ASTM D4895-18(2023)

(Specification)Standard Specification for Polytetrafluoroethylene (PTFE) Resin Produced From Dispersion

Standard Specification for Polytetrafluoroethylene (PTFE) Resin Produced From Dispersion

ABSTRACT

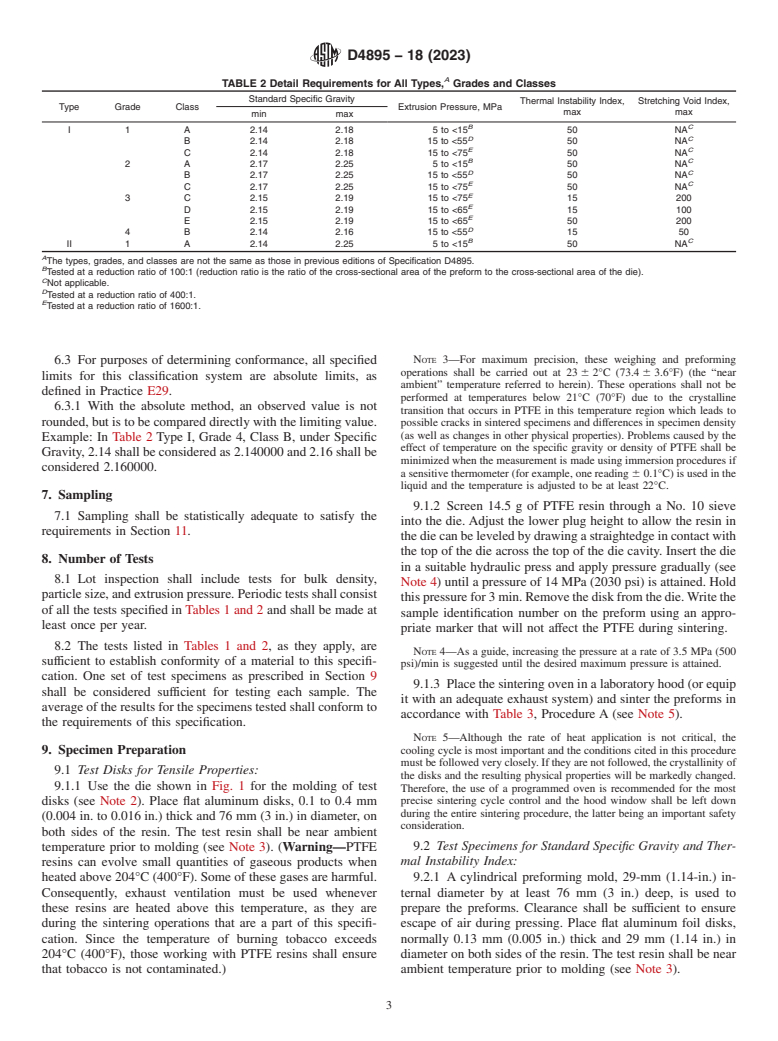

This specification covers dry-powder resins of polytetrafluoroethylene (PTFE) resin produced from dispersion. PTFE mixtures with additives are not covered in this specification. This specification covers type I and type II PTFE. The resins shall be tested for bulk density, particle size, water content, melting peak temperature, tensile strength, elongation at break, standard specific gravity, extrusion pressure, thermal instability index, and stretching void index. Specimen preparation, testing, inspection, and packaging shall be in accordance to the procedures indicated in this specification.

SCOPE

1.1 This specification2 covers polytetrafluoroethylene (PTFE) prepared by coagulation of a dispersion. These PTFE resins are homopolymers of tetrafluoroethylene or modified homopolymers containing not more than 1 % by weight of other fluoromonomers. The materials covered herein do not include mixtures of PTFE with additives such as colors, fillers, or plasticizers; nor do they include reprocessed or reground resin or any fabricated articles because the properties of such materials have been irreversibly changed when they were fibrillated or sintered.

