ASTM E123-92(1996)

(Specification)Standard Specification for Apparatus for Determination of Water by Distillation

Standard Specification for Apparatus for Determination of Water by Distillation

SCOPE

1.1 This specification covers apparatus used in Test Method D95 and other similar ASTM methods.

General Information

Relations

Standards Content (Sample)

Designation: E 123 – 92 (Reapproved 1996)

Standard Specification for

Apparatus for Determination of Water by Distillation

This standard is issued under the fixed designation E 123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers apparatus used in Test Method

D 95 and other similar ASTM test methods.

2. Referenced Documents

2.1 ASTM Standards:

D 95 Test Method for Water in Petroleum Products and

Bituminous Materials by Distillation

3. Apparatus Assembly

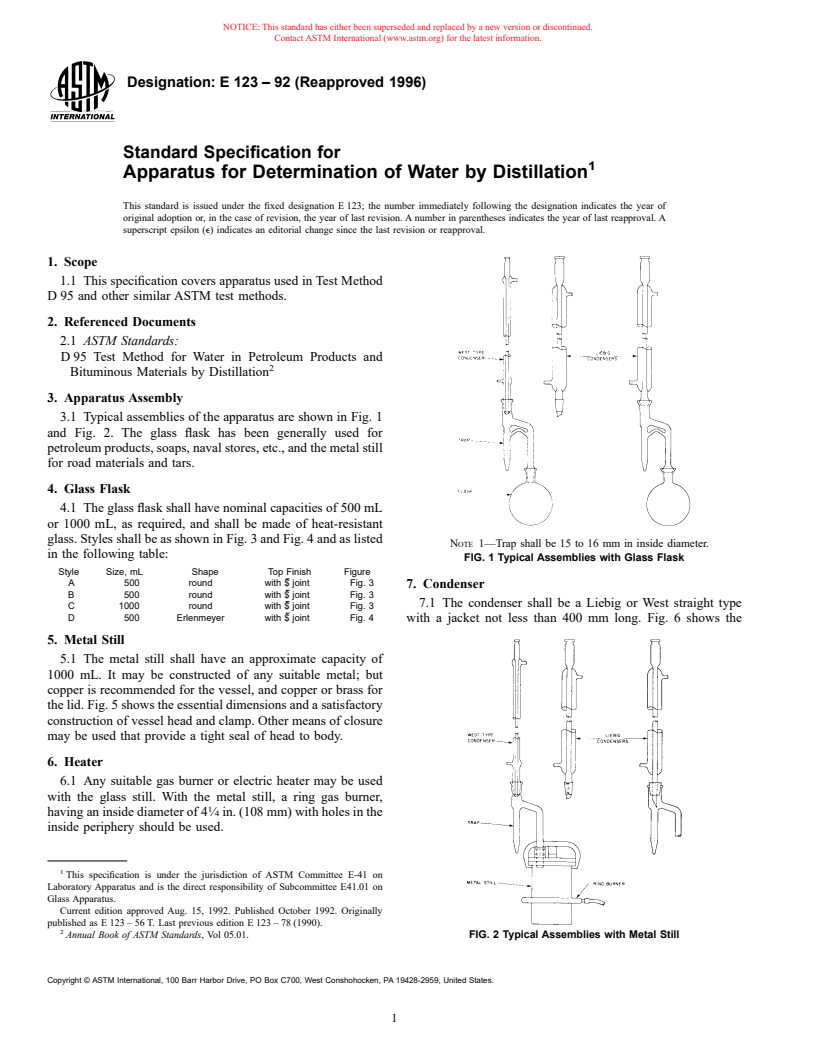

3.1 Typical assemblies of the apparatus are shown in Fig. 1

and Fig. 2. The glass flask has been generally used for

petroleum products, soaps, naval stores, etc., and the metal still

for road materials and tars.

