ASTM C1365-98

(Test Method)Standard Test Method for Determination of the Proportion of Phases in Portland Cement and Portland-Cement Clinker Using X-Ray Powder Diffraction Analysis

Standard Test Method for Determination of the Proportion of Phases in Portland Cement and Portland-Cement Clinker Using X-Ray Powder Diffraction Analysis

SCOPE

1.1 This test method covers direct determination of the proportion by mass of individual phases in portland cement or portland-cement clinker using quantitative X-ray (QXRD) analysis. The following phases are covered by this standard: aluminate (tricalcium aluminate, C3A), ferrite (tetracalcium aluminoferrite, C4AF), and periclase (magnesium oxide, M) (see Note 1).

Note 1-In the future, Subcommittee C1.23 plans to add additional phases: alite (tricalcium silicate, C3S, belite (dicalcium silicate, C2S), gypsum (CSH2) hemihydrate (CSH1/2), and anhydrite (CS).

1.2 This test method specifies certain general aspects of the analytical procedure, but does not specify detailed aspects. A recommended procedure is described, but not specified. Regardless of the procedure selected, the user must demonstrate by analysis of reference materials (RM's) that the particular analytical procedure selected for this purpose qualifies (that is, provides acceptable precision and bias) (Note 2). The recommended procedure is the one used in the round-robin analysis to determine the precision and bias levels of this test method.

Note 2-A similar approach was used in the performance requirements for alternative methods for chemical analysis in Test methods C 114.

1.3 The values stated in SI units shall be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards, see Section 9.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

Designation:C 1365–98

Standard Test Method for

Determination of the Proportion of Phases in Portland

Cement and Portland-Cement Clinker Using X-Ray Powder

Diffraction Analysis

This standard is issued under the fixed designation C 1365; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (ϵ) indicates an editorial change since the last revision or reapproval.

1. Scope C114 Test Methods for Chemical Analysis of Hydraulic

Cement

1.1 This test method covers direct determination of the

C 150 Specification for Portland Cement

proportion by mass of individual phases in portland cement or

C 183 Practice for Sampling and the Amount of Testing of

portland-cement clinker using quantitative X-ray (QXRD)

Hydraulic Cement

analysis. The following phases are covered by this standard:

2 C 219 Terminology Relating to Hydraulic Cement

aluminate (tricalcium aluminate, C A), ferrite (tetracalcium

C 670 Practice for Preparing Precision and Bias Statements

aluminoferrite, C AF), and periclase (magnesium oxide, M)

for Test Methods for Construction Materials

(see Note 1).

E29 Practice for Using Significant Digits in Test Data to

NOTE 1—In the future, Subcommittee C1.23 plans to add additional 5

Determine Conformance with Specifications

phases: alite (tricalcium silicate, C S), belite (dicalcium silicate, C S),

3 2

E 691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

gypsum ~CSH ! , hemihydrate ~CSH |n$ ! , and anhydrite ~CS! .

3. Terminology

1.2 This test method specifies certain general aspects of the

3.1 Definitions are in accordance with Terminology

analytical procedure, but does not specify detailed aspects. A

C 219C 219.

recommended procedure is described, but not specified. Re-

3.2 Phases (1):

gardless of the procedure selected, the user must demonstrate

3.2.1 alite, n—tricalcium silicate (C S) modified in compo-

by analysis of reference materials (RM’s) that the particular

sition and crystal structure by incorporation of foreign ions;

analytical procedure selected for this purpose qualifies (that is,

occurs typically between 30 to 70 % (by mass) of the Portland-

provides acceptable precision and bias) (see Note 2). The

cement clinker; and is normally either the M or M crystal

recommended procedure is the one used in the round-robin

1 3

polymorph, each of which is monoclinic.

analysis to determine the precision and bias levels of this test

3.2.2 aluminate, n—tricalcium aluminate (C A) modified in

method.

composition and sometimes in crystal structure by incorpora-

NOTE 2—Asimilarapproachwasusedintheperformancerequirements

tion of a substantial proportion of foreign ions; occurs as

for alternative methods for chemical analysis in Test Methods C 114.

