ASTM B901-01

(Specification)Standard Specification for Compressed Round Stranded Aluminum Conductors Using Single Input Wire Construction

Standard Specification for Compressed Round Stranded Aluminum Conductors Using Single Input Wire Construction

SCOPE

1.1 This specification covers aluminum 1350-H19 (extra hard), 1350-H16 or -H26 (3/4 hard), 1350-H14 or -H24 (1/2 hard), 1350-H142 or -H242 (1/2 hard), and aluminum alloy 8XXX series as listed in Specification B 800 for tempers "O" and H1X or H2X, bare stranded conductors composed of one or more roller shaped or die compressed layers of helically layed wires. The conductors are for general use for electrical purposes (Explanatory Note 1 and Note 2).Note 1—For the purposes of this specification, single input wire (SIW) construction is defined as follows: a stranded conductor design methodology that varies the number of wires within a range of conductor sizes in order to permit that range of conductor sizes to be constructed from a single wire size.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.Note 2—Prior to 1975, aluminum 1350 was designated as EC aluminum.Note 3—The aluminum and temper designations conform to ANSI H35.1. Aluminum 1350 corresponds to Unified Numbering System A91350 in accordance with Practice E 527. Aluminum alloys in the 8000 series correspond to Unified Numbering System A98XXX in accordance with Practice E 527.

Note 4—This specification also permits conductors for use as covered or insulated electrical conductors.

Note 5—Sealed conductors, which are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within the guidelines of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 901 – 01

Standard Specification for

Compressed Round Stranded Aluminum Conductors Using

Single Input Wire Construction

This standard is issued under the fixed designation B 901; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Standards:

B 193 Test Method for Resistivity of Electrical Conductor

1.1 This specification covers aluminum 1350-H19 (extra

3 1 Materials

hard), 1350-H16 or -H26 ( ⁄4 hard), 1350-H14 or -H24 ( ⁄2

B 230/B 230M Specification for Aluminum 1350–H19

hard), 1350-H142 or -H242 ( ⁄2 hard), and aluminum alloy

Wire for Electrical Purposes

8XXX series as listed in Specification B 800 for tempers “O”

B 263 Test Method for Determination of Cross-Sectional

and H1X or H2X, bare stranded conductors composed of one

Area of Stranded Conductors

or more roller shaped or die compressed layers of helically

B 354 Terminology Relating to Uninsulated Metallic Elec-

layed wires. The conductors are for general use for electrical

trical Conductors

purposes (Explanatory Notes 1 and 2).

B 609 Specification for Aluminum 1350 Round Wire, An-

NOTE 1—For the purposes of this specification, single input wire (SIW) 2

nealed and Intermediate Tempers, for Electrical Purposes

construction is defined as follows: a stranded conductor design method-

B 800 Specification for 8000 Series Aluminum Alloy Wire

ology that varies the number of wires within a range of conductor sizes in

for Electrical Purposes—Annealed and Intermediate Tem-

order to permit that range of conductor sizes to be constructed from a

pers

single wire size.

B 801 Specification for Concentric-Lay-Stranded Conduc-

1.2 The values stated in inch-pound or SI units are to be

tors of 8000 Series Aluminum Alloy for Subsequent

regarded separately as standard. The values in each system are

Covering or Insulation

not exact equivalents; therefore, each system shall be used

E 29 Practice for Using Significant Digits in Test Data to

independently of the other. Combining values from the two

Determine Conformance with Specifications

systems may result in nonconformance with the specification.

E 527 Practice for Numbering Metals and Alloys (UNS)

1.2.1 For density, resistivity, and temperature, the values

2.3 Other Standards:

stated in SI units are to be regarded as standard.

ANSI H35.1 American National Standard Alloy and Tem-

NOTE 2—Prior to 1975, aluminum 1350 was designated as EC alumi-

per Designation System for Aluminum

num.

NBS Handbook 100—Copper Wire Tables

NOTE 3—The aluminum and temper designations conform to ANSI

H35.1. Aluminum 1350 corresponds to Unified Numbering System

3. Classification

A91350 in accordance with Practice E 527. Aluminum alloys in the 8000

3.1 The conductors described in this specification are in-

series correspond to Unified Numbering System A98XXX in accordance

tended for subsequent insulation or covering. The classification

with Practice E 527.

