ASTM C1652/C1652M-06

(Test Method)Standard Test Method for Measuring Optical Distortion in Flat Glass Products Using Digital Photography of Grids

Standard Test Method for Measuring Optical Distortion in Flat Glass Products Using Digital Photography of Grids

SIGNIFICANCE AND USE

This test provides accurate data for evaluation of the optical properties of the glass being inspected.

The procedure described is useful for measuring the roll wave introduced during the tempering process of flat architectural glass. (1)

5.3 This test method is also useful for inspection of laminated and tempered automotive glass in transmitted light, in both flat and curved geometries.

SCOPE

1.1 This test method covers the determination of optical distortion of heat-strengthened and fully tempered architectural glass substrates which have been processed in a heat controlled continuous or oscillating conveyance oven. See Specifications C 1036 and C 1048 for discussion of the characteristics of glass so processed. In this test method the reflected image of processed glass is photographed and the photographic image analyzed to quantify the distortion due to surface waviness. The test method is also useful to quantify optical distortion observed in transmitted light in laminated glass assemblies.

1.2 The values stated in either SI units or inch-pound units are regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the standard.

1.3 There is no known ISO equivalent to this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1652/C1652M − 06

StandardTest Method for

Measuring Optical Distortion in Flat Glass Products Using

Digital Photography of Grids

This standard is issued under the fixed designation C1652/C1652M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Transmitted and reflected distortion in annealed, heat strengthened, and tempered glass can be

measured by several methods.(1,2,7,8,) Qualitative methods are based on the observation of

wavinessintheglassasviewedinofreflectedortransmittedimagesinasetofequidistantlines,called

Zebra Lines. Quantitative measuring techniques are based on several methods, some of which are:

1) Measuring local curvature using mechanical radius gages ((1, 6,9)

2) Moire Fringe analysis (3, 4)

3) Double exposure of transmitted grid images (Practice F733)

4) Projection of an array of round dots (5)

5) Dual laser beams (10)

The user should be familiar with techniques that are available so as to select the most suitable after

considering the precision, speed, and test specification requirements.The test method described in this

document uses a digital camera to capture a transmitted or reflected image of a set of equidistant lines.

Changes in the spacing of lines are used to quantifying the distortion.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of optical

responsibility of the user of this standard to establish appro-

distortionofheat-strengthenedandfullytemperedarchitectural

priate safety and health practices and determine the applica-

glass substrates which have been processed in a heat controlled

bility of regulatory limitations prior to use.

continuous or oscillating conveyance oven. See Specifications

C1036 and C1048 for discussion of the characteristics of glass

2. Referenced Documents

so processed. In this test method the reflected image of

2.1 ASTM Standards:

processed glass is photographed and the photographic image

C162 Terminology of Glass and Glass Products

analyzed to quantify the distortion due to surface waviness.

C1036 Specification for Flat Glass

The test method is also useful to quantify optical distortion

C1048 Specification for Heat-Strengthened and Fully Tem-

observed in transmitted light in laminated glass assemblies.

pered Flat Glass

1.2 The values stated in either SI units or inch-pound units

F733 Practice for Optical Distortion and Deviation ofTrans-

are regarded separately as standard. The values stated in each

parent Parts Using the Double-Exposure Method

system may not be exact equivalents; therefore, each system

shall be used independently of the other. Combining values

3. Terminology

from the two systems may result in nonconformance with the

3.1 See Terminology C162 Terminology of Glass and Glass

standard.

Products

1.3 There is no known ISO equivalent to this standard.

3.2 Definitions:

3.2.1 focal length, F—The focal length of a specular

reflector,duetothecurvatureatapointequalsR/2.(See3.2.3.)

This test method is under the jurisdiction of ASTM Committee C14 on Glass

and Glass Products and is the direct responsibility of Subcommittee C14.11 on

Optical Properties.

Current edition approved Oct. 1, 2006. Published November 2006. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/C1652_C1652M-06. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to a list of references at the end of Standards volume information, refer to the standard’s Document Summary page on

this standard. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1652/C1652M − 06

In

C1652/C1652M − 06

transmitted light, local thickness changes introduce a conver- makes it possible to quantify the lens power or optical

gence or divergence, equivalent to a lens with a focal length F. distortion of each element of the glass surface defined by the

grid.

