ASTM E1636-94(1999)

(Practice)Standard Practice for Analytically Describing Sputter-Depth-Profile Interface Data by an Extended Logistic Function

Standard Practice for Analytically Describing Sputter-Depth-Profile Interface Data by an Extended Logistic Function

SCOPE

1.1 This practice covers a systematic method for analyzing sputter-depth-profile interface data and for accurately characterizing the shape of the interface region. Interface profile data are described with an appropriate analytic function; the parameters of this function define the interface width, its asymmetry, and its depth from the original surface. The use of this practice is recommended in order that the shapes of composition profiles of interfaces acquired with different instruments and techniques on different materials can be unambiguously compared and interpreted.

1.2 This practice is intended to be used to describe the shape of depth profile data obtained at an interface between two dissimilar materials for that case in which the measured concentration of the outer material goes from 100 to 0% and the inner material goes from 0 to 100%.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1636 – 94 (Reapproved 1999)

Standard Practice for

Analytically Describing Sputter-Depth-Profile Interface Data

by an Extended Logistic Function

This standard is issued under the fixed designation E1636; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.1 Throughout this practice, the regions of the sigmoidal

profile will be referred to as the pre-interface, interface, and

1.1 This practice covers a systematic method for analyzing

post-interface regions. These terms are not dependent on

sputter-depth-profile interface data and for accurately charac-

whether a particular interface profile is a growth or a decay

terizing the shape of the interface region. Interface profile data

curve. The terms pre- and post- are taken in the sense of

aredescribedwithanappropriateanalyticfunction;theparam-

increasing values of the independent variable X, the sputtered

eters of this function define the interface width, its asymmetry,

depth.

anditsdepthfromtheoriginalsurface.Theuseofthispractice

is recommended in order that the shapes of composition

4. Summary of Practice

profiles of interfaces acquired with different instruments and

4.1 Sputter depth profile interface data (composition versus

techniques on different materials can be unambiguously com-

depth) is fitted to an analytic function, an extended form of the

pared and interpreted.

logistic function, in order to describe the shape of such

1.2 Thispracticeisintendedtobeusedtodescribetheshape

interface profiles. Least-squares fitting techniques are em-

of depth profile data obtained at an interface between two

ployed to determine the values of the parameters of this

dissimilar materials for that case in which the measured

extended logistic function which characterize the shape of the

concentration of the outer material goes from 100 to 0% and

interface. Interface width, depth, and asymmetry are deter-

the inner material goes from 0 to 100%.

mined by these parameters.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 Information on interface composition is frequently ob-

priate safety and health practices and determine the applica-

tained by measuring surface composition while the specimen

bility of regulatory limitations prior to use.

material is gradually removed by ion bombardment (see Guide

E1127 and Practice E1162). In this way, interfaces are

2. Referenced Documents

revealedandcharacterizedbythemeasurementofcomposition

2.1 ASTM Standards:

2 versus depth to obtain a sputter-depth profile. The shape of

E 673 Terminology Relating to Surface Analysis

such interface profiles contains information about the physical

E 1127 Guide for Depth Profiling in Auger Electron Spec-

2 and chemical properties of the interface region. In order to

troscopy

accurately and unambiguously describe this interface region

E1162 PracticeforReportingSputterDepthProfileDatain

2 and to determine its width (see Guide E1438), it is necessary

Secondary Ion Mass Spectrometry (SIMS)

to define the shape of the entire interface profile with a single

E1438 GuideforMeasuringWidthsofInterfacesinSputter

2 analytic function.

Depth Profiling Using SIMS

5.2 Although no general physical model currently exists for

3. Terminology describing the shape of interface sputter-depth profiles, inter-

face profiles do have a sigmoidal shape characteristic of the

3.1 Definitions—For definitions of terms used in this prac-

cumulativelogisticdistribution.Useofsuchalogisticfunction

tice, see Terminology E673.

is physically plausible and is superior to other functions (for

3.2 Definitions of Terms Specific to This Standard:

example, polynomials) that have heretofore been used for

This practice is under the jurisdiction of ASTM Committee E-42 on Surface

Analysis and is the direct responsibility of Subcommittee E42.08 on Ion Beam

Sputtering. Kirchhoff,W. H., Chambers, G. P., and Fine, J., “AnAnalytical Expression for

Current edition approved Sept. 15, 1994. Published November 1994. Describing Auger Sputter Depth Profile Shapes of Interfaces,” Journal of Vacuum

