ASTM B488-01(2006)

(Specification)Standard Specification for Electrodeposited Coatings of Gold for Engineering Uses

Standard Specification for Electrodeposited Coatings of Gold for Engineering Uses

ABSTRACT

This specification establishes the requirements for electrodeposited gold coatings for engineering applications, employed specifically for their corrosion and tarnish resistance (including resistance to fretting corrosion and catalytic polymerization), bondability, low and stable contact resistance, solderability, and infrared reflectivity. This specification does not cover gold coatings produced from autocatalytic, immersion, and vapor deposition. Coatings shall be classified into types, which characterize minimum purity, and codes, which designate Knoop hardness. Coatings shall be sampled, tested and conform to specified requirements as to purity, hardness, appearance, thickness, mass per unit area, ductility, adhesion (assessed by either bend, heat, or cutting test), and integrity (including gross defects, mechanical damage, and porosity).

SCOPE

1.1 This specification covers requirements for electrodeposited gold coatings that contain not less than 99.00 mass % gold and that are used for engineering applications.

1.2 Specifically excluded from this specification are autocatalytic, immersion, and vapor deposited gold coatings.

1.3 Gold coatings conforming to this specification are employed for their corrosion and tarnish resistance (including resistance to fretting corrosion and catalytic polymerization), bondability, low and stable contact resistance, solderability, and infrared reflectivity. Several types of coatings, differing in gold purity and hardness, are covered by this specification.

1.4 The values stated in SI units are to be regarded as the standard. Values provided in parentheses are for information only.

The following hazards caveat pertains only to the test methods section, Section , of this specification:This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B488 – 01 (Reapproved 2006)

Standard Specification for

Electrodeposited Coatings of Gold for Engineering Uses

This standard is issued under the fixed designation B488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope B281 Practice for Preparation of Copper and Copper-Base

Alloys for Electroplating and Conversion Coatings

1.1 This specification covers requirements for electrodepos-

B322 Guide for Cleaning Metals Prior to Electroplating

ited gold coatings that contain not less than 99.00 mass % gold

B343 Practice for Preparation of Nickel for Electroplating

and that are used for engineering applications.

with Nickel

1.2 Specifically excluded from this specification are auto-

B374 Terminology Relating to Electroplating

catalytic, immersion, and vapor deposited gold coatings.

B481 Practice for Preparation of Titanium and Titanium

1.3 Gold coatings conforming to this specification are em-

Alloys for Electroplating

ployed for their corrosion and tarnish resistance (including

B482 Practice for Preparation of Tungsten and Tungsten

resistance to fretting corrosion and catalytic polymerization),

Alloys for Electroplating

bondability, low and stable contact resistance, solderability,

B487 Test Method for Measurement of Metal and Oxide

and infrared reflectivity. Several types of coatings, differing in

CoatingThicknessbyMicroscopicalExaminationofCross

gold purity and hardness, are covered by this specification.

Section

1.4 The values stated in SI units are to be regarded as the

B489 Practice for Bend Test for Ductility of Electrodepos-

standard. Values provided in parentheses are for information

ited and Autocatalytically Deposited Metal Coatings on

only.

Metals

1.5 The following hazards caveat pertains only to the test

B499 Test Method for Measurement of Coating Thick-

methods section, Section 9, of this specification: This standard

nessesbytheMagneticMethod:NonmagneticCoatingson

does not purport to address all of the safety concerns, if any,

Magnetic Basis Metals

associated with its use. It is the responsibility of the user of this

B504 Test Method for Measurement of Thickness of Me-

standard to establish appropriate safety and health practices

tallic Coatings by the Coulometric Method

and determine the applicability of regulatory limitations prior

B507 Practice for Design ofArticles to Be Electroplated on

to use.

Racks

2. Referenced Documents

B542 Terminology Relating to Electrical Contacts and

Their Use

2.1 ASTM Standards:

B558 Practice for Preparation of NickelAlloys for Electro-

B183 Practice for Preparation of Low-Carbon Steel for

plating

Electroplating

B567 Test Method for Measurement of Coating Thickness

B242 Guide for Preparation of High-Carbon Steel for Elec-

by the Beta Backscatter Method

troplating

B568 Test Method for Measurement of Coating Thickness

B253 Guide for Preparation of Aluminum Alloys for Elec-

by X-Ray Spectrometry

troplating

B571 Practice for Qualitative Adhesion Testing of Metallic

B254 Practice for Preparation of and Electroplating on

Coatings

Stainless Steel

B578 Test Method for Microhardness of Electroplated

Coatings

This specification is under the jurisdiction of ASTM Committee B08 on

B602 Test Method for Attribute Sampling of Metallic and

Metallic and Inorganic Coatings and is the direct responsibility of Subcommittee

Inorganic Coatings

B08.08.02 on Precious Metal Coatings.