NOTE 4—This specification also permits conductors for use as covered of these conductors is SIW compressed.

or insulated electrical conductors.

4. Ordering Information

NOTE 5—Sealed conductors, which are intended to prevent longitudinal

water propagation and are further covered/insulated, are also permitted

4.1 Orders for material under this specification shall include

within the guidelines of this specification.

the following information:

4.1.1 Quantity,

2. Referenced Documents

4.1.2 Conductor size: circular-mil area of AWG (see Section

2.1 The following documents of the issue in effect on the

8 and Table 1),

date of material purchase form a part of this specification to the

extent referenced herein.

Annual Book of ASTM Standards, Vol 02.03.

Annual Book of ASTM Standards, Vol 14.02.

1 4

This specification is under the jurisdiction of ASTM Committee B01 of Annual Book of ASTM Standards, Vol 01.01.

5 nd th

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Available from American National Standards Institute, 11 W 42 Street, 13

Conductors of Light Metals. Floor, New York, NY 10017.

Current edition approved Oct. 10, 2001. Published November 2001. Originally Available from National Technical Information Service, 5285 Port Royal Road,

published as B 901 – 00. Last previous edition B 901 – 00. Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 901

TABLE 1 Construction Requirements of Compressed Round SIW Stranded

Aluminum Conductors

Conductor Size Hard Drawn Copper Nominal Nominal

Equivalent Diameter of Diameter of

Minimum SIW Com- SIW Com-

Number pressed pressed DC Resistance at

of Conductor Conductor Mass 20°C

2 2

cmils AWG mm cmils AWG mm Wires in. mm lb/1000ft kg/km V/1000ft V/km

4 000 000 2027 2 520 000 1277 217 2.168 55.07 3823 5688 0.00442 0.0145

3 500 000 1773 2 200 000 1115 169 2.028 51.51 3345 4977 0.00505 0.0166

3 000 000 1520 1 890 000 957.7 169 1.878 47.69 2839 4225 0.00584 0.0192

2 500 000 1267 1 570 000 795.5 127 1.714 43.54 2366 3521 0.00701 0.0230

2 000 000 1013 1 260 000 638.5 127 1.533 38.94 1875 2789 0.00867 0.0284

1 900 000 962.7 1 195 000 605.5 127 1.494 37.95 1781 2650 0.00913 0.0300

1 800 000 912.1 1 132 000 573.6 127 1.454 36.93 1687 2510 0.00963 0.0316

1 750 000 886.7 1 101 000 557.9 127 1.434 36.42 1640 2441 0.0099 0.0325

1 700 000 861.4 1 069 000 541.7 127 1.413 35.89 1593 2371 0.0102 0.0335

1 600 000 810.7 1 006 000 509.7 127 1.371 34.82 1500 2232 0.0109 0.0358

1 500 000 760.1 943 000 477.8 90 1.327 33.71 1406 2092 0.0116 0.0381

1 400 000 709.4 880 000 445.9 90 1.282 32.56 1312 1953 0.0124 0.0407

1 300 000 658.7 818 000 414.5 90 1.236 31.39 1218 1813 0.0133 0.0436

1 250 000 633.4 786 000 398.3 90 1.212 30.78 1172 1743 0.0138 0.0453

1 200 000 608.0 755 000 382.6 90 1.187 30.15 1125 1674 0.0144 0.0472

1 100 000 557.4 692 000 350.6 90 1.137 28.88 1030 1533 0.0158 0.0518

