ASTM B798-95(2014)

(Test Method)Standard Test Method for Porosity in Gold or Palladium Coatings on Metal Substrates by Gel-Bulk Electrography

Standard Test Method for Porosity in Gold or Palladium Coatings on Metal Substrates by Gel-Bulk Electrography

SIGNIFICANCE AND USE

5.1 Noble metal coatings, particularly gold or palladium, are often specified for the contacts of separable electrical connectors and other devices. Electrodeposits are the form of gold or palladium which is most used on contacts, although gold and palladium are also employed as clad metal and as weldments on the contact surface. The intrinsic nobility of gold and to a certain extent palladium enables them to resist the formation of insulating films that could interfere with reliable contact operation.

5.2 In order that the nobility of gold be assured, porosity, cracks, and other defects in the coating that expose base metal substrates and underplates must be minimal or absent, except in those cases where it is feasible to use the contacts in structures that shield the surface from the environment or where corrosion inhibiting surface treatments for the deposit are employed. The level of porosity in the coating that may be tolerable depends on the severity of the environment to the underplate or substrate, design factors for the contact device like the force with which it is mated, circuit parameters, and the reliability of contact operation that it is necessary to maintain. Also, when present, the location of pores on the surface is important. If the pores are few in number or are outside of the zone of contact of the mating surfaces, their presence can often be tolerated.

5.3 Methods for determining pores on a contact surface are most suitable if they enable their precise location and numbers to be determined. Contact surfaces are often curved or irregular in shape, and testing methods should be suitable for them. In addition, the severity of porosity-determining tests may vary from procedures capable of detecting all porosity to procedures that detect only gross defects. The test method in this document is generally regarded as severe.

5.4 The relationship of porosity levels revealed by particular tests to contact behavior must be made by the user of the...

SCOPE

1.1 This test method covers equipment and techniques for determining porosity in noble metal coatings, particularly electrodeposits and clad metals used on electrical contacts.

1.2 The test method is designed to show whether the porosity level is less or greater than some value which by experience is considered by the user to be acceptable for the intended application.

1.3 Other porosity testing methods are outlined in Guide B765. Detailed critical reviews of porosity testing are also available.2 Other porosity test methods are B735, B741, B799, and B809.

1.4 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 7 and 8.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B798 − 95 (Reapproved 2014)

Standard Test Method for

Porosity in Gold or Palladium Coatings on Metal Substrates

1

by Gel-Bulk Electrography

This standard is issued under the fixed designation B798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