B678 Test Method for Solderability of Metallic-Coated

Current edition approved April 1, 2006. Published April 2006. Originally

´1

approved in 1968. Last previous edition approved in 2001 as B488 – 01 . DOI:

Products

10.1520/B0488-01R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B488 – 01 (2006)

B697 Guide for Selection of Sampling Plans for Inspection 4.1.2 Code, designating Knoop hardness in accordance with

of Electrodeposited Metallic and Inorganic Coatings 4.2.3, and

B735 Test Method for Porosity in Gold Coatings on Metal 4.1.3 a numeral designating thickness in micrometres in

Substrates by Nitric Acid Vapor accordance with 4.3.

B741 Test Method for Porosity In Gold Coatings On Metal 4.2 Purity and Hardness:

Substrates By Paper Electrography 4.2.1 Purity—The issue of this standard establishes a new

B748 Test Method for Measurement of Thickness of Me- ASTM Type designation, which is identical to the original

tallic Coatings by Measurement of Cross Section with a standard (MILG-45204), established for electrodeposited gold

Scanning Electron Microscope and is outlined in the following table.

B762 Test Method of Variables Sampling of Metallic and

Mass Percent Gold, Minimum, New ASTM MIL-G45204 Old ASTM

Excluding Potassium, Carbon & Type Type Type

Inorganic Coatings

Nitrogen

B765 Guide for Selection of Porosity and Gross Defect

99.70 I I 2

Tests for Electrodeposits and Related Metallic Coatings

99.00 II II 3

99.90 III III 1

B799 Test Method for Porosity in Gold and Palladium

Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

NOTE 1—It is commonly accepted that a gold purity of 99.7 % is

B809 Test Method for Porosity in Metallic Coatings by defined as no more than 0.3 % of total codeposited metallic components,

excludingpotassiumandsodium.Likewise,99.9 %purityisrecognizedto

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

mean no more than 0.1 % of total codeposited metal impurities, excluding

D1125 Test Methods for Electrical Conductivity and Resis-

potassium and sodium. Almost all gold electrodeposits will contain

tivity of Water

potassium, carbon and nitrogen that are occluded or precipitated in the

D3951 Practice for Commercial Packaging

deposit.InthecaseofTypeIgold,theoccludedpotassiumhasbeenshown

,

6 7

F390 Test Method for Sheet Resistance of Thin Metallic

to improve durability and is desirable for that reason.

Films With a Collinear Four-Probe Array

4.2.2 Gold purity is calculated by subtraction of the sum of

2.2 U.S. Government Standards:

all non-gold metals in mass %, excluding potassium and

MIL-G-45204 Gold Plating, Electrodeposited

sodium, from 100 %. The presence of C, N, H, Na, and K

MIL-STD-1916 DOD Preferred Methods forAcceptance of

contained in the electrodeposit are not included in the calcu-

Product

lation.

2.3 ANSI/ASQC Standard:

4.2.3 Hardness—Hardness values shall be specified by

ANSI/ASQC Z1.4-1993 Sampling Procedures and Tables

ASTM code. The military standard designation of grade is

for Inspection by Attributes

included for reference.

Knoop Hardness Range ASTM Code MIL-G-45204

3. Terminology

90 HK maximum A A

91–129 HK BB

3.1 Definitions—For definitions of terms used in this speci-

90–200 HK (see Note 2) .

ficationrefertoTerminologiesB374orB542,B374,andB542.

130–200 HK CC

3.2 Definitions of Terms Specific to This Standard: >200 HK DD

3.2.1 significant surfaces—defined as those normally vis-

NOTE 2—ASTM Code B has previously been specified for hardness

ible (directly or by reflection) or essential to the serviceability

grade 90–200. This hardness grade has been eliminated and replaced with

or function of the article. Can be the source of corrosion

hardness grade 91–129 in accordance with MIL-G-45204.

products or tarnish films that interfere with the function or

4.2.4 Relationship Between Purity and Hardness—The fol-

desirable appearance of the article. The significant surfaces

lowing combinations of purity and hardness ranges are repre-

shall be indicated on the drawings of the parts or by the

sentative of good commercial practice:

provision of suitably marked samples.

