ASTM D3840-99

(Specification)Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Fittings for Nonpressure Applications

Standard Specification for "Fiberglass" (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe Fittings for Nonpressure Applications

SCOPE

1.1 This specification covers fiberglass pipe fittings intended for use in gravity flow systems for conveying sanitary sewage, storm water, and those industrial wastes for which the fittings are determined to be suitable. Elbows, tees, laterals, crosses, reducers, and adapters are included. Both glass-fiber-reinforced and thermosetting-resin pipe (RTRP) and glass-fiber-reinforced plastic mortar pipe (RPMP) are fiberglass pipes.

Note 1—For the purpose of this standard, polymer does not include natural polymers.

1.2 This specification is intended to cover only dimensions, material properties, and workmanship rather than the structural design of the fittings. The structural design of the fittings shall be as agreed upon between purchaser and supplier and should take into consideration the anticipated conditions of installation and service.

1.3 This specification covers only fittings fabricated from cut sections of pipe, or from a combination of pipe sections and contact molded (hand layup), or machine fabricated components.

1.4 The values given in parentheses are provided for information purposes only.

1.5 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification. This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 2 —There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 3840 – 99

Standard Specification for

“Fiberglass” (Glass-Fiber-Reinforced Thermosetting-Resin)

Pipe Fittings for Nonpressure Applications

This standard is issued under the fixed designation D 3840; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * D 1763 Specification for Epoxy Resins

D 2290 Test Method for Apparent Tensile Strength of Ring

1.1 This specification covers fiberglass pipe fittings in-

or Tubular Plastics and Reinforced Plastics by Split Disk

tended for use in gravity flow systems for conveying sanitary

Method

sewage, storm water, and those industrial wastes for which the

D 3262 Specification for “Fiberglass’’ (Glass-Fiber-

fittings are determined to be suitable. Elbows, tees, laterals,

Reinforced Thermosetting-Resin) Sewer Pipe

crosses, reducers, and adapters are included. Both glass-fiber-

D 3567 Practice for Determining Dimensions of Fiberglass

reinforced and thermosetting-resin pipe (RTRP) and glass-

(Glass-Fiber-Reinforced Thermosetting Resin) Pipe and

fiber-reinforced plastic mortar pipe (RPMP) are fiberglass

Fittings

pipes.

D 3892 Practice for Packaging/Packing of Plastics

1.2 This specification is intended to cover only dimensions,

F 412 Terminology Relating to Plastic Piping Systems

material properties, and workmanship rather than the structural

F 477 Specification for Elastomeric Seals (Gaskets) for

design of the fittings. The structural design of the fittings shall

Joining Plastic Pipe

be as agreed upon between purchaser and supplier and should

take into consideration the anticipated conditions of installation

3. Terminology

and service.

3.1 Definitions:

1.3 This specification covers only fittings fabricated from

3.1.1 General—Definitions are in accordance with Termi-

cut sections of pipe, or from a combination of pipe sections and

nologies D 883 and F 412. Abbreviations are in accordance

contact molded (hand layup), or machine fabricated compo-

with Terminology D 1600, unless otherwise indicated.

nents.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values given in parentheses are provided for infor-

3.2.1 fiberglass pipe—a tubular product containing glass

mation purposes only.

fiber reinforcements embedded in or surrounded by cured

1.5 The following safety hazards caveat pertains only to the

thermosetting resin. The composite structure may contain

test method portion, Section 11, of this specification. This

aggregate, granular or platelet fillers, thixotropic agents, pig-

standard does not purport to address all of the safety concerns,

ments or dyes. Thermoplastic or thermosetting liners or coat-

if any, associated with its use. It is the responsibility of the user

ings may be included.

of this standard to establish appropriate safety and health

3.2.2 reinforced plastic mortar pipe—a fiberglass pipe with

practices and determine the applicability of regulatory limita-

aggregate.

tions prior to use.