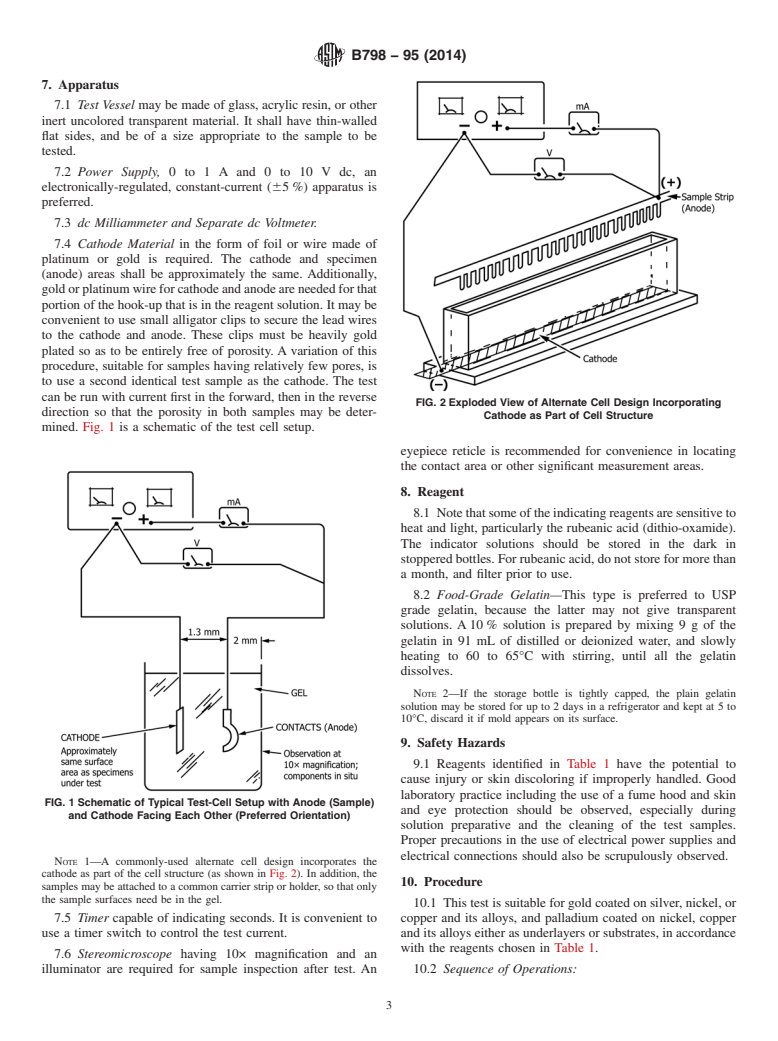

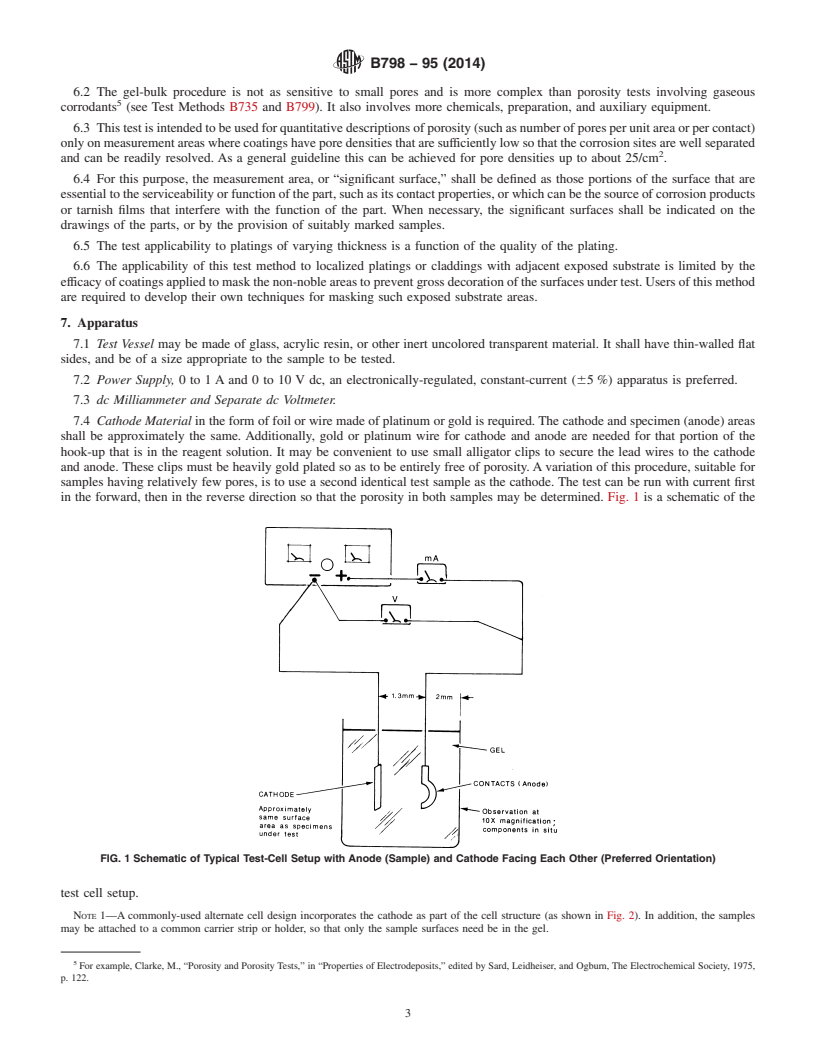

1. Scope B735Test Method for Porosity in Gold Coatings on Metal

Substrates by Nitric Acid Vapor

1.1 This test method covers equipment and techniques for

B741Test Method for Porosity In Gold Coatings On Metal

determining porosity in noble metal coatings, particularly

4

Substrates By Paper Electrography (Withdrawn 2005)

electrodeposits and clad metals used on electrical contacts.

B765GuideforSelectionofPorosityandGrossDefectTests

1.2 The test method is designed to show whether the

for Electrodeposits and Related Metallic Coatings

porosity level is less or greater than some value which by

B799Test Method for Porosity in Gold and Palladium

experience is considered by the user to be acceptable for the

Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

intended application.

B809Test Method for Porosity in Metallic Coatings by

Humid Sulfur Vapor (“Flowers-of-Sulfur”)

1.3 Other porosity testing methods are outlined in Guide

B765. Detailed critical reviews of porosity testing are also

3. Terminology

2

available. Other porosity test methods are B735, B741, B799,

3.1 Definitions—Many terms used in this test method are

and B809.

defined in Terminology B542 and terms relating to metallic

1.4 The values stated in SI units are to be regarded as

coatings are defined in Terminology B374.

standard. The values in parentheses are for information only.

3.2 Definitions of Terms Specific to This Standard:

1.5 This standard does not purport to address all of the

3.2.1 decorations, n—those reaction products emanating

safety concerns, if any, associated with its use. It is the

from the pores that provide visual contrast with the gel

responsibility of the user of this standard to become familiar

medium.

with all hazards including those identified in the appropriate

3.2.2 measurement area (or “significant surface”), n—the

Material Safety Data Sheet (MSDS) for this product/material

surface that is examined for the presence of porosity. The

as provided by the manufacturer, to establish appropriate

significant surfaces or measurement areas of the part to be

safety and health practices, and determine the applicability of

tested shall be indicated on the drawing of the part or by

regulatory limitations prior to use. For specific hazard

provision of suitably marked samples.

statements, see Sections 7 and 8.

