ASTM B98/B98M-08

(Specification)Standard Specification for Copper-Silicon Alloy Rod, Bar and Shapes

Standard Specification for Copper-Silicon Alloy Rod, Bar and Shapes

ABSTRACT

This specification covers rods, bars, and shapes of copper-silicon alloys with UNS Alloy UNS Nos. C65100, C65500, and C66100. The starting materials shall be cast billets or rods of such soundness and structure as to enable them to be processed by hot working, cold working, straightening, and annealing to produce a uniform wrought structure in the finished product. Tempers available under this specification are O60 (soft annealed), H01 (¼-hard), H02 (½-hard), H04 (hard), H06 (extra-hard), M20 (as hot rolled), and M30 (as hot extruded). Products shall be tested and shall adhere to dimensional (mass, diameter, shape, length, straightness, and edge contour), mechanical (tensile and yield strength, elongation, and Rockwell hardness), and chemical composition requirements.

SCOPE

1.1 This specification establishes requirements for copper-silicon rod, bar, and shapes for UNS Alloys C65100, C65500, and C66100.

Note 1—Material for hot forging is covered by Specification B 124/B 124M.

Note 2—For ASME Boiler and Pressure Vessel Code applications, see Specification SB-98 in Section II of that code.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B98/B98M −08

StandardSpecification for

1

Copper-Silicon Alloy Rod, Bar and Shapes

This standard is issued under the fixed designation B98/B98M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E18 Test Methods for Rockwell Hardness of Metallic Ma-

terials

1.1 This specification establishes requirements for copper-

E62 Test Methods for Chemical Analysis of Copper and

silicon rod, bar, and shapes for UNS Alloys C65100, C65500,

3

CopperAlloys (Photometric Methods) (Withdrawn 2010)

and C66100.

E478 Test Methods for ChemicalAnalysis of CopperAlloys

NOTE 1—Material for hot forging is covered by Specification B124/

B124M.

3. General Requirements

NOTE 2—ForASME Boiler and Pressure Vessel Code applications, see

Specification SB-98 in Section II of that code.

3.1 The following sections of Specification B249/B249M

constitute a part of this specification:

1.2 The values stated in either SI units or inch-pound units

are to be regarded separately as standard. The values stated in 3.1.1 Terminology,

3.1.2 Materials and Manufacture,

each system may not be exact equivalents; therefore, each

system shall be used independently of the other. Combining 3.1.3 Workmanship, Finish, and Appearance,

values from the two systems may result in non-conformance 3.1.4 Sampling,

with the standard.

3.1.5 Number of Tests and Retests,

3.1.6 Specimen Preparation,

2. Referenced Documents

3.1.7 Test Methods,

3.1.8 Significance of Numerical Limits,

2.1 The following documents of the issue in effect on date

3.1.9 Inspection,

of material purchase form a part of this specification to the

3.1.10 Rejection and Rehearing,

extent referenced herein:

3.1.11 Certification,

2

2.2 ASTM Standards:

3.1.12 Test Report (Mill),

B124/B124M Specification for Copper and Copper Alloy

3.1.13 Packaging and Package Marking, and

Forging Rod, Bar, and Shapes

3.1.14 Supplemental Requirements.

B249/B249M Specification for General Requirements for

Wrought Copper and Copper-Alloy Rod, Bar, Shapes and

3.2 In addition, when a section with a title identical to one

Forgings

of those referenced in 3.1 appears in this specification, it

B601 Classification forTemper Designations for Copper and

contains additional requirements that supplement those which

Copper Alloys—Wrought and Cast

appear in Specification B249/B249M.

E8 Test Methods for Tension Testing of Metallic Materials

E8M Test Methods forTensionTesting of Metallic Materials

4. Ordering Information

3

[Metric] (Withdrawn 2008)

4.1 Include the following information in orders for product

under this specification:

4.1.1 ASTM Designation and year of issue,

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

4.1.2 Copper Alloy UNS No. designation,

and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod,

4.1.3 Temper designation,

Bar, Wire, Shapes and Forgings.

