ASTM D4473-08(2021)

(Test Method)Standard Test Method for Plastics: Dynamic Mechanical Properties: Cure Behavior

Standard Test Method for Plastics: Dynamic Mechanical Properties: Cure Behavior

SIGNIFICANCE AND USE

5.1 This test method provides a simple means of characterizing the cure behavior of thermosetting resins using very small amounts of material (fewer than 3 to 5 g). The data obtained may be used for quality control, research and development, and establishment of optimum processing conditions.

5.2 Dynamic mechanical testing provides a sensitive method for determining cure characteristics by measuring the elastic and loss moduli as a function of temperature or time, or both. Plots of cure behavior and tan delta of a material versus time provide graphical representation indicative of cure behavior under a specified time-temperature profile.

5.3 This test method can be used to assess the following:

5.3.1 Cure behavior, including rate of cure, gel, and cure time.

5.3.2 Processing behavior, as well as changes as a function of time/temperature.

Note 3: The presence of the substrate prevents an absolute measure, but allows relative measures of flow behavior during cure.

5.3.3 The effects of processing treatment.

5.3.4 Relative resin behavioral properties, including cure behavior and damping.

5.3.5 The effects of substrate types on cure.

Note 4: Due to the rigidity of a supporting braid, the gel time obtained from dynamic mechanical traces will be longer than actual gel time of the unsupported resin measured at the same frequency. This difference will be greater for composites having greater support-to-polymer rigidity ratios.3

5.3.6 Effects of formulation additives that might affect processability or performance.

5.4 For many materials, there may be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that material specification before using this test method. Table 1 of Classification System D4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 This test method covers the use of dynamic-mechanical-oscillation instrumentation for gathering and reporting the thermal advancement of cure behavior of thermosetting resin. It may be used for determining the cure properties of both unsupported resins and resins supported on substrates subjected to various oscillatory deformations.

1.2 This test method is intended to provide a means for determining the cure behavior of supported and unsupported thermosetting resins over a range of temperatures by free vibration as well as resonant and nonresonant forced-vibration techniques, in accordance with Practice D4065. Plots of modulus, tan delta, and damping index as a function of time/temperature are indicative of the thermal advancement or cure characteristics of a resin.

1.3 This test method is valid for a wide range of frequencies, typically from 0.01 to 100 Hz. However, it is strongly recommended that low-frequency test conditions, generally below 1.5 Hz, be utilized as they generally will result in more definitive cure-behavior information.

1.4 This test method is intended for resin/substrate composites that have an uncured effective elastic modulus in shear greater than 0.5 MPa.

1.5 Apparent discrepancies may arise in results obtained under differing experimental conditions. These apparent differences from results observed in another study can usually be reconciled, without changing the observed data, by reporting in full (as described in this test method) the conditions under which the data were obtained.

1.6 Due to possible instrumentation compliance, especially in the compressive mode, the data generated may indicate relative and not necessarily absolute property values.

1.7 Test data obtained by this test method are relevant and appropriate for use in engineering design.

1.8 The values stated in SI units are to be regarded as the standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use....

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4473 − 08 (Reapproved 2021)

Standard Test Method for

Plastics: Dynamic Mechanical Properties: Cure Behavior

This standard is issued under the fixed designation D4473; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.8 The values stated in SI units are to be regarded as the

standard.

1.1 This test method covers the use of dynamic-mechanical-

1.9 This standard does not purport to address all of the

oscillation instrumentation for gathering and reporting the

safety concerns, if any, associated with its use. It is the

thermal advancement of cure behavior of thermosetting resin.

responsibility of the user of this standard to establish appro-

It may be used for determining the cure properties of both

priate safety, health, and environmental practices and deter-

unsupported resins and resins supported on substrates sub-

mine the applicability of regulatory limitations prior to use.

jected to various oscillatory deformations.

Specific precautionary statements are given in Note 5.

1.2 This test method is intended to provide a means for

determining the cure behavior of supported and unsupported NOTE 1—There is no known ISO equivalent to this standard.

thermosetting resins over a range of temperatures by free

1.10 This international standard was developed in accor-

vibration as well as resonant and nonresonant forced-vibration

dance with internationally recognized principles on standard-

techniques, in accordance with Practice D4065. Plots of

ization established in the Decision on Principles for the

modulus, tan delta, and damping index as a function of

Development of International Standards, Guides and Recom-

time/temperature are indicative of the thermal advancement or

mendations issued by the World Trade Organization Technical

cure characteristics of a resin.