3.2.2.1 Discussion—For specification purposes, the signifi-

2. Referenced Documents

cant surfaces or measurement areas are often defined as those

3

portionsofthesurfacethatareessentialtotheserviceabilityor

2.1 ASTM Standards:

functionofthepart,suchasitscontactproperties,orwhichcan

B374Terminology Relating to Electroplating

be the source of corrosion products or tarnish films that

B542Terminology Relating to Electrical Contacts andTheir

interfere with the function of the part.

Use

3.2.3 metallic coatings, n—include platings, claddings, or

1

other metallic layers applied to the substrate. The coatings can

This test method is under the jurisdiction of ASTM Committee B02 on

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

comprise a single metallic layer or a combination of metallic

B02.11 on Electrical Contact Test Methods.

layers.

Current edition approved Oct. 1, 2014. Published October 2014. Originally

approved in 1988. Last previous edition approved in 2009 as B798–95(2009).

3.2.4 porosity, n—the presence of any discontinuity, crack,

DOI: 10.1520/B0798-95R14.

orholeinthecoatingthatexposesadifferentunderlyingmetal.

2

Nobel, F. J., Ostrow, B. D., and Thompson, D. W., “Porosity Testing of Gold

3.2.5 underplate, n—a metallic coating layer between the

Deposity,” Plating,Vol 52, 1965, p. 1001, and Krumbein S. J., “PorosityTesting of

Contact Platings,” Proceedings, Connectors and Interconnection Technology

substrate and the topmost layer or layers. The thickness of an

Symposium, October 1987, p. 47.

underplate is usually greater that 0.8 µm (30 µin.).

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B798 − 95 (Reapproved 2009) B798 − 95 (Reapproved 2014)

Standard Test Method for

Porosity in Gold or Palladium Coatings on Metal Substrates

1

by Gel-Bulk Electrography

This standard is issued under the fixed designation B798; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers equipment and techniques for determining porosity in noble metal coatings, particularly

electrodeposits and clad metals used on electrical contacts.

1.2 The test method is designed to show whether the porosity level is less or greater than some value which by experience is

considered by the user to be acceptable for the intended application.

2

1.3 Other porosity testing methods are outlined in Guide B765. Detailed critical reviews of porosity testing are also available.

Other porosity test methods are B735, B741, B799, and B809.

1.4 The values stated in SI units are to be regarded as standard. The values in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data

Sheet (MSDS) for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and

determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Sections 7 and 8.

2. Referenced Documents

3

2.1 ASTM Standards:

B374 Terminology Relating to Electroplating

B542 Terminology Relating to Electrical Contacts and Their Use

B735 Test Method for Porosity in Gold Coatings on Metal Substrates by Nitric Acid Vapor

4

B741 Test Method for Porosity In Gold Coatings On Metal Substrates By Paper Electrography (Withdrawn 2005)

B765 Guide for Selection of Porosity and Gross Defect Tests for Electrodeposits and Related Metallic Coatings

B799 Test Method for Porosity in Gold and Palladium Coatings by Sulfurous Acid/Sulfur-Dioxide Vapor

B809 Test Method for Porosity in Metallic Coatings by Humid Sulfur Vapor (“Flowers-of-Sulfur”)

3. Terminology

3.1 Definitions—Many terms used in this test method are defined in Terminology B542 and terms relating to metallic coatings

are defined in Terminology B374.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 decorations, n—those reaction products emanating from the pores that provide visual contrast with the gel medium.

3.2.2 measurement area (or “significant surface”), n—the surface that is examined for the presence of porosity. The significant

surfaces or measurement areas of the part to be tested shall be indicated on the drawing of the part or by provision of suitably

marked samples.

1

This test method is under the jurisdiction of ASTM Committee B02 on Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee B02.11 on

Electrical Contact Test Methods.

Current edition approved Oct. 1, 2009Oct. 1, 2014. Published October 2009October 2014. Originally approved in 1988. Last previous edition approved in 20052009 as

B798 – 95 (2005).(2009). DOI: 10.1520/B0798-95R09.10.1520/B0798-95R14.

2

Nobel, F. J., Ostrow, B. D., and Thompson, D. W., “Porosity Testing of Gold Deposity,” Plating, Vol 52, 1965, p. 1001, and Krumbein S. J., “Porosity Testing of Contact

Platings,” Proceedings, Connectors and Interconnection Technology Symposium, October 1987, p. 47.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

4

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B798 − 95 (2014)

3.2.2.1 Discussion—

For specification purposes, the significant surfaces or measurement areas are often defined as those portions of the surface that are

essential to the serviceability or function of the part, such as its contact properties, or which can be the source of corrosion products

or tarnish films that interfere

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.