ASTM B711-99

(Specification)Standard Specification for Concentric-Lay-Stranded Aluminum-Alloy Conductors, Steel Reinforced (AACSR) (6201)

Standard Specification for Concentric-Lay-Stranded Aluminum-Alloy Conductors, Steel Reinforced (AACSR) (6201)

SCOPE

1.1 This specification covers concentric-lay-stranded conductors made from round aluminum-alloy 6201-T81 hard: solution heat treated, cold worked, and then artificially aged wire and round zinc-coated, aluminum-coated, or aluminum-clad steel core wire for use as overhead electric conductors (Explanatory Notes 1 and 2). Note 1-All values are stated in SI units. No inch-pound equivalents are presented, nor is an inch-pound companion specification proposed. Note 2-The alloy and temper designations conform to ANSI H35.1. Aluminum alloy 6201 corresponds to Unified Numbering System alloy A96201 in accordance with Practice E527. Note 3-It is proposed that references to inch-pound documents be changed to metric companions of applicable documents as they are developed, possibly requiring minor changes in some values in this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 711 – 99

Standard Specification for

Concentric-Lay-Stranded Aluminum-Alloy Conductors, Steel

Reinforced (AACSR) (6201)

This standard is issued under the fixed designation B 711; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Aluminum Conductors,Aluminum-Clad Steel Reinforced

B 606 Specification for High-Strength Zinc-Coated (Galva-

1.1 This specification covers concentric-lay-stranded con-

nized) Steel Core Wire for Aluminum and Aluminum-

ductors made from round aluminum-alloy 6201-T81 hard:

Alloy Conductors, Steel Reinforced

solution heat treated, cold worked, and then artificially aged

B 802M Specification for Zinc-5% Aluminum-Mischmetal

wire and round zinc-coated, Zn-5Al-MM coated, aluminum-

Alloy-Coated Steel Core Wire for Aluminum Conductors,

coated, or aluminum-clad steel core wire for use as overhead

Steel Reinforced (ACSR) [Metric]

electric conductors (Explanatory Note 1 and Note 2).

B 803 Specification for High-Strength Zinc-5%Aluminum-

NOTE 1—All values are stated in SI units. No inch-pound equivalents

Mischmetal Alloy-Coated Steel Core Wire for Aluminum

are presented, nor is an inch-pound companion specification proposed.

and Aluminum-Alloy Conductors, Steel Reinforced

NOTE 2—The alloy and temper designations conform to ANSI H35.1.

E29 Practice for Using Significant Digits in Test Data to

Aluminum alloy 6201 corresponds to Unified Numbering System alloy

Determine Conformance with Specifications

A96201 in accordance with Practice E 527.

E 527 Practice for Numbering Metals and Alloys (UNS)

2. Referenced Documents

2.3 American National Standards Institute Standard:

H35.1M Alloy and Temper Designation Systems for Alu-

2.1 The following documents of the issue in effect on date

minum

of material purchase form a part of this specification to the

2.4 Other Standard:

extent referenced herein.

NBS Handbook 100—Copper Wire Tables

2.2 ASTM Standards:

B 263 Test Method for Determination of Cross-Sectional

2 3. Terminology

Area of Stranded Conductors

3.1 Definitions of Terms Specific to This Standard:

B 341 Specification for Aluminum-Coated (Aluminized)

3.1.1 AACSR—covered by this specification has five types

Steel Core Wire for Aluminum Conductors, Steel Rein-

of coated steel and one type of aluminum-clad steel core wire

forced (ACSR/AZ)

which are designated by abbreviations as follows (Explanatory

B 354 Terminology Relating to Uninsulated Metallic Elec-

Note 2):

trical Conductors

3.1.1.1 AACSR/GA-AACSR—using Class A zinc-coated

B 398 Specification for Aluminum-Alloy 6201-T81 Wire

steel wire (B 498).

for Electrical Purposes

3.1.1.2 AACSR/GB-AACSR—using Class B zinc-coated

B 398M Specification for Aluminum-Alloy 6201-T81 Wire

steel wire (B 498).

for Electrical Purposes [Metric]

3.1.1.3 AACSR/GC-AACSR—using Class C zinc-coated

B 498M Specification for Zinc-Coated (Galvanized) Steel

steel wire (B 498).

Core Wire for Aluminum Conductors, Steel Reinforced

3.1.1.4 AACSR/AZ-AACSR—using aluminum-coated (alu-

(ACSR) [Metric]

minized) steel wire (B 341).

B 500 Specification for Metallic Coated Stranded Steel

3.1.1.5 AACSR/HS-AACSR—using extra high-strength steel

Core for Aluminum Conductors, Steel Reinforced

wire (B 606).

