ASTM D2202-00

(Test Method)Standard Test Method for Slump of Sealants

Standard Test Method for Slump of Sealants

SCOPE

1.1 This test method covers a laboratory procedure for the determination of the degree of slump of a sealant when used in a vertical joint in a structure.

1.2 The values stated in either inch-pound or SI (metric) units are to be separately regarded as the standard. Within the text, the inch-pound units are shown in parentheses.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2202–00

Standard Test Method for

Slump of Sealants

This standard is issued under the fixed designation D 2202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Apparatus

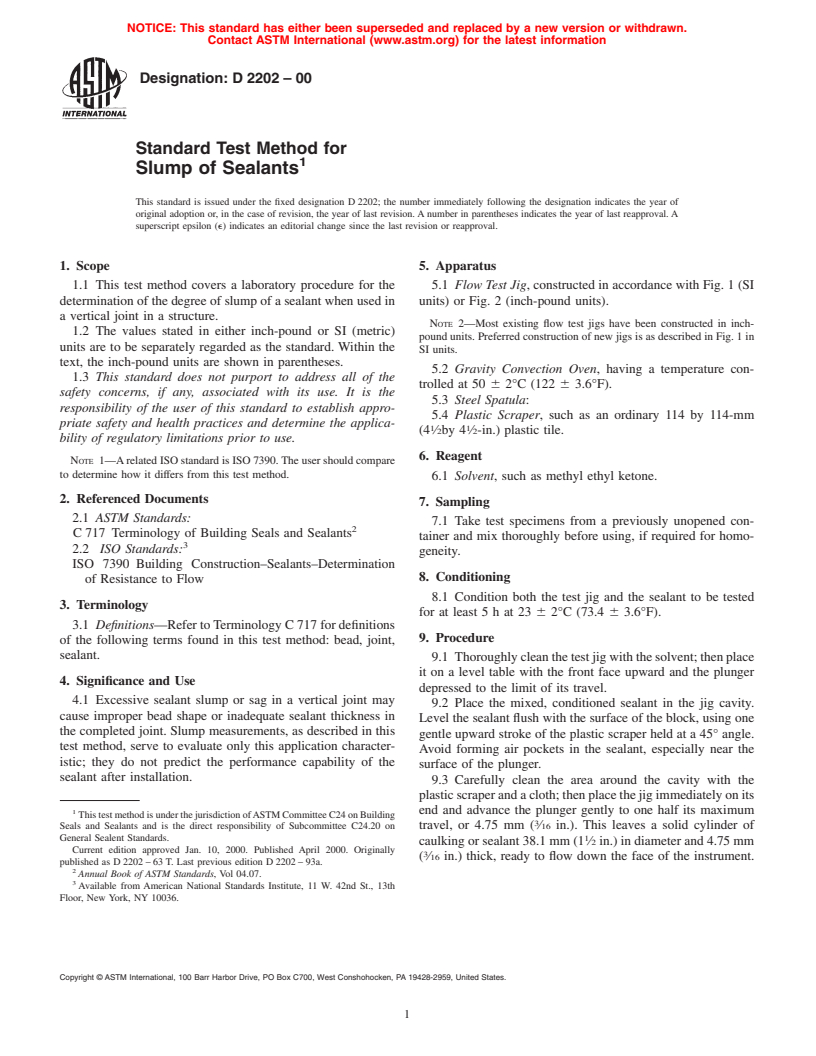

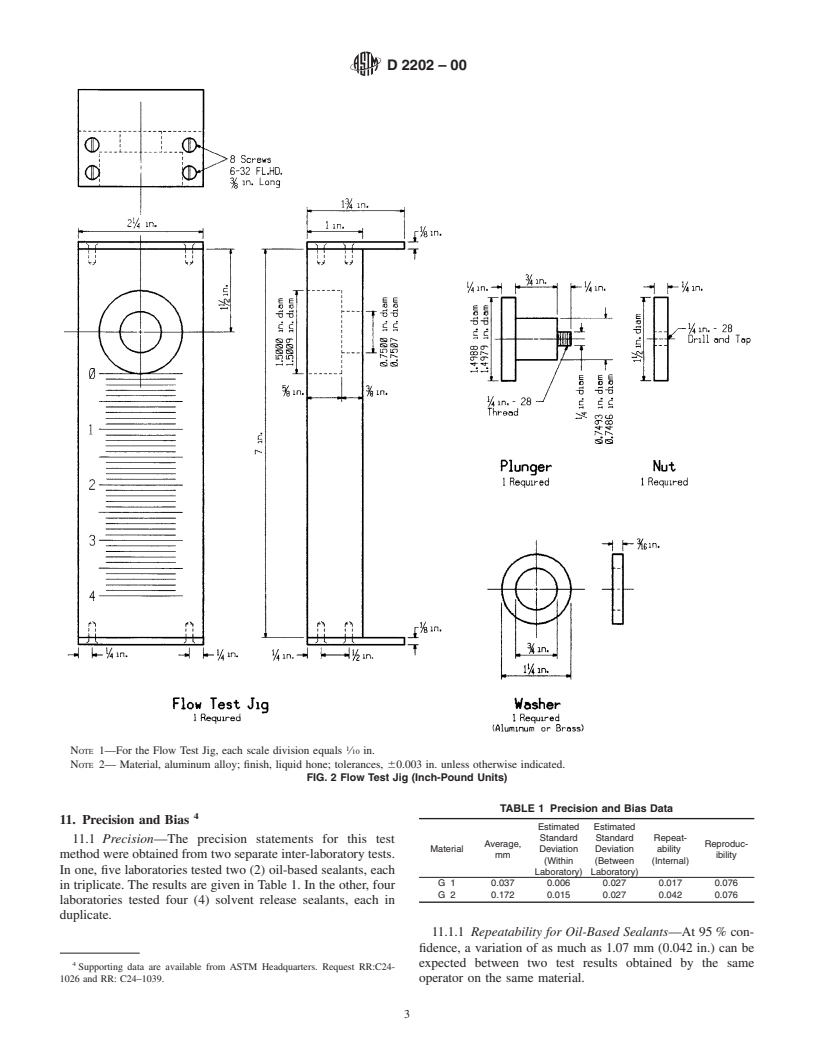

1.1 This test method covers a laboratory procedure for the 5.1 Flow Test Jig, constructed in accordance with Fig. 1 (SI

determination of the degree of slump of a sealant when used in units) or Fig. 2 (inch-pound units).

a vertical joint in a structure.

NOTE 2—Most existing flow test jigs have been constructed in inch-

1.2 The values stated in either inch-pound or SI (metric)

pound units. Preferred construction of new jigs is as described in Fig. 1 in

units are to be separately regarded as the standard. Within the

SI units.

text, the inch-pound units are shown in parentheses.

5.2 Gravity Convection Oven, having a temperature con-

1.3 This standard does not purport to address all of the

trolled at 50 6 2°C (122 6 3.6°F).

safety concerns, if any, associated with its use. It is the

5.3 Steel Spatula:

responsibility of the user of this standard to establish appro-

5.4 Plastic Scraper, such as an ordinary 114 by 114-mm

priate safety and health practices and determine the applica-

1 1

(4 ⁄2by 4 ⁄2-in.) plastic tile.

bility of regulatory limitations prior to use.

6. Reagent

NOTE 1—Arelated ISO standard is ISO 7390.The user should compare

to determine how it differs from this test method.

6.1 Solvent, such as methyl ethyl ketone.

2. Referenced Documents

7. Sampling

2.1 ASTM Standards:

7.1 Take test specimens from a previously unopened con-

C 717 Terminology of Building Seals and Sealants

