ASTM C758-04(2010)

(Test Method)Standard Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-Grade Plutonium Metal

Standard Test Methods for Chemical, Mass Spectrometric, Spectrochemical, Nuclear, and Radiochemical Analysis of Nuclear-Grade Plutonium Metal

SIGNIFICANCE AND USE

These test methods are designed to show whether a given material meets the purchaser's specifications.

An assay is performed to determine whether the material has the specified plutonium content.

Determination of the isotopic content of the plutonium is made to establish whether the effective fissile content is in compliance with the purchaser's specifications.

Impurity content is verified by a variety of methods to ensure that the maximum concentration limit of specified impurities is not exceeded. Determination of impurities is also required for calculation of the equivalent boron content (EBC).

SCOPE

1.1 These test methods cover procedures for the chemical, mass spectrometric, spectrochemical, nuclear, and radiochemical analysis of nuclear-grade plutonium metal to determine compliance with specifications.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C758 − 04 (Reapproved 2010)

Standard Test Methods for

Chemical, Mass Spectrometric, Spectrochemical, Nuclear,

and Radiochemical Analysis of Nuclear-Grade Plutonium

Metal

This standard is issued under the fixed designation C758; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 These test methods cover procedures for the chemical,

responsibility of the user of this standard to establish appro-

mass spectrometric, spectrochemical, nuclear, and radiochemi-

priate safety and health practices and determine the applica-

cal analysis of nuclear-grade plutonium metal to determine

bility of regulatory limitations prior to use. For specific

compliance with specifications.

safeguard and safety hazards statements, see Section 6.

1.2 Theanalyticalproceduresappearinthefollowingorder:

Sections 2. Referenced Documents

Dissolution Procedure

2.1 ASTM Standards:

Plutonium by Controlled-Potential Coulometry

Plutonium by Amperometric Titration with Iron (II)

C697Test Methods for Chemical, Mass Spectrometric, and

Plutonium by Ceric Sulfate Titration Test Method

Spectrochemical Analysis of Nuclear-Grade Plutonium

Plutonium by Diode Array Spectrophotometry

Dioxide Powders and Pellets

Uranium by Arsenazo I Spectrophotometric Test Method 8–10

Thorium by Thorin Spectrophotometric Test Method 11–13

C698Test Methods for Chemical, Mass Spectrometric, and

Iron by 1,10-Phenanthroline Spectrophotometric Test Method 14–16

Spectrochemical Analysis of Nuclear-Grade Mixed Ox-

Iron by 2,2-Bipyridyl Spectrophotometric Test Method 17–23

ides ((U, Pu)O )

Impurities by ICP-AES

Chloride by the Thiocyanate Spectrophotometric Test Method 24–26

C759Test Methods for Chemical, Mass Spectrometric,

Fluoride by Distillation-Spectrophotometric Test Method 27–28

Spectrochemical,Nuclear,andRadiochemicalAnalysisof

Nitrogen by Distillation-Nessler Reagent Spectrophotometric Test 29–30

Nuclear-Grade Plutonium Nitrate Solutions

Method

Carbon by the Direct Combustion-Thermal Conductivity Test 31–33

C852Guide for Design Criteria for Plutonium Gloveboxes

Method

C1009Guide for Establishing and Maintaining a Quality

Sulfur by Distillation-Spectrophotometric Test Method 34–36

AssuranceProgramforAnalyticalLaboratoriesWithinthe

Isotopic Composition by Mass Spectrometry 37 and

Nuclear Industry

Plutonium-238 Isotopic Abundance by Alpha Spectrometry

C1068Guide for Qualification of Measurement Methods by

Americium-241 by Extraction and Gamma Counting 39–41

Americium-241 by Gamma Counting a Laboratory Within the Nuclear Industry

Gamma-Emitting Fission Products, Uranium, and Thorium by 42–49

C1108Test Method for Plutonium by Controlled-Potential

Gamma-Ray Spectroscopy

Coulometry

Rare Earths by Copper Spark Spectrochemical Test Method 50–52

Tungsten, Niobium (Columbium), and Tantalum by Spectro- 53–55 C1128Guide for Preparation of Working Reference Materi-

chemical Test Method

als for Use in Analysis of Nuclear Fuel Cycle Materials

Sample Preparation for Spectrographic Analysis for Trace Impuri 56–60

C1156Guide for Establishing Calibration for a Measure-

ties

ment Method Used toAnalyze Nuclear Fuel Cycle Mate-

1.3 The values stated in SI units are to be regarded as

rials

standard. No other units of measurement are included in this

C1165 Test Method for Determining Plutonium by

standard.

Controlled-Potential Coulometry in H SO at a Platinum

2 4

Working Electrode

C1168PracticeforPreparationandDissolutionofPlutonium

These test methods are under the jurisdiction of ASTM Committee C26 on

Materials for Analysis

Nuclear Fuel Cycle and are the direct responsibility of Subcommittee C26.05 on

Methods of Test.