3.2.2 optical power, D—The optical power due to the

curvature at a point is D = 1/F. The optical power is expressed

4.2 A uniformly spaced set of parallel lines, usually set at

in diopters, (Units 1/m), or as is typical, in millidiopters. The

45° angle to horizontal, may be used instead of a grid. If such

optical power is also used to quantify optical distortion, the

a set of lines is used, the mathematics of calculation will be

deformation of images reflected from flat glass, or transmitted

slightly altered from those expressed in Appendix X1.

by laminated or bent glass, or both.

5. Significance and Use

3.2.3 radius of curvature, R—The local radius of curvature

at a point on the surface, in meters. R and R are respectively

x y

5.1 This test provides accurate data for evaluation of the

measured in planes x (usually horizontal) and y (usually

optical properties of the glass being inspected.

vertical)

5.2 The procedure described is useful for measuring the roll

3.2.4 roll wave—A repetitive, wave-like departure from

wave introduced during the tempering process of flat architec-

flatness in otherwise flat glass that results from heat-treating

tural glass. (1)

the glass in a horizontal conveyance system. Roll wave

5.3 This test method is also useful for inspection of

excludes edge effects such as edge kink, and distortion induced

laminated and tempered automotive glass in transmitted light,

by assembly or installation.

in both flat and curved geometries.

4. Summary of Test Method

6. Apparatus

4.1 This test procedure was designed to provide an accurate

method of quantifying the optical distortion of glass as it is

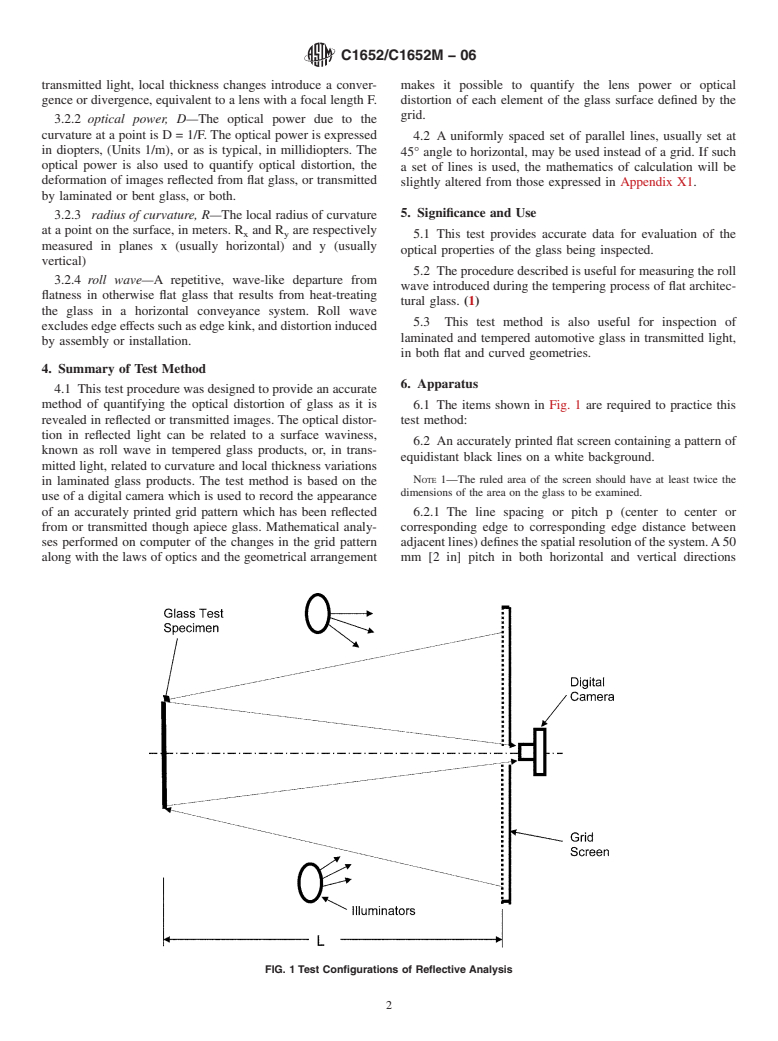

6.1 The items shown in Fig. 1 are required to practice this

revealed in reflected or transmitted images. The optical distor- test method:

tion in reflected light can be related to a surface waviness,

6.2 An accurately printed flat screen containing a pattern of

known as roll wave in tempered glass products, or, in trans-

equidistant black lines on a white background.

