ASTM F2855-12

(Specification)Standard Specification for Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure Tubing

Standard Specification for Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure Tubing

ABSTRACT

This specification covers a Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), (CPVC AL CPVC), composite pressure tubing with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer CPVC layers are bonded to the aluminum tube by a melt adhesive. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems. This specification covers only composite tubing incorporating a continuously welded aluminum tube.

SCOPE

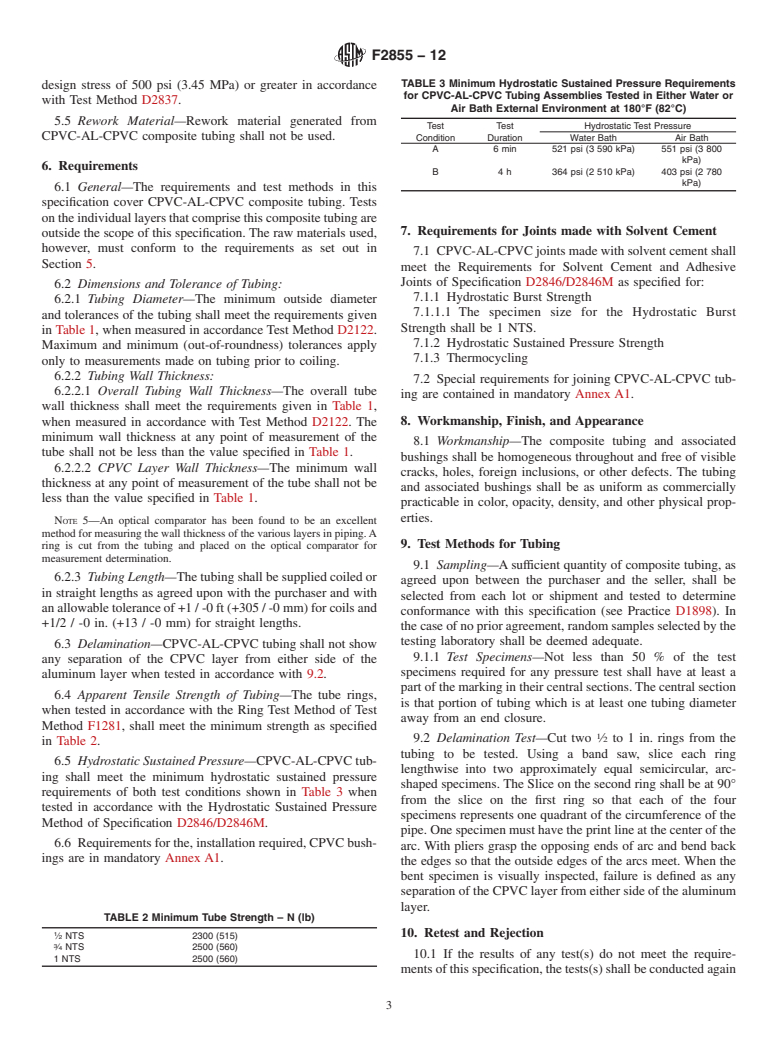

1.1 This specification covers a Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), (CPVC AL CPVC), composite pressure tubing with a welded aluminum tube reinforcement between the inner and outer layers. The inner and outer CPVC layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the composite tubing, the requirements and test methods for materials, the dimensions of the component layers and finished tubing, adhesion tests, hydrostatic burst and sustained pressure and thermocycling performance. Also given are the requirements and methods of marking. The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water distribution systems.

Note 1—The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.2 This specification covers only composite tubing incorporating a continuously welded aluminum tube. Tubing consisting of metallic layers not continuously welded together are outside the scope of this specification.

1.3 Specifications for internal bushings for use with composite tubing meeting the requirements of this specification are given in Annex A1.

Note 2—In order to assure the expected life expectancy of CPVC-AL-CPVC composite tubing by preventing corrosion of the Aluminum, a bushing meeting the requirements of Annex A1 is required to be solvent cemented into the cut ends of the CPVC-AL-CPVC tubing prior to making solvent cement joints in the piping. This bushing seals off the cut ends of the tubing preventing any contact of the AL layer with any liquids being transported by the tubing.

1.4 Tubing meeting the requirements of this standard are designed to be used with fittings and solvent cements meeting the requirements of Specification D2846/D2846M when assembled in accordance with Appendix X3.

1.5 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are chemically compatible with the tubing materials. Due to inherent hazards associated with testing components and systems with compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with specific product manufacturers for their specific testing procedures prior to pneumatic testing.

Note 3—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should a system fail for any reason.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

Note 4—Suggested hydrostatic design pressures and pressure ratings for tubing are listed in Appendix X1.

1.7 The following safety hazards caveat pertains only to the test method portion, Section 9. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2855 −12 An American National Standard

Standard Specification for

Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated

Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure

1

Tubing

This standard is issued under the fixed designation F2855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* the requirements of Specification D2846/D2846M when as-

sembled in accordance with Appendix X3.

