ASTM A970/A970M-12

(Specification)Standard Specification for Headed Steel Bars for Concrete Reinforcement

Standard Specification for Headed Steel Bars for Concrete Reinforcement

ABSTRACT

This specification covers deformed and plain steel reinforcing bars in cut lengths with a head attached to one or both ends for reinforcing concrete structures. This standard applies only to headed bars with welded, threaded or forged heads. Material, manufacturing and testing requirements for the reinforcing bars shall be in accordance with other ASTM documents listed herein.

SCOPE

1.1 This specification covers deformed steel reinforcing bars in cut lengths, with a head attached to one or both ends, for concrete reinforcement. Heads are forge-formed, machined from bar stock, or cut from plate. Attachment can be accomplished through:

1.1.1 Welding;

1.1.2 Integrally hot forging of a head from the reinforcing bar end;

1.1.3 Internal threads in the head mating to threads on the bar end;

1.1.4 Cold-swaging an externally threaded coupling sleeve onto the reinforcing bar;

1.1.5 Cold-extruding an external coupling sleeve onto the reinforcing bar;

1.1.6 Cold-swaging an external coupling sleeve or headed sleeve onto the reinforcing bar;

1.1.7 Attaching a coupling sleeve to the end of the reinforcing bar by means of the means of a ferrous-filler medium; or

1.1.8 Separate threaded nut to secure the head to the bar.

Note 1—The requirements of this specification are only applicable to headed bars where the attachment of the head is accomplished by one of the methods listed in 1.1.

1.2 Limitations on head dimensions and on obstructions and interruptions of bar deformations on the non-planar features on the bearing face of the head are presented in Annex A1. The requirements in Annex A1 only apply when specified by the purchaser (see 4.1.13).

1.3 This specification is applicable for orders in either inch-pound units as Specification A970 or SI units as Specification A970M.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification.

1.5 This specification does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A970/A970M −12

StandardSpecification for

1

Headed Steel Bars for Concrete Reinforcement

This standard is issued under the fixed designationA970/A970M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* shall be used independently of the other. Combining values

from the two systems may result in non-conformance with the

1.1 This specification covers deformed steel reinforcing

specification.

barsincutlengths,withaheadattachedtooneorbothends,for

1.5 This specification does not purport to address all of the

concrete reinforcement. Heads are forge-formed, machined

safety concerns, if any, associated with its use. It is the

from bar stock, or cut from plate. Attachment can be accom-

responsibility of the user of this standard to establish appro-

plished through:

priate safety and health practices and determine the applica-

1.1.1 Welding;

bility of regulatory limitations prior to use.

1.1.2 Integrally hot forging of a head from the reinforcing

bar end;