Annual Book of ASTM Standards, Vol 03.06. Science and Technology, , p. 1666, 1986.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1636

interface profile analysis in that it contains the minimum fit requires an iterative solution. Consequently, Y, as expressed

number of parameters for describing interface shapes. by Eq 3 , can be expanded in a Taylor series about the current

5.3 Manyattemptshavebeenmadetocharacterizeinterface values of the parameters and the Taylor series terminated after

profiles with general functions (such as polynomials or error the first (that is, linear) term for each parameter. Y (obs)− Y

functions) but these have suffered from instabilities and an (calc) is fit to this linear expression and the least-squares

inabilitytohandlepoorlystructureddata.Choiceofthelogistic routine returns the corrections to the parameters. The param-

function along with a specifically written least-squares proce- eters are updated and the procedure is repeated until the

dure (described in Appendix X1) can provide statistically corrections to the parameters are deemed to be insignificant

evaluated parameters that describe the width, asymmetry, and compared to their standard deviations. Values for interface

depth of interface profiles in a reproducible and unambiguous width, depth, and asymmetry can be calculated from the

way. parameters of the fitted logistic function.

6.3 Implementation of this procedure can be readily accom-

6. Description of the Analysis

plishedbymakinguseofaspecializedcomputeralgorithmand

6.1 Logistic Function Data Analysis—In its simplest form, supporting software (LOGIT) developed specifically for this

the logistic function may be written as: application and described in Appendix X1.

7. Interpretation of Results

Y 5 (1)

2x

1 1 e

7.1 The seven parameters necessary to characterize the

inwhich Yprogressesfrom0to1as Xvariesfrom−`to+`.

interface profile shape are determined by a least-squares fit of

The differential equation generating this function is:

the interface data to the extended logistic function. These

parameters are related to the three distinct regions of the

dY/dX 5 Y 1 2 Y (2)

~ !

interface profile. Two parameters, an intercept A and a slope

and in this form describes a situation where a measurable

A arenecessarytodefinethepre-interfaceasymptotewhiletwo

s

quantity Y grows in proportion to Y and in proportion to finite

more, B and B , define the post-interface asymptote. For the

s

resources required by Y. The logistic function was first named

analysis of typical interface profiles, it is usual to assume that

and applied to population growth in the last century by

both of these slopes are zero.Two more parameters, D and X ,

4 o o

Verhulst. The logistic function as a distribution function and

define the slope and position of the transition region. In

growth curve has been extensively reviewed by Johnson and

addition, an asymmetry parameter Q that causes the width

Kotz. Interfaceprofiledataisfittedtoanextendedformofthe

parameter to vary logistically from O to 2D , is introduced as

o

logistic function:

a measure of the difference in curvature in the pre- and

z

Y 5 @A 1 A ~X 2 X !#/~1 1 e !

post-transition ends of the transition region. If Q < O, the

s o

2z

1 @B 1 B ~X 2 X !#/~1 1 e ! (3)

pre-transition region has the greatest (sharpest) curvature. If Q

s o

> O, the post-transition region has the greatest curvature. If

where:

Q 5O, D 5 D and the transition profile is symmetric. The

o

z 5 ~X 2 X !/D (4)

o

parameter Q has the dimensions of 1/X whereas D has the

o

and:

dimensions of X. The product QD is dimensionless and is a

o

Q~X2X ! measure of the asymmetry of the profile independent of its

o

D 52 D / 1 1 e (5)

@ #

o

width. If the absolute magnitude of QD is less than 0.1, the

o

6.1.1 Y is a measure of the elemental surface concentration

asymmetry in the transition profile should be barely discern-

of one of the components and X, the independent variable, is a

ible.

measure of the sputtered depth, usually expressed as a sputter-

7.2 The final results should include the calculated values of

ing time. Pre-interface and post-interface elemental surface

Y and associated statistics, the values of the determined

concentrations are described by the parameters A and B,

parameters and their uncertainties, and statistics related to the

respectively,theparametersA andB areintroducedtoaccount

s s

overall quality of the least-squares fit.

