, except

function of the part. When necessary, the significant surfaces

in those cases where it is feasible to use the contacts in

shall be indicated on the drawings of the parts, or by the

structures that shield the surface from the environment or

provision of suitably marked samples.

where corrosion inhibiting surface treatments for the deposit

6.5 The test applicability to platings of varying thickness is

are employed. The level of porosity in the coating that may be

a function of the quality of the plating.

tolerable depends on the severity of the environment to the

6.6 The applicability of this test method to localized plat-

underplate or substrate, design factors for the contact device

ings or claddings with adjacent exposed substrate is limited by

liketheforcewithwhichitismated,circuitparameters,andthe

the efficacy of coatings applied to mask the non-noble areas to

reliability of contact operation that it is necessary to maintain.

prevent gross decoration of the surfaces under test. Users of

Also, when present, the location of pores on the surface is

this method are required to develop their own techniques for

important. If the pores are few in number or are outside of the

masking such exposed substrate areas.

zone of contact of the mating surfaces, their presence can often

be tolerated.

7. Apparatus

5.3 Methods for determining pores on a contact surface are

7.1 Test Vessel maybemadeofglass,acrylicresin,orother

most suitable if they enable their precise location and numbers

inert uncolored transparent material. It shall have thin-walled

tobedetermined.Contactsurfacesareoftencurvedorirregular

flat sides, and be of a size appropriate to the sample to be

in shape, and testing methods should be suitable for them. In

tested.

addition, the severity of porosity-determining tests may vary

7.2 Power Supply,0to1 A and0to10 V dc, an

fromprocedurescapableofdetectingallporositytoprocedures

electronically-regulated, constant-current (65 %) apparatus is

thatdetectonlygrossdefects.Thetestmethodinthisdocument

preferred.

is generally regarded as severe.

7.3 dc Milliammeter and Separate dc Voltmeter.

5.4 Therelationshipofporositylevelsrevealedbyparticular

teststocontactbehaviormustbemadebytheuserofthesetests

through practical experience or judgment. Thus, absence of

porosity in the coating may be a requirement for some

For example, Clarke, M., “Porosity and Porosity Tests,” in “Properties of

applications, while a few pores in the contact zone may be

Electrodeposits,” edited by Sard, Leidheiser, and Ogburn, The Electrochemical

acceptable for others. Society, 1975, p. 122.

B798–95 (2005)

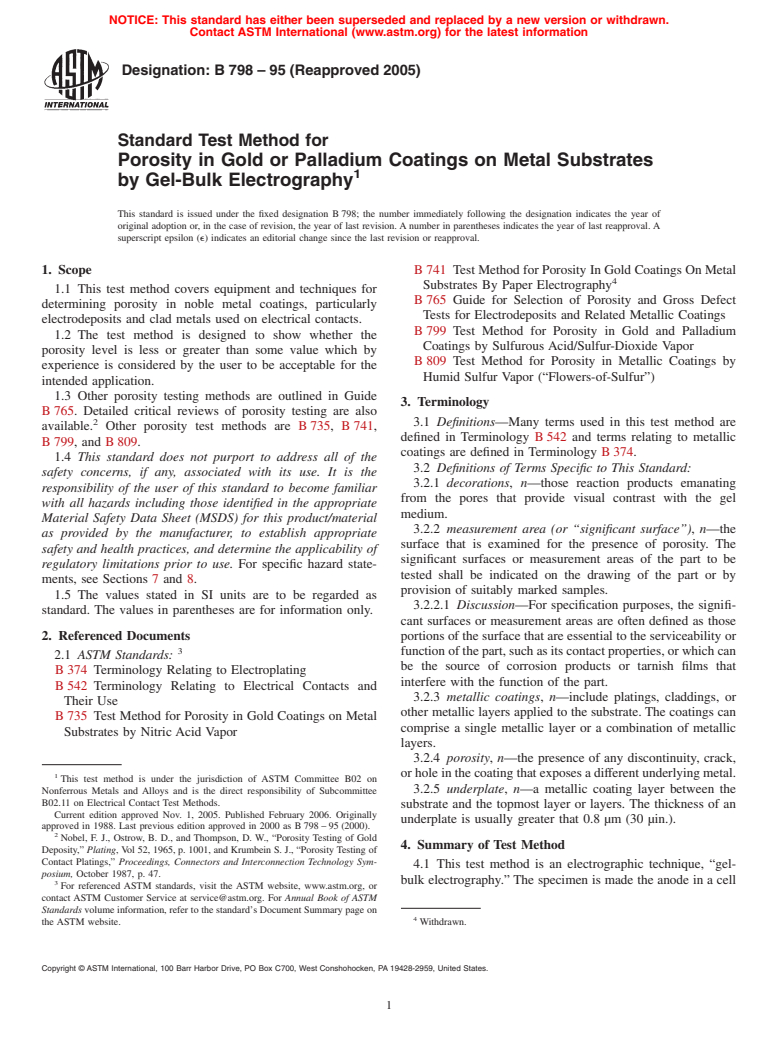

7.4 Cathode Material in the form of foil or wire made of

platinum or gold is required. The cathode and specimen

(anode) areas shall be approximately the same. Additionally,

goldorplatinumwireforcathodeandanodeareneededforthat

portion of the hook-up that is in the reagent solution. It may be

convenient to use small alligator clips to secure the lead wires

to the cathode and anode. These clips must be heavily gold

plated so as to be entirely free of porosity. A variation of this

procedure, suitable for samples having relatively few pores, is

to use a second identical test sample as the cathode. The test

can be run with current first in the forward, then in the reverse

direction so that the porosity in both samples may be deter-

mined. Fig. 1 is a schematic of the test cell setup.

