ASTM D4180-13

(Test Method)Standard Test Method for Vibratory Packing Density of Formed Catalyst Particles and Catalyst Carriers

Standard Test Method for Vibratory Packing Density of Formed Catalyst Particles and Catalyst Carriers

SIGNIFICANCE AND USE

5.1 This test method is to be used for measuring the vibratory packing density of formed particles that will not break up during sampling, filling, or vibrating of the measuring cylinder under test conditions.

SCOPE

1.1 This test method covers the determination of the vibratory packing density of formed catalyst and catalyst carriers. For the purpose of this test, catalyst particles are defined as extrudates, spheres, or formed pellets of 0.8 to 4.8-mm (1/32 to 3/16-in.) nominal diameter.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D4180 − 13

Standard Test Method for

Vibratory Packing Density of Formed Catalyst Particles and

1

Catalyst Carriers

This standard is issued under the fixed designation D4180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers the determination of the vibra- 5.1 This test method is to be used for measuring the

tory packing density of formed catalyst and catalyst carriers. vibratory packing density of formed particles that will not

For the purpose of this test, catalyst particles are defined as break up during sampling, filling, or vibrating of the measuring

1

extrudates, spheres, or formed pellets of 0.8 to 4.8-mm ( ⁄32 to cylinder under test conditions.

3

⁄16-in.) nominal diameter.

6. Apparatus

1.2 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information 6.1 Glass Cylinders, capacity 250 mL, feed and measuring,

conforming to Specification E1272, Class A.

only.

3

1.3 This standard does not purport to address all of the

6.2 Vibrator, conventional handheld, with hard rubber or

safety concerns, if any, associated with its use. It is the metal impactor.

responsibility of the user of this standard to establish appro-

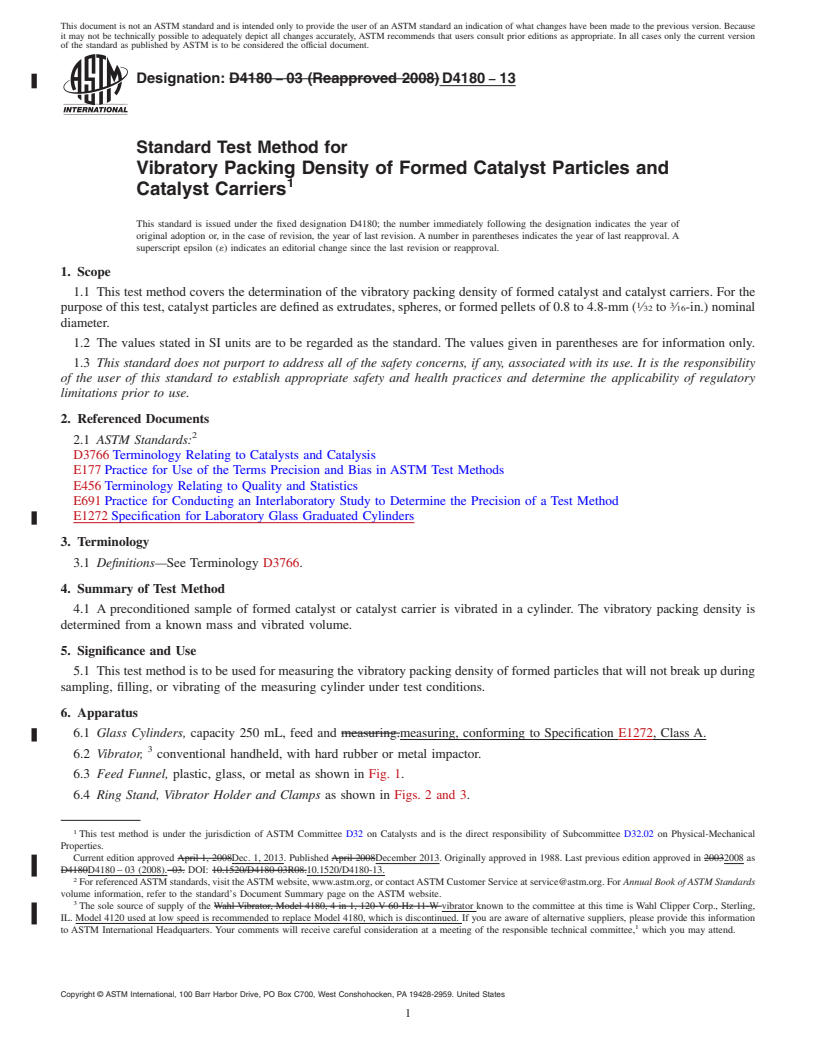

6.3 Feed Funnel, plastic, glass, or metal as shown in Fig. 1.

priate safety and health practices and determine the applica-

6.4 Ring Stand, Vibrator Holder and Clamps as shown in

bility of regulatory limitations prior to use.