1 000 000 506.7 629 000 318.7 53 1.084 27.53 937 1395 0.0173 0.0568

900 000 456.0 566 000 286.8 53 1.028 26.11 844 1255 0.0193 0.0633

800 000 405.4 503 000 254.9 53 0.969 24.61 750 1116 0.0217 0.0712

750 000 380.0 472 000 239.2 53 0.939 23.85 703 1046 0.0231 0.0758

700 000 354.7 440 000 223.0 34 0.907 23.04 656 976 0.0248 0.0814

650 000 329.4 409 000 207.2 34 0.874 22.20 609 907 0.0267 0.0876

636 000 322.3 400 000 202.7 34 0.865 21.96 596 887 0.0273 0.0896

600 000 304.0 377 000 191.0 34 0.840 21.34 562 837 0.0289 0.0948

550 000 278.7 346 000 175.3 34 0.804 20.42 516 767 0.0315 0.103

500 000 253.4 314 000 159.1 30 0.766 19.46 469 697 0.0347 0.114

477 000 241.7 300 000 152.0 30 0.747 18.96 447 665 0.0364 0.119

450 000 228.0 283 000 143.4 30 0.727 18.47 422 628 0.0385 0.126

400 000 202.7 252 000 127.7 24 0.685 17.40 375 558 0.0434 0.142

350 000 177.3 220 000 111.5 24 0.641 16.28 328 488 0.0495 0.162

336 400 170.5 211 600 0000 107.2 18 0.629 15.96 315 469 0.0516 0.169

300 000 152.0 188 700 95.62 18 0.594 15.09 281 418 0.0578 0.190

266 800 135.2 167 800 000 85.03 18 0.560 14.22 250 372 0.0650 0.213

250 000 126.7 157 200 79.65 18 0.542 13.77 234 349 0.0694 0.228

211 600 0000 107.2 133 100 00 67.44 17 0.498 12.65 198 295 0.082 0.269

167 800 000 85.03 105 600 0 53.51 15 0.443 11.25 157 234 0.103 0.338

133 100 00 67.44 83 690 1 42.41 11 0.395 10.03 125 186 0.130 0.426

105 600 0 53.51 66 360 2 33.63 7 0.352 8.94 99.0 147 0.164 0.538

83 690 1 42.41 52 620 3 26.66 7 0.313 7.95 78.4 117 0.207 0.679

66 360 2 33.63 41 740 4 21.15 6 0.283 7.19 62.2 92.6 0.261 0.856

52 620 3 26.66 33 090 5 16.77 6 0.252 6.40 49.3 73.4 0.330 1.08

41 740 4 21.15 26 240 6 13.30 6 0.225 5.72 39.1 58.2 0.416 1.36

33 090 5 16.77 20 820 7 10.55 6 0.200 5.08 31.0 46.2 0.523 1.72

26 240 6 13.30 16 510 8 8.366 6 0.178 4.52 24.6 36.6 0.661 2.17

20 820 7 10.55 13 090 9 6.633 6 0.159 4.04 19.5 29.0 0.834 2.74

16 510 8 8.366 10 380 10 5.260 6 0.142 3.61 15.5 23.0 1.05 3.44

13 090 9 6.633 8 234 11 4.172 6 0.126 3.20 12.3 18.3 1.32 4.33

10 380 10 5.260 6 530 12 3.309 6 0.113 2.87 9.73 14.5 1.67 5.48

6 530 12 3.309 4 110 14 2.083 6 0.089 2.26 6.12 9.11 2.67 8.76

4 110 14 2.083 2 580 16 1.307 6 0.071 1.80 3.85 5.73 4.22 13.8

2 580 16 1.307 1620 18 0.8209 6 0.054 1.37 2.42 3.60 6.71 22.0

1 620 18 0.8209 1020 20 0.5168 6 0.043 1.09 1.52 2.26 10.7 35.1

1 020 20 0.5168 642 22 0.3253 6 0.034 0.86 0.96 1.42 16.9 55.4

4.1.3 Alloy designation, 4.1.10 Heavy wood lagging, if required (see 19.2), and

4.1.4 Class (see 3.1), 4.1.11 Place of inspection (see Section 18).

4.1.5 Temper (see 5.1 and 5.3),

5. Requirements for Wires

4.1.6 Details of special-purpose lays, when required (see 7.2

and 7.3), 5.1 The purchaser shall designate the temper of conductors

4.1.7 When tension tests are required on the completed of SIW compressed or SIW conductor.

conductor (see Section 15), 5.1.1 For conductor tempers other than H19, the manufac-