Current edition approved Oct. 1, 2008. Published November 2008. Originally

4.1.4 Quantity; total weight or length, or number of pieces

approved in 1934. Last previous edition approved in 2003 as B98/B98M – 03. DOI:

of each temper, form, or alloy,

10.1520/B0098_B0098M-08.

2 4.1.5 Dimensions; diameter or distance between parallel

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

surfaces,

Standards volume information, refer to the standard’s Document Summary page on

4.1.6 Type of edge; edge contours,

the ASTM website.

3

4.1.7 How furnished; specific lengths with or without ends,

The last approved version of this historical standard is referenced on

www.astm.org. and

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B98/B98M − 08

1

4.1.8 When material is purchased for agencies of the U.S. 7.1.3 ⁄2-hard H02,

Government (see Specification B249/B249M). 7.1.4 Hard H04,

7.1.5 Extra-hard H06,

4.2 The following options are available under this specifi-

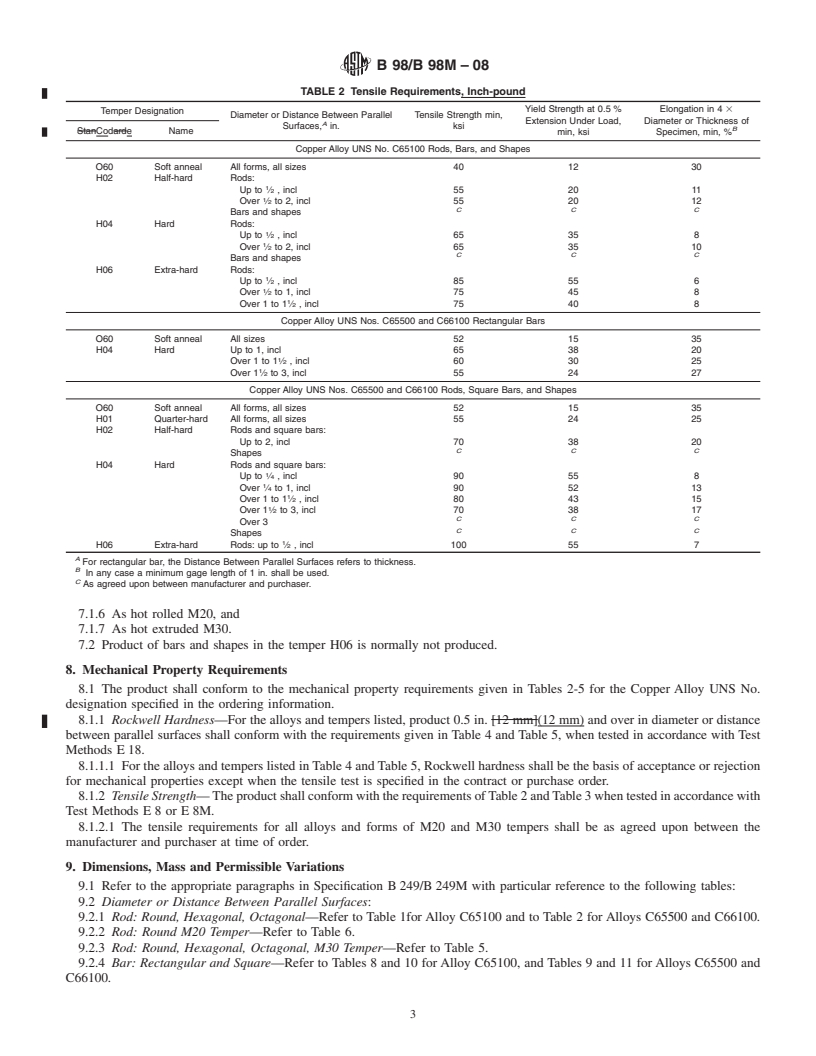

7.1.6 As hot rolled M20, and

cation and should be specified in the contract or purchase order

7.1.7 As hot extruded M30.

when required:

