ASTM B130-02

(Specification)Standard Specification for Commercial Bronze Strip for Bullet Jackets

Standard Specification for Commercial Bronze Strip for Bullet Jackets

SCOPE

1.1 This specification establishes general requirements for (commercial bronze) strip for manufacture of bullet jacket cups and ammunition components from Copper Alloy UNS No. C22000.

1.2 Values stated in inch-pound units are to be regarded as the standard except for grain size which is stated in metric units. SI values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 130 – 02

Standard Specification for

1

Commercial Bronze Strip for Bullet Jackets

This standard is issued under the fixed designation B 130; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

7

1. Scope* E 527 Practice for Numbering Metals and Alloys (UNS)

1.1 This specification establishes general requirements for

3. Terminology

(commercialbronze)stripformanufactureofbulletjacketcups

3.1 For definition of terms related to copper and copper

and ammunition components from Copper Alloy UNS No.

2 alloys, refer to Terminology B 846.

C22000.

1.2 Values stated in inch-pound units are to be regarded as

4. Ordering Information

the standard except for grain size which is stated in metric

4.1 Orderforproductunderthisspecificationshouldinclude

units. SI values given in parentheses are for information only.

the following information:

4.1.1 Specification designation and year of issue,

2. Referenced Documents

4.1.2 Quantity or weight for each size,

2.1 The following documents of the issue in effect on date

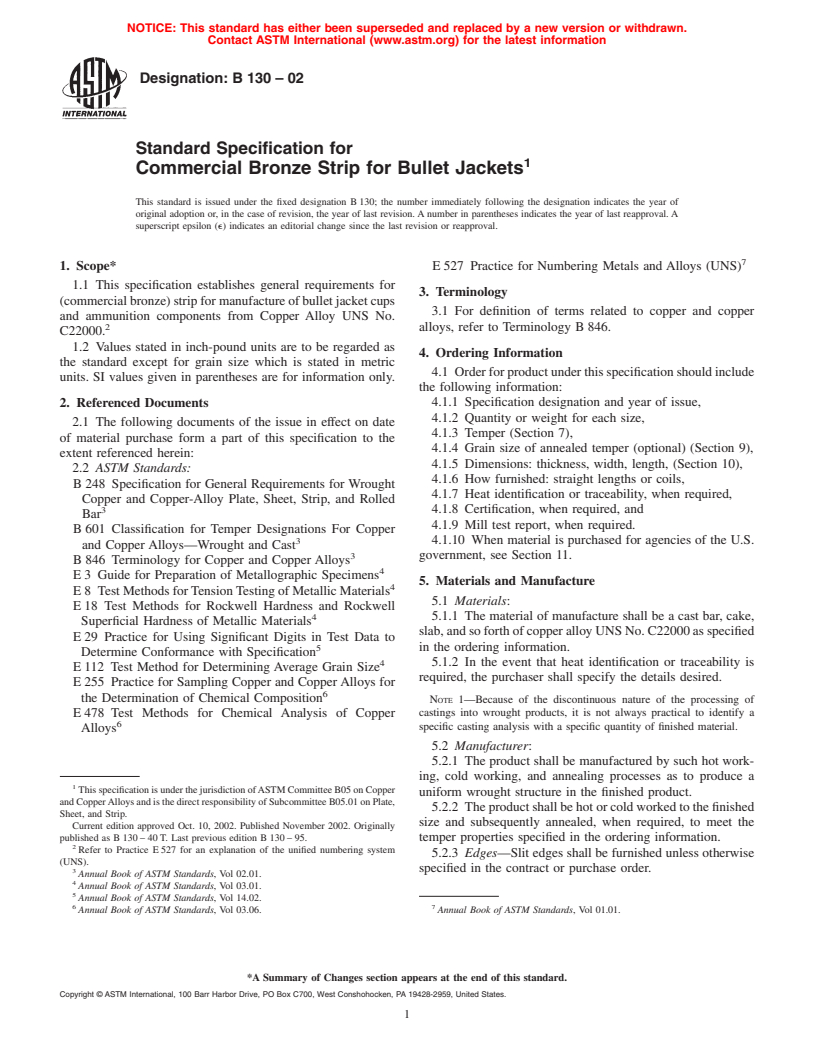

4.1.3 Temper (Section 7),

of material purchase form a part of this specification to the

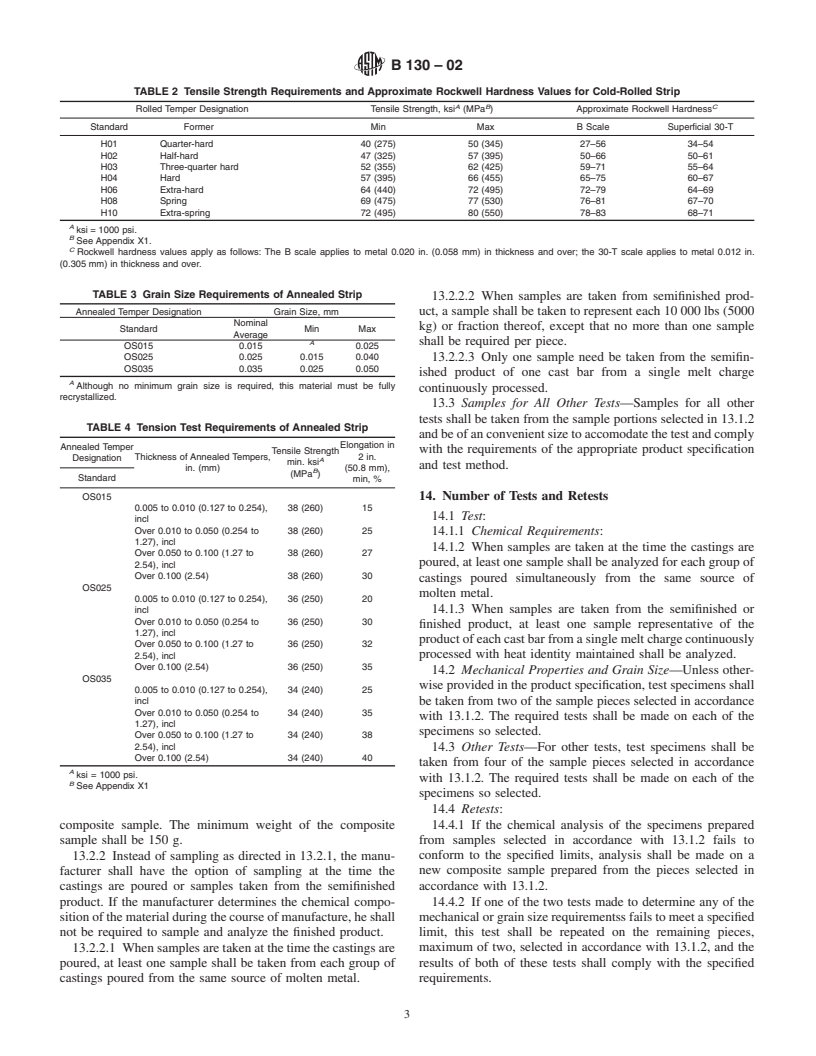

4.1.4 Grain size of annealed temper (optional) (Section 9),

extent referenced herein:

4.1.5 Dimensions: thickness, width, length, (Section 10),

2.2 ASTM Standards:

4.1.6 How furnished: straight lengths or coils,

B 248 Specification for General Requirements for Wrought

4.1.7 Heat identification or traceability, when required,

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

3

4.1.8 Certification, when required, and

Bar

4.1.9 Mill test report, when required.

B 601 Classification for Temper Designations For Copper

3

4.1.10 When material is purchased for agencies of the U.S.

and Copper Alloys—Wrought and Cast

3 government, see Section 11.

B 846 Terminology for Copper and Copper Alloys

4

E 3 Guide for Preparation of Metallographic Specimens

5. Materials and Manufacture

4

