ASTM C1311-22

(Specification)Standard Specification for Solvent Release Sealants

Standard Specification for Solvent Release Sealants

ABSTRACT

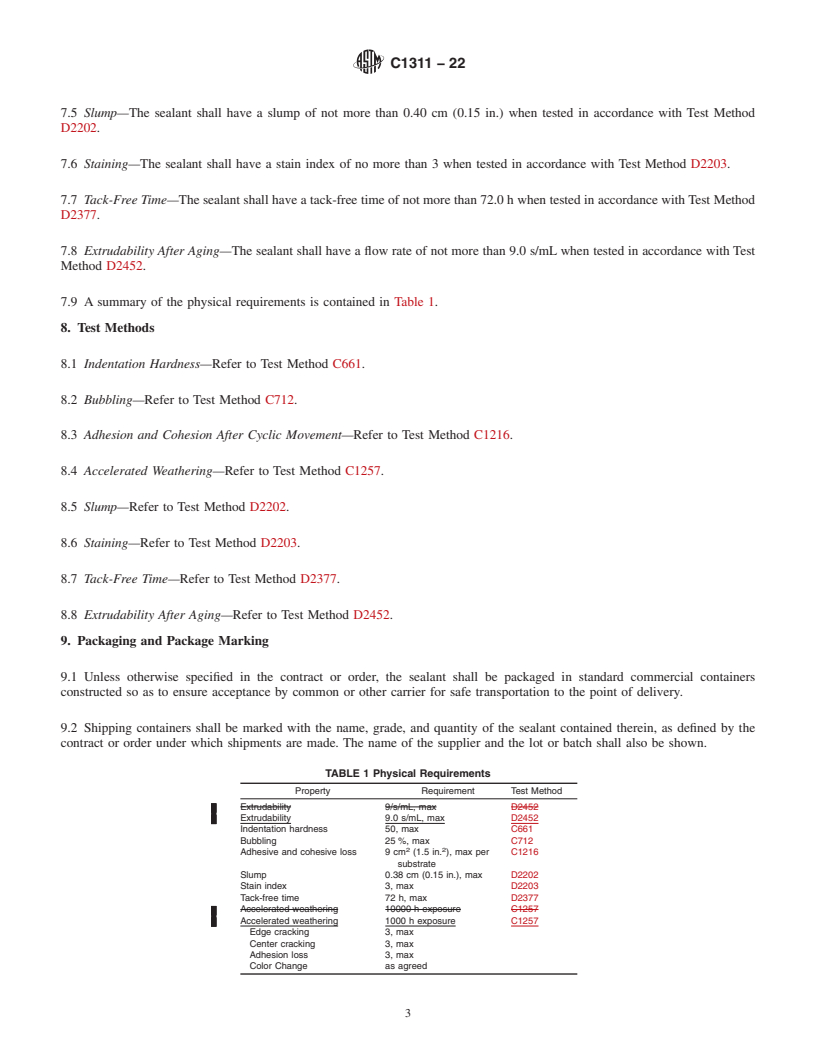

This specification describes the properties of one-component solvent release sealants for use in building construction. These sealants are generally formulated to withstand a specified maximum joint movement in extension and compression of the nominal joint width. The sealants shall be tested, and is expected to conform to the following physical properties: extrudability after aging, shore A hardness, indentation hardness, bubbling, adhesive and cohesive loss after cyclic movement, slump, stain index, tack-free time, and accelerated weathering (edge cracking, center cracking, adhesion loss, and color change).

SIGNIFICANCE AND USE

6.1 This specification describes solvent release sealants for general caulking and sealing operations in building construction. However, it should be recognized by the user that not all sealants meeting this specification are suitable for all applications and all substrates and that there is no implication that the sealants are equivalent in all physical properties.

6.2 Refer to Guide C1193 for information on the proper use of sealants meeting this specification.

SCOPE

1.1 This specification describes the properties of a one-component solvent release sealant for use in building construction. These sealants are generally formulated to withstand a maximum joint movement of 7.5 % in extension and 7.5 % in compression of the nominal joint width.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The committee with jurisdiction of this specification is not aware of any similar specification within ISO or any other organization.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:C1311 −22

Standard Specification for

1

Solvent Release Sealants

This standard is issued under the fixed designation C1311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2202 Test Method for Slump of Sealants

D2203 Test Method for Staining from Sealants

1.1 This specification describes the properties of a one-

D2377 Test Method for Tack-Free Time of Caulking Com-

component solvent release sealant for use in building construc-

pounds and Sealants

tion. These sealants are generally formulated to withstand a

D2452 TestMethodforExtrudabilityofOil-andResin-Base

maximum joint movement of 7.5 % in extension and 7.5 % in

Caulking Compounds

compression of the nominal joint width.

1.2 The values stated in SI units are to be regarded as the

3. Terminology

standard. The values given in parentheses are for information

3.1 Definitions—Definitions of the following terms used in

only.

this specification are found in Terminology C717: adhesive

1.3 The committee with jurisdiction of this specification is

failure (adhesion loss), caulk (v), compound, durometer,

not aware of any similar specification within ISO or any other

hardness, joint, primer, seal, sealant, sealing material, solvent

organization.

release sealant, and standard conditions.