3.2.3 reinforced thermosetting resin pipe—a fiberglass pipe

NOTE 1—There is no similar or equivalent ISO standard.

without aggregate.

3.2.4 qualification—One or more tests used to prove the

2. Referenced Documents

design of a product. Not a routine quality control test.

2.1 ASTM Standards:

NOTE 2—Qualification requirements appear in 6.1, 7.2, and 12.3.

D 638 Test Method for Tensile Properties of Plastics

D 883 Terminology Relating to Plastics

4. Materials

D 1600 Terminology for Abbreviated Terms Relating to

2 4.1 Laminating Resin:

Plastics

4.1.1 Type 1—Polyester thermosetting resin, with or with-

out fillers or thixotropic agents or both.

This specification is under the jurisdiction of ASTM Committee D-20 on

Plastics and is the direct responsibility of Subcommittee D 20.23 on Reinforced

NOTE 3—For the purpose of this standard, polyester includes vinyl ester

Plastic Piping Systems and Chemical Equipment.

resins.

Current edition approved July 10, 1999. Published October 1999. Originally

published as D 3840 – 79. Last previous edition D 3840 – 88 (1994). This specifi-

cation replaces Specification D 4160.

Annual Book of ASTM Standards, Vol 08.02.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 08.04.

Annual Book of ASTM Standards, Vol 08.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

D 3840

4.1.2 Type 2—Epoxy resin, conforming to the requirements 5.2 Bonding and Laminate Overlay Reinforcements:

of Specification D 1763, with or without fillers or thixotropic

5.2.1 Sections of the fitting shall be aligned and bonded

agents, or both.

together using polyester (Type 1) or epoxy (Type 2) resin

4.2 Reinforcement:

materials with or without fiberglass reinforcement. Fiberglass

4.2.1 Grade 1 —A commercial grade of glass fibers with a

reinforcement materials shall be compatible with the laminat-

polyester-compatible finish.

ing resin; Grade 1 reinforcements shall be used with Type 1

4.2.2 Grade 2—A commercial grade of glass fibers with an

laminating resin, and Grade 2 reinforcements shall be used

epoxy-compatible finish.

with Type 2 laminating resin.

4.3 Gaskets—The elastomeric gaskets used with the fittings

5.2.2 Laminated reinforcing overlays of bonded seams may

joined to pipe shall conform to the requirements of Specifica-

be applied to either the outside or inside surface of the fitting,

tion F 477.

or to both inside and outside surfaces. The laminate shall be of

chemically resistant construction suitable for the purpose and

5. Fabrication

shall provide the additional strength necessary to meet the

5.1 Permissible Components:

physical requirements shown in Table 1. Finished seam over-

5.1.1 Fittings covered under this specification shall be

lays shall be built up in two or more successive layers of

fabricated from cut section of pipe that conform to the

reinforcement and shall be as crevice free as described in this

requirements of Specification D 3262, or from a combination

paragraph and 5.2.3. The width of the first layer shall be 2 in.

of such pipe sections and contact molded (hand layup) or

(50 mm) minimum. Successive layers shall increase uniformly

machine fabricated components.

in width to provide the specified minimum total width of

5.1.2 Saddles, wrappers, necked flanges, and other compo-

overlay that shall be centered on the seam. Table 1 shows

nents of metal or other dissimilar materials may be incorpo-

minimum widths of overlays required. The ends of each layer

rated as agreed upon between purchaser and supplier, provided

the materials of such components are resistant to the corrosive of reinforcement shall be overlapped a minimum of 1 in. (25

mm). Crevices between joined sections shall be filled with a

effects of the internal and external environments anticipated in

service, or are lined or coated or both with materials that filled resin paste, leaving a smooth inner surface. The interior

provide equivalent protection. of the seams shall also be sealed by covering with not less than

TABLE 1 Minimum Properties of Structural Laminates

Nominal Diameter, in. (mm) Minimum Hoop Tensile Minimum Axial Tensile Minimum Total Width of

