ASTM D7153-05(2010)

(Test Method)Standard Test Method for Freezing Point of Aviation Fuels (Automatic Laser Method)

Standard Test Method for Freezing Point of Aviation Fuels (Automatic Laser Method)

SIGNIFICANCE AND USE

The freezing point of an aviation fuel is the lowest temperature at which the fuel remains free of solid hydrocarbon crystals which, if present in the fuel system of the aircraft, can restrict the flow of fuel through filters. The temperature of the fuel in the aircraft tank normally decreases during flight depending on aircraft speed, altitude, and flight duration. The freezing point of the fuel shall always be lower than the minimum operational fuel temperature.

Petroleum blending operations require precise measurement of the freezing point.

This test method expresses results to the nearest 0.1°C, and it eliminates most of the operator time and judgment required by Test Method D2386.

When a specification requires Test Method D2386, do not substitute this test method or any other test method.

SCOPE

1.1 This test method covers the determination of the temperature below which solid hydrocarbon crystals may form in aviation turbine fuels.

1.2 This test method is designed to cover the temperature range of -80 to 20°C; however, the interlaboratory study mentioned in 12.4 has only demonstrated the test method with fuels having freezing points in the range of -60 to -42°C.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7153 − 05(Reapproved 2010)

IP 529

Standard Test Method for

Freezing Point of Aviation Fuels (Automatic Laser Method)

This standard is issued under the fixed designation D7153; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 freezing point, n—in aviation fuels, the fuel tempera-

ture at which solid hydrocarbon crystals, formed on cooling,

1.1 This test method covers the determination of the tem-

disappear when the temperature of the fuel is allowed to rise

perature below which solid hydrocarbon crystals may form in

under specified conditions of test.

aviation turbine fuels.

3.2 Definitions of Terms Specific to This Standard:

1.2 This test method is designed to cover the temperature

range of -80 to 20°C; however, the interlaboratory study

3.2.1 automatic laser method, n—the procedures of auto-

mentioned in 12.4 has only demonstrated the test method with

matically cooling a liquid aviation fuel specimen until solid

fuels having freezing points in the range of -60 to -42°C.

hydrocarbon crystals appear, followed by controlled warming

and recording of temperature at which hydrocarbon crystals

1.3 The values stated in SI units are to be regarded as

completely redissolve into the liquid phase.

standard. No other units of measurement are included in this

standard.

3.3 Symbols:

1.4 This standard does not purport to address all of the

Cd = the specimen temperature at which the appearance of

safety concerns, if any, associated with its use. It is the

the first crystals are detected in the specimen by an

responsibility of the user of this standard to establish appro-

optical crystal detector under specified conditions of

priate safety and health practices and to determine the

test.

applicability of regulatory limitations prior to use.

Co = the specimen temperature at which the appearance of

opacity in the specimen is detected by an optical

2. Referenced Documents

opacity detector under specified conditions of test.

2.1 ASTM Standards:

Do = the specimen temperature at which the disappearance

D2386 Test Method for Freezing Point of Aviation Fuels

of opacity in the specimen is detected by an optical

D4057 Practice for Manual Sampling of Petroleum and

opacity detector under specified conditions of test.

Petroleum Products

D4177 Practice for Automatic Sampling of Petroleum and

4. Summary of Test Method

Petroleum Products

4.1 A specimen is cooled at a rate of 10 6 5°C/min while

2.2 Energy Institute Standard:

continuously being illuminated by a laser light source. The

IP 16 Determination Freezing Point of Aviation Fuels

specimen is continuously monitored by optical crystal and

3. Terminology opacity detectors for the first formation of solid hydrocarbon

crystals. Once the hydrocarbon crystals are detected by both

3.1 Definitions:

sets of optical detectors, the specimen is then warmed at a rate

of 3 6 0.5°C/min. When initial opacity in the specimen

1 disappears, the specimen is then warmed at a rate of 12 6

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

l°C/min. The specimen temperature at which the last hydro-

D02.07 on Flow Properties.

carbon crystals return to the liquid phase, as detected by the

Current edition approved May 1, 2010. Published May 2010. Originally

crystal detector, is recorded as the freezing point.

approved in 2005. Last previous edition approved in 2005 as D7152–05. DOI:

10.1520/D7153-05R10.