Barriers to Trade (TBT) Committee.

1.3 Thistestmethodisvalidforawiderangeoffrequencies,

2. Referenced Documents

typically from 0.01 to 100 Hz. However, it is strongly

2.1 ASTM Standards:

recommended that low-frequency test conditions, generally

D4000 Classification System for Specifying Plastic Materi-

below 1.5 Hz, be utilized as they generally will result in more

als

definitive cure-behavior information.

D4065 Practice for Plastics: Dynamic Mechanical Proper-

1.4 This test method is intended for resin/substrate compos-

ties: Determination and Report of Procedures

ites that have an uncured effective elastic modulus in shear

D4092 Terminology for Plastics: Dynamic Mechanical

greater than 0.5 MPa.

Properties

1.5 Apparent discrepancies may arise in results obtained

ASTM/IEEE SI–10 Standard for Use of the International

under differing experimental conditions. These apparent differ-

System of Units (SI): The Modern Metric System

ences from results observed in another study can usually be

3. Terminology

reconciled, without changing the observed data, by reporting in

full (as described in this test method) the conditions under

3.1 Definitions—For definitions applicable to this test

which the data were obtained.

method refer to Terminology D4092.

1.6 Due to possible instrumentation compliance, especially

4. Summary of Test Method

in the compressive mode, the data generated may indicate

relative and not necessarily absolute property values. 4.1 A known amount of thermosetting liquid resin or resin-

impregnated substrate is placed in mechanical oscillation at

1.7 Test data obtained by this test method are relevant and

either a fixed or natural resonant frequency or by free vibration

appropriate for use in engineering design.

and at either isothermal conditions, with a linear temperature

increase or using a time-temperature relation simulating a

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2021. Published July 2021. Originally approved contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in 1985. Last previous edition approved in 2016 as D4473 - 08(2016). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D4473-08R21. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4473 − 08 (2021)

processing condition. The elastic or loss modulus, or both, of 7. Apparatus

the composite specimen are measured in shear or compression

7.1 The function of the apparatus is to hold a neat (unmodi-

as a function of time. The point in time when tan delta is

fied) resin or uncured supported composite formulation or

maximum, and the elastic modulus levels off after an increase,

coated substrate of known volume and dimensions. The mate-

is calculated as the gel time of the resin under the conditions of

rialactsastheelasticanddissipativeelementinamechanically

the test.

drivenoscillatoryshearordynamiccompressionsystem.These

NOTE 2—The particular method for measuring the elastic and loss dynamic mechanical instruments operate in one or more of the

moduli and tan delta depends upon the individual instrument’s operating

followingmodesformeasuringcurebehaviorintorsionalshear

principles.

or dynamic compression:

7.1.1 Forced, constant amplitude, fixed frequency,

5. Significance and Use

7.1.2 Forced, constant amplitude, resonant oscillation,

5.1 This test method provides a simple means of character-

7.1.3 Freely decaying oscillation.

izingthecurebehaviorofthermosettingresinsusingverysmall

7.2 The apparatus shall consist of the following:

amounts of material (fewer than 3 to 5 g). The data obtained

7.2.1 Test Fixtures, a choice of the following:

maybeusedforqualitycontrol,researchanddevelopment,and

7.2.1.1 Polished Cone and Plate (Having a Known Cone

establishment of optimum processing conditions.

Angle)—Usually a 25 or 50-mm diameter cone and plate or

5.2 Dynamic mechanical testing provides a sensitive

parallel plates are recommended for neat resins. Variations of

method for determining cure characteristics by measuring the

this tooling, such as bottom plates with concentric overflow

elastic and loss moduli as a function of temperature or time, or

rims, may be used as necessary.

both. Plots of cure behavior and tan delta of a material versus

7.2.1.2 Parallel Plates, having either smooth, polished, or

time provide graphical representation indicative of cure behav-

serrated surfaces are recommended for neat resins or prepregs

ior under a specified time-temperature profile.

having less than 6 % volatiles.

5.3 This test method can be used to assess the following:

7.2.1.3 Clamps—Aclamping arrangement that permits grip-

5.3.1 Cure behavior, including rate of cure, gel, and cure

ping of the composite sample.

time.

7.2.2 Oscillatory Deformation (Strain Device)—A device

5.3.2 Processing behavior, as well as changes as a function

for applying a continuous oscillatory deformation (strain) to

of time/temperature.

the specimen. The deformation (strain) may be applied and

then released, as in free-vibration devices, or continuously

NOTE 3—The presence of the substrate prevents an absolute measure,

but allows relative measures of flow behavior during cure.

applied, as in forced-vibration devices (see Table 1 of Practice

D4065).