Figs. 2 and 3.

2. Referenced Documents

6.5 Desiccator, with a desiccant grade molecular sieve such

2

2.1 ASTM Standards:

as a No. 4A.

D3766 Terminology Relating to Catalysts and Catalysis

6.6 Balance having sensitivity of 0.1 g.

E177 Practice for Use of the Terms Precision and Bias in

6.7 Drying Oven.

ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

7. Procedure

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

7.1 Heat an adequate sample(s) at 400 6 15°C for not less

E1272 Specification for Laboratory Glass Graduated Cylin-

than 3 h. Normally, this treatment can take place in air.

ders

However, in the case of materials that might react with air at

elevated temperatures (such as prereduced catalysts) the heat

3. Terminology

treatment should take place in an inert atmosphere. Cool after

3.1 Definitions—See Terminology D3766.

heating the test sample(s) in a desiccator or other suitable

container to eliminate the possibility of moisture adsorption

4. Summary of Test Method

prior to testing.

4.1 A preconditioned sample of formed catalyst or catalyst

NOTE 1—These conditions may not be appropriate for all materials.

carrier is vibrated in a cylinder. The vibratory packing density

NOTE 2—Since many catalyst formulations are strong adsorbents, the

is determined from a known mass and vibrated volume.

use of a No. 4A indicating (cobalt-treated) molecular sieve as a desiccat-

ing medium is suggested. The desiccant should be regenerated at 220 to

1

260°C as required.

This test method is under the jurisdiction of ASTM Committee D32 on

Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-

Mechanical Properties.

Current edition approved Dec. 1, 2013. Published December 2013. Originally

3

approved in 1988. Last previous edition approved in 2008 as D4180 – 03 (2008). The sole source of supply of the vibrator known to the committee at this time

DOI: 10.1520/D4180-13. is Wahl Clipper Corp., Sterling, IL. Model 4120 used at low speed is recommended

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or to replace Model 4180, which is discontinued. If you are aware of alternative

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM suppliers, please provide this information to ASTM International Headquarters.

Standards volume information, refer to the standard’s Document Summary page on Your comments will receive careful consideration at a meeting of the responsible

1

the ASTM website. technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4180 − 13