(ACSR)

3.1.1.6 AACSR/AW-AACSR—using aluminum-clad steel

B 502 SpecificationforAluminum-CladSteelCoreWirefor

wire (B 502).

1 3

This specification is under the jurisdiction of ASTM Committee B-1 on Annual Book of ASTM Standards, Vol 14.02.

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Annual Book of ASTM Standards, Vol 01.01.

Conductors of Light Metals. Available from American National Standards Institute, 11 West 42nd Street,

Current edition approved April 10, 1999. Published June 1999. Originally 13th Floor, New York, NY 10036.

published as B 711 – 82. Last previous edition B 711 – 93. Available from National Institute of Standards and Technology, (NIST),

Annual Book of ASTM Standards, Vol 02.03. Gaithersburg, MD 20899.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 711–99

3.1.1.7 AACSR/MA—using Zn-5Al-MM coated steel core 4.1.2 Conductor size, square millimetres (Section 8 and

wire, coating Class A in accordance with Specification Table 1),

B B 802M.

4.1.3 Number of wires, aluminum and steel,

3.1.1.8 AACSR/MB—using Zn-5Al-MM coated steel core

4.1.4 Type of steel core wire and, if galvanized or Zn-

wire, coating Class B in accordance with Specification

5Al-MM coated, class (A, B, or C) of coating (see 5.2),

B 802M.

4.1.5 Direction of lay of outer layer of aluminum wires if

3.1.1.9 AACSR/MC—using Zn-5Al-MM coated steel core

other than right-hand (see 7.2),

wire, coating Class C in accordance with Specification

4.1.6 Special tension test, if required (see 9.2),

B 802M.

4.1.7 Place of inspection (Section 15),

3.1.1.10 AACSR/MC—using high-strength Zn-5Al-MM

4.1.8 Special package marking, if required (Section 16),

coated steel core wire, coating Class A in accordance with

4.1.9 Package size (see 17.1), and

Specification B 803.

4.1.10 Heavy wood lagging, if required (see 17.3).

4. Ordering Information

5. Requirement for Wires

4.1 Orders for material under this specification shall include

the following information: 5.1 Before stranding, the aluminum-alloy wire shall meet

4.1.1 Quantity of each size and stranding, the requirements of Specification B 398M.

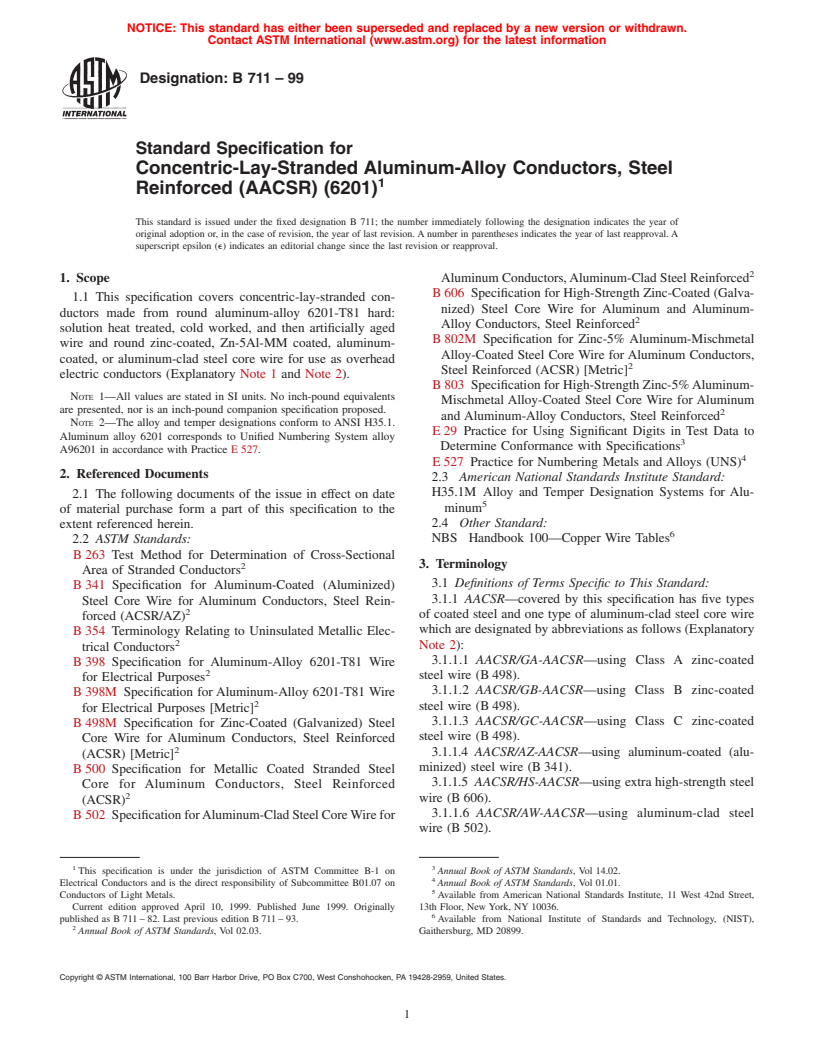

TABLE 1 Construction Requirements of Aluminum-Alloy Conductors, Steel Reinforced, Concentric-Lay-Stranded