4.2.1 Certification (Specification B249/B249M), and 7.2 Product of bars and shapes in the temper H06 is

4.2.2 Mill Test Report (Specification B249/B249M). normally not produced.

4.2.3 Tensile test required for alloys in Table 4 or Table 5

(see 8.1.1.1). 8. Mechanical Property Requirements

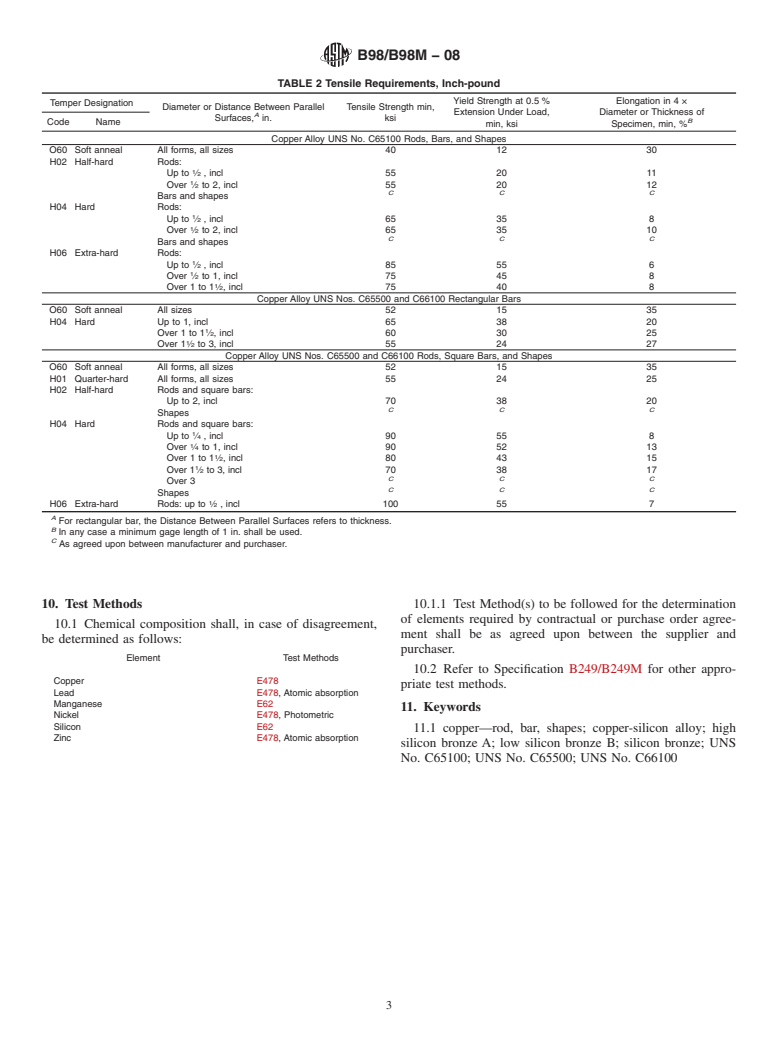

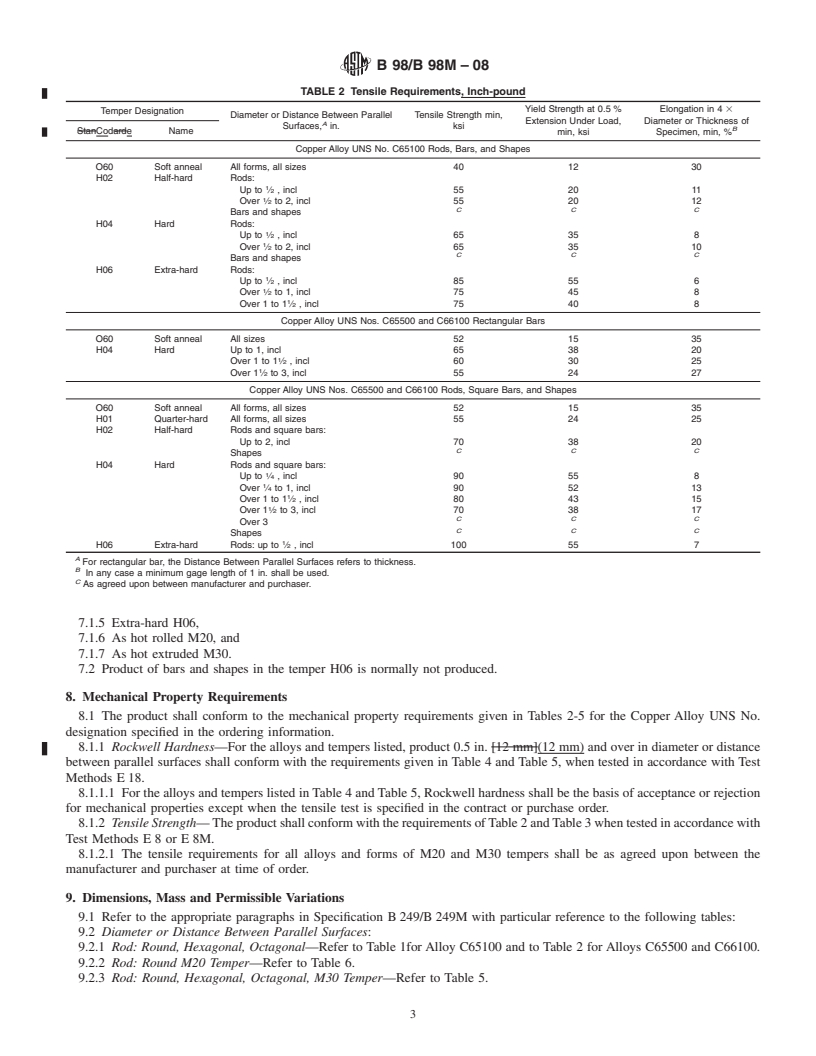

8.1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 98/B 98M–03 Designation: B 98/B 98M – 08

Standard Specification for

1

Copper-Silicon Alloy Rod, Bar and Shapes

This standard is issued under the fixed designation B 98/B 98M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes requirements for copper-silicon rod, bar, and shapes for UNS Alloys C65100, C65500, and

C66100.

NOTE 1—Material for hot forging is covered by Specification B 124/B 124M.

NOTE 2—For ASME Boiler and Pressure Vessel Code applications, see Specification SB-98 in Section II of that code.

1.2 The values stated in inch-pound either SI units or SIinch-pound units are to be regarded separately as standard. Within the

text, SI units are shown in brackets.The values stated in each system aremay not be exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

standard.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B 124/B 124M Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

B 249/B 249M Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes and Forgings

B 601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

