ASTM E619-17

(Practice)Standard Practice for Evaluating Foreign Odors and/or Flavors from Paper Packaging

Standard Practice for Evaluating Foreign Odors and/or Flavors from Paper Packaging

SIGNIFICANCE AND USE

3.1 Use—This practice should be used by assessors, trained as described in ASTM STP 758,2 under the direction of a knowledgeable panel leader.

3.2 Significance—This practice can be used to evaluate type and intensity of indigenous and foreign odors and/or flavors in paper packaging materials. A knowledgeable panel leader may be able to determine the source of a foreign odor/flavor from the information obtained from this procedure.

SCOPE

1.1 This practice covers the evaluation of odors in paper packaging and establishes smelling and testing procedures for trained sensory panels.

1.2 This practice covers the evaluation of odors and flavors transferred to various food media from paper packaging.

1.3 This practice covers effective techniques for determining the type and source of the odor/flavor and establishing the severity of the off-note.

1.4 The techniques used in this practice are applicable to all paper packaging products and to auxiliary components, such as coatings, inks, and adhesives, as well as plastic materials used in conjunction with paper.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E619 − 17

Standard Practice for

Evaluating Foreign Odors and/or Flavors from Paper

1

Packaging

This standard is issued under the fixed designation E619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope of a numerical rating scale and also attempt to give a

qualitative description of the off-odor and/or off flavor. The

1.1 This practice covers the evaluation of odors in paper

assembled observations are then interpreted by the panel

packaging and establishes smelling and testing procedures for

leader.

trained sensory panels.

1.2 This practice covers the evaluation of odors and flavors

3. Significance and Use

transferred to various food media from paper packaging.

3.1 Use—This practice should be used by assessors, trained

1.3 This practice covers effective techniques for determin-

2

as described in ASTM STP 758, under the direction of a

ing the type and source of the odor/flavor and establishing the

knowledgeable panel leader.

severity of the off-note.

3.2 Significance—This practice can be used to evaluate type

1.4 The techniques used in this practice are applicable to all

and intensity of indigenous and foreign odors and/or flavors in

paper packaging products and to auxiliary components, such as

paper packaging materials. A knowledgeable panel leader may

coatings, inks, and adhesives, as well as plastic materials used

be able to determine the source of a foreign odor/flavor from

in conjunction with paper.

the information obtained from this procedure.

1.5 The values stated in SI units are to be regarded as

standard. No other units of measurement are included in this

4. Sensory Test Panel Selection and Training

standard.

4.1 General—Sensory panel selection and training are de-

1.6 This standard does not purport to address all of the

scribed in STP 758 and in references therein.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 4.2 Size—The panel on a specific odor and/or flavor prob-

priate safety, health, and environmental practices and deter- lem should consist of at least five (5) members. When possible,

mine the applicability of regulatory limitations prior to use. the assessors should be drawn from a larger pool of qualified

1.7 This international standard was developed in accor- assessors.

dance with internationally recognized principles on standard-

4.3 Selection—The important criteria in panel selection are:

ization established in the Decision on Principles for the

(a) normal ability to detect and identify odors and flavors; (b)

Development of International Standards, Guides and Recom-

ability to discriminate differences, and reproduce results; and

mendations issued by the World Trade Organization Technical

(c) interest in the testing work for which the assessors are to be

Barriers to Trade (TBT) Committee.

trained. Usually a suitable panel can be recruited from avail-

able employees unless their number is limited. It is helpful if

2. Summary of Practice

panel members have a scientific background, with some

2.1 Under the guidance of the panel leader, qualified and

knowledge of chemistry or food technology; however, this

trained assessors individually examine sample specimens by

should not be a criterion for selection. Nontechnical personnel

one or more of the test procedures described in this practice.

have often proved to be excellent panel members after appro-

Assessors judge the intensity of a perceived off-notes in terms

priate training. No willing and available person should be

excluded from consideration. Panel members should be re-

1 qualified periodically.

This practice is under the jurisdiction of ASTM Committee E18 on Sensory

Evaluation and is the direct responsibility of Subcommittee E18.05 on Sensory

Applications--General.

