ASTM D3619-77(1996)e1

(Specification)Standard Specification for Aluminum Silicate Pigments (Anhydrous) (Withdrawn 2004)

Standard Specification for Aluminum Silicate Pigments (Anhydrous) (Withdrawn 2004)

SCOPE

1.1 This specification covers the white pigments that consist substantially of anhydrous (calcined) natural aluminum silicates (of the 1+1 layer type) and are restricted to those minerals which conform to the chemical compositional limits prescribed herein and which can be suitably processed to what is known as paint pigment quality.

WITHDRAWN RATIONALE

This specification covers the white pigments that consist substantially of anhydrous (calcined) natural aluminum silicates (of the 1+1 layer type) and are restricted to those minerals which conform to the chemical compositional limits prescribed herein and which can be suitably processed to what is known as paint pigment quality.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this specification was withdrawn in June 2004. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

An American National Standard

´1

Designation: D 3619 – 77 (Reapproved 1996)

Standard Specification for

Aluminum Silicate Pigments (Anhydrous)

This standard is issued under the fixed designation D 3619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Keywords were added editorially in May 1996.

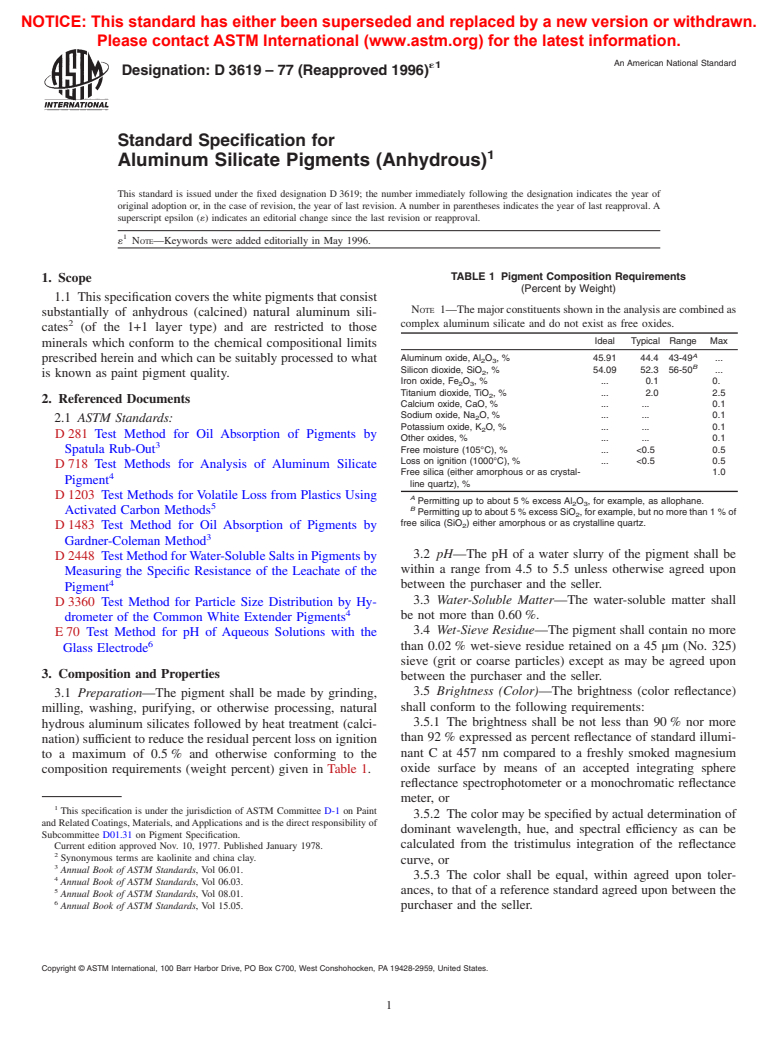

TABLE 1 Pigment Composition Requirements

1. Scope

(Percent by Weight)

1.1 This specification covers the white pigments that consist

NOTE 1—The major constituents shown in the analysis are combined as

substantially of anhydrous (calcined) natural aluminum sili-

2 complex aluminum silicate and do not exist as free oxides.

cates (of the 1+1 layer type) and are restricted to those

Ideal Typical Range Max

minerals which conform to the chemical compositional limits

A

prescribed herein and which can be suitably processed to what Aluminum oxide, Al O , % 45.91 44.4 43-49 .