tainer and mix thoroughly before using, if required for homo-

2.2 ISO Standards:

geneity.

ISO 7390 Building Construction–Sealants–Determination

8. Conditioning

of Resistance to Flow

8.1 Condition both the test jig and the sealant to be tested

3. Terminology

for at least5hat23 6 2°C (73.4 6 3.6°F).

3.1 Definitions—Refer toTerminology C 717 for definitions

9. Procedure

of the following terms found in this test method: bead, joint,

sealant.

9.1 Thoroughlycleanthetestjigwiththesolvent;thenplace

it on a level table with the front face upward and the plunger

4. Significance and Use

depressed to the limit of its travel.

4.1 Excessive sealant slump or sag in a vertical joint may

9.2 Place the mixed, conditioned sealant in the jig cavity.

cause improper bead shape or inadequate sealant thickness in

Level the sealant flush with the surface of the block, using one

the completed joint. Slump measurements, as described in this

gentle upward stroke of the plastic scraper held at a 45° angle.

test method, serve to evaluate only this application character-

Avoid forming air pockets in the sealant, especially near the

istic; they do not predict the performance capability of the

surface of the plunger.

sealant after installation.

9.3 Carefully clean the area around the cavity with the

plasticscraperandacloth;thenplacethejigimmediatelyonits

1 end and advance the plunger gently to one half its maximum

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

Seals and Sealants and is the direct responsibility of Subcommittee C24.20 on travel, or 4.75 mm ( ⁄16 in.). This leaves a solid cylinder of

General Sealent Standards.

caulking or sealant 38.1 mm (1 ⁄2 in.) in diameter and 4.75 mm

Current edition approved Jan. 10, 2000. Published April 2000. Originally

( ⁄16 in.) thick, ready to flow down the face of the instrument.

published as D 2202 – 63 T. Last previous edition D 2202 – 93a.

Annual Book of ASTM Standards, Vol 04.07.

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2202–00

NOTE 1—For the Flow Test Jig, each scale division equals 2 mm.

NOTE 2— Material, aluminum alloy; finish, liquid ho

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.