ASTM B101-02

(Specification)Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

Standard Specification for Lead-Coated Copper Sheet and Strip for Building Construction

SCOPE

1.1 This specification establishes the requirements for lead-coated copper sheet and strip in flat lengths (or in coils) in ounce-weight thicknesses for roofing, flashing, gutters, downspouts, and for the general sheet metalwork in building construction. The lead coating is applied by hot dipping.

1.2 Materials made to this specification are not intended for electrical applications.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units, which are provided for information only and are not considered standard.

Note 1—A companion specification for copper sheet and strip for building construction is Specification B 370.

1.4 The following hazard caveat pertains to the test method portion, Section 17, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 101 – 02

Standard Specification for

Lead-Coated Copper Sheet and Strip for Building

1

Construction

This standard is issued under the fixed designation B 101; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * B 601 Classification for Temper Designations for Copper

2

and Copper Alloys—Wrought and Cast

1.1 This specification establishes the requirements for lead-

2

B 846 Terminology for Copper and Copper Alloys

coated copper sheet and strip in flat lengths (or in coils) in

3

E 8 TestMethodsforTensionTestingofMetallicMaterials

ounce-weight thicknesses for roofing, flashing, gutters, down-

4

E 37 Test Methods for Chemical Analysis of Pig Lead

spouts, and for the general sheet metalwork in building

E 46 Test Methods for Chemical Analysis of Lead- and

construction. The lead coating is applied by hot dipping.

5

Tin-Base Solders

1.2 Materials made to this specification are not intended for

E 62 Test Methods for Chemical Analysis of Copper and

electrical applications.

4

Copper Alloys (Photometric Methods)

1.3 Units—The values stated in inch-pound units are to be

3

E 112 Test Methods for Determining Average Grain Size

regarded as standard. The values given in parentheses are

E 478 Test Methods for Chemical Analysis of Copper

mathematical conversions to SI units, which are provided for

6

Alloys

information only and are not considered standard.

NOTE 1—A companion specification for copper sheet and strip for 3. General Requirements

building construction is Specification B 370.

3.1 The following sections of Specification B 248 constitute

1.4 The following hazard caveat pertains to the test method

a part of this specification:

portion, Section 17, of this specification. This standard does

3.1.1 Significance of numerical limits,

not purport to address all of the safety concerns, if any,

3.1.2 Inspection,

associatedwithitsuse.Itistheresponsibilityoftheuserofthis

3.1.3 Rejection and rehearing,

standard to establish appropriate safety and health practices

3.1.4 Certification,

and determine the applicability of regulatory limitations prior

3.1.5 Mill test reports, and

to use.

3.1.6 Packaging and package marking.

2. Referenced Documents

4. Terminology

2.1 The following documents in the current issue of the

4.1 For definitions of terms related to copper and copper

Annual Book of ASTM Standards form a part of this specifi-

alloys, refer to Terminology B 846.

cation to the extent referenced herein:

4.2 Definitions of Terms Specific to This Standard:

2.2 ASTM Standards:

4.2.1 coil—a length of the product wound into a series of

B 248 Specification for General Requirements for Wrought

connected turns.

Copper and Copper-Alloy Plate, Sheet, Strip, and Rolled

4.2.1.1 Discussion—The unqualified term “coil” as applied

2

Bar

to “flat product” usually refers to a coil in which the product is

B 370 Specification for Copper Sheet and Strip for Building

spirally wound, with the successive layers on top of one

2

Construction

another. (Sometimes called a “roll.”)

1

This specification is under the jurisdiction of Committee B05 on Copper and

Copper Alloys and is the direct responsibility of Subcommittee B05.01 on Plate,

3

Sheet, and Strip. Annual Book of ASTM Standards, Vol 03.01.

4

Current edition approved Apr. 10, 2002. Published June 2002. Originally Annual Book of ASTM Standards, Vol 03.05.

5

published as B 101 – 35 T. Last previous edition B 101 – 01. Discontinued, see 1994 Annual Book of ASTM Standards, Vol 03.05.