1.4 This international standard was developed in accor-

4. Materials and Manufacture

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

4.1 The sealing compound shall be a solvent release mate-

Development of International Standards, Guides and Recom-

rial compounded to conform to the requirements prescribed in

mendations issued by the World Trade Organization Technical this specification.

Barriers to Trade (TBT) Committee.

4.2 All material and workmanship shall be in accordance

with good commercial practice. The producer is permitted a

2. Referenced Documents

wide latitude in choice of raw materials for making these

2

2.1 ASTM Standards:

products. Consequently, there is no implication that the com-

C661 Test Method for Indentation Hardness of Elastomeric-

pounds are equivalent in all physical properties.

Type Sealants by Means of a Durometer

4.3 The manufacturing process shall be such as will ensure

C712 Test Method for Bubbling of One-Part, Elastomeric,

a homogeneous mix, free of defects that would affect

Solvent-Release Type Sealants

serviceability, and of a consistency suitable for immediate

C717 Terminology of Building Seals and Sealants

application.

C1193 Guide for Use of Joint Sealants

C1216 Test Method forAdhesion and Cohesion of One-Part

5. General Requirements

Elastomeric Solvent Release Sealants

5.1 Standard Conditions—Perform all of the tests in a

C1257 Test Method for Accelerated Weathering of Solvent-

controlled environment at standard conditions. Condition seal-

Release-Type Sealants

ant samples for at least5hat these conditions before any tests

C1442 Practice for Conducting Tests on Sealants Using

are performed.

Artificial Weathering Apparatus

5.2 The sealant in the original container shall be suitable for

use for at least 12 months from the date of manufacture when

1

This specification is under the jurisdiction of ASTM Committee C24 on

stored at a temperature neither below 5 °C (41.0 °F) nor

Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10

exceeding 27 °C (80.6 °F).

on Specifications, Guides and Practices.

Current edition approved June 1, 2022. Published June 2022. Originally

5.3 The color of the sealant shall be as agreed upon between

approved in 1995. Last previous edition approved in 2014 as C1311–14. DOI:

the purchaser and the manufacturer.

10.1520/C1311-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.4 The sealant shall be intended for use only on clean, dry

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

surfaces. When a primer is recommended by a manufacturer

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. for a specific substrate, all tests on that substrate shall include

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1311−22

the primer. The proper use of primers (or surface conditioners) 7.8 ExtrudabilityAfterAging—The sealant shall have a flow

with the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: C1311 − 14 C1311 − 22

Standard Specification for

1

Solvent Release Sealants

This standard is issued under the fixed designation C1311; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification describes the properties of a one-component solvent release sealant for use in building construction. These

sealants are generally formulated to withstand a maximum joint movement of 7.5 % in extension and 7.5 % in compression of the

nominal joint width.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The committee with jurisdiction of this specification is not aware of any similar specification within ISO or any other

organization.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

C661 Test Method for Indentation Hardness of Elastomeric-Type Sealants by Means of a Durometer

C712 Test Method for Bubbling of One-Part, Elastomeric, Solvent-Release Type Sealants

C717 Terminology of Building Seals and Sealants

C1193 Guide for Use of Joint Sealants

C1216 Test Method for Adhesion and Cohesion of One-Part Elastomeric Solvent Release Sealants

C1257 Test Method for Accelerated Weathering of Solvent-Release-Type Sealants

C1442 Practice for Conducting Tests on Sealants Using Artificial Weathering Apparatus

D2202 Test Method for Slump of Sealants

D2203 Test Method for Staining from Sealants

D2377 Test Method for Tack-Free Time of Caulking Compounds and Sealants

D2452 Test Method for Extrudability of Oil- and Resin-Base Caulking Compounds

3. Terminology

3.1 Definitions—Definitions of the following terms used in this specification are found in Terminology C717: adhesive failure

(adhesion loss), caulk (v), compound, durometer, hardness, joint, primer, seal, sealant, sealing material, solvent release sealant, and

standard conditions.

1

This specification is under the jurisdiction of ASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10 on

Specifications, Guides and Practices.

Current edition approved June 1, 2014June 1, 2022. Published July 2014June 2022. Originally approved in 1995. Last previous edition approved in 20102014 as

C1311–10.–14. DOI: 10.1520/C1311-14.10.1520/C1311-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C1311 − 22

4. Materials and Manufacture

4.1 The sealing compound shall be a solvent release material compounded to conform to the requirements prescribed in this

specification.

4.2 All material and workmanship shall be in accordance with good commercial practice. The producer is permitted a wide latitude

in choice of raw materials for making these products. Consequently, there is no implication that the compounds are equivalent in

all physical properties.

4.3 The manufacturing process shall be such as will ensure a homogeneous mix, free of defects that would affect serviceability,

and of a consistency suitable for immediate application.

5. General Requirements

5.1 Standard Conditions—Perform all of the tests in a controlled environment at standard conditions. Condition sealant samples

for at least 5 h at these conditions before any tests are performed.

5.2 The sealant in the original container shall be suitable for use for at least 12 months from the date of manufacture when stored

at a temperature neither below 5°C (41.0°F)5 °C (41.0 °F) nor exceeding 27°C (80.6°F).27 °C (80.6 °F).

5.3 The color of the sealant shall be as agreed upon between the purchaser and the manufacturer.

5.4 The sealant shall be intended for use only on clean, dry surfaces. When a primer is recommended by a manufactu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.