2. Referenced Documents

1.1.3 Internal threads in the head mating to threads on the

2

2.1 ASTM Standards:

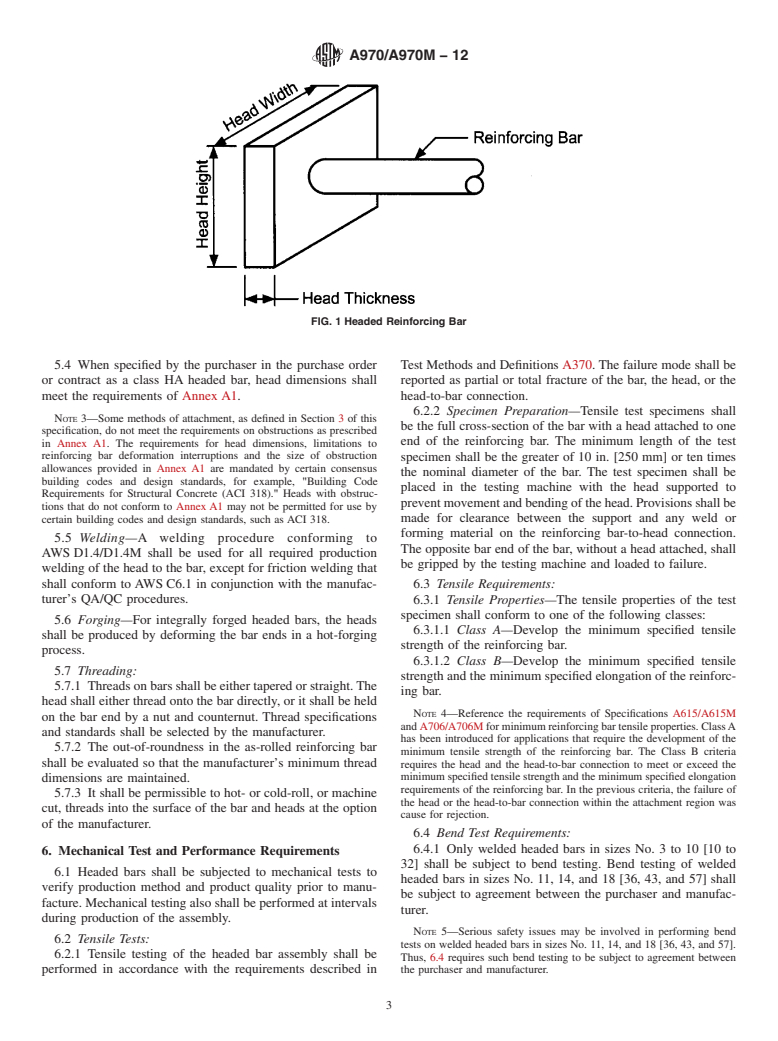

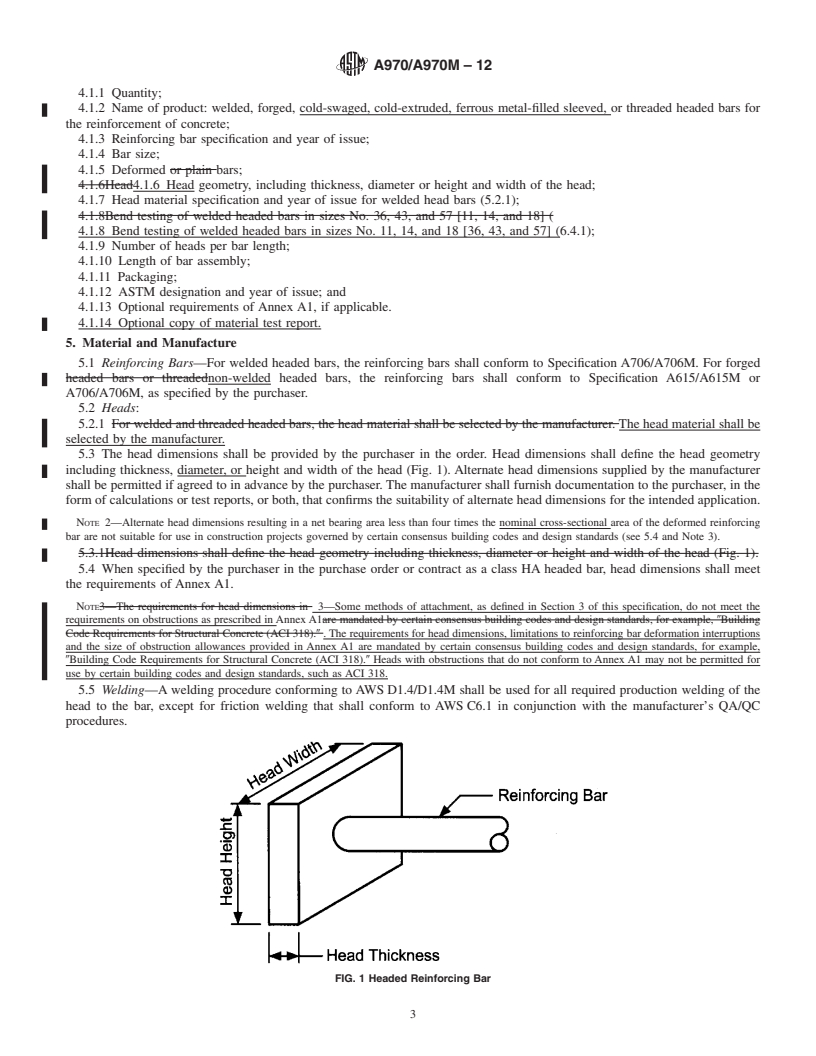

bar end;

A370 Test Methods and Definitions for Mechanical Testing

1.1.4 Cold-swaging an externally threaded coupling sleeve

of Steel Products

onto the reinforcing bar;

A615/A615M Specification for Deformed and Plain Carbon-

1.1.5 Cold-extruding an external coupling sleeve onto the

Steel Bars for Concrete Reinforcement

reinforcing bar;

A700 Practices for Packaging, Marking, and Loading Meth-

1.1.6 Cold-swaging an external coupling sleeve or headed

ods for Steel Products for Shipment

sleeve onto the reinforcing bar;

A706/A706M Specification for Low-Alloy Steel Deformed

1.1.7 Attaching a coupling sleeve to the end of the reinforc-

and Plain Bars for Concrete Reinforcement

ing bar by means of the means of a ferrous-filler medium; or

3

2.2 AWS Standards:

1.1.8 Separate threaded nut to secure the head to the bar.

AWS C6.1 Recommended Practices for Friction Welding

NOTE 1—The requirements of this specification are only applicable to

AWS D1.4/D1.4M Structural Welding Code - Reinforcing

headed bars where the attachment of the head is accomplished by one of

Steel

the methods listed in 1.1.