2–15 % (by mass) of the Portland-cement clinker; is normally

1.3 The values stated in SI units shall be regarded as the

cubic when relatively pure and orthorhombic when in solid

standard.

solution with significant amounts of sodium, though tetragonal

1.4 This standard does not purport to address all of the

aluminate containing a substantial amount of potassium has

safety concerns, if any, associated with its use. It is the

been reported (2).

responsibility of the user of this standard to establish appro-

3.2.3 belite, n—dicalcium silicate (C S) modified in com-

priate safety and health practices and determine the applica-

position and crystal structure by incorporation of foreign ions;

bility of regulatory limitations prior to use. For specific

occurs typically as 15 to 45 % (by mass) of the Portland-

hazards, see Section 9.

cement clinker as normally the β polymorph, which is mono-

clinic. In lesser amounts, other polymorphs can be present.

2. Referenced Documents

3.2.4 ferrite, n—tetracalcium aluminoferrite solid solution

2.1 ASTM Standards:

of approximate composition C (A,F) modified in composition

1 3

This test method is under the jurisdiction ofASTM Committee C-1 on Cement Annual Book of ASTM Standards, Vol 04.01.

and is the direct responsibility of Subcommittee C01.23 on CompositionalAnalysis. Annual Book of ASTM Standards, Vol 04.02.

Current edition approved July 10, 1998. Published December 1998. Annual Book of ASTM Standards, Vol 14.02.

2 6

When expressing chemical formulae, C = CaO, S-SiO ,A=Al O ,F=Fe O , The boldface numbers in parentheses refer to the list of references at the end of

2 2 3 2 3

M = MgO, S =SO , and H = H O. this test method.

3 2

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C 1365–98

by variation in theAl/Fe ratio and by substantial incorporation 5.1.2 Standardization,

of foreign ions as C A F whereO

4 X 2-X

to 15 % (by mass) of a portland-cement clinker; and is various effects on intensity besides phase proportion),

orthorhombic. 5.1.4 Analysis of the sample (in which the intensity of

3.2.5 periclase, n—free magnesium oxide (M); cubic. selected XRD peaks is measured), and

3.3 Definitions of Terms Specific to This Standard: 5.1.5 Calculation of the proportion of each phase.

3.3.1 standardization, n—process of determining the rela- 5.2 This test method does not specify details of the proce-

tionship between XRD intensity and phase proportion for one dure. The user must demonstrate by analysis of reference

or more phases. materials that the particular analytical procedure selected for

3.3.1.1 Discussion—In the literature of X-ray powder dif- thispurposeprovidesacceptablelevelsofprecisionandbias.A

fraction analysis, this process has been commonly referred to recommended procedure (the procedure used to determine the

as calibration; however, we have determined that standardiza- acceptable levels of precision and bias) is given in Appendix

tion is a more accurate term. X1.

3.3.2 diffractometer, n—the instrument, an X-ray powder

diffractometer, for determining the X-ray diffraction pattern of 6. Significance and Use

a crystalline powder.

6.1 This test method covers direct determination of the

3.3.3 phase, n—a homogeneous, physically distinct, and

proportion of some individual phases in portland cement or

mechanically separable portion of a material, identifiable by its

portland-cement clinker. Thus it provides an alternative to the

chemical composition and crystal structure.

indirect estimation of phase proportion using the equations in

3.3.3.1 Phases in portland-cement clinker that are included

SpecificationC 150C 150(seeNoteCofTable1andNoteBof

inthistestmethodaretwomajorphases(aluminateandferrite)

Table 2 of C 150C 150).

and one minor phase (periclase).

6.2 Thistestmethodassumesthattheoperatorisqualifiedto

3.3.4 qualification, n—process by which a QXRD proce-

operate an X-ray diffractometer and to interpret X-ray diffrac-

dure is shown to be valid.

tion spectra.

3.3.5 Reference Material (RM) Clinkers, n—three cement

6.3 Thistestmethodmaybeusedaspartofaqualitycontrol

clinkerswithknownproportionsofeachmajorphase,available

program in cement manufacturing.

as RM’s, which shall be used in demonstrating qualification of

6.4 This test method may be used in predicting properties

a particular procedure for determination of the phases in

and performance of hydrated cement and concrete, to the

portland cement or portland-cement clinker.

extent that properties and performance are a function of phase

3.3.6 Standard Reference Material (SRM), n—a material

composition.

whose properties (in this case XRD peak position or intensity,

6.5 QXRD provides a bulk analysis (that is, the weighted

or both) are known and certified.

average composition of several grams of material). Results

3.3.7 X-ray diffraction (XRD), n—the process by which

may not agree precisely with results of microscopical methods.

