ASTM B171/B171M-04

(Specification)Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

Standard Specification for Copper-Alloy Plate and Sheet for Pressure Vessels, Condensers, and Heat Exchangers

SCOPE

1.1 This specification establishes the requirements for copper-alloy plate and sheet for pressure vessels, condensers, and heat exchangers. The following alloys are covered:Copper AlloyPreviously Used DesignationC36500Leaded Muntz MetalC44300Admirality, ArsenicalC44400Admirality, AntimonialC44500Admirality, PhosphorizedC46400Naval Brass, UninhibitedC46500Naval Brass, ArsenicalC61300Aluminum BronzeC61400Aluminum Bronze DC6300010 % Aluminum-Nickel BronzeC632009 % Aluminum-Nickel BronzeC7060090-10 Copper NickelC7062090-10 Copper Nickel -(modified for welding)C7150070-30 Copper NickelC7152070-30 Copper Nickel-(modified for welding)C72200. . .

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

General Information

Relations

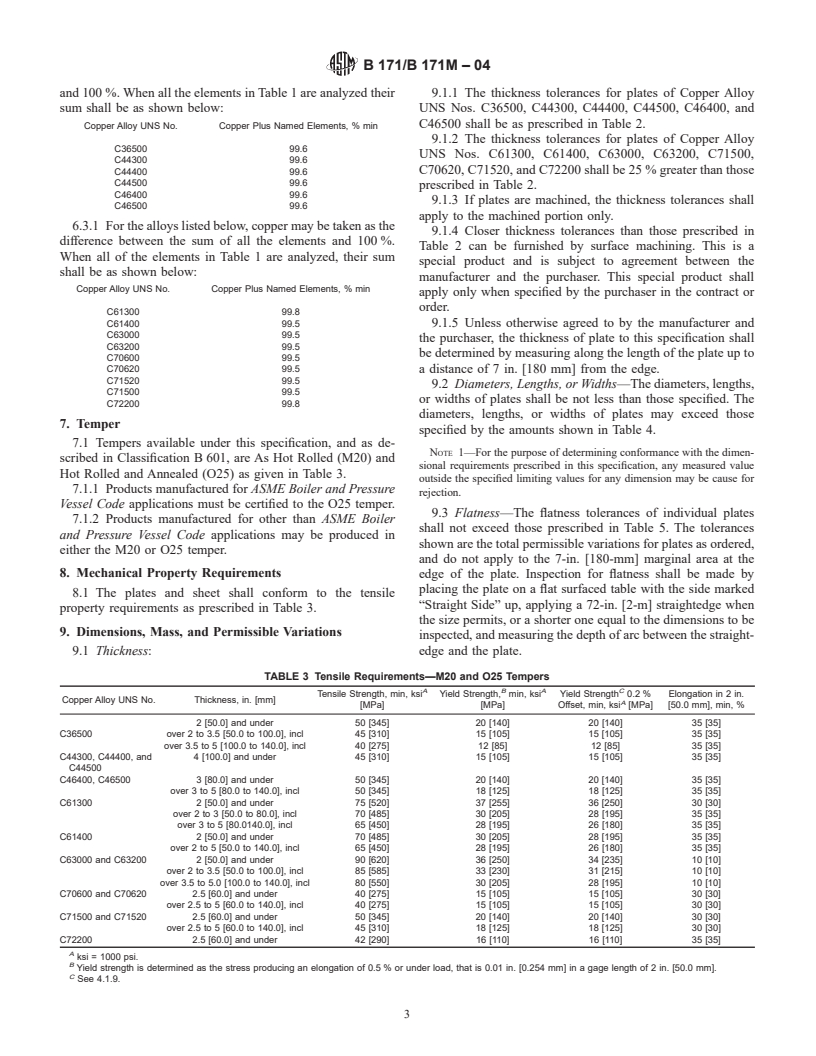

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 171/B 171M – 04

Standard Specification for

Copper-Alloy Plate and Sheet for Pressure Vessels,

1

Condensers, and Heat Exchangers

This standard is issued under the fixed designation B 171/B 171M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B 248 Specification for General Requirements for Wrought