4. Glass Flask

4.1 The glass flask shall have nominal capacities of 500 mL

or 1000 mL, as required, and shall be made of heat-resistant

glass. Styles shall be as shown in Fig. 3 and Fig. 4 and as listed

NOTE 1—Trap shall be 15 to 16 mm in inside diameter.

in the following table:

FIG. 1 Typical Assemblies with Glass Flask

Style Size, mL Shape Top Finish Figure

A 500 round with $ joint Fig. 3

7. Condenser

B 500 round with $ joint Fig. 3

7.1 The condenser shall be a Liebig or West straight type

C 1000 round with $ joint Fig. 3

D 500 Erlenmeyer with $ joint Fig. 4

with a jacket not less than 400 mm long. Fig. 6 shows the

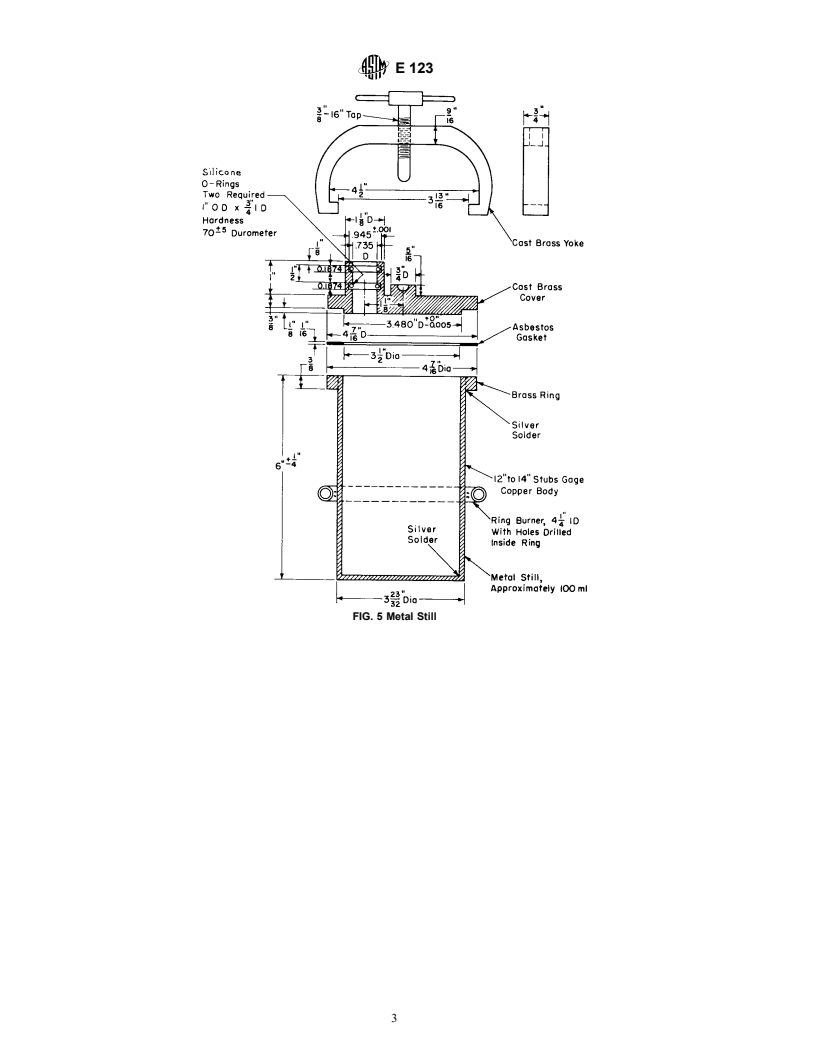

5. Metal Still

5.1 The metal still shall have an approximate capacity of

1000 mL. It may be constructed of any suitable metal; but

copper is recommended for the vessel, and copper or brass for

the lid. Fig. 5 shows the essential dimensions and a satisfactory

construction of vessel head and clamp. Other means of closure

may be used that provide a tight seal of head to body.

6. Heater

6.1 Any suitable gas burner or electric heater may be used

with the glass still. With the metal still, a ring gas burner,

having an inside diameter of 4 ⁄4 in. (108 mm) with holes in the

inside periphery should be used.

This specification is under the jurisdiction of ASTM Committee E-41 on

Laboratory Apparatus and is the direct responsibility of Subcommittee E41.01 on

Glass Apparatus.

Current edition approved Aug. 15, 1992. Published October 1992. Originally

published as E 123 – 56 T. Last previous edition E 123 – 78 (1990).

Annual Book of ASTM Standards, Vol 05.01. FIG. 2 Typical Assemblies with Metal Still

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 123

Note—All dimensions are in millimetres.

A. 500 mL with Taper Joint. B. 500 mL with Ball-and-Socket Joint. C. 1000 mL with T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.