4

2.3 U.S. Military Standard:

1.2 Limitations on head dimensions and on obstructions and

MIL-STD-129 Marking for Shipment and Storage

interruptions of bar deformations on the non-planar features on

4

2.4 U.S. Federal Standard:

the bearing face of the head are presented in Annex A1. The

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

requirements in Annex A1 only apply when specified by the

5

2.5 ACI Standard:

purchaser (see 4.1.13).

ACI 318 Building Code Requirements for Structural Con-

1.3 This specification is applicable for orders in either

crete

inch-pound units as Specification A970 or SI units as Specifi-

3. Terminology

cation A970M.

3.1 Definitions:

1.4 The values stated in either inch-pound units or SI units

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

system may not be exact equivalents; therefore, each system

contact ASTM customer service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

1

This specification is under the jurisdiction of ASTM A01 on Steel, Stainless Miami, FL 33126, http://www.aws.org.

4

Steel and Related Alloys and is the direct responsibility of A01.05 on Steel Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Reinforcement. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS. Or visit: http://

Current edition approved Feb. 15, 2012. Published August 2012. Originally assist.daps.dla.mil/online.

5

approved in 1997. Last previous edition approved in 2009 as A970/A970M – 09. Available fromAmerican Concrete Institute (ACI), P.O. Box 9094, Farmington

DOI: 10.1520/A0970_A0970M-12. Hills, MI 48333-9094, http://www.concrete.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A970/A970M−12

3.1.1 cold-extruded coupling sleeve headed bar—(similar to 3.1.8 net bearing area—gross cross-sectional area of the

cold-swaged threaded coupling sleeve headed bar); steel rein- head minus the nominal cross-sectional area of the deforme

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A970/A970M–09 Designation: A970/A970M – 12

Standard Specification for

1

Headed Steel Bars for Concrete Reinforcement

This standard is issued under the fixed designationA970/A970M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1This specification covers deformed and plain steel reinforcing bars in cut lengths, with a head attached to one or both ends,

for concrete reinforcement. Attachment can be accomplished through welding, by integrally hot forging of a head from the

reinforcing bar end, by internal threads in the head mating to threads on the bar end, or by a separate threaded nut to secure the

head to the bar. Heads are forge formed, machined from bar stock, or cut from plate.

1.1 This specification covers deformed steel reinforcing bars in cut lengths, with a head attached to one or both ends, for

concrete reinforcement. Heads are forge-formed, machined from bar stock, or cut from plate. Attachment can be accomplished

through:

1.1.1 Welding;

1.1.2 Integrally hot forging of a head from the reinforcing bar end;

1.1.3 Internal threads in the head mating to threads on the bar end;

1.1.4 Cold-swaging an externally threaded coupling sleeve onto the reinforcing bar;

1.1.5 Cold-extruding an external coupling sleeve onto the reinforcing bar;

1.1.6 Cold-swaging an external coupling sleeve or headed sleeve onto the reinforcing bar;

1.1.7 Attaching a coupling sleeve to the end of the reinforcing bar by means of the means of a ferrous-filler medium; or

1.1.8 Separate threaded nut to secure the head to the bar.

NOTE1—This specification is applicable for headed bars produced with welded, threaded, or forged heads and used for reinforcement of concrete

structures. The requirements of this specification are not applicable to headed bars where the attachment of the head is accomplished by alternate means.

1.2Limitations on head dimensions and on obstructions and interruptions of bar deformations on the non-planar features on the

bearing face of the head are presented in 1—The requirements of this specification are only applicable to headed bars where the

attachment of the head is accomplished by one of the methods listed in 1.1.

1.2 Limitations on head dimensions and on obstructions and interruptions of bar deformations on the non-planar features on the

bearing face of the head are presented in Annex A1. The requirements in Annex A1 only apply when specified by the purchaser

(see 4.1.13).

1.3 This specification is applicable for orders in either SIinch-pound units as SpecificationA970MA970 or inch-poundSI units

shown in the text in brackets [Specification A970]. as Specification A970M.

1.4 The values stated in either SIinch-pound units or inch-poundSI units are to be regarded separately as standard. Within the

text,theSIunitsareshowninbrackets.Thevaluesstatedineachsystemmaynotbeexactequivalents;therefore,eachsystemshall

be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

specification.

1.5 This standardspecification does not purport to address all of the safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of

regulatory limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A615/A615M Specification for Deformed and Plain Carbon-Steel Bars for Concrete Reinforcement

A700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Shipment

A706/A706M Specification for Low-Alloy Steel Deformed and Plain Bars for Concrete Reinforcement

1

This specification is under the jurisdiction ofASTMA01 on Steel, Stainless Steel and RelatedAlloys and is the direct responsibility ofA01.05 on Steel Reinforcement.

Current edition approved Nov.Feb. 15, 2009.2012. Published December 2009.August 2012. Originally approved in 1997. Last previous edition approved in 20072009 as

A970/A970M – 079. DOI: 10.1520/A0970_A0970M-0912.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM customer service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.