ASTM D5939-96

(Test Method)Standard Test Method for Injection Moulding of Test Specimens of Thermoplatic Materials (Withdrawn 1998)

Standard Test Method for Injection Moulding of Test Specimens of Thermoplatic Materials (Withdrawn 1998)

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5939 – 96

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Preparing Multipurpose Test Specimens and Bars of

1

Thermoplastics by Injection Moulding

This standard is issued under the fixed designation D 5939; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 5942 Test Method for Determining Charpy Impact

3

Strength of Plastics

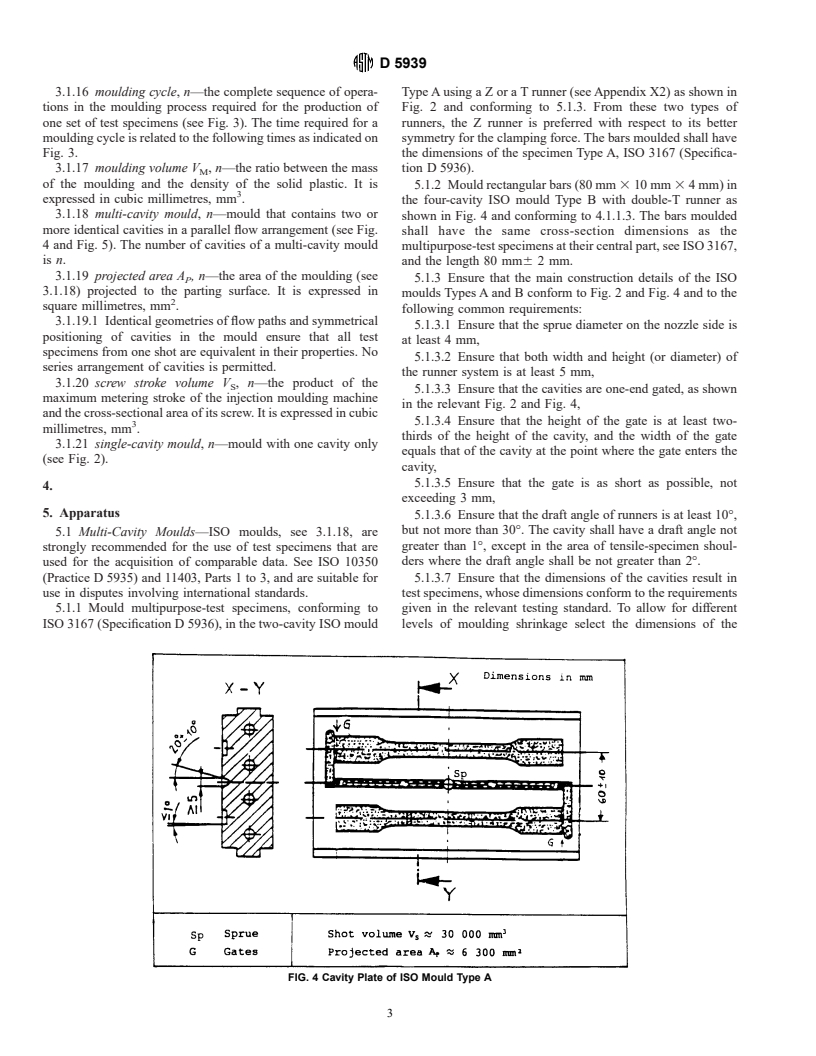

1.1 This practice covers the general principles to be fol-

4

2.2 ISO Standards:

lowed for injection moulding test specimens of thermoplastics

ISO 179:1993 Plastics—Determination of Charpy Impact

and gives details of mould designs for preparing specimen

Strength

types for reference data, that is, for multipurpose-test speci-

ISO 294-1 Injection Moulding of Test Specimens of Ther-

mens according to ISO 3167 (Specification D 5936) and for

moplastic Materials—Part 1: General Principles, Multi-

bars 80 mm 3 10 mm 3 4 mm. This practice provides a basis

purpose Test Specimens and Bars

for establishing reproducible moulding conditions. This prac-

ISO 294-2 Plastics—Injection Moulding of Test Specimens

tice promotes uniformity in describing the various essential

of Thermoplastics—Part 2: Small Tensile Bars (ISO

parameters of the moulding operation and also establishes a

Mould Type C)

uniform practice in reporting moulding conditions. The special

ISO 294-3 Plastics—Injection Moulding of Test Specimens

conditions required to prepare test specimens in a comparable

of Thermoplastics—Part 3: Small Plates (ISO Moulds

and reproducible state will vary for each material used. These

Type D)

conditions are given in the ISO standard for the relevant

ISO 294-4 Plastics—Injection Moulding of Test Specimens

material or are to be agreed upon between interested parties.

of Thermoplastics—Part 4: Determination of Moulding

NOTE 1—ISO round-robin tests with acrylonitrile/butadiene/styrene

Shrinkage

(ABS), styrene/butadiene (S/B) and polymethylmethacrylate (PMMA)

ISO 3167:1993 Plastics—Multipurpose Test Specimens

showed that design of the mould is one of the important factors in

ISO 10350:1993 Plastics—The Acquisition and Presenta-

preparation of test specimens.

tion of Comparable Single-Point Data

1.2 This practice is identical to ISO 294-1. This standard is

ISO 11403-1:1994 Plastics—Acquisition and Presentation

comparable to Practice D 3641 but neither standard should be

of Comparable Multipoint Data—Part 1: Mechanical

substituted for the other.

Properties

1.3 This standard does not purport to address all of the

ISO 11403-2 Plastics—Acquisition and Presentation of

safety concerns, if any, associated with its use. It is the

Comparable Multipoint Data—Part 2: Thermal and Pro-

responsibility of the user of this standard to establish appro-

cessing Properties

priate safety and health practices and determine the applica-

ISO 11403-3 Plastics—Acquisition and Presentation of

bility of regulatory limitations prior to use.

Comparable Multipoint Data—Part 3: Environmental In-

fluences on Properties

2. Referenced Documents

2.1 ASTM Standards:

3. Terminology

D 3641 Practice for Injection Molding Test Specimens of

3.1 Definitions of Terms Specific to This Standard:

2

Thermoplastic Molding and Extrusion Materials

3.1.1 cavity, n—the part of hollow space of the mould that

D 5935 Practice for Plastics—Acquisition and Presentation

forms one specimen.

3

of Comparable Single-Point Data

3.1.2 clamping force F , n—the force clamping the plates

M

D 5936 Specification for Multipurpose Test Specimens

of the mould. It is expressed in kilonewton, kN. The minimum

3

Used for Testing Plastics

clamping force is calculated according to Eq 1.

D 5940 Practice for Preparing Small Plate Test Specimens

23

3

F $ A 3 P 3 10 (1)

of Thermoplastics by Injection Moulding M P max

where:

1

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

and is the direct responsibility of Subcommittee D20.61 on U.S. Technical Advisory

Group for ISO/TC 61 on Plastics.

Current edition approved June 10, 1996. Published August 1996.

2 4

Annual Book of ASTM Standards, Vol 08.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

3

Annual Book of ASTM Standards, Vol 08.03. Floor, New York, NY 10036.

1

---------------------- Page: 1 ----------------------

D 5939

F 5 the clamping force (see 3.1.2), in kN,

M

2

A 5 the projected area (see 3.1.18), in mm , and

P

P 5 the maximum value of the melt pressure (see

max

3.1.12), in MPa.

3.1.3 cooling time t , n—the time from th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.