for time dependent instrumental effects. X is the midpoint of

o

7.3 The width of the interface region, I, is the depth (time)

f

theinterfaceregion(interfacedepthortime).Thescalingfactor

required for the decay or growth curve to progress from a

D is the characteristic depth for sputtering through the

o

fraction f of completion to (1− f) of completion. For the case

interface region; Q, an asymmetry parameter, is a measure of

where Q 5O, I is proportional to D and is given by the

f o

thedifferenceincurvatureinthepre-andpost-interfaceendsof

simple formula:

theinterfaceregion.Allmeasuresoftheinterfacewidthcanbe

I 52 D 1n @~1 2 f!/f# (6)

f o

determined from D and Q.

o

6.2 Fitting of interface profile data to the above functions, so that, for example, the traditional 16 to 84% interface

Eq 3 , can be accomplished by using least-squares techniques. width is 3.32 D .

o

Because these equations are non-linear functions of the three 7.4 Introduction of the asymmetry parameter Q into the

transition-region parameters, X , D , and Q, the least-squares extended logistic function makes the calculation of the 16 to

o o

84% points of the interface more complicated. In particular,

for fractions f and (1− f) of completion of the interface

Verhulst, P. F., Acad. Brux. Vol 18, p. 1, 1845.

transition:

Johnson,N.L.andKotz,S.,“DistributionsinStatistics:ContinuousUnivariate

Q X 2X !

~

f o

Distributions,” Houghton Mifflin Co., Boston, 2, Chapter 22, 1970. X 5 X 12 D 1n @f/~1 2 f!#/@1 1 e # (7)

f o o

E 1636

and:

Q~X 2X !

12f o

X 5 X 12 D 1n @~1 2 f!/f#/@1 1 e # (8)

~12f! o o

X and X can be evaluated most readily by Newton’s

f (1−f)

method of successive approximations.

8. Reporting of Results

8.1 Interface profile shapes can be accurately characterized

bytheextendedlogisticfunctionanditsparameters.Resultsof

such interface analysis should report these parameters (X , D ,

o o

Q) together with their uncertainties, the standard deviation of

the fit, and an interface width obtained from D and Q that is

o

based on some accepted definition (for example, 16 to 84%

concentration change).