5.3.3 The effects of processing treatment.

7.2.3 Detectors—A device or devices for determining de-

5.3.4 Relative resin behavioral properties, including cure

pendent and independent experimental parameters, such as

behavior and damping.

force (stress or strain), frequency, and temperature. Tempera-

5.3.5 The effects of substrate types on cure.

ture should be measurable with a precision of 61°C, frequency

NOTE 4—Due to the rigidity of a supporting braid, the gel time obtained

to 61 %, and force to 61%.

from dynamic mechanical traces will be longer than actual gel time of the

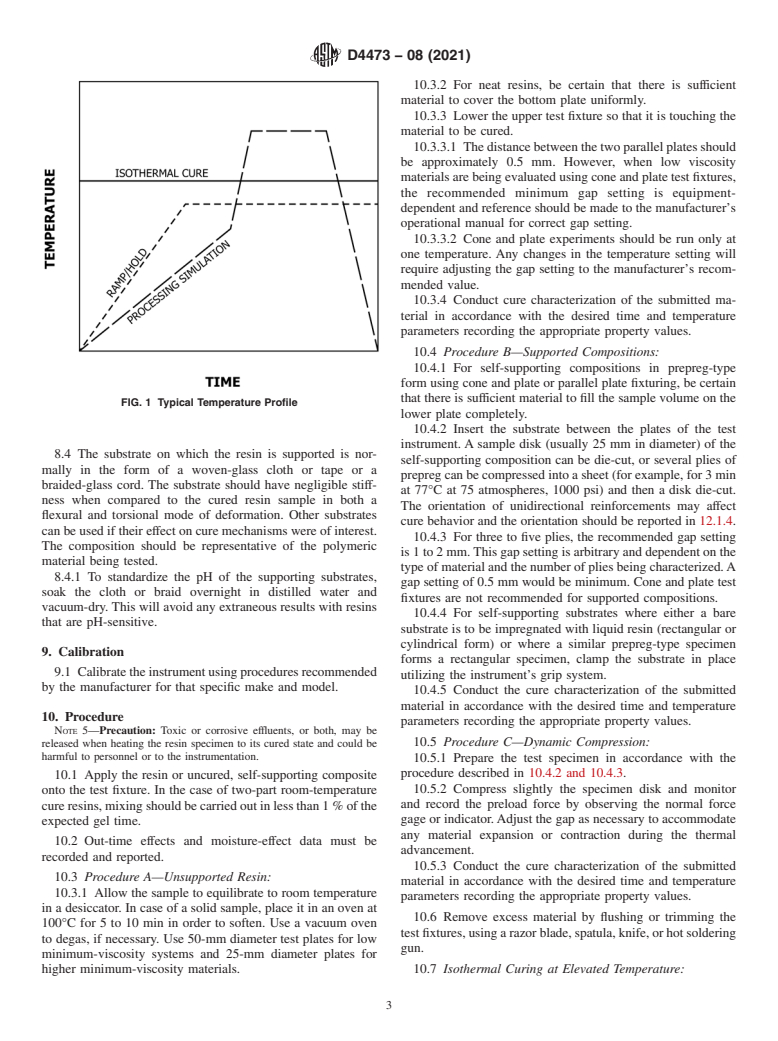

7.2.4 Temperature Controller and Oven—A device for con-

unsupported resin measured at the same frequency. This difference will be

trolling the temperature, either by heating (in steps or ramps),

greater for composites having greater support-to-polymer rigidity ratios.

cooling (in steps or ramps), maintaining a constant specimen

5.3.6 Effects of formulation additives that might affect

environment,oracombinationthereof.Fig.1illustratestypical

processability or performance.

time-temperature profiles. A temperature controller should be

5.4 For many materials, there may be a specification that

sufficiently stable to permit measurement of sample tempera-

requires the use of this test method, but with some procedural

ture to within 1°C.

modifications that take precedence when adhering to the

7.3 Nitrogen, or other inert gas supply for purging purposes.

specification. Therefore, it is advisable to refer to that material

specification before using this test method. Table 1 of Classi-

8. Test Specimens

fication System D4000 lists theASTM materials standards that

currently exist.

8.1 The neat resin or the self-supporting composition, or

both, should be representative of the polymeric material being

6. Interferences

tested.