New ASTM Old ASTM Type Code

3.2.2 underplating—a metallic coating layer between the

I 2 A, B and C

basis metal or substrate and the topmost metallic coating. The II 3 B, C and D

III 1 A only

thickness of an underplating is usually greater than 1 µm (40

µin.), in contrast to a strike or flash, which is thinner.

4.3 Thickness—Thickness shall be specified by an Arabic

numeral that designates the minimum linear thickness in

4. Classification

micrometres. Examples of commonly specified thicknesses are

shown in Table 1.

4.1 Types of Coatings—A coating shall be specified by a

4.3.1 See 7.4.2 for thickness tolerances.

combination of the following:

4.3.2 Insteadofspecifyingthethicknessinmicrometres,the

4.1.1 Type, characterizing minimum purity in accordance

purchaser may specify the mass of gold per unit area (coating

with 4.2.1,

weight) in milligrams per square centimeter. Unless otherwise

specified, the density of gold is assumed to be 19.3 g/cm for

Type III and 17.5 g/cm for Type I and Type II.

Withdrawn. The last approved version of this historical standard is referenced

on www.astm.org.

4 6

Available from Standardization Documents Order Desk, DODSSP, Bldg. 4, Whitlaw, K. J., Souter, J.W., Trans. Inst. Metal Fin., “The Role of Codeposited

Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098. Elements in Gold Plated Contacts,” 1984, 62(1), pp. 29–31.

5 7

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Whitlaw, K. J., Souter, J., Wright, I.S., Nottingham, M., Electrical Contacts,

th.

4th Floor, New York, NY 10036. “Wear Properties of High Speed Gold Electrodeposits,” (1984), 30 pp. 33–45.

B488 – 01 (2006)

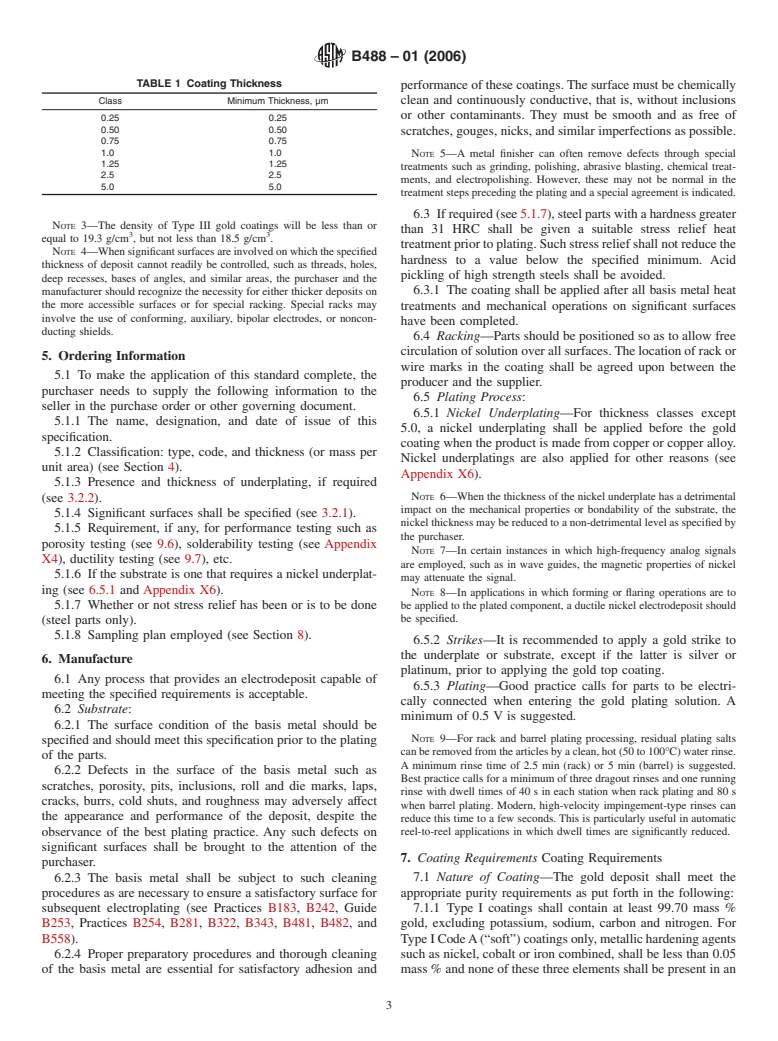

TABLE 1 Coating Thickness

performance of these coatings.The surface must be chemically

Class Minimum Thickness, µm clean and continuously conductive, that is, without inclusions

or other contaminants. They must be smooth and as free of

0.25 0.25

0.50 0.50

scratches, gouges, nicks, and similar imperfections as possible.