Current edition approved Jan. 1, 2010. Published February 2010. Originally

approved in 1973. Last previous edition approved in 2004 as C758–04. DOI: For referenced ASTM Standards, visit the ASTM website, www.astm.org, or

10.1520/C0758-10. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Discontinued as of February 10, 1998. Standardsvolume information, refer to the standard’s Document Summary page on

Discontinued as of November 15, 1992 the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C758 − 04 (2010)

C1206Test Method for Plutonium by Iron (II)/Chromium 5. Reagents and Materials

(VI) Amperometric Titration (Withdrawn 2015)

5.1 Purity of Reagents—Reagent grade chemicals shall be

C1210Guide for Establishing a Measurement System Qual-

used in all test methods. Unless otherwise indicated, it is

ity Control Program for Analytical Chemistry Laborato-

intended that all reagents shall conform to the specifications of

ries Within the Nuclear Industry

theCommitteeonAnalyticalReagentsoftheAmericanChemi-

C1235 Test Method for Plutonium by Titanium(III)/

cal Society, where such specifications are available. Other

Cerium(IV) Titration (Withdrawn 2005)

grades may be used, provided it is first ascertained that the

C1268 Test Method for Quantitative Determination of

reagent is of sufficient high purity to permit its use without

Am in Plutonium by Gamma-Ray Spectrometry

lessening the accuracy of the determination.

C1297Guide for Qualification of Laboratory Analysts for

5.2 Purity of Water—Unless otherwise indicated, reference

the Analysis of Nuclear Fuel Cycle Materials

towatershallbeunderstoodtomeanreagentwaterconforming

C1307Test Method for PlutoniumAssay by Plutonium (III)

to Specification D1193.

Diode Array Spectrophotometry

C1415Test Method for Pu Isotopic Abundance By Alpha

6. Safety Hazards

Spectrometry

6.1 Since plutonium bearing materials are radioactive and

C1432Test Method for Determination of Impurities in

toxic,adequatelaboratoryfacilities,glovedboxes,fumehoods,

Plutonium: Acid Dissolution, Ion Exchange Matrix

etc., along with safe techniques, must be used in handling

Separation, and Inductively Coupled Plasma-Atomic

samplescontainingthesematerials.Adetaileddiscussionofall

Emission Spectroscopic (ICP/AES) Analysis

the precautions necessary is beyond the scope of these test

D1193Specification for Reagent Water

methods; however, personnel who handle these materials

should be familiar with such safe handling practices as are

3. Significance and Use

given in Guide C852 and in Refs. (1-3).

3.1 These test methods are designed to show whether a

given material meets the purchaser’s specifications.

7. Sampling

3.1.1 An assay is performed to determine whether the

7.1 In the absence of ASTM test methods for sampling

material has the specified plutonium content.

plutonium metal, alternative techniques are recommended

3.1.2 Determinationoftheisotopiccontentoftheplutonium

(3-6).

is made to establish whether the effective fissile content is in

7.2 Cognizance shall be taken of the fact that various

compliance with the purchaser’s specifications.

3.1.3 Impurity content is verified by a variety of methods to impuritiescanbeintroducedintosamplesduringtheprocessof

sampling. The particular impurities introduced are a function

ensure that the maximum concentration limit of specified

impurities is not exceeded. Determination of impurities is also of the method of sampling (for example, iron and alloying

elementsindrillturning,oxygenorcomponentsofcoolingoil,

requiredforcalculationoftheequivalentboroncontent(EBC).

or both, from lathe turnings, etc.). It is necessary for the

4. Committee C-26 Safeguards Statement

purchaser and the seller to recognize this possibility for

contaminationduringsamplingandmutuallyagreeonthemost

4.1 The material (plutonium metal) to which these test

suitable method.

methods apply is subject to nuclear safeguards regulations

governing its possession and use. The following analytical

7.3 Samplesizeshallbesufficienttoperformthefollowing:

procedures in these test methods have been designed as

7.3.1 Quality verification tests at the seller’s plant,

technicallyacceptableforgeneratingsafeguardsaccountability

7.3.2 Acceptance tests at the purchaser’s plant, and

measurement data: Plutonium by Controlled-Potential Cou-

7.3.3 Referee tests in the event these become necessary.

lometry; Plutonium by Ceric Sulfate Titration; Plutonium by

7.4 All samples shall be identified clearly by the seller’s

Amperometric Titration with Iron(II); Plutonium by Diode

button number and by the lot number, and all pieces of metal

Array Spectrophotometry and Isotopic Composition by Mass

in that lot shall be identified clearly by the lot number and the

Spectrometry.

piece number.