4.1.8 Package size (see 19.1), turer shall have the following options on manufacturing

4.1.9 Special package marking, if required (see Section 20), method:

B 901

5.1.1.1 Strand the conductor from wires drawn to final nominal wire diameters and the specified minimum average

temper; tensile strength given in Specification B 800 for 8000 series

5.1.1.2 Strand the conductor from wires drawn to H19 wire.

temper and annealed to final temper prior to stranding; or 9.3 Calculations for rated strengths of 1350-H16, -H26,

5.1.1.3 Strand the conductor from H19 wires and anneal the -H14, -H24, -H142, and -H242 conductors shall be made on

stranded conductor to final temper. the basis of the strengths of the component wires, using the

5.2 Before stranding, the aluminum wire used shall meet the nominal wire diameters and the specified maximum and

requirements of Specifications B 230/B 230M, B 609, or minimum tensile strengths for the appropriate temper of the

B 800, whichever is applicable. respective component wires given in Specification B 609. The

5.3 All wires in the conductor shall be of the same temper. minimum rated strengths of the conductors shall be taken as the

sum of the calculated minimum strengths of the component

6. Joints

wires multiplied by the rating factor given in Table 2. The

maximum rated strength of the conductors shall be taken as the

6.1 Only cold-pressure joints or electric-butt, cold-upset

sum of the calculated maximum strength of the component

joints may be made in the wires of SIW compressed or SIW

wires multiplied by the rating factors given in Table 2.

conductor.

9.4 Calculations for rated strengths of 8000 series “O”

6.2 The minimum distance between joints in the wires of the

temper H1X and H2X conductors shall be made on the basis of

completed conductor shall be no less than 1 ft (0.3 m).

the strengths of the component wires, using the nominal wire

diameter for the noncompacted construction and the specified

7. Lay

maximum and minimum tensile strengths of the appropriate

7.1 For SIW compressed stranded conductors manufactured

temper of the respective component wires given in Specifica-

for subsequent covering or insulating, the average lay length of

tion B 800. The minimum rated strengths of the conductors

the wires shall be not less than 8, nor more than 16, times the

shall be taken as the sum of the calculated minimum strengths

outer diameter of the finished conductor. For conductors of 37

of the component wires multiplied by the rating factor given in

wires or more, this requirement shall apply to the wires in the

Specification B 801. The maximum rated strength of the

outer two layers only, unless otherwise agreed upon.

conductors shall be taken as the sum of the calculated

7.2 Other lays for special purposes shall be furnished by

maximum strengths of the component wires.

special agreement between the manufacturer and the purchaser

9.5 Rated-strength and breaking-strength values shall be

(Explanatory Note 3).

rounded to three significant figures, in the final value only, in

7.3 For conductors manufactured for subsequent covering

accordance with the rounding method of Practice E 29.

or insulating, the direction of lay of the outer layer shall be left

hand and may be reversed or unidirectional/unilay in succes-

10. Density

sive layers, unless otherwise specified by the purchaser.

10.1 For the purpose of calculating mass, cross sections,

etc., the density of aluminum 1350 shall be taken as 0.0975

8. Construction

3 3

lb/in. (2705 kg/m ) at 20°C. The density of 8000 series

3 3

8.1 The areas of cross section, the minimum number of

aluminum alloys shall be taken as 0.098 lb/in. (2.710 g/cm )at

wires, and diameters of the finished strand shall conform to the

20°C.

requirements prescribed in Table 1.

11. Mass and Electrical Resistance

9. Rated Strength of Conductor

11.1 The mass and electrical resistance of a unit length of a

9.1 The rated strength of 1350-H19 conductors shall be stranded conductor are a function of the length of lay. The

approximate mass and electrical resistance may be determined

taken as the percent, indicated in Table 2, of the sum of the

using the standard increments shown in Table 3. When greater

strengths of the component wires, calculated using the nominal

accuracy is desired, the increment based on the specific lay of

wire diameters and the specified minimum average tensile

the conductor may be calculated (Explanatory Note 6).

strength given in Specification B 230/B 230M for 1350-H19

11.2 The maximum electrical resistance of a unit length of

wire.

stranded conductor shall not exceed 2 % over the nominal dc

9.2 The rated strengths of 8000 series conductors shall be

taken as the percent, indicated in Specification B 801, of the resistance shown in Table 1 (Explanatory Note 8). When dc

resistance is measured at other than 20°C, it is to be corrected

sum of strengths of the component wires, calculated using the

by using the multiplying factor given in Table 4.