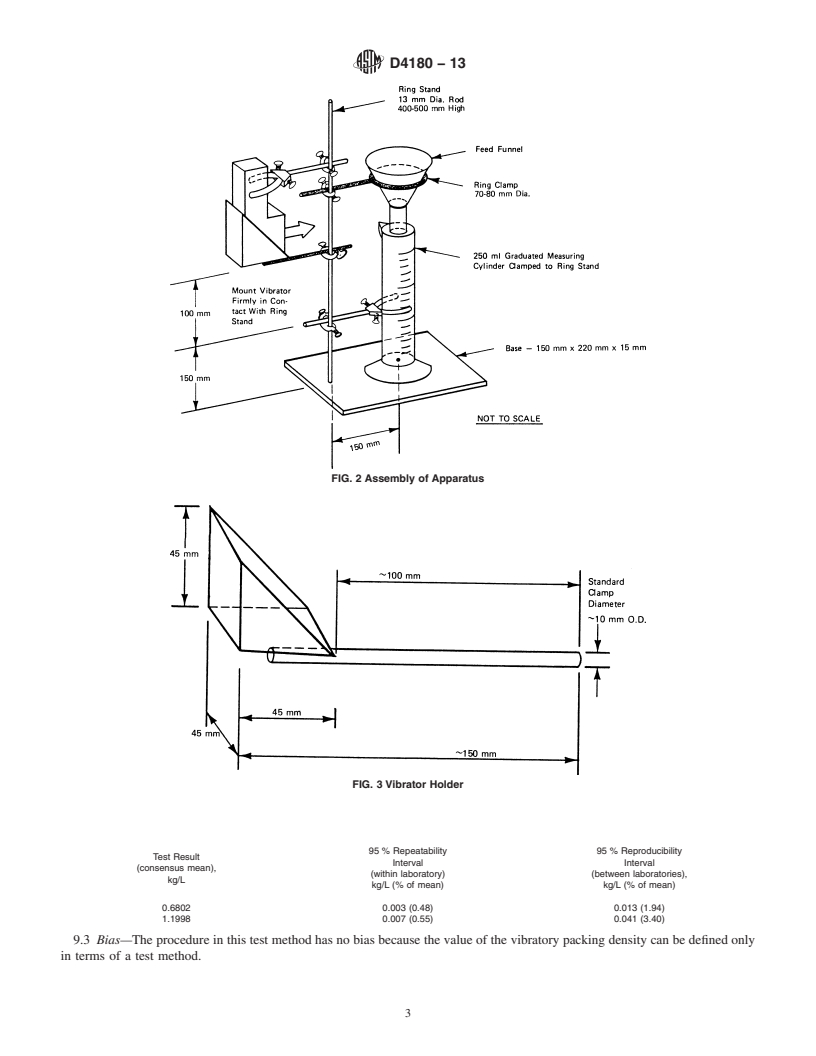

where:

W = mass of catalyst particles, g, and

V = volume occupied by catalyst particles in measuring

cylinder, mL.

8.2 Vibratory packing densities are typically reported to

three significant figures.

4

9. Precision and Bias

9.1 Test Program—An interlaboratory study was conducted

inwhichthenamedpropertywasmeasuredintwoseparatetest

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D4180 − 03 (Reapproved 2008) D4180 − 13

Standard Test Method for

Vibratory Packing Density of Formed Catalyst Particles and

1

Catalyst Carriers

This standard is issued under the fixed designation D4180; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the vibratory packing density of formed catalyst and catalyst carriers. For the

1 3

purpose of this test, catalyst particles are defined as extrudates, spheres, or formed pellets of 0.8 to 4.8-mm ( ⁄32 to ⁄16-in.) nominal

diameter.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D3766 Terminology Relating to Catalysts and Catalysis

E177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E1272 Specification for Laboratory Glass Graduated Cylinders

3. Terminology

3.1 Definitions—See Terminology D3766.

4. Summary of Test Method

4.1 A preconditioned sample of formed catalyst or catalyst carrier is vibrated in a cylinder. The vibratory packing density is

determined from a known mass and vibrated volume.

5. Significance and Use

5.1 This test method is to be used for measuring the vibratory packing density of formed particles that will not break up during

sampling, filling, or vibrating of the measuring cylinder under test conditions.

6. Apparatus

6.1 Glass Cylinders, capacity 250 mL, feed and measuring.measuring, conforming to Specification E1272, Class A.

3

6.2 Vibrator, conventional handheld, with hard rubber or metal impactor.

6.3 Feed Funnel, plastic, glass, or metal as shown in Fig. 1.

6.4 Ring Stand, Vibrator Holder and Clamps as shown in Figs. 2 and 3.

1

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.02 on Physical-Mechanical

Properties.

Current edition approved April 1, 2008Dec. 1, 2013. Published April 2008December 2013. Originally approved in 1988. Last previous edition approved in 20032008 as

D4180D4180 – 03 (2008).–03. DOI: 10.1520/D4180-03R08.10.1520/D4180-13.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The sole source of supply of the Wahl Vibrator, Model 4180, 4 in 1, 120-V 60-Hz 11-W vibrator known to the committee at this time is Wahl Clipper Corp., Sterling,

IL. Model 4120 used at low speed is recommended to replace Model 4180, which is discontinued. If you are aware of alternative suppliers, please provide this information

1

to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D4180 − 13

FIG. 1 Feed Funnel

6.5 Desiccator, with a desiccant grade molecular sieve such as a No. 4A.

6.6 Balance having sensitivity of 0.1 g.

6.7 Drying Oven.

7. Procedure

7.1 Heat an adequate sample(s) at 400 6 15°C for not less than 3 h. Normally, this treatment can take place in air. However,

in the case of materials that might react with air at elevated temperatures (such as prereduced catalysts) the heat treatment should

take place in an inert atmosphere. Cool after heating the test sample(s) in a desiccator or other suitable container to eliminate the

possibility of moisture adsorption prior to testing.

NOTE 1—These conditions may not be appropriate for all materials.

NOTE 2—Since many catalyst formulations are strong adsorbents, the use of a No. 4A indicating (cobalt-treated) molecular sieve

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.