ASTM D3620-04

(Specification)Standard Specification for Glacial Acetic Acid

Standard Specification for Glacial Acetic Acid

ABSTRACT

This specification covers glacial acetic acid for use in paint, varnish, lacquer, and related products. Glacial acetic acid shall be tested for purity, freezing point, color, water content, iron content, acetaldehyde content, and formic acid content, and shall conform to the requirements of the specification. Test methods, sampling, and packaging shall be in accordance with ASTM standard methods.

SCOPE

1.1 This specification covers glacial (99.8 %) acetic acid for use in paint, varnish, lacquer, and related products.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following applies to all specified limits in this standard; for purposes of determining conformance with this standard, an observed value or a calculated value shall be rounded off "to the nearest unit" in the last right-hand digit used in expressing the specification limit, in accordance with the rounding-off method of Practice E 29.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 For specific hazard information and guidance, see the supplier's Material Safety Data Sheet for materials listed in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 3620 – 04

Standard Specification for

1

Glacial Acetic Acid

This standard is issued under the fixed designation D 3620; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 U.S. Federal Specification:

PPP-C-2020 Chemicals, Liquid, Dry, and Paste: Packaging

1.1 This specification covers glacial (99.8 %) acetic acid for

3

of

use in paint, varnish, lacquer, and related products.

1.2 The values stated in SI units are to be regarded as the

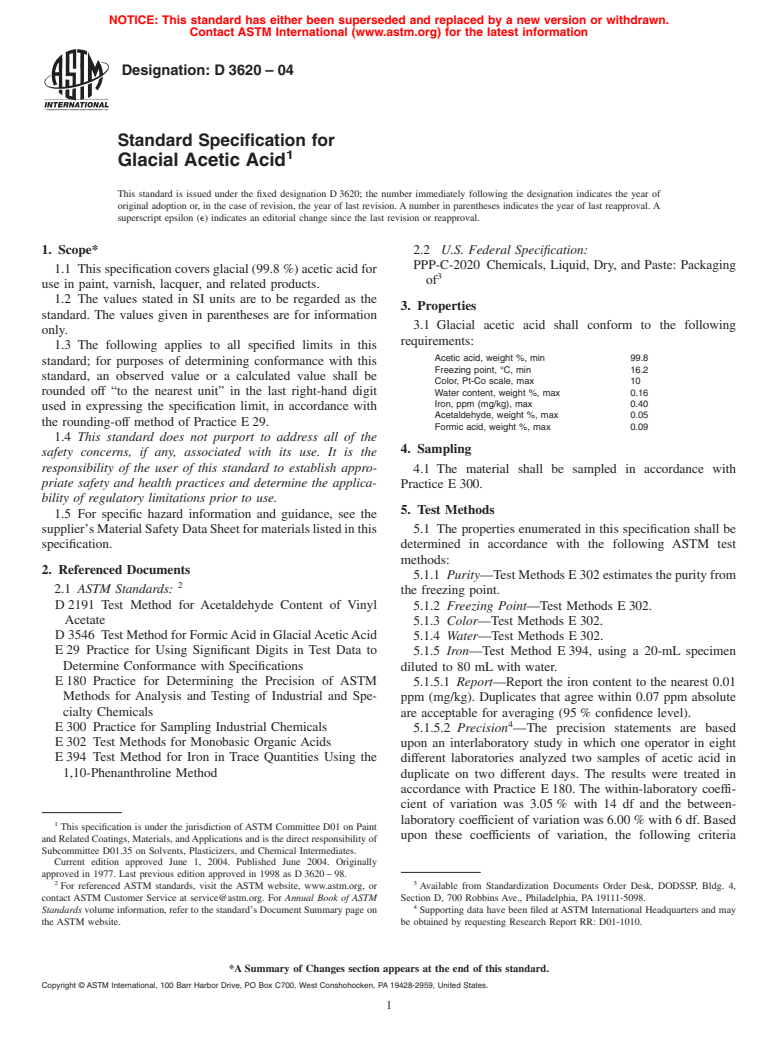

3. Properties

standard. The values given in parentheses are for information

3.1 Glacial acetic acid shall conform to the following

only.

requirements:

1.3 The following applies to all specified limits in this

Acetic acid, weight %, min 99.8

standard; for purposes of determining conformance with this

Freezing point, °C, min 16.2

standard, an observed value or a calculated value shall be

Color, Pt-Co scale, max 10

rounded off “to the nearest unit” in the last right-hand digit

Water content, weight %, max 0.16

Iron, ppm (mg/kg), max 0.40

used in expressing the specification limit, in accordance with

Acetaldehyde, weight %, max 0.05

the rounding-off method of Practice E 29.

Formic acid, weight %, max 0.09

1.4 This standard does not purport to address all of the

4. Sampling

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.1 The material shall be sampled in accordance with

priate safety and health practices and determine the applica-

Practice E 300.

bility of regulatory limitations prior to use.

5. Test Methods

1.5 For specific hazard information and guidance, see the

supplier’sMaterialSafetyDataSheetformaterialslistedinthis 5.1 The properties enumerated in this specification shall be

specification. determined in accordance with the following ASTM test

methods:

2. Referenced Documents

5.1.1 Purity—Test Methods E 302 estimates the purity from

2

2.1 ASTM Standards:

the freezing point.

D 2191 Test Method for Acetaldehyde Content of Vinyl

5.1.2 Freezing Point—Test Methods E 302.

Acetate

5.1.3 Color—Test Methods E 302.

D 3546 Test Method for FormicAcid in GlacialAceticAcid

5.1.4 Water—Test Methods E 302.

E 29 Practice for Using Significant Digits in Test Data to

5.1.5 Iron—Test Method E 394, using a 20-mL specimen

Determine Conformance with Specifications

diluted to 80 mL with water.

E 180 Practice for Determining the Precision of ASTM

5.1.5.1 Report—Report the iron content to the nearest 0.01

Methods for Analysis and Testing of Industrial and Spe-

ppm (mg/kg). Duplicates that agree within 0.07 ppm absolute

cialty Chemicals

are acceptable for averaging (95 % confidence level).

4

E 300 Practice for Sampling Industrial Chemicals

5.1.5.2 Precision —The precision statements are based

E 302 Test Methods for Monobasic Organic Acids upon an interlaboratory study in which one operator in eight

E 394 Test Method for Iron in Trace Quantities Using the

different laboratories analyzed two samples of acetic acid in

1,10-Phenanthroline Method duplicate on two different days. The results were treated in

accordance with Practice E 180. The within-laboratory coeffi-

cient of variation was 3.05 % with 14 df and the between-

laboratory coefficient of variation was 6.00 % with 6 df. Based

1

This specification is under the jurisdiction of ASTM Committee D01 on Paint

upon these coefficients of variation, the following criteria

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.35 on Solvents, Plasticizers, and Chemical Intermediates.

Current edition approved June 1, 2004. Published June 2004. Originally

approved in 1977. Last previous edition approved in 1998 as D 3620 – 98.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Standardization Documents Order Desk, DODSSP, Bldg. 4,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Section D, 700 Robbins Ave., Philadelphia, PA 19111-5098.

4

Standards volume information, refer to the standard’s Document Summary page on Supporting data have been filed at ASTM International Headquarters and may

the ASTM website. be obtained by requesting Research Report RR: D01-1010.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3620–04

should be used for judging the acceptability of results at the tions, the following criteria should be used for judging the

95 % confidence level.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.