2 4.2 In certain circumstances, as measured by the apparatus,

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

the specimen is reheated to approximately 10°C, then cooled at

Standards volume information, refer to the standard’s Document Summary page on

the rate in 4.1 until hydrocarbon crystals are detected by the

the ASTM website.

3 crystaldetector.Thespecimenisthenwarmedatarateof12 6

Annual Book of IP Standards Methods, Vol 1.Available from Energy Institute,

61 New Cavendish St., London, WIG 7AR, U.K. l°C/min, until the last hydrocarbon crystals return to the liquid

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D7153 − 05 (2010)

phase. The specimen temperature at which the last hydrocar- 6.6 Waste Receiving Container, capable of collecting the

bon crystals return to the liquid phase, as detected by the overflow when the specimen is injected into the test cell. A

crystal detector, is recorded as the freezing point. 400-mL standard glass beaker has been found suitable.

7. Sampling

5. Significance and Use

7.1 Obtain a sample in accordance with Practice D4057 or

5.1 The freezing point of an aviation fuel is the lowest

D4177.

temperature at which the fuel remains free of solid hydrocar-

bon crystals which, if present in the fuel system of the aircraft,

7.2 At least 30 mL of sample is required for each test.

can restrict the flow of fuel through filters. The temperature of

the fuel in the aircraft tank normally decreases during flight

8. Preparation of Apparatus

depending on aircraft speed, altitude, and flight duration. The

8.1 Install the apparatus for operation in accordance with

freezing point of the fuel shall always be lower than the

the manufacturer’s instructions.

minimum operational fuel temperature.

8.2 Turn on the main power switch of the analyzer.

5.2 Petroleum blending operations require precise measure-

ment of the freezing point.

9. Calibration and Standardization

5.3 This test method expresses results to the nearest 0.1°C,

9.1 Ensure that all of the manufacturer’s instructions for

and it eliminates most of the operator time and judgment

calibration of the mechanical and electronic systems and

required by Test Method D2386.

operation of the apparatus are followed.

5.4 When a specification requires Test Method D2386,do

9.2 To verify the performance of the apparatus, an aviation

not substitute this test method or any other test method.

turbine fuel sample for which extensive data has been obtained

by Test Method D2386 may be used. Samples such as those

6. Apparatus

used in theASTM interlaboratory cross–check program would

6.1 Automatic Apparatus —This apparatus consists of a

meet this criterion. Such verification materials can also be

microprocessor-controlled test cell that is capable of cooling prepared from intra-company cross–checks.

and heating the specimen, dual optical detectors to monitor the

10. Procedure

appearance and disappearance of crystals and opacity, and

recording the temperature of the specimen.Adetailed descrip-

10.1 Draw 10 6 2 mL bubble-free portion of sample into a

tion of the apparatus is provided in Annex A1.

syringe.Connectthesyringetotheinletport(Fig.1).Rinsethe

test cell by injecting 10 6 2 mL of specimen into the test cell;

6.2 The apparatus shall be equipped with a specimen

chamber, optical detectors, laser light source, digital display, the specimen excess will flow into the waste receiving con-

tainer (Fig. 2)

cooling and heating systems, and a specimen temperature

measuring device.

10.2 Rinse the test cell a second time by repeating 10.1.

6.3 The temperature measuring device in the specimen

chamber shall be capable of measuring the temperature of the

specimen from -80 to +20°C at a resolution of 0.1°C and

accuracy of 0.1°C.

6.4 The apparatus shall be capable of cooling the specimen

at a rate of 10 6 5°C/min, heating the specimen at rates of 3 6

0.5°C/minand12 61°C/minoverthetemperaturerangeof-80

to +20°C.

NOTE 1—The apparatus described is covered by a patent. If you are

aware of an alternative(s) to the patented item, please attach to your ballot

return a description of the alternatives.All suggestions will be considered

by the committee.

NOTE 2—The software version used in this apparatus is version V 5.3.

6.5 Standard Syringe,capableofinjectingapproximately10

6 2 mL of the specimen, with a tip or an adapter tip that will

fit the inlet of the test cell. A disposable 10-mL syringe with a

Luer type cone connection has been found suitable.