Current edition approved Dec. 1, 2017. Published December 2017. Originally

2

approved in 1984. Last previous edition approved in 2009 as E619 – 09. DOI: Guidelines for the Selection and Training of Sensory Evaluation Panels, ASTM

10.1520/E0619-17. STP 758, ASTM, 1981.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E619 − 17

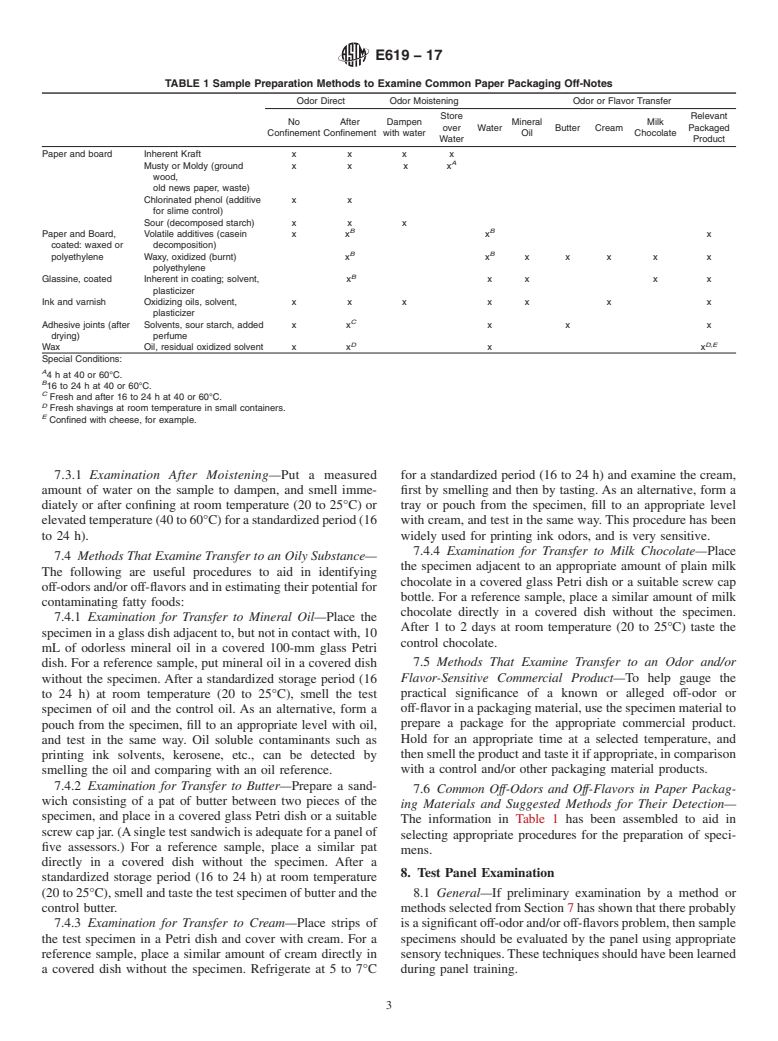

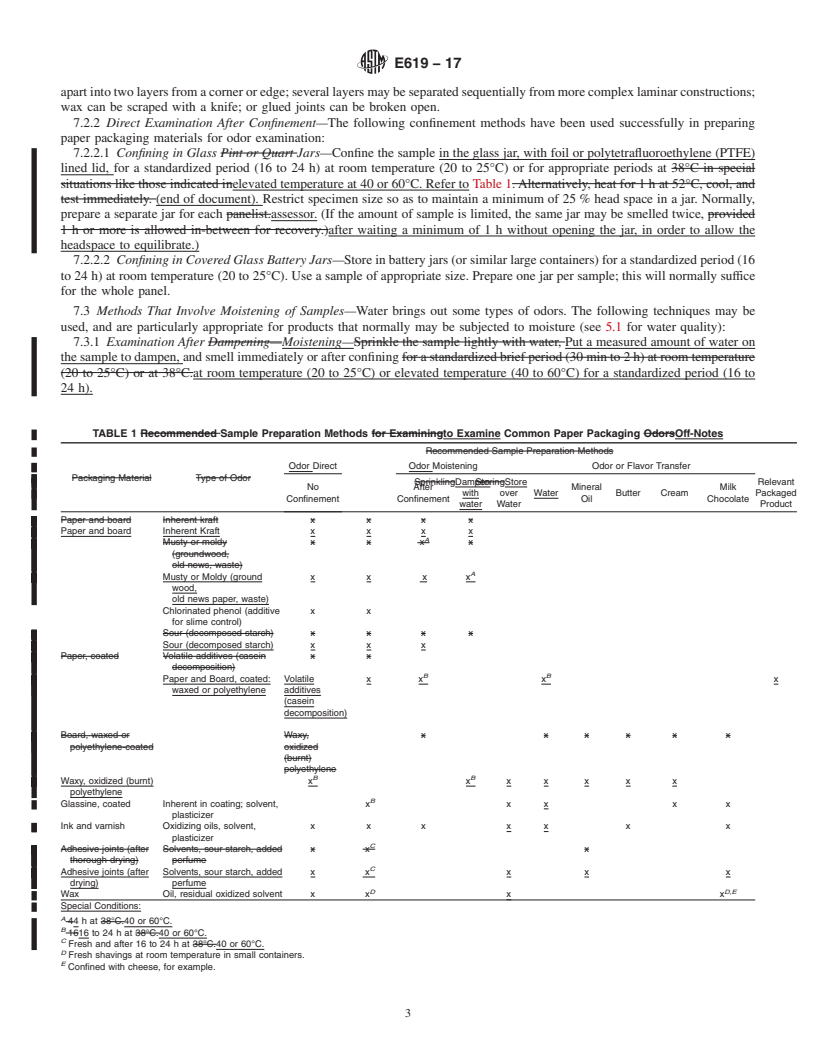

5. Testing Facilities and Apparatus standardize the particular preparation procedures that seem

best for specific products with which it is concerned.

5.1 General—Appropriate physical conditions for sensory

3

panel operations are describe

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E619 − 09 E619 − 17

Standard Practice for

Evaluating Foreign Odors in and/or Flavors from Paper

1

Packaging

This standard is issued under the fixed designation E619; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This practice covers the evaluation of odors in paper packaging and establishes smelling and testing procedures for trained

sensory panels.

1.2 This practice covers the evaluation of odors and flavors transferred to various food media from paper packaging.

1.3 This practice covers effective techniques for determining the type and source of the odorodor/flavor and establishing the

severity of contamination.the off-note.

1.4 The techniques used in this practice are applicable to all paper packaging products and to auxiliary components, such as

coatings, inks, and adhesives, as well as plastic materials used in conjunction with paper.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Summary of Practice

2.1 Under the leadershipguidance of the test supervisor,panel leader, qualified and trained subjectsassessors individually

examine sample specimens by one or more of the test procedures described in this practice. SubjectsAssessors judge the intensity

of a perceived off-odoroff-notes in terms of a numerical rating scale and also attempt to give a qualitative description of the taint.