1.2 The values stated in SI units as detailed in IEEE/ASTM SI-10 are to be regarded as standard. The values given in parentheses are for information only.

1.3 The following safety hazards caveat pertains only to the Specimen Preparation Section, Section 9, and the Test Methods Section, Section 10, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. See Warning note in 9.1.1 for a specific hazards statement.

Note 1: Information in this specification is technically equivalent to related information in ISO 20568-1 and ISO 20568-2.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4895 − 18 (Reapproved 2023)

Standard Specification for

Polytetrafluoroethylene (PTFE) Resin Produced From

1

Dispersion

This standard is issued under the fixed designation D4895; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

3

2

2.1 ASTM Standards:

1.1 This specification covers polytetrafluoroethylene

D618 Practice for Conditioning Plastics for Testing

(PTFE) prepared by coagulation of a dispersion. These PTFE

D638 Test Method for Tensile Properties of Plastics

resins are homopolymers of tetrafluoroethylene or modified

D792 Test Methods for Density and Specific Gravity (Rela-

homopolymers containing not more than 1 % by weight of

tive Density) of Plastics by Displacement

other fluoromonomers. The materials covered herein do not

D883 Terminology Relating to Plastics

include mixtures of PTFE with additives such as colors, fillers,

D1708 Test Method for Tensile Properties of Plastics by Use

or plasticizers; nor do they include reprocessed or reground

of Microtensile Specimens

resin or any fabricated articles because the properties of such

D1895 Test Methods for Apparent Density, Bulk Factor, and

materials have been irreversibly changed when they were

Pourability of Plastic Materials

fibrillated or sintered.

D3892 Practice for Packaging/Packing of Plastics

1.2 The values stated in SI units as detailed in IEEE/ASTM

D4052 Test Method for Density, Relative Density, and API

SI-10 are to be regarded as standard. The values given in

Gravity of Liquids by Digital Density Meter

parentheses are for information only.

D4441 Specification for Aqueous Dispersions of Polytet-

1.3 The following safety hazards caveat pertains only to the

rafluoroethylene

Specimen Preparation Section, Section 9, and the Test Methods

D4591 Test Method for Determining Temperatures and

Section, Section 10, of this specification: This standard does

Heats of Transitions of Fluoropolymers by Differential

not purport to address all of the safety concerns, if any,

Scanning Calorimetry

associated with its use. It is the responsibility of the user of this

D4894 Specification for Polytetrafluoroethylene (PTFE)

standard to establish appropriate safety, health, and environ-

Granular Molding and Ram Extrusion Materials

mental practices and determine the applicability of regulatory

E11 Specification for Woven Wire Test Sieve Cloth and Test

limitations prior to use. See Warning note in 9.1.1 for a specific

Sieves

hazards statement.

E29 Practice for Using Significant Digits in Test Data to

Determine Conformance with Specifications

NOTE 1—Information in this specification is technically equivalent to

E177 Practice for Use of the Terms Precision and Bias in

related information in ISO 20568-1 and ISO 20568-2.

ASTM Test Methods

1.4 This international standard was developed in accor-

IEEE/ASTM SI-10 Use of the International System of Units

dance with internationally recognized principles on standard-

(SI): The Modern Metric System

ization established in the Decision on Principles for the

4

2.2 ISO Standards:

Development of International Standards, Guides and Recom-

ISO 20568-1 Plastics Fluoropolymer Dispersions and Mold-

mendations issued by the World Trade Organization Technical

ing and Extrusion Materials—Part 1: Designation and

Barriers to Trade (TBT) Committee.

Specification

ISO 20568-2 Plastics Fluoropolymer Dispersions and

Molding and Extrusion Materials—Part 2: Preparation of

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic

3

Materials. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2023. Published May 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1989. Last previous edition approved in 2018 as D4895 – 18. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4895-18R23. the ASTM website.

2 4

Specifications for other forms of polytetrafluoroethylene are found in Specifi- Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

cations D4441 and D4894. 4th Floor, New York, NY 10036, http://www.ansi.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.