B

Strength, lbf/in. (kN/m) of Strength, lbf/in. (kN/m) Overlay, in. (mm)

A A

width of circumference

8 (203) 1600 (280) 1600 (280) 4 (100)

10 (254) 1600 (280) 1600 (280) 4 (100)

12 (305) 1600 (280) 1600 (280) 4 (100)

14 (356) 1600 (280) 1600 (280) 4 (100)

15 (381) 1600 (280) 1600 (280) 4 (100)

16 (406) 1600 (280) 1600 (280) 4 (100)

18 (457) 1600 (280) 1600 (280) 4 (100)

20 (508) 1600 (280) 1600 (280) 4 (100)

21 (533) 1600 (280) 1600 (280) 4 (100)

24 (610) 1600 (280) 1600 (280) 4 (100)

27 (686) 1600 (280) 1600 (280) 4 (100)

30 (762) 1600 (280) 1600 (280) 4 (100)

33 (838) 1700 (300) 1700 (300) 6 (150)

36 (914) 1800 (315) 1800 (315) 6 (150)

39 (991) 2000 (350) 2000 (350) 6 (150)

42 (1067) 2100 (368) 2100 (368) 6 (150)

45 (1143) 2300 (403) 2300 (403) 6 (150)

48 (1219) 2400 (420) 2400 (420) 8 (200)

51 (1295) 2600 (455) 2600 (455) 8 (200)

54 (1372) 2700 (473) 2700 (473) 8 (200)

60 (1524) 3000 (525) 3000 (525) 8 (200)

66 (1676) 3300 (578) 3300 (578) 10 (250)

72 (1829) 3600 (630) 3600 (630) 10 (250)

78 (1981) 3900 (683) 3900 (683) 10 (250)

84 (2134) 4200 (736) 4200 (736) 12 (300)

90 (2286) 4500 (788) 4500 (788) 12 (300)

96 (2438) 4800 (841) 4800 (841) 14 (350)

102 (2591) 5100 (893) 5100 (893) 16 (400)

108 (2743) 5400 (946) 5400 (946) 16 (400)

114 (2896) 5700 (998) 5700 (998) 16 (400)

120 (3048) 6000 (1051) 6000 (1051) 16 (400)

132 (3353) 6600 (1156) 6600 (1156) 18 (450)

144 (3658) 7200 (1261) 7200 (1261) 20 (500)

A

The values given are minimums only. Sound engineering practice dictates that all fittings be designed to withstand the loads and conditions anticipated in the service

for which they are intended.

B

The dimensions given are minimums for“ butt-and-strap’’ type joints.