X-rays are coherently scattered by electrons in a crystalline

material.

7. Apparatus

7.1 X-Ray Diffractometer—The X-ray diffractometer allows

4. Background

measurement of the X-ray diffraction pattern from which the

4.1 This test method assumes general knowledge concern-

crystalline phases within the sample may be qualitatively

ing the composition of portland cement and portland-cement

identified and the proportion of each phase may be quantita-

clinker. Necessary background information may be obtained

tively determined. X-ray diffractometers are manufactured

from a number of references (1,3).

commercially and a number of instruments are available. The

4.2 This test method also assumes general expertise in XRD

suitability of the diffractometer for this test method shall be

and QXRD analysis. Important background information may

established using the qualification procedure outlined in this

be obtained from a number of references (4,5,6,7).

test method.

4.3 QXRD analysis is difficult and time-consuming and

QXRD of portland cement and portland-cement clinker is

8. Materials

especially difficult due to the complex and variable nature of

8.1 Standardization Phases—The use of standardization

the individual clinker phases.

phases is recommended. These phases must usually be synthe-

5. Summary

sized (8).

8.2 RM Clinkers—The use of RM clinkers is required to

5.1 A QXRD test procedure includes some or all of the

qualify the QXRD procedure.

following:

8.3 Internal Standard—The use of an internal standard is

5.1.1 Specimen preparation,

recommended. Suitable materials include chemical reagents

(see 8.4) or SRM’s (see Appendix X1).

In this test method, RM clinkers refer specifically to RM 8486, RM 8487, and

8.4 Reagent Chemicals—Reagent grade chemicals, if used

RM 8488. These are available from the Standard Reference Material Program,

either as an internal standard or during chemical extraction of

National Institute of Standards and Technology.

the calcium silicate phases, shall meet the specifications of the

SRM’s are available from the Standard Reference Material Program, National

Institute of Standards and Technology. Committee on Analytical Reagents of the American Chemical

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Please contact ASTM International (www.astm.org) for the latest information.

C 1365–98

NOTE 4—It is recommended that at least two replicate analyses be

Society where such specifications are available. Other grades

carried out.