2 3

B

Silicon dioxide, SiO , % 54.09 52.3 56-50 .

is known as paint pigment quality.

Iron oxide, Fe O , % . 0.1 0.

2 3

Titanium dioxide, TiO , % . 2.0 2.5

2. Referenced Documents

Calcium oxide, CaO, % . . 0.1

Sodium oxide, Na O, % . . 0.1

2.1 ASTM Standards:

Potassium oxide, K O, % . . 0.1

D 281 Test Method for Oil Absorption of Pigments by

Other oxides, % . . 0.1

Free moisture (105°C), % . <0.5 0.5

Spatula Rub-Out

Loss on ignition (1000°C), % . <0.5 0.5

D 718 Test Methods for Analysis of Aluminum Silicate

Free silica (either amorphous or as crystal- 1.0

Pigment

line quartz), %

D 1203 Test Methods for Volatile Loss from Plastics Using

A

Permitting up to about 5 % excess Al O , for example, as allophane.

2 3

B

Activated Carbon Methods Permittinguptoabout5 %excessSiO ,forexample,butnomorethan1 %of

free silica (SiO ) either amorphous or as crystalline quartz.

D 1483 Test Method for Oil Absorption of Pigments by

Gardner-Coleman Method

3.2 pH—The pH of a water slurry of the pigment shall be

D 2448 TestMethodforWater-SolubleSaltsinPigmentsby

within a range from 4.5 to 5.5 unless otherwise agreed upon

Measuring the Specific Resistance of the Leachate of the

between the purchaser and the seller.

Pigment

3.3 Water-Soluble Matter—The water-soluble matter shall

D 3360 Test Method for Particle Size Distribution by Hy-

be not more than 0.60 %.

drometer of the Common White Extender Pigments

3.4 Wet-Sieve Residue—The pigment shall contain no more

E70 Test Method for pH of Aqueous Solutions with the

than 0.02 % wet-sieve residue retained on a 45 µm (No. 325)

Glass Electrode

sieve (grit or coarse particles) except as may be agreed upon

3. Composition and Properties

between the purchaser and the seller.

3.5 Brightness (Color)—The brightness (color reflectance)

3.1 Preparation—The pigment shall be made by grinding,

shall conform to the following requirements:

milling, washing, purifying, or otherwise processing, natural

3.5.1 The brightness shall be not less than 90 % nor more

hydrous aluminum silicates followed by heat treatment (calci-

than 92 % expressed as percent reflectance of standard illumi-

nation) sufficient to reduce the residual percent loss on ignition

nant C at 457 nm compared to a freshly smoked magnesium

to a maximum of 0.5 % and otherwise conforming to the

oxide surface by means of an accepted integrating sphere

composition requirements (weight percent) given in Table 1.

reflectance spectrophotometer or a monochromatic reflectance

meter, or

This specification is under the jurisdiction of ASTM Committee D-1 on Paint

3.5.2 The color may be specified by actual determination of

and Related Coatings, Materials, andApplications and is the direct responsibility of

dominant wavelength, hue, and spectral efficiency as can be

Subcommittee D01.31 on Pigment Specification.

calculated from the tristimulus integration of the reflectance

Current edition approved Nov. 10, 1977. Published January 1978.

Synonymous terms are kaolinite and china clay.

curve, or

Annual Book of ASTM Standards, Vol 06.01.

3.5.3 The color shall be equal, within agreed upon toler-

Annual Book of ASTM Standards, Vol 06.03.

ances, to that of a reference standard agreed upon between the

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 15.05. p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.