0.75 0.75

1.0 1.0 NOTE 5—A metal finisher can often remove defects through special

1.25 1.25

treatments such as grinding, polishing, abrasive blasting, chemical treat-

2.5 2.5

ments, and electropolishing. However, these may not be normal in the

5.0 5.0

treatment steps preceding the plating and a special agreement is indicated.

6.3 Ifrequired(see5.1.7),steelpartswithahardnessgreater

NOTE 3—The density of Type III gold coatings will be less than or

than 31 HRC shall be given a suitable stress relief heat

3 3

equal to 19.3 g/cm , but not less than 18.5 g/cm .

treatmentpriortoplating.Suchstressreliefshallnotreducethe

NOTE 4—Whensignificantsurfacesareinvolvedonwhichthespecified

hardness to a value below the specified minimum. Acid

thickness of deposit cannot readily be controlled, such as threads, holes,

pickling of high strength steels shall be avoided.

deep recesses, bases of angles, and similar areas, the purchaser and the

manufacturer should recognize the necessity for either thicker deposits on 6.3.1 The coating shall be applied after all basis metal heat

the more accessible surfaces or for special racking. Special racks may

treatments and mechanical operations on significant surfaces

involve the use of conforming, auxiliary, bipolar electrodes, or noncon-

have been completed.

ducting shields.

6.4 Racking—Parts should be positioned so as to allow free

circulation of solution over all surfaces.The location of rack or

5. Ordering Information

wire marks in the coating shall be agreed upon between the

5.1 To make the application of this standard complete, the

producer and the supplier.

purchaser needs to supply the following information to the

6.5 Plating Process:

seller in the purchase order or other governing document.

6.5.1 Nickel Underplating—For thickness classes except

5.1.1 The name, designation, and date of issue of this

5.0, a nickel underplating shall be applied before the gold

specification.

coating when the product is made from copper or copper alloy.

5.1.2 Classification: type, code, and thickness (or mass per

Nickel underplatings are also applied for other reasons (see

unit area) (see Section 4).

Appendix X6).

5.1.3 Presence and thickness of underplating, if required

NOTE 6—When the thickness of the nickel underplate has a detrimental

(see 3.2.2).

impact on the mechanical properties or bondability of the substrate, the

5.1.4 Significant surfaces shall be specified (see 3.2.1).

nickel thickness may be reduced to a non-detrimental level as specified by

5.1.5 Requirement, if any, for performance testing such as

the purchaser.

porosity testing (see 9.6), solderability testing (see Appendix

NOTE 7—In certain instances in which high-frequency analog signals

X4), ductility testing (see 9.7), etc.

are employed, such as in wave guides, the magnetic properties of nickel

5.1.6 If the substrate is one that requires a nickel underplat-

may attenuate the signal.

ing (see 6.5.1 and Appendix X6).

NOTE 8—In applications in which forming or flaring operations are to

5.1.7 Whether or not stress relief has been or is to be done be applied to the plated component, a ductile nickel electrodeposit should

be specified.

(steel parts only).

5.1.8 Sampling plan employed (see Section 8).

6.5.2 Strikes—It is recommended to apply a gold strike to

the underplate or substrate, except if the latter is silver or

6. Manufacture

platinum, prior to applying the gold top coating.

6.1 Any process that provides an electrodeposit capable of

6.5.3 Plating—Good practice calls for parts to be electri-

meeting the specified requirements is acceptable.

cally connected when entering the gold plating solution. A

6.2 Substrate:

minimum of 0.5 V is suggested.

6.2.1 The surface condition of the basis metal should be

NOTE 9—For rack and barrel plating processing, residual plating salts

specified and should meet this specification prior to the plating

canberemovedfromthearticlesbyaclean,hot(50to100°C)waterrinse.

of the parts.

A minimum rinse time of 2.5 min (rack) or 5 min (barrel) is suggested.

6.2.2 Defects in the surface of the basis metal such as

Best practice calls for a minimum of three dragout rinses and one running

scratches, porosity, pits, inclusions, roll and die marks, laps,

rinse with dwell times of 40 s in each station when rack plating and 80 s

cracks, burrs, cold shuts, and roughness may adversely affect

when barrel plating. Modern, high-velocity impingement-type rinses can

the appearance and performance of the deposit, despite the

reduce this time to a few seconds. This is particularly useful in automatic

observance of the best plating practice. Any such defects on reel-to-reel applications in which

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.