1.1 This specification covers a Chlorinated Poly(Vinyl

Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), 1.5 The products covered by this specification are intended

(CPVC AL CPVC), composite pressure tubing with a welded for use with the distribution of pressurized liquids only, which

aluminum tube reinforcement between the inner and outer are chemically compatible with the tubing materials. Due to

layers. The inner and outer CPVC layers are bonded to the inherent hazards associated with testing components and sys-

aluminum tube by a melt adhesive. Included is a system of tems with compressed air or other compressed gases some

nomenclature for the composite tubing, the requirements and manufacturersdonotallowpneumatictestingoftheirproducts.

test methods for materials, the dimensions of the component Consult with specific product manufacturers for their specific

layersandfinishedtubing,adhesiontests,hydrostaticburstand testing procedures prior to pneumatic testing.

sustained pressure and thermocycling performance.Also given

NOTE 3—Pressurized (compressed) air or other compressed gases

aretherequirementsandmethodsofmarking.Thecomponents

contain large amounts of stored energy which present serious safety

covered by this specification are intended for use in residential

hazards should a system fail for any reason.

and commercial, hot and cold, potable water distribution

1.6 The values stated in inch-pound units are to be regarded

systems.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

NOTE1—Thetextofthisstandardreferencesnotesandfootnoteswhich

provide explanatory material. These notes and footnotes (excluding those

and are not considered standard.

in tables and figures) shall not be considered as requirements of the

NOTE 4—Suggested hydrostatic design pressures and pressure ratings

standard.

for tubing are listed in Appendix X1.

1.2 This specification covers only composite tubing incor-

1.7 The following safety hazards caveat pertains only to the

porating a continuously welded aluminum tube. Tubing con-

test method portion, Section 9. This standard does not purport

sisting of metallic layers not continuously welded together are

to address all of the safety concerns, if any, associated with its

outside the scope of this specification.

use. It is the responsibility of the user of this standard to

1.3 Specifications for internal bushings for use with com-

establish appropriate safety and health practices and deter-

positetubingmeetingtherequirementsofthisspecificationare

mine the applicability of regulatory limitations prior to use.

given in Annex A1.

2. Referenced Documents

NOTE 2—In order to assure the expected life expectancy of CPVC-AL-

2

CPVC composite tubing by preventing corrosion of the Aluminum, a

2.1 ASTM Standards:

bushing meeting the requirements of Annex A1 is required to be solvent

D696TestMethodforCoefficientofLinearThermalExpan-

cementedintothecutendsoftheCPVC-AL-CPVCtubingpriortomaking

sion of Plastics Between −30°C and 30°C with a Vitreous

solvent cement joints in the piping. This bushing seals off the cut ends of

the tubing preventing any contact of the AL layer with any liquids being Silica Dilatometer

transported by the tubing.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

tics

1.4 Tubing meeting the requirements of this standard are

D1784Specification for Rigid Poly(Vinyl Chloride) (PVC)

designed to be used with fittings and solvent cements meeting

Compounds and Chlorinated Poly(Vinyl Chloride)

1

This specification is under the jurisdiction ofASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2012. Published May 2012. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2011. Last previous edition approved in 2011 as F2855–11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2855–12. the ASTM website.

*A Summary of Changes section appears at the end of this standa

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F2855–11 Designation: F2855 – 12

Standard Specification for

Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated

Poly(Vinyl Chloride) (CPVC-AL-CPVC) Composite Pressure

1

Tubing

This standard is issued under the fixed designation F2855; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers a Chlorinated Poly(Vinyl Chloride)/Aluminum/Chlorinated Poly(Vinyl Chloride), (CPVC AL

CPVC), composite pressure tubing with a welded aluminum tube reinforcement between the inner and outer layers. The inner and

outer CPVC layers are bonded to the aluminum tube by a melt adhesive. Included is a system of nomenclature for the composite

tubing,therequirementsandtestmethodsformaterials,thedimensionsofthecomponentlayersandfinishedtubing,adhesiontests,

hydrostatic burst and sustained pressure and thermocycling performance.Also given are the requirements and methods of marking.

The components covered by this specification are intended for use in residential and commercial, hot and cold, potable water

distribution systems.

NOTE 1—The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in

tables and figures) shall not be considered as requirements of the standard.

1.2 This specification covers only composite tubing incorporating a continuously welded aluminum tube. Tubing consisting of

metallic layers not continuously welded together are outside the scope of this specification.

1.3 Specifications for internal bushings for use with composite tubing meeting the requirements of this specification are given

in Annex A1.

NOTE 2—In order to assure the expected life expectancy of CPVC-AL-CPVC composite tubing by preventing corrosion of the Aluminum, a bushing

meetingtherequirementsofAnnexA1isrequiredtobesolventcementedintothecutendsoftheCPVC-AL-CPVCtubingpriortomakingsolventcement

joints in the piping. This bushing seals off the cut ends of the tubing preventing any contact of the AL layer with any liquids being transported by the

tubing.

1.4 Tubing meeting the requirements of this standard are designed to be used with fittings and solvent cements meeting the

requirements of Specification D2846/D2846M when assembled in accordance with Appendix X3.

1.5 The products covered by this specification are intended for use with the distribution of pressurized liquids only, which are

chemically compatible with the tubing materials. Due to inherent hazards associated with testing components and systems with

compressed air or other compressed gases some manufacturers do not allow pneumatic testing of their products. Consult with

specific product manufacturers for their specific testing procedures prior to pneumatic testing.

NOTE 3—Pressurized (compressed) air or other compressed gases contain large amounts of stored energy which present serious safety hazards should

a system fail for any reason.

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

NOTE 4—Suggested hydrostatic design pressures and pressure ratings for tubing are listed in Appendix X1.

1.7 The following safety hazards caveat pertains only to the test method portion, Section 9. This standard does not purport to

address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish

appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

Current edition approved Feb. 1, 2011. Published February 2011. DOI: 10.1520/F2855–11.

Current edition approvedApril 1, 2012. Published May 2012. Originally approved in 2011. Last previous edition approved in 2011 as F2855–11. DOI: 10.1520/F2855–12.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F285

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.