2 A

Conductor Area, mm Stranding and Wire Diameter Diameter, mm

B C

Rated Strength Mass

Alloy Steel

Alloy

Steel Total Conductor Steel Core

Nominal

Number mm Number mm kN kg/km

1250 102 1352 84 4.35 19 2.61 47.8 13.0 490 4255

1120 91 1211 84 4.12 19 2.47 45.3 12.4 439 3816

1000 81 1081 84 3.89 19 2.33 42.8 11.6 391 3400

900 73 973 84 3.69 19 2.21 40.6 11.0 355 3060

800 101 901 54 4.34 19 2.60 39.0 13.0 363 3003

710 90 800 54 4.09 19 2.45 36.8 12.2 322 2664

630 80 710 54 3.85 19 2.31 34.6 11.6 286 2365

560 71 631 54 3.63 19 2.18 32.7 10.9 257 2104

500 63 563 54 3.43 19 2.06 30.9 10.3 229 1878

450 59 509 54 3.26 19 1.98 29.5 9.90 215 1706

400 91 491 30 4.12 19 2.47 28.8 12.4 237 1818

400 65 465 26 4.43 7 3.45 28.1 10.4 207 1616

355 81 436 30 3.88 19 2.33 27.2 11.6 211 1614

355 58 413 26 4.17 7 3.24 26.4 9.72 183 1430

315 72 387 30 3.66 19 2.20 25.6 11.0 190 1438

315 52 367 26 3.93 7 3.06 24.9 9.18 163 1272

280 65 345 30 3.45 7 3.45 24.2 10.4 171 1286

280 46 326 26 3.70 7 2.88 23.4 8.64 144 1127

250 58 308 30 3.26 7 3.26 22.8 9.78 156 1149

250 41 291 26 3.50 7 2.72 22.2 8.16 129 1008

224 52 276 30 3.08 7 3.08 21.6 9.24 139 1025

224 36 260 26 3.31 7 2.57 21.0 7.71 118 901

200 47 247 30 2.91 7 2.91 20.4 8.73 124 915

200 32 232 26 3.13 7 2.43 19.8 7.29 106 805

180 42 222 30 2.76 7 2.76 19.3 8.28 112 823

180 29 209 26 2.97 7 2.31 18.8 6.93 95.1 731

160 38 198 30 2.61 7 2.61 18.3 7.83 106 736

160 26 186 26 2.80 7 2.18 17.7 6.54 85.6 646

140 33 173 30 2.44 7 2.44 17.1 7.32 87.4 643

140 23 163 26 2.62 7 2.04 16.6 6.12 75.0 565

A

Only those strandings with a relatively high steel content are listed. Other strandings are available by agreement between the purchaser and the producer.

B

Rated strengths are for AACSR/GA and AACSR/MA conductors. Strengths were calculated in accordance with 9.1.

C

Mass applies to AACSR/GA, AACSR/MA, and AACSR/AZ conductors.