mitted light, related to curvature and local thickness variations

NOTE 1—The ruled area of the screen should have at least twice the

in laminated glass products. The test method is based on the

dimensions of the area on the glass to be examined.

use of a digital camera which is used to record the appearance

of an accurately printed grid pattern which has been reflected 6.2.1 The line spacing or pitch p (center to center or

from or transmitted though apiece glass. Mathematical analy- corresponding edge to corresponding edge distance between

ses performed on computer of the changes in the grid pattern adjacentlines)definesthespatialresolutionofthesystem.A50

along with the laws of optics and the geometrical arrangement mm [2 in] pitch in both horizontal and vertical directions

FIG. 1 Test Configurations of Reflective Analysis

C1652/C1652M − 06

provides satisfactory resolution for the examination of tem- 8. Calibration and Standardization

pered glass in reflection mode. A smaller pitch can be used

8.1 System calibration is a two-step procedure.

when examination of smaller deformations in laminated glass

8.2 Verification of System Zero

iscarriedoutusingthistestmethod.Thewidthoftheblackline

8.2.1 Set the camera at a distance 2L from the screen.

is typically 6 mm [ ⁄4 in]. The line-to-line distance must be

Capture the image of the screen without a glass panel in place

uniform, in both horizontal and vertical directions. The unifor-

and process the image through the analysis software. The

mity of the line-to-line spacing, p, is critical, because the

image analysis should indicate small values of D throughout

systeminterpretsanon-uniformspacingasopticaldistortion.A

the inspection area, typically less than 5 mdpt.

uniformity of the pitch of 0.2 mm [0.008 in] is satisfactory in

reflective measurements.

8.3 Verification of Calibration (Span Calibration)

8.3.1 This system calibration is determined by the screen

6.3 A digital camera equipped with an a planar lens and an

uniformity and distance, L, to the camera as shown in Fig. 1,

image pixel resolution compatible with the software require-

Fig. 2, and Fig. 3.

ments. These requirements are met by most commercially

8.3.2 Place a panel with known distortion in the test

available digital cameras.

position. Record the screen image and process it through the

6.4 Acomputer using an operating system compatible with

software. The calculated distortion should not differ from the

the software and any peripherals needed to satisfy the data

known value by more than 5 mdpt.

logging and reporting requirements.

8.3.3 The known value of distortion should be established

usingtraceable,curvaturemeasuringmethods.Duallaserbeam

6.5 A software program capable of performing the evalua-

and interferometry are suitable for this purpose.

tion of changes in line-spacing, p, and computation of the

optical distortion, D, throughout the inspected region.

9. Procedure

6.6 Lighting sufficient to provide photographic contrast.

9.1 Set up the grid screen:

6.6.1 Auniform illumination of the screen must be ensured.

9.1.1 Ruled screen board should be vertical, in an upright

In average lighting conditions, four Quartz-Halogen flood-

position.

lamps, 500 watt each, are satisfactory.

9.1.2 When used in reflective mode, the board should have

6.6.2 In a brightly illuminated area, two times higher

a hole, sufficient for viewing through with a digital camera, cut

illumination power is needed to assure good photographic

in its center.

contrast.

9.1.3 When the screen is wall-mounted, so that viewing

through a hole in its center is not possible, the camera can be

7. Sampling

mounted next to the screen or above it. In this configuration

7.1 The number of specimens and frequency of testing is to (see Fig. 2), a V-shaped line drawn from the center of the glass

be determined by the user. to the center of the screen (L ), and from the center of the glass

FIG. 2 Test Configuration for Off-Set Camera

C1652/C1652M − 06

FIG. 3 Test Configuration in Transmitted Light

to the center of the camera lens (L ) represents a geometric, 9.5.5 Add an identification number for the glass by printing

specular reflection. The screen must be perpendicular to the with a felt marker on an erasable board just above or below the

bisector of line L and L and the camera back must be sample

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.