off-odor and/or off flavor. The assembled observations are then interpreted by the supervisor.panel leader.

3. Significance and Use

2

3.1 Use—This practice should be used by panelists,assessors, trained as described in ASTM STP 758, under the direction of

a knowledgeable supervisor.panel leader.

3.2 Significance—This practice can be used to evaluate type and intensity of indigenous and foreign odors and/or flavors in

paper packaging materials as to type and intensity. A knowledgeable supervisor materials. A knowledgeable panel leader may be

able to determine the source of a foreign odorodor/flavor from the information obtained from this procedure.

4. Sensory Test Panel Selection and Training

4.1 General—Sensory panel selection and training are described in STP 758 and in references therein.

4.2 Size—The test panel on a specific odor and/or flavor problem should consist of at least five members and should render a

minimum total of ten judgments per sample. A maximum of twelve subjects may be used, if available. (5) members. When

possible, the subjectsassessors should be drawn from a larger pool of qualified panelists.assessors.

1

This practice is under the jurisdiction of ASTM Committee E18 on Sensory Evaluation and is the direct responsibility of Subcommittee E18.05 on Sensory

Applications--General.

Current edition approved Sept. 1, 2009Dec. 1, 2017. Published October 2009December 2017. Originally approved in 1984. Last previous edition approved in 20032009

as E619 – 84 (2003).E619 – 09. DOI: 10.1520/E0619-09.10.1520/E0619-17.

2

Guidelines for the Selection and Training of Sensory Evaluation Panels, ASTM STP 758, ASTM, 1981.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E619 − 17

4.3 Selection—The important criteria in panel selection are: (a) normal ability to detect and identify odors and flavors; (b) ability

to discriminate differences, and reproduce results; and (c) interest in the testing work for which the panelistsassessors are to be

trained. Usually a suitable panel can be recruited from available empl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.