E8 Test Methods for Tension Testing of Metallic Materials

E8M Test Methods for Tension Testing of Metallic Materials [Metric]

3

E18 Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Test Methods for

Rockwell Hardness of Metallic Materials

E62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Method)Methods)

E 478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 The following sections of Specification B 249/B 249M constitute a part of this specification:

3.1.1 Terminology,

3.1.2 Materials and Manufacture,

3.1.3 Workmanship, Finish, and Appearance,

3.1.4 Sampling,

3.1.5 Number of Tests and Retests,

3.1.6 Specimen Preparation,

3.1.7 Test Methods,

3.1.8 Significance of Numerical Limits,

3.1.9 Inspection,

3.1.10 Rejection and Rehearing,

3.1.11 Certification,

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes,Shapes and Forgings.

Current edition approvedApr. 10, 2003.Oct. 1, 2008. Published May 2003.November 2008. Originally approved in 1934. Last previous edition approved in 19982003 as

B98/B98M–98.B 98/B 98M – 03.

2

Annual Book of ASTM Standards, Vol 02.01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 98/B 98M – 08

3.1.12 Test Report (Mill),

3.1.13 Packaging and Package Marking, and

3.1.14 Supplemental Requirements.

3.2 In addition, when a section with a title identical to one of those referenced in 3.1 appears in this specification, it contains

additional requirements that supplement those which appear in Specification B 249/B 249M.