E 8 Test Methods forTensionTesting of Metallic Materials

5.1 Materials:

E 18 Test Methods for Rockwell Hardness and Rockwell

5.1.1 The material of manufacture shall be a cast bar, cake,

4

Superficial Hardness of Metallic Materials

slab,andsoforthofcopperalloyUNSNo.C22000asspecified

E 29 Practice for Using Significant Digits in Test Data to

in the ordering information.

5

Determine Conformance with Specification

4 5.1.2 In the event that heat identification or traceability is

E 112 Test Method for Determining Average Grain Size

required, the purchaser shall specify the details desired.

E 255 Practice for Sampling Copper and CopperAlloys for

6

the Determination of Chemical Composition

NOTE 1—Because of the discontinuous nature of the processing of

E 478 Test Methods for Chemical Analysis of Copper castings into wrought products, it is not always practical to identify a

6

specific casting analysis with a specific quantity of finished material.

Alloys

5.2 Manufacturer:

5.2.1 The product shall be manufactured by such hot work-

ing, cold working, and annealing processes as to produce a

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

uniform wrought structure in the finished product.

andCopperAlloysandisthedirectresponsibilityofSubcommitteeB05.01onPlate,

5.2.2 Theproductshallbehotorcoldworkedtothefinished

Sheet, and Strip.

size and subsequently annealed, when required, to meet the

Current edition approved Oct. 10, 2002. Published November 2002. Originally

published as B 130 – 40 T. Last previous edition B 130 – 95.

temper properties specified in the ordering information.

2

Refer to Practice E 527 for an explanation of the unified numbering system

5.2.3 Edges—Slit edges shall be furnished unless otherwise

(UNS).

3 specified in the contract or purchase order.

Annual Book of ASTM Standards, Vol 02.01.

4

Annual Book of ASTM Standards, Vol 03.01.

5

Annual Book of ASTM Standards, Vol 14.02.

6 7

Annual Book of ASTM Standards, Vol 03.06. Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B130–02

6. Chemical Composition 10. Dimensions, Mass, and Permissible Variations

6.1 The product shall conform to the composition pre- 10.1 Thickness—The standard method of specifying thick-

scribed in Table 1. ness shall be in decimal fractions of an inch. The tolerances

6.2 These composition limits do not preclude the presence shall be as shown in Table 5.

of other elements. Limits for unnamed elements may be 10.2 Width—The width tolerances of stri

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.