may be used, provided it is first ascertained that the chemical

is sufficiently pure to permit its use without lessening the

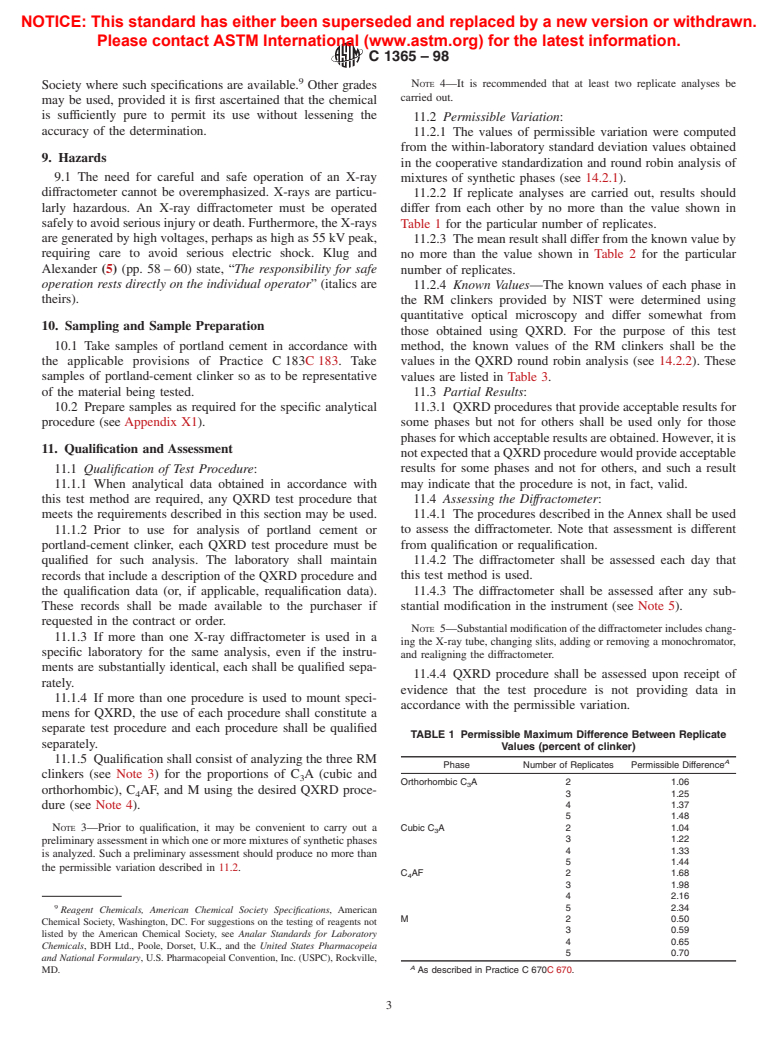

11.2 Permissible Variation:

accuracy of the determination.

11.2.1 The values of permissible variation were computed

from the within-laboratory standard deviation values obtained

9. Hazards

in the cooperative standardization and round robin analysis of

9.1 The need for careful and safe operation of an X-ray mixtures of synthetic phases (see 14.2.1).

diffractometer cannot be overemphasized. X-rays are particu-

11.2.2 If replicate analyses are carried out, results should

larly hazardous. An X-ray diffractometer must be operated differ from each other by no more than the value shown in

safelytoavoidseriousinjuryordeath.Furthermore,theX-rays

Table 1 for the particular number of replicates.

are generated by high voltages, perhaps as high as 55 kV peak,

11.2.3 The mean result shall differ from the known value by

requiring care to avoid serious electric shock. Klug and

no more than the value shown in Table 2 for the particular

Alexander (5) (pp. 58 – 60) state, “The responsibility for safe

number of replicates.

operation rests directly on the individual operator” (italics are

11.2.4 Known Values—The known values of each phase in

theirs).

the RM clinkers provided by NIST were determined using

quantitative optical microscopy and differ somewhat from

10. Sampling and Sample Preparation

those obtained using QXRD. For the purpose of this test

10.1 Take samples of portland cement in accordance with method, the known values of the RM clinkers shall be the

the applicable provisions of Practice C 183C 183. Take values in the QXRD round robin analysis (see 14.2.2). These

samples of portland-cement clinker so as to be representative values are listed in Table 3.

of the material being tested. 11.3 Partial Results:

10.2 Prepare samples as required for the specific analytical 11.3.1 QXRD procedures that provide acceptable results for

procedure (see Appendix X1). some phases but not for others shall be used only for those

phasesforwhichacceptableresultsareobtained.However,itis

11. Qualification and Assessment

notexpectedthataQXRDprocedurewouldprovideacceptable

11.1 Qualification of Test Procedure: results for some phases and not for others, and such a result

11.1.1 When analytical data obtained in accordance with may indicate that the procedure is not, in fact, valid.

this test method are required, any QXRD test procedure that 11.4 Assessing the Diffractometer:

meets the requirements described in this section may be used. 11.4.1 The procedures described in theAnnex shall be used

11.1.2 Prior to use for analysis of portland cement or to assess the diffractometer. Note that assessment is different

portland-cement clinker, each QXRD test procedure must be from qualification or requalification.

qualified for such analysis. The laboratory shall maintain 11.4.2 The diffractometer shall be assessed each day that

records that include a description of the QXRD procedure and this test method is used.

the qualification data (or, if applicable, requalification data). 11.4.3 The diffractometer shall be assessed after any sub-

stantial modification in the instrument (see Note 5).

These records shall be made available to the purchaser if

requested in the contract or order.

NOTE 5—Substantialmodificationofthediffractometerincludeschang-

11.1.3 If more than one X-ray diffractometer is used in a

ing the X-ray tube, changing slits, adding or removing a monochromator,

specific laboratory for the same analysis, even if the instru-

and realigning the diffractometer.

ments are substantially identical, each shall be qualified sepa-

11.4.4 QXRD procedure shall be assessed upon receipt of

rately.

evidence that the test procedure is not providing data in

11.1.4 If more than one procedure is used to mount speci-

accordance with the permissible variation.

mens for QXRD, the use of each procedure shall constitute a

separate test procedure and each procedure shall be qualified

TABLE 1 Permissible Maximum Difference Be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.