The sole source of supply of the apparatus known to the committee at this time

is ISL model FZP 5G2s series Freezing Point Analyzer, available from PAC - ISL,

BP 70285 - VERSON, 14653 CARPIQUET Cedex, France. If you are aware of

alternative suppliers, please provide this information to ASTM International

Headquarters.Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. FIG. 1 Syringe Inserted in Inlet Port

D7153 − 05 (2010)

10.4 Connect the syringe to the inlet port (Fig. 1). Dispense

the specimen into the test cell; the specimen excess will flow

into the waste receiving container (Fig. 2). Leave the syringe

connected to the sample inlet for the entire duration of the test.

10.5 Start the operation of the apparatus according the

manufacturer’s instructions. From this point through Section

11, the apparatus automatically controls the procedure.

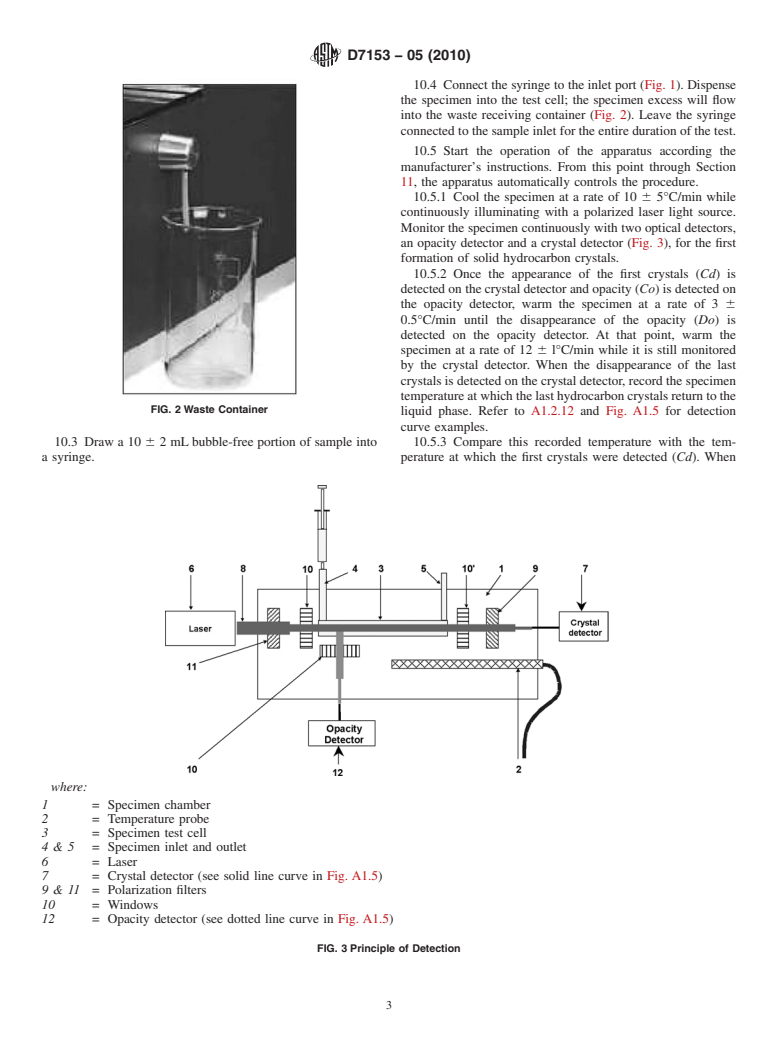

10.5.1 Cool the specimen at a rate of 10 6 5°C/min while

continuously illuminating with a polarized laser light source.

Monitor the specimen continuously with two optical detectors,

an opacity detector and a crystal detector (Fig. 3), for the first

formation of solid hydrocarbon crystals.

10.5.2 Once the appearance of the first crystals (Cd)is

detected on the crystal detector and opacity (Co) is detected on

the opacity detector, warm the specimen at a rate of 3 6

0.5°C/min until the disappearance of the opacity (Do)is

detected on the opacity detector. At that point, warm the

specimen at a rate of 12 6 l°C/min while it is still monitored

by the crystal detector. When the disappearance of the last

crystals is detected on the crystal detector, record the specimen

temperatureatwhichthelasthydrocarboncrystalsreturntothe

FIG. 2 Waste Container

liquid phase. Refer to A1.2.12 and Fig. A1.5 for detection

curve examples.