D 3840

A

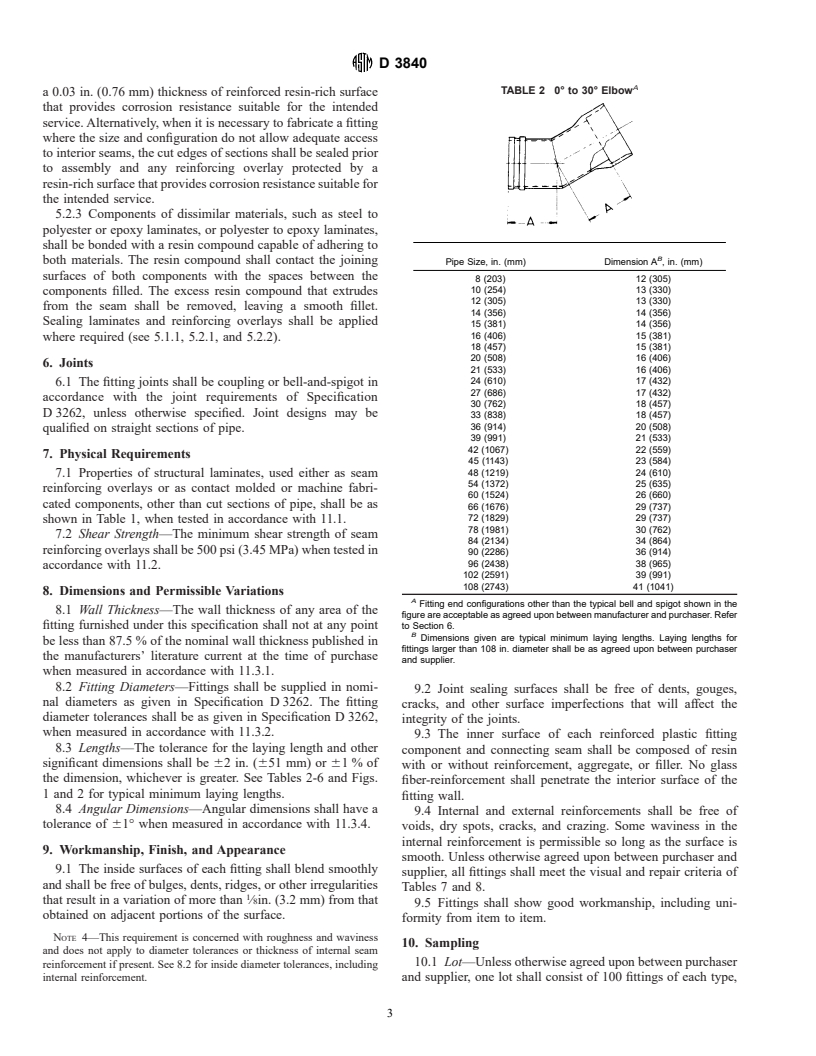

TABLE 2 0° to 30° Elbow

a 0.03 in. (0.76 mm) thickness of reinforced resin-rich surface

that provides corrosion resistance suitable for the intended

service. Alternatively, when it is necessary to fabricate a fitting

where the size and configuration do not allow adequate access

to interior seams, the cut edges of sections shall be sealed prior

to assembly and any reinforcing overlay protected by a

resin-rich surface that provides corrosion resistance suitable for

the intended service.

5.2.3 Components of dissimilar materials, such as steel to

polyester or epoxy laminates, or polyester to epoxy laminates,

shall be bonded with a resin compound capable of adhering to

B

both materials. The resin compound shall contact the joining Pipe Size, in. (mm) Dimension A , in. (mm)

surfaces of both components with the spaces between the

8 (203) 12 (305)

10 (254) 13 (330)

components filled. The excess resin compound that extrudes

12 (305) 13 (330)

from the seam shall be removed, leaving a smooth fillet.

14 (356) 14 (356)

Sealing laminates and reinforcing overlays shall be applied

15 (381) 14 (356)

16 (406) 15 (381)

where required (see 5.1.1, 5.2.1, and 5.2.2).

18 (457) 15 (381)

20 (508) 16 (406)

6. Joints

21 (533) 16 (406)

24 (610) 17 (432)

6.1 The fitting joints shall be coupling or bell-and-spigot in

27 (686) 17 (432)

accordance with the joint requirements of Specification

30 (762) 18 (457)

D 3262, unless otherwise specified. Joint designs may be

33 (838) 18 (457)

36 (914) 20 (508)

qualified on straight sections of pipe.

39 (991) 21 (533)

42 (1067) 22 (559)

7. Physical Requirements

45 (1143) 23 (584)

48 (1219) 24 (610)

7.1 Properties of structural laminates, used either as seam

54 (1372) 25 (635)

reinforcing overlays or as contact molded or machine fabri-

60 (1524) 26 (660)

cated components, other than cut sections of pipe, shall be as

66 (1676) 29 (737)

72 (1829) 29 (737)

shown in Table 1, when tested in accordance with 11.1.

78 (1981) 30 (762)

7.2 Shear Strength—The minimum shear strength of seam

84 (2134) 34 (864)

reinforcing overlays shall be 500 psi (3.45 MPa) when tested in

90 (2286) 36 (914)

96 (2438) 38 (965)

accordance with 11.2.