4. Ordering Information

4.1 Include the following information in orders for product under this specification:

4.1.1 ASTM Designation and year of issue,

4.1.2 Copper Alloy UNS No. designation,

4.1.3 Temper designation,

4.1.4 Quantity; total weight or length, or number of pieces of each temper, form, or alloy,

4.1.5 Dimensions; diameter or distance between parallel surfaces,

4.1.6 Type of edge; edge contours,

4.1.7 How furnished; specific lengths with or without ends, and

4.1.8 When material is purchased for agencies of the U.S. Government (see Specification B 249/B 249M).

4.2 The following options are available under this specification and should be specified in the cont

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:B 98/B 98M–03 Designation: B 98/B 98M – 08

Standard Specification for

1

Copper-Silicon Alloy Rod, Bar and Shapes

This standard is issued under the fixed designation B 98/B 98M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

1.1 This specification establishes requirements for copper-silicon rod, bar, and shapes for UNS Alloys C65100, C65500, and

C66100.

NOTE 1—Material for hot forging is covered by Specification B 124/B 124M.

NOTE 2—For ASME Boiler and Pressure Vessel Code applications, see Specification SB-98 in Section II of that code.

1.2 The values stated in inch-pound either SI units or SIinch-pound units are to be regarded separately as standard. Within the

text, SI units are shown in brackets.The values stated in each system aremay not be exact equivalents; therefore, each system shall

be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

standard.

2. Referenced Documents

2.1 The following documents of the issue in effect on date of material purchase form a part of this specification to the extent

referenced herein:

2.2 ASTM Standards:

2

B124/B124M Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

B 124/B 124M Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes

B 249/B 249M Specification for General Requirements for Wrought Copper and Copper-Alloy Rod, Bar, Shapes and Forgings

B 601 Classification for Temper Designations for Copper and Copper Alloys—Wrought and Cast

E 8 Test Methods for Tension Testing of Metallic Materials

E 8M Test Methods for Tension Testing of Metallic Materials [Metric]

3

E 18Test Methods for Rockwell Hardness and Rockwell Superficial Hardness of Metallic Materials Test Methods for

Rockwell Hardness of Metallic Materials

E 62 Test Methods for Chemical Analysis of Copper and Copper Alloys (Photometric Method) Methods)

E 478 Test Methods for Chemical Analysis of Copper Alloys

3. General Requirements

3.1 The following sections of Specification B 249/B 249M constitute a part of this specification:

3.1.1 Terminology,

3.1.2 Materials and Manufacture,

3.1.3 Workmanship, Finish, and Appearance,

3.1.4 Sampling,

3.1.5 Number of Tests and Retests,

3.1.6 Specimen Preparation,

3.1.7 Test Methods,

3.1.8 Significance of Numerical Limits,

3.1.9 Inspection,

3.1.10 Rejection and Rehearing,

1

This specification is under the jurisdiction ofASTM Committee B05 on Copper and CopperAlloys and is the direct responsibility of Subcommittee B05.02 on Rod, Bar,

Wire, Shapes,Shapes and Forgings.

Current edition approvedApr. 10, 2003.Oct. 1, 2008. Published May 2003.November 2008. Originally approved in 1934. Last previous edition approved in 19982003 as

B98/B98M–98.B 98/B 98M – 03.

2

Annual Book of ASTM Standards, Vol 02.01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 98/B 98M – 08

3.1.11 Certification,

3.1.12 Test Report (Mill),

3.1.13 Packaging and Package Marking, and

3.1.14 Supplemental Requirements.

3.2 In addition, when a section with a title identical to one of those referenced in 3.1 appears in this specification, it contains

additional requirements that supplement those which appear in Specification B 249/B 249M.

4. Ordering Information

4.1 Include the following information in orders for product under this specification:

4.1.1 ASTM Designation and year of issue,

4.1.2 Copper Alloy UNS No. designation,

4.1.3 Temper designation,

4.1.4 Quantity; total weight or length, or number of pieces of each temper, form, or alloy,

4.1.5 Dimensions; diameter or distance between parallel surfaces,

4.1.6 Type of edge; edge contours,

4.1.7 How furnished; specific lengths with or without ends, and

4.1.8 When material is purchased for agencies of the U.S. Government (see Specification B 249/B 249M).

4.2 The follo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.