A

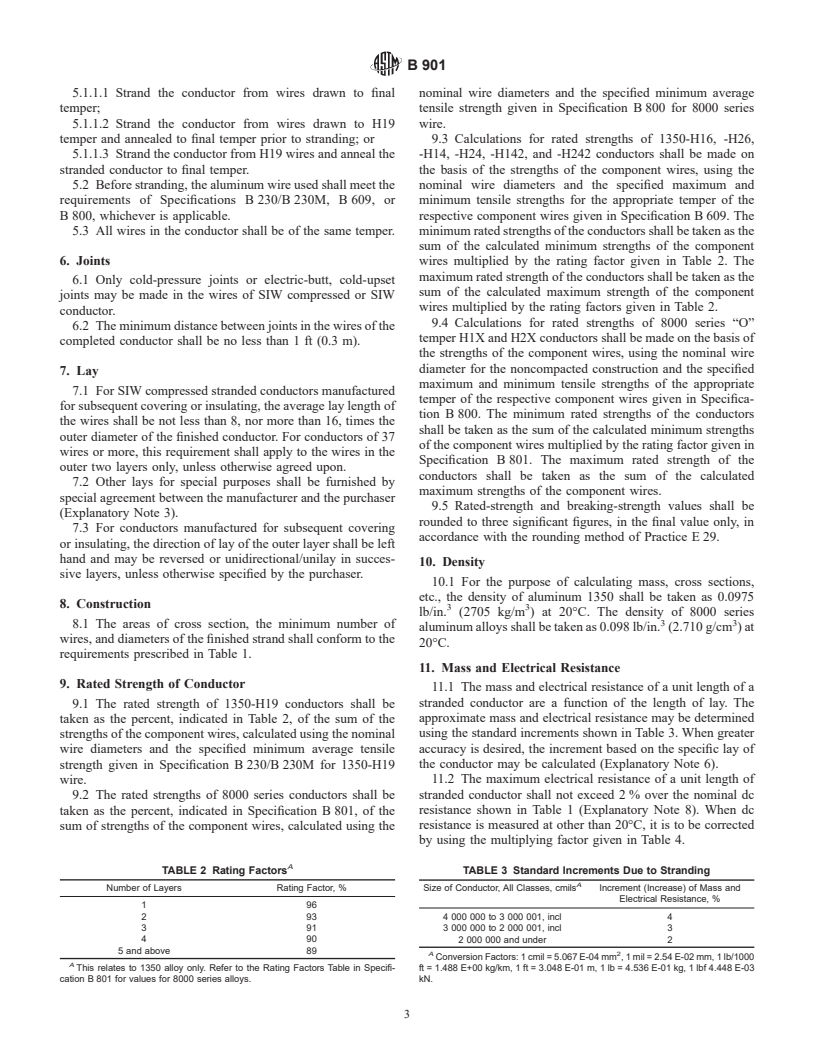

TABLE 2 Rating Factors TABLE 3 Standard Increments Due to Stranding

A

Number of Layers Rating Factor, % Size of Conductor, All Classes, cmils Increment (Increase) of Mass and

Electrical Resistance, %

293 4 000 000 to 3 000 001, incl 4

391 3 000 000 to 2 000 001, incl 3

490 2 000 000 and under 2

5 and above 89

A 2

Conversion Factors: 1 cmil = 5.067 E-04 mm , 1 mil = 2.54 E-02 mm, 1 lb/1000

A

This relates to 1350 alloy only. Refer to the Rating Factors Table in Specifi- ft = 1.488 E+00 kg/km, 1 ft = 3.048 E-01 m, 1 lb = 4.536 E-01 kg, 1 lbf 4.448 E-03

cation B 801 for values for 8000 series alloys. kN.

B 901

TABLE 4 Temperature Correction Factors

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.