102 (2591) 39 (991)

108 (2743) 41 (1041)

8. Dimensions and Permissible Variations

A

Fitting end configurations other than the typical bell and spigot shown in the

8.1 Wall Thickness—The wall thickness of any area of the

figure are acceptable as agreed upon between manufacturer and purchaser. Refer

fitting furnished under this specification shall not at any point to Section 6.

B

Dimensions given are typical minimum laying lengths. Laying lengths for

be less than 87.5 % of the nominal wall thickness published in

fittings larger than 108 in. diameter shall be as agreed upon between purchaser

the manufacturers’ literature current at the time of purchase

and supplier.

when measured in accordance with 11.3.1.

8.2 Fitting Diameters—Fittings shall be supplied in nomi-

9.2 Joint sealing surfaces shall be free of dents, gouges,

nal diameters as given in Specification D 3262. The fitting

cracks, and other surface imperfections that will affect the

diameter tolerances shall be as given in Specification D 3262,

integrity of the joints.

when measured in accordance with 11.3.2.

9.3 The inner surface of each reinforced plastic fitting

8.3 Lengths—The tolerance for the laying length and other

component and connecting seam shall be composed of resin

significant dimensions shall be 62 in. (651 mm) or 61% of

with or without reinforcement, aggregate, or filler. No glass

the dimension, whichever is greater. See Tables 2-6 and Figs.

fiber-reinforcement shall penetrate the interior surface of the

1 and 2 for typical minimum laying lengths.

fitting wall.

8.4 Angular Dimensions—Angular dimensions shall have a

9.4 Internal and external reinforcements shall be free of

tolerance of 61° when measured in accordance with 11.3.4.

voids, dry spots, cracks, and crazing. Some waviness in the

internal reinforcement is permissible so long as the surface is

9. Workmanship, Finish, and Appearance

smooth. Unless otherwise agreed upon between purchaser and

9.1 The inside surfaces of each fitting shall blend smoothly

supplier, all fittings shall meet the visual and repair criteria of

and shall be free of bulges, dents, ridges, or other irregularities

Tables 7 and 8.

that result in a variation of more than ⁄8in. (3.2 mm) from that

9.5 Fittings shall show good workmanship, including uni-

obtained on adjacent portions of the surface.

formity from item to item.

NOTE 4—This requirement is concerned with roughness and waviness

10. Sampling

and does not apply to diameter tolerances or thickness of internal seam

10.1 Lot—Unless otherwise agreed upon between purchaser

reinforcement if present. See 8.2 for inside diameter tolerances, including

internal reinforcement. and supplier, one lot shall consist of 100 fittings of each type,

D 3840

A A

TABLE 3 31° to 60° Elbow TABLE 4 61° to 90° Elbow

B

Pipe Size, in. Dimension C , R1 (45°), in.

(mm) in. (mm) (mm)

8 (203) 18.5 (470) 12.0 (305)

B

Pipe Size, in. Dimension E , R2 (90°), in.

10 (254) 19.5 (495) 15.0 (381)

(mm) in. (mm) (mm)

12 (305) 20.5 (521) 18.0 (457)

14 (356) 22.0 (559) 21.0 (533)

8 (203) 26.0 (660) 12.0 (305)

15 (381) 22.5 (572) 22.5 (572)

10 (254) 28.5 (724) 15.0 (381)

16 (406) 23.0 (584) 24.0 (610)

12 (305) 31.0 (787) 18.0 (457)

18 (457) 25.0 (635) 27.0 (686)

14 (356) 34.5 (876) 21.0 (533)

20 (508) 25.5 (648) 30.0 (762)

15 (381) 35.5 (902) 22.5 (572)

21 (533) 26.0 (660) 31.5 (800)

16 (406) 37.0 (940) 24.0 (610)

24 (610) 27.5 (699) 36.0 (914)

18 (

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.