10.5.3 Compare this recorded temperature with the tem-

10.3 Draw a 10 6 2 mL bubble-free portion of sample into

a syringe. perature at which the first crystals were detected (Cd). When

where:

1 = Specimen chamber

2 = Temperature probe

3 = Specimen test cell

4&5 = Specimen inlet and outlet

6 = Laser

7 = Crystal detector (see solid line curve in Fig. A1.5)

9&11 = Polarization filters

10 = Windows

12 = Opacity detector (see dotted line curve in Fig. A1.5)

FIG. 3 Principle of Detection

D7153 − 05 (2010)

the recorded temperature is warmer than the (Cd) temperature, 12.1.1 Repeatability—The difference between two test re-

it is recorded as the freezing point. sults obtained by the same operator with the same apparatus

under constant operating conditions on identical test material

NOTE 3—In most cases, 10.5.3 is considered the termination of the test.

would, in the long run, in the normal and correct operation of

(See 10.5.4.)

this test method, exceed 0.6°C only in one case in twenty.

10.5.4 In certain circumstances, as measured by the

12.1.2 Reproducibility—The difference between two single

apparatus, perform a second test cycle as follows in 10.6.

and independent results obtained by different operators work-

NOTE4—Thiscircumstancemayindicatethepresenceofcontamination

ing in different laboratories on identical test material would, in

of the specimen with material other than aviation fuel and the stated

the long run, in the normal and correct operation of this test

precisions may not apply.

method, exceed 0.9°C only in one case in twenty.

10.6 Second Test Cycle:

10.6.1 The original specimen is warmed up to approxi-

12.2 Bias—Because there are no liquid hydrocarbon mix-

mately 10°C and then cooled at a rate of 10 6 5°C/min while

tures of known freezing point, which simulate aviation fuels,

continuously being illuminated by a polarized laser light

bias cannot be established.

source. Monitor the specimen continuously with the optical

12.3 Relative Bias—The results for all the samples from the

crystal detector (Fig. 3) for the first formation of solid

interlaboratory program were examined for biases relative to

hydrocarbon crystals.

Test Method D2386 and IP 16. A systemic bias was observed

10.6.2 Once the appearance of the first crystals (Cd) are

and is quantified with the following equation:

detected on the crystal detector, continue to cool the specimen

an additional 5°C and then discontinue the cooling.

D2386 and IP 16 5 X 2 0.347 (1)

10.6.3 Warm the specimen a rate of 12 6 l°C/min while it

where:

is still monitored by the crystal detector. When the disappear-

D2386 and IP 16 = mean of the result tested by D2386 and

ance of the last crystals is detected on the crystal detector,

IP 16.

record the specimen temperature at which the last hydrocarbon

X = mean of the result tested by this test

crystals return to the liquid phase as the freezing point.

method (D7153).

NOTE 5—When condition described in 10.5.4 is encountered, this

12.3.1 As example: For a D2386 and IP 16 result of -60°C,

indicates that the sample may be contaminated. In that case, in order to

minimize the test duration, only the 12 6 1°C warming rate is used. the result from this test method is -59.65°C , or 0.347°C

warmer than the D2386 and IP 16 result.

10.7 Once the freezing point is recorded, the test cell is

warmed up to ambient temperature.Fig. A1.5 gives two ex- 12.3.2 However, the relative bias is within the reproducibil-

amples of the testing process: one with a neat jet fuel, and one

ity of both test methods.

with a contaminated jet fuel.

12.3.3 The cross method reproducibility (Rxy), identified in

the research report, between this test method andTest Method

10.8 The freezing point value will be automatically rounded

to the nearest 0.1°C and displayed by the apparatus. D2386 is 1.9. (See research report for further information on

relative bias and the methods used to derive them.)

10.9 Disconnect the injection syringe from the sample inlet.

The cleaning of the test cell will be carried out during the

12.4 The precision statements were derived from a 2003

performance of the next test.

interlaboratory cooperative test program. Participants ana-

lyzed 13 samples sets comprised of various aviation fuels over

11. Report

the temperature range of -42 to -60°C. Thirteen laboratories

11.1 Report the temperature recorded in 10.8 as the freezing

participated with the automatic laser method and fifteen with

point,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.