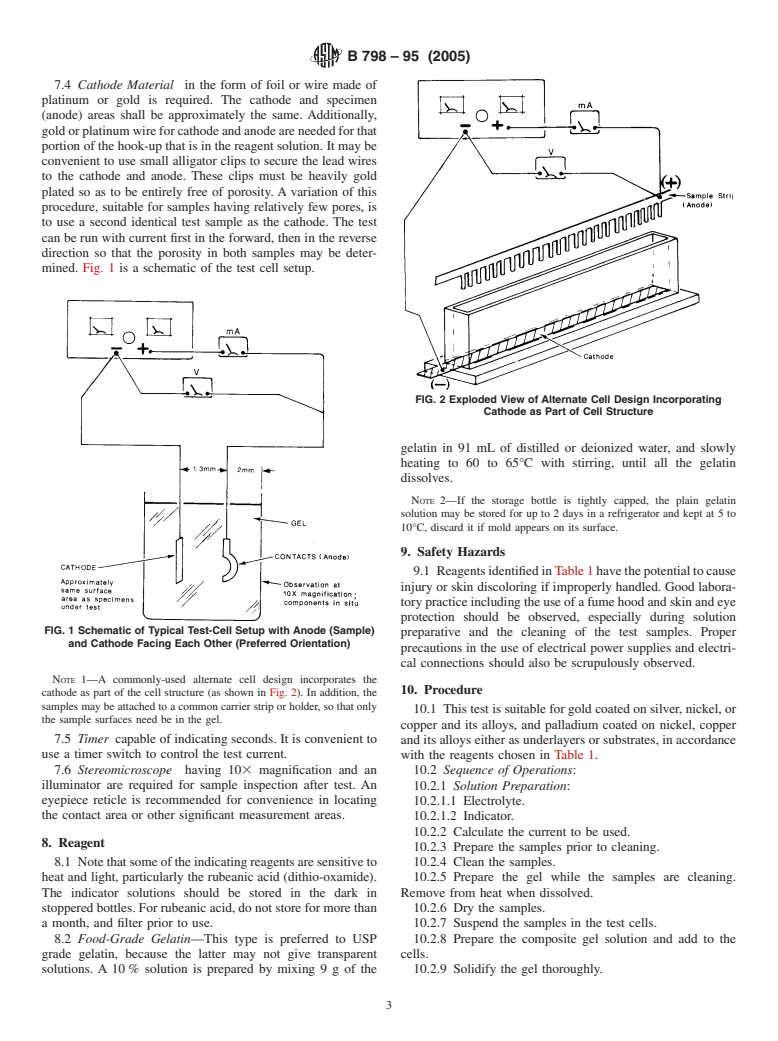

FIG. 2 Exploded View of Alternate Cell Design Incorporating

Cathode as Part of Cell Structure

gelatin in 91 mL of distilled or deionized water, and slowly

heating to 60 to 65°C with stirring, until all the gelatin

dissolves.

NOTE 2—If the storage bottle is tightly capped, the plain gelatin

solution may be stored for up to 2 days in a refrigerator and kept at 5 to

10°C, discard it if mold appears on its surface.

9. Safety Hazards

9.1 ReagentsidentifiedinTable1havethepotentialtocause

injury or skin discoloring if improperly handled. Good labora-

torypracticeincludingtheuseofafumehoodandskinandeye

protection should be observed, especially during solution

FIG. 1 Schematic of Typical Test-Cell Setup with Anode (Sample)

preparative and the cleaning of the test samples. Proper

and Cathode Facing Each Other (Preferred Orientation)

precautions in the use of electrical power supplies and electri-

cal connections should also be scrupulously observed.

NOTE 1—A commonly-used alternate cell design incorporates the

10. Procedure

cathode as part of the cell structure (as shown in Fig. 2). In addition, the

samples may be attached to a common carrier strip or holder, so that only

10.1 This test is suitable for gold coated on silver, nickel, or

the sample surfaces need be in the gel.

copper and its alloys, and palladium coated on nickel, copper

7.5 Timer capable of indicating seconds. It is convenient to

and its alloys either as underlayers or substrates, in accordance

use a timer switch to control the test current. with the reagents chosen in Table 1.

7.6 Stereomicroscope having 103 magnification and an

10.2 Sequence of Operations:

illuminator are required for sample inspection after test. An 10.2.1 Solution Preparation:

eyepiece reticle is recommended for convenience in locating

10.2.1.1 Electrolyte.

the contact area or other significant measurement areas. 10.2.1.2 Indicator.

10.2.2 Calculate the current to be used.

8. Reagent

10.2.3 Prepare the samples prior to cleaning.

8.1 Notethatsomeoftheindicatingreagentsaresensitiveto 10.2.4 Clean the samples.

heat and light, particularly the rubeanic acid (dithio-oxamide). 10.2.5 Prepare the gel while the samples are cleaning.

The indicator solutions should be stored in the dark in Remove from heat when dissolved.

stoppered bottles. For rubeanic acid, do not store for more than 10.2.6 Dry the samples.

a month, and filter prior to use. 10.2.7 Suspend the samples in the test cells.

8.2 Food-Grade Gelatin—This type is preferred to USP 10.2.8 Prepare the composite gel solution and add to the

grade gelatin, because the latter may not give transparent cells.

solutions. A 10 % solution is prepared by mixing9gofthe 10.2.9 Solidify the gel thoroughly.

B798–95 (2005)

TABLE 1 Guide to Gel Porosity Testing Solutions

Test for Electrolyte (Aqueous) Indicator Indicating Color Comment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.