2 Copper and Copper-Alloy Plate, Sheet, Strip and Rolled

1.1 This specification establishes the requirements for

Bar

copper-alloy plate and sheet for pressure vessels, condensers,

B 248M Specification for General Requirements for

and heat exchangers. The following alloys are covered:

Wrought Copper and Copper-Alloy Plate, Sheet, Strip and

Copper Alloy Previously Used Designation

Rolled Bar [Metric]

C36500 Leaded Muntz Metal

B 601 Classification for Temper Designations for Copper

C44300 Admirality, Arsenical

and Copper Alloys-Wrought and Cast

C44400 Admirality, Antimonial

B 846 Terminology for Copper and Copper Alloys

C44500 Admirality, Phosphorized

C46400 Naval Brass, Uninhibited

E 8 Test Methods for Tension Testing of Metallic Materials

C46500 Naval Brass, Arsenical

E 8M Test Methods for Tension Testing of Metallic Mate-

C61300 Aluminum Bronze

rials [Metric]

C61400 Aluminum Bronze D

C63000 10 % Aluminum-Nickel Bronze

E 29 Practice for Using Significant Digits in Test Data to

C63200 9 % Aluminum-Nickel Bronze

Determine Conformance with Specification

C70600 90-10 Copper Nickel

C70620 90-10 Copper Nickel -(modified for welding) E 54 Test Methods for Chemical Analysis of Special

4

C71500 70-30 Copper Nickel

Brasses and Bronzes

C71520 70-30 Copper Nickel-(modified for welding)

E 62 Test Methods for Chemical Analysis of Copper and

C72200 . . .

Copper Alloys (Photometric Method)

1.2 The values stated in either inch-pound units or SI units

E 255 Practice for Sampling Copper and Copper Alloys for

are to be regarded separately as standard. Within the text, the

Determination of Chemical Composition

SI units are shown in brackets. The values in each system are

E 478 Test Methods for Chemical Analysis of Copper

not exact equivalents; therefore, each system shall be used

Alloys

independently of the other. Combining values from the two

E 527 Practice for Numbering Metals and Alloys (UNS)

systems may result in nonconformance with the specification.

3. Terminology

2. Referenced Documents

3.1 Definitions—For definitions of terms used in this speci-

2.1 The following documents in the current issue of the

fication, refer to Terminology B 846.

Book of Standards form a part of this specification to the extent

referenced herein: 4. Ordering Information

3

2.2 ASTM Standards:

4.1 Orders for product under this specification shall include

the following information:

4.1.1 ASTM Specification B 171/B 171M, year of issue,

1

This specification is under the jurisdiction of ASTM Committee B05 on Copper

4.1.2 Whether inch-pound or SI units are applicable (see

and Copper Alloys and is the direct responsibility of Subcommittee B5.01 on Plate,

Sheet, and Strip.

1.2),

Current edition approved May 1, 2004. Published May 2004. Originally

4.1.3 Copper Alloy UNS. No. (see Section 6, Table 1),

e2

approved in 1942. Last previous edition approved in 1999 as B 171/B 171M – 99 .

2 4.1.4 Whether the alloy ordered will be used in applications

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

requiring it to be welded (see Table 1, footnotes B and C for

cation SB-171 in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

4

the ASTM website. Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 171/B 171M – 04

TABLE 1 Chemical Requirements

Composition, % max (Unless Shown as a Range)

Copper Alloy

A

Copper, incl Manganese, Other Named

UNS No.

Tin Nickel, incl Cobalt Lead Iron Zinc Aluminum Chromium

Silver max Elements

C36500 58.0-61.0 0.25 . . . . . . 0.25-0.7 0.15 remainder . . . . . . . . .

C44300 70.0-73.0 0.8-1.2 . . . . . . 0.07 0.06 remainder . . . . . . 0.02-0.06 As

C44400 70.0-73.0 0.8-1.2 . . . . . . 0.07 0.06 remainder . . . . . . 0.02-0.10 Sb

C44500 70.0-73.0 0.8-1.2 . . . . . . 0.07 0.06 remainder . . . . . . 0.02-0.10 P

C46400 59.0-62

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.