ASTM D5006-96(2001)

(Test Method)Standard Test Method for Measurement of Fuel System Icing Inhibitors (Ether Type) in Aviation Fuels

Standard Test Method for Measurement of Fuel System Icing Inhibitors (Ether Type) in Aviation Fuels

SCOPE

1.1 This test method describes a technique for measuring the concentration of Ethylene Glycol Monomethyl Ether (EGME) and Diethylene Glycol Monomethyl Ether (DiEGME) in aviation fuels. The HB and Brix scale refractometers are specified to determine the concentration of these fuel system icing inhibitors (FSII) by measuring the refractive index of a water extract. Precision estimates have been determined for the EGME and DiEGME additives using specific extraction ratios with a wide variety of fuel types. The extraction ratios are high enough that portable hand-held refractometers can be used, but not so high as to sacrifice accuracy or linearity, or both, in the 0.01 to 0.25 vol % range of interest.

1.2 This test method does not identify which FSII additive is present. The analyst must know which additive is to be measured prior to performing the test. Consult the appropriate fuel specification to determine which additive is to be measured.

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 4.1, 8.2, 9.2.1.1, 9.3.1.1, 9.3.2, and 9.3.10

General Information

Relations

Standards Content (Sample)

An American National Standard

Designation: D 5006 – 96 (Reapproved 2001)

Standard Test Method for

Measurement of Fuel System Icing Inhibitors (Ether Type) in

Aviation Fuels

This standard is issued under the fixed designation D 5006; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1 Brix scale—a refractometer with a refractive index

scale calibrated to weight percent cane sugar (sucrose).

1.1 This test method describes a technique for measuring

3.1.2 HB—a refractometer that can be used in a temperature

the concentration of Ethylene Glycol Monomethyl Ether

range from 18 to 35°C without incorporating a temperature

(EGME) and Diethylene Glycol Monomethyl Ether (DiEGME)

correction factor.

in aviation fuels. The HB and Brix scale refractometers are

specified to determine the concentration of these fuel system

4. Summary of Test Method

icing inhibitors (FSII) by measuring the refractive index of a

4.1 In order to determine the concentration of fuel system

water extract. Precision estimates have been determined for the

icing inhibitor in aviation fuel, a measured volume of fuel is

EGME and DiEGME additives using specific extraction ratios

extracted with a fixed ratio of water. The extraction procedure

with a wide variety of fuel types. The extraction ratios are high

includes sufficient agitation and contacting time to ensure that

enough that portable hand-held refractometers can be used, but

equilibrium distributions are attained. With the HB refracto-

not so high as to sacrifice accuracy or linearity, or both, in the

meter, several drops of the water extract are placed on the

0.01 to 0.25 vol % range of interest.

prism face and the volume percent FSII is read directly from a

1.2 This test method does not identify which FSII additive is

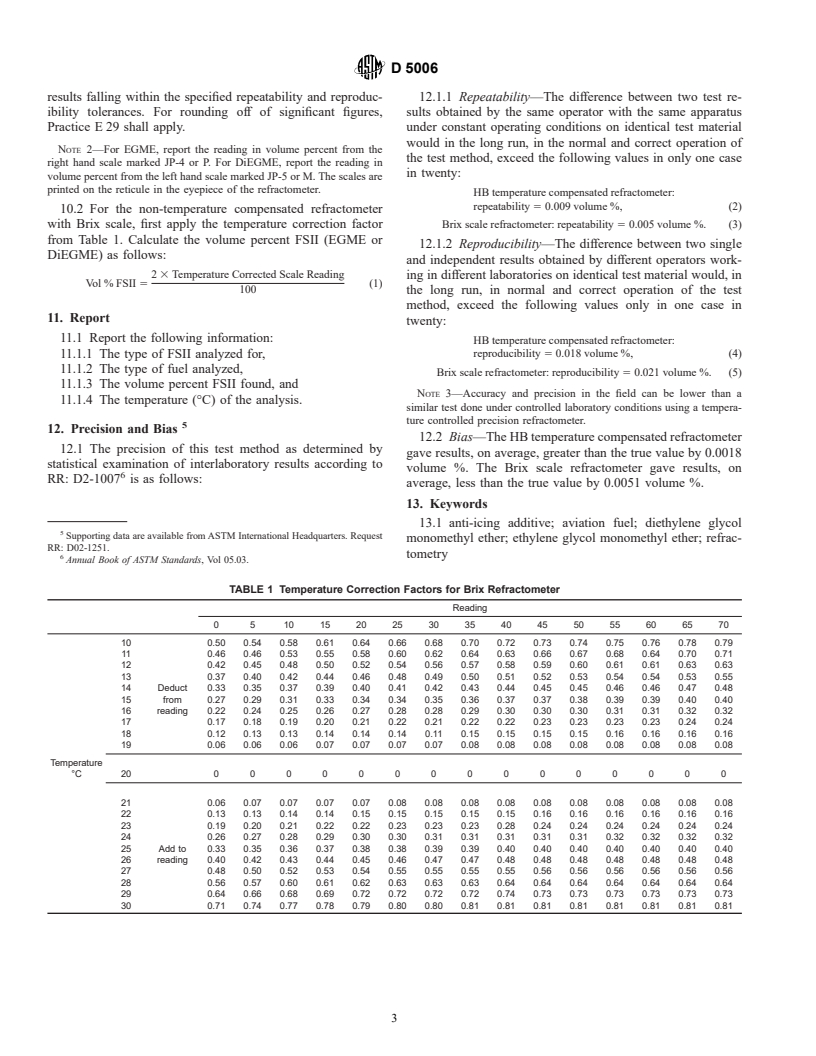

custom graduated scale printed on the reticule. If the Brix

present. The analyst must know which additive is to be

refractometer is used, a temperature correction factor is first

measured prior to performing the test. Consult the appropriate

applied to the reading, multiplied by 2 and divided by 100 to

fuel specification to determine which additive is to be mea-

calculate volume percent FSII. (Warning—Ethylene glycol

sured.