2 6

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 03.06.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B101–02

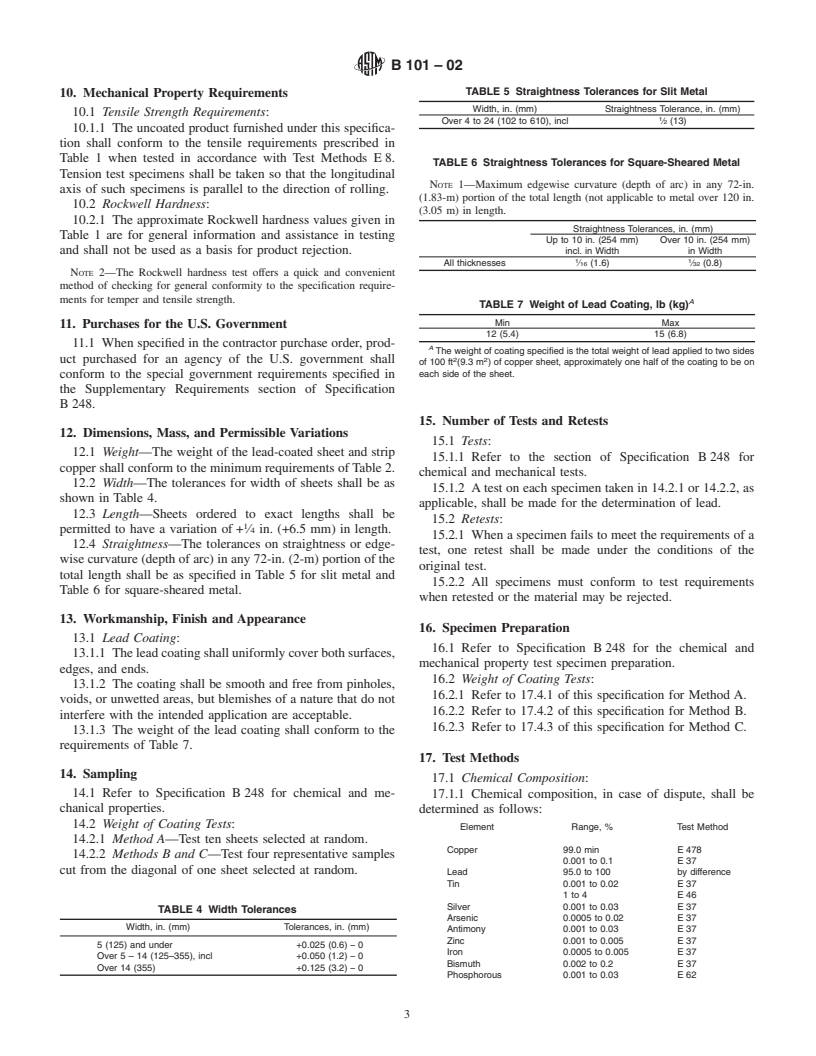

TABLE 2 Sheet Weights

4.2.2 lead-coated copper sheet (for building construction),

n—a rolled flat product over 24 in. (610 mm) in width and of Minimum Weight of

Nominal Weights and Thickness

Lead–Coated

ounce-weight thickness from 8 oz (227 g) to 48 oz (1361 g).

of Bare Copper Sheets

Copper Sheet

4.2.3 lead-coated strip (for building construction), n—a

Ounce-Weight, Ounce-Weight

2 2

rolledflatproductuptoandincluding24in.(610mm)inwidth oz/ft (g/m )

2 A

oz/ft Thickness , in. (mm)

andofounce-weightthicknessfrom8oz(227g)to48oz(1361

24 0.0323 (0.820) 24.8 (7560)

g).

20 0.0270 (0.686) 21.0 (6405)

16 0.0216 (0.549) 17.0 (5185)

4.2.4 lengths, mill, n—straight lengths, including ends, that

12 0.0162 (0.411) 13.0 (3960)

a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.