B 711–99

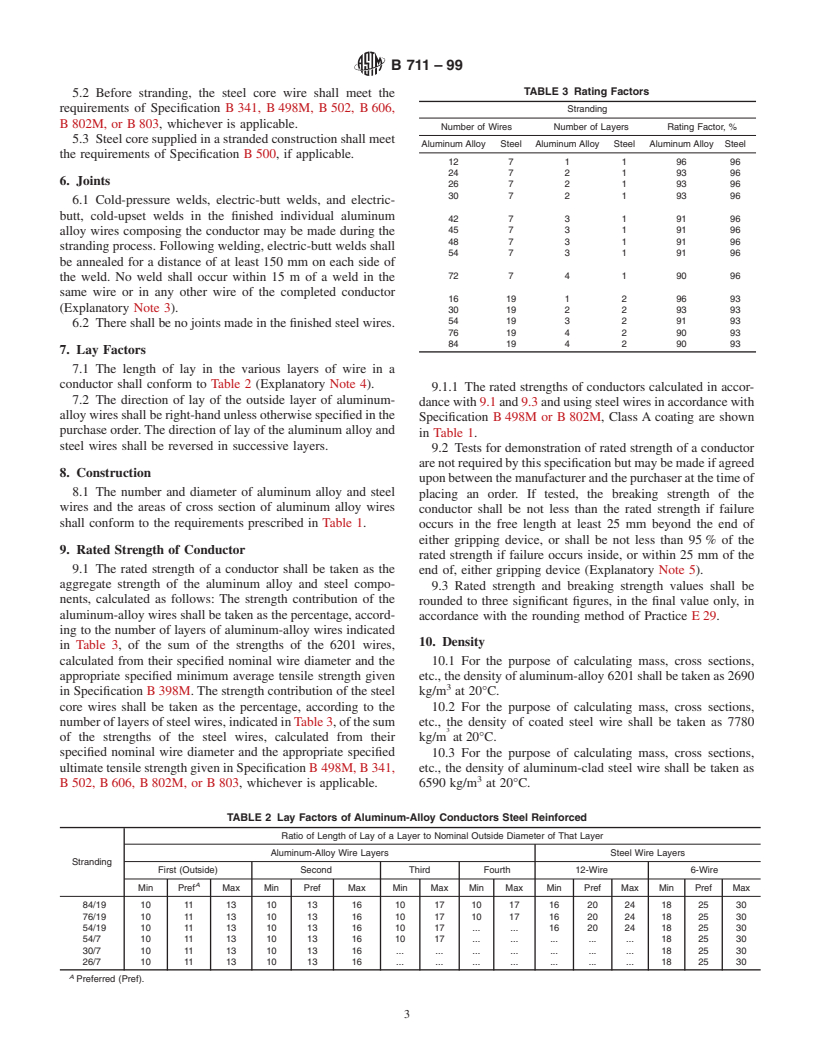

TABLE 3 Rating Factors

5.2 Before stranding, the steel core wire shall meet the

requirements of Specification B 341, B 498M, B 502, B 606, Stranding

B 802M, or B 803, whichever is applicable.

Number of Wires Number of Layers Rating Factor, %

5.3 Steel core supplied in a stranded construction shall meet

Aluminum Alloy Steel Aluminum Alloy Steel Aluminum Alloy Steel

the requirements of Specification B 500, if applicable.

12 7 1 1 96 96

24 7 2 1 93 96

6. Joints

26 7 2 1 93 96

30 7 2 1 93 96

6.1 Cold-pressure welds, electric-butt welds, and electric-

butt, cold-upset welds in the finished individual aluminum

42 7 3 1 91 96

45 7 3 1 91 96

alloy wires composing the conductor may be made during the

48 7 3 1 91 96

stranding process. Following welding, electric-butt welds shall

54 7 3 1 91 96

be annealed for a distance of at least 150 mm on each side of

72 7 4 1 90 96

the weld. No weld shall occur within 15 m of a weld in the

same wire or in any other wire of the completed conductor

16 19 1 2 96 93

(Explanatory Note 3).

30 19 2 2 93 93

54 19 3 2 91 93

6.2 There shall be no joints made in the finished steel wires.

76 19 4 2 90 93

84 19 4 2 90 93

7. Lay Factors

7.1 The length of lay in the various layers of wire in a

conductor shall conform to Table 2 (Explanatory Note 4).

9.1.1 The rated strengths of conductors calculated in accor-

7.2 The direction of lay of the outside layer of aluminum-

dancewith9.1and9.3andusingsteelwiresinaccordancewith

alloywiresshallberight-handunlessotherwisespecifiedinthe

Specification B 498M or B 802M, Class A coating are shown

purchase order. The direction of lay of the aluminum alloy and

in Table 1.

steel wires shall be reversed in successive layers.

9.2 Tests for demonstration of rated strength of a conductor

arenotrequiredbythisspecificationbutmaybemadeifagreed

8. Construction

uponbetweenthemanufacturerandthepurchaseratthetimeof

8.1 The number and diameter of aluminum alloy and steel

placing an order. If tested, the breaking strength of the

wires and the areas of cross section of aluminum alloy wires

conductor shall be not less than the rated strength if failure

shall conform to the requirements prescribed in Table 1.

occurs in the free length at least 25 mm beyond the end of

either gripping device, or shall be not less than 95 % of the

9. Rated Strength of Conductor

rated strength if failure occurs inside, or within 25 mm of the

9.1 The rated strength of a conductor shall be taken as the

end of, either gripping device (Explanatory Note 5).

aggregate strength of the aluminum alloy and steel compo-

9.3 Rated strength and breaking strength values shall be

nents, calculated as follows: The strength contribution of the

rounded to three significant figures, in the final value only, in

aluminum-alloy wires shall be taken as the percentage, accord-

accordance with the rounding method of PracticeE29.

ing to the number of layers of aluminum-alloy wires indicated

10. Density

in Table 3, of the sum of the strengths of the 6201 wires,

calculated from their specified nominal wire diameter and the 10.1 For the purpose of calculating mass, cross sections,

appropriate specified minimum average tensile strength given

etc., the density of aluminum-alloy 6201 shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.