monomethyl ether, (EGME). Combustible, toxic material. )

1.3 The values stated in SI units are to be regarded as the

(Warning—In addition to other precautions, EGME has been

standard.

shown to be a teratogen in animals. Avoid inhalation. Do not

1.4 This standard does not purport to address all of the

get in eyes, on skin, or on clothing. Wash thoroughly after

safety concerns, if any, associated with its use. It is the

handling.) (Warning—Diethylene glycol monomethyl ether

responsibility of the user of this standard to establish appro-

(Di-EGME), Slightly toxic material. This material caused

priate safety and health practices and determine the applica-

slight embryo-fetal toxicity (delayed development) but no

bility of regulatory limitations prior to use. For specific hazard

increase in birth defects in laboratory animals. Consult the

statements, see 4.1, 8.2, 9.2.1.1, 9.3.1.1, 9.3.2, and 9.3.10.

suppliers’ material safety data sheet.)

2. Referenced Documents

NOTE 1—This test method is semi-quantitative if mixtures of the

2.1 ASTM Standards:

ether-type additives are used. Methanol is not detected because of the

similarity of water/methanol refractive indices, and the presence of

E 1 Specification for ASTM Thermometers

methanol in fuel containing other additives results in lower than true

E 29 Practice for Using Significant Digits in Test Data to

3 measurements.

Determine Conformance with Specifications

5. Significance and Use

3. Terminology

5.1 Fuel system icing inhibitors are miscible with water and

3.1 Definitions of Terms Specific to This Standard:

can be readily extracted from the fuel by contact with water

during shipping and in storage. Methods are therefore needed

This test method is under the jurisdiction of ASTM Committee D02 on

to check the additive content in the fuel to ensure proper

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

D02.J0.09 on Additive-Related Properties.

Current edition approved Dec. 10, 1996. Published February 1997. Originally

published as D 5006 – 89. Last previous edition D 5006 – 90 (1995). For more detailed information on ethylene glycol monomethyl ether, refer to

Annual Book of ASTM Standards, Vol 14.03. the Federal Register, Vol 51, No. 97, dated Tuesday, May 20, 1986. Consult the

Annual Book of ASTM Standards, Vol 14.02. supplier’s material safety data sheet.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 5006

additive concentration in the aircraft. 9.3 Procedure for the Determination of Fuel System Icing

5.2 This test method is applicable to analyses performed in Inhibitor:

the field or in a laboratory. 9.3.1 Shake the extraction vessel vigorously for a minimum

of 5 min for all fuels.

6. Apparatus

9.3.1.1 Mechanical shakers may be used provided thorough

6.1 Refractometer—The HB temperature compensated, di- intermixing of the aqueous and fuel phases occurs, similar to

rect reading refractometer and the 0 to 30 or 0 to 16 Brix have

that obtained by hand shaking. (Warning—Following the

been found satisfactory for use. extraction procedures is most critical. Failure to extract for the

6.2 Extraction Vessel—Any suitable vessel of at least 200

specified time or failure to provide vigorous agitation can result

mL with provisions for isolating a small column of water in false readings. If lower than expected readings are obtained,

extract. Examples are separatory funnels, (glass or plastic), or

a second test should be done with a longer extraction time.)

plastic dropping bottles. 9.3.2 Allow the extraction vessel to sit undisturbed at

6.3 Measuring Vessel—Any vessel capable of measuring up

ambient temperature for a period of at least 2 min to allow the

to 160 mL of fuel to an accuracy of 62 mL, such as a 250-mL water to settle to the bottom. (Warning—Fuel entrained in the

graduated cylinder, or other calibrated container.

water causes an indistinct refractometer reading. In most cases

6.4 Water Dispenser—2.0-mL pipettes are preferred, but fuel residue can be eliminated by SLOWLY lowering the

syringes or burettes not exceeding 5.0-mL capacity that can

refractometer cover. The surface tension of water will sweep

dispense 2.0 6 0.2 mL may be used. fuel off the prism surface.)

6.5 Thermometer—The thermometer must have suitable

9.3.3 Open the cover of the refractometer prism and wipe it

range to measure air and fuel temperature in the field. Accurate

clean with a tissue. Place several drops of the water used for

to 61°C and meeting Specification E 1. the extraction on the prism face.

9.3.4 Close the cover and view the scale through the

7. Reagents and Materials.

eyepiece. Adjust the focus if necessary to bring the numbered

7.1 Water—Distilled or deionized water is preferred for the

scale into focus. Observe the position of the shadow line on the

extraction procedure, but potable water may be used.

numbered scale.

9.3.5 Rotate the zero adjustment knob or set screw so that

8. Calibration

the shadow line intersects at 0.0 on the HB or Brix scale

8.1 Calibration of the HB or Brix scale refractometer

refractometer.

consists of setting the reading obtained with water at ambient

9.3.6 Open the prism cover and wipe the surface clean with

temperature to 0.0 with the zero adjustment.

a tissue.

8.2 The calibration step is incorporated into the procedure to

9.3.7 Isolate several drops of the water extract from the

minimize the effect of temperature changes between the time of

extraction vessel and place on the prism face.

calibration and measurement. (Warning—The extraction, cali-

9.3.7.1 If a separatory funnel is used, it may be necessary to

bration, and measurement steps should be done at ambient

collect some extract into a smal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.