6.1 Since small quantities of resin are used, it is essential

8.2 Due to the various geometries that might be used for

that the specimens be representative of the polymeric material

dynamic mechanical curing of thermosetting resins/

being tested.

composites, specimen size is not fixed by this test method.

6.2 The result is a response of the thermal advancement or

Cure rates may be influenced by specimen thickness, so equal

cure behavior of the resin in combination with any substrate

volumes of material should be used for any series of compari-

used to support the resin.

sons.

8.3 For convenience, low-viscosity neat resins can be stud-

Hedvat, S., Polymer Engineering and Science, Vol 21, No. 3, February 1981. ied using a supporting substrate.

D4473 − 08 (2021)

10.3.2 For neat resins, be certain that there is sufficient

material to cover the bottom plate uniformly.

10.3.3 Lower the upper test fixture so that it is touching the

material to be cured.

10.3.3.1 Thedistancebetweenthetwoparallelplatesshould

be approximately 0.5 mm. However, when low viscosity

materials are being evaluated using cone and plate test fixtures,

the recommended minimum gap setting is equipment-

dependent and reference should be made to the manufacturer’s

operational manual for correct gap setting.

10.3.3.2 Cone and plate experiments should be run only at

one temperature. Any changes in the temperature setting will

require adjusting the gap setting to the manufacturer’s recom-

mended value.

10.3.4 Conduct cure characterization of the submitted ma-

terial in accordance with the desired time and temperature

parameters recording the appropriate property values.

10.4 Procedure B—Supported Compositions:

10.4.1 For self-supporting compositions in prepreg-type

form using cone and plate or parallel plate fixturing, be certain

that there is sufficient material to fill the sample volume on the

FIG. 1 Typical Temperature Profile

lower plate completely.

10.4.2 Insert the substrate between the plates of the test

instrument. A sample disk (usually 25 mm in diameter) of the

8.4 The substrate on which the resin is supported is nor-

self-supporting composition can be die-cut, or several plies of

mally in the form of a woven-glass cloth or tape or a

prepreg can be compressed into a sheet (for example, for 3 min

braided-glass cord. The substrate should have negligible stiff-

at 77°C at 75 atmospheres, 1000 psi) and then a disk die-cut.

ness when compared to the cured resin sample in both a

The orientation of unidirectional reinforcements may affect

flexural and torsional mode of deformation. Other substrates

cure behavior and the orientation should be reported in 12.1.4.

can be used if their effect on cure mechanisms were of interest.

10.4.3 For three to five plies, the recommended gap setting

The composition should be representative of the polymeric

is 1 to 2 mm.This gap setting is arbitrary and dependent on the

material being tested.

type of material and the number of plies being characterized.A

8.4.1 To standardize the pH of the supporting substrates,

gap setting of 0.5 mm would be minimum. Cone and plate test

soak the cloth or braid overnight in distilled water and

fixtures are not recommended for supported compositions.

vacuum-dry. This will avoid any extraneous results with resins

10.4.4 For self-supporting substrates where either a bare

that are pH-sensitive.

substrate is to be impregnated with liquid resin (rectangular or

cylindrical form) or where a similar prepreg-type specimen

9. Calibration

forms a rectangular specimen, clamp the substrate in place

9.1 Calibratetheinstrumentusingproceduresrecommended

utilizing the instrument’s grip system.

by the manufacturer for that specific make and model.

10.4.5 Conduct the cure characterization of the submitted

material in accordance with the desired time and temperature

10. Procedure

parameters recording the appropriate property values.

NOTE 5—Precaution: Toxic or corrosive effluents, or both, may be

released when heating the resin specimen to its cured state and could be 10.5 Procedure C—Dynamic Compression:

harmful to personnel or to the instrumentation.

10.5.1 Prepare the test specimen in accordance with the

procedure described in 10.4.2 and 10.4.3.

10.1 Apply the resin or uncured, self-supporting composite

10.5.2 Compress slightly the specimen disk and monitor

onto the test fixture. In the case of two-part room-temperature

and record the preload force by observing the normal force

cureresins,mixingshouldbecarriedoutinlessthan1 %ofthe

gage or indicator.Adjust the gap as necessary to accommodate

expected gel time.

any material expansion or contraction during the thermal

10.2 Out-time effects and moisture-effect data must be

advancement.

recorded and reported.

10.5.3 Conduct the cure characterization of the submitted

10.3 Procedure A—Unsupported Resin:

material in accordance with the desired time and temperature

10.3.1 Allow the sample to equilibrate to room temperature

parameters recording the appropriate property values.

i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.