8.2 Sputtereddepth, X,isoftendifficulttodetermineexperi-

mentally so that depth profile data are normally acquired with

time as the independent variable. This sputtered time can be

referenced with respect to a removal time obtained with a

calibrated sputtering standard under the same sputtering con-

ditions of ion energy, beam angle, current density, etc. as the

interface measurement itself. In this way, time can be trans-

formed into an equivalent depth derived from a standard

material and this equivalent depth should be used in reporting

the interface parameters and analysis results. Sputtering stan-

dardsareavailablefromtheNationalInstituteofStandardsand

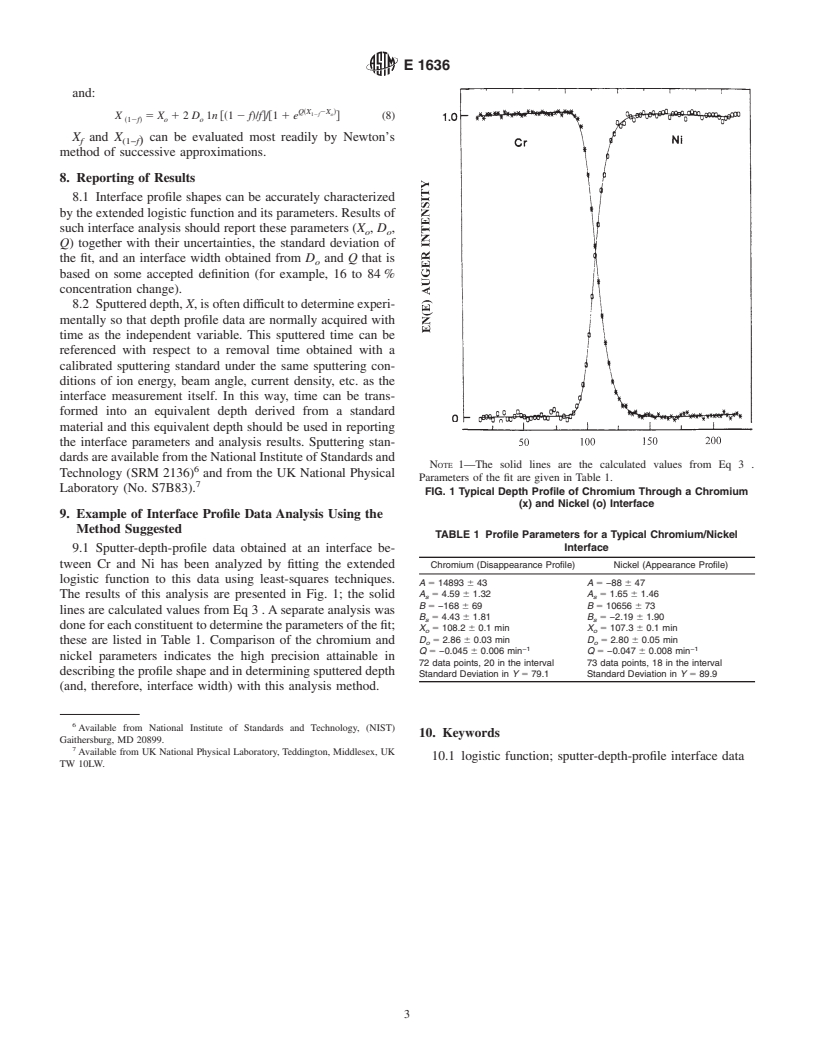

NOTE 1—The solid lines are the calculated values from Eq 3 .

Technology (SRM 2136) and from the UK National Physical

Parameters of the fit are given in Table 1.

Laboratory (No. S7B83).

FIG. 1 Typical Depth Profile of Chromium Through a Chromium

(x) and Nickel (o) Interface

9. Example of Interface Profile Data Analysis Using the

Method Suggested

TABLE 1 Profile Parameters for a Typical Chromium/Nickel

Interface

9.1 Sputter-depth-profile data obtained at an interface be-

tween Cr and Ni has been analyzed by fitting the extended

Chromium (Disappearance Profile) Nickel (Appearance Profile)

logistic function to this data using least-squares techniques.

A 5 14893 6 43 A 5 −88 6 47

A 5 4.59 6 1.32 A 5 1.65 6 1.46

The results of this analysis are presented in Fig. 1; the solid

s s

B 5 −168 6 69 B 5 10656 6 73

lines are calculated values from Eq 3 .Aseparate analysis was

B 5 4.43 6 1.81 B 5 −2.19 6 1.90

s s

doneforeachconstituenttodeterminetheparametersofthefit;

X 5 108.2 6 0.1 min X 5 107.3 6 0.1 min

o o

D 5 2.86 6 0.03 min D 5 2.80 6 0.05 min

these are listed in Table 1. Comparison of the chromium and o o

−1 −1

Q 5 −0.045 6 0.006 min Q 5 −0.047 6 0.008 min

nickel parameters indicates the high precision attainable in

72 data points, 20 in the interval 73 data points, 18 in the interval

describingtheprofileshapeandindeterminingsputtereddepth

Standard Deviation in Y 5 79.1 Standard Deviation in Y 5 89.9

(and, therefore, interface width) with this analysis method.

Available from National Institute of Standards and Technology, (NIST)

10. Keywords

Gaithersburg, MD 20899.

Available from UK National Physical Laboratory, Teddington, Middlesex, UK

10.1 logistic function; sputter-depth-profile interface data

TW 10LW.

E 1636

APPENDIX

(Nonmandatory Information)

X1. FITTING OF DEPTH PROFILE INTERFACE DATA TO THE LOGISTIC FUNCTION BY MEANS OFA

SPECIALIZED COMPUTER ALGORITHM, LOGIT

X1.1 Scope X1.4 Description of the Fitting Procedure Used in

LOGIT

X1.1.1 This appendix describes a specialized computer

algorithm and supporting software (LOGIT) developed for the X1.4.1 Data in the form of X, Y pairs and saved in a file are

fit by the method of least-squares to the following equation:

fitting of depth profile interface data to the extended logistic

function in order to determine the parameters of this fitted

z

Y 5 A 1 A X 2 X / 1 1 e

@ ~ !# ~ !

s o

function. These parameters characterize the shape of the

2z

1 @B 1 B ~X 2 X !#/~1 1 e ! (X1.1)

s o

interface region and so define the interface width, its asymme-

where:

try, and its depth from the original surface.

Q~X2X !

o

z 5 ~X 2 X !/D,and D 52D /@1 1 e # (X1.2)

o o

X1.2 Significance and Use

X1.4.1.1 Because these equations are non-linear functions

X1.2.1 LOGIT has been developed to fit interface profile

of the three transition region parameters, X , D , and Q, the

o o

data to the extended logistic function. The specifically written

least-squaresfitrequiresaniterativesolution.Consequently, Y,

least-squares procedure used in LOGIT

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.