4.2 When used in conjunction with appropriate Certified

7.4.1 Alotisdefinedasasinglebutton,fractionofabutton,

Reference Materials (CRMs), these procedures can demon-

or multiple castings from a single melt of plutonium metal.

strate traceability to the national measurement base. However,

Buttons, fractions of buttons, or multiple castings are usually

adherence to these procedures does not automatically guaran-

supplied in pieces of not less than 50 g. All pieces shall be

tee regulatory acceptance of the resulting safeguards measure-

identified positively as coming from a particular button,

ments.Itremainsthesoleresponsibilityoftheuserofthesetest

fraction of a button, or casting.

methods to assure that their application to safeguards has the

approval of the proper regulatory authorities.

Reagent Chemicals, American Chemical Society Specifications,” American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

The last approved version of this historical standard is referenced on Chemicals,BDHLtd.,Poole,Dorset,U.K.,andthe Unites States Pharmacopeia and

www.astm.org. National Foundary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, MD.

6 8

Based upon Committee C-26 Safeguards Matrix (C1009, C1068, C1128, Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

C1156, C1210, C1297). these test methods.

C758 − 04 (2010)

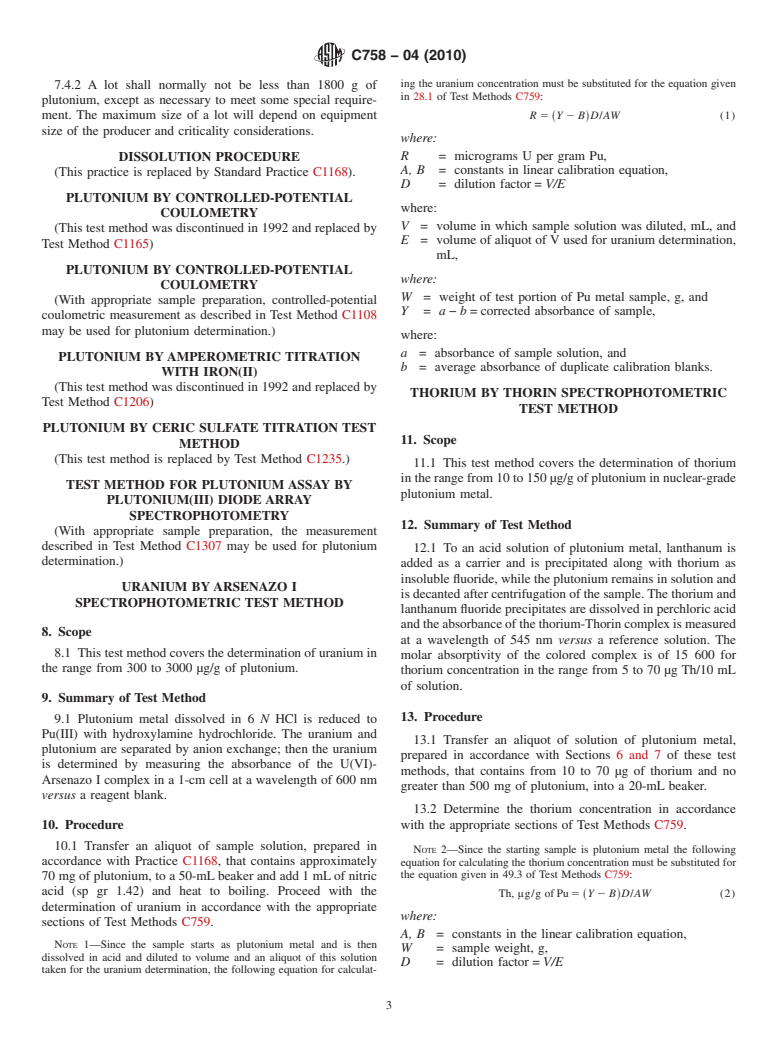

ing the uranium concentration must be substituted for the equation given

7.4.2 A lot shall normally not be less than 1800 g of

in 28.1 of Test Methods C759:

plutonium, except as necessary to meet some special require-

ment. The maximum size of a lot will depend on equipment R 5 Y 2 B D/AW (1)

~ !

size of the producer and criticality considerations.

where:

DISSOLUTION PROCEDURE R = micrograms U per gram Pu,

A, B = constants in linear calibration equation,

(This practice is replaced by Standard Practice C1168).

D = dilution factor= V/E

PLUTONIUM BY CONTROLLED-POTENTIAL

where:

COULOMETRY

V = volume in which sample solution was diluted, mL, and

(This test method was discontinued in 1992 and replaced by

E = volume of aliquot of V used for uranium determination,

Test Method C1165)

mL,

PLUTONIUM BY CONTROLLED-POTENTIAL

where:

COULOMETRY

W = weight of test portion of Pu metal sample, g, and

(With appropriate sample preparation, controlled-potential

Y = a− b=corrected absorbance of sample,

coulometric measurement as described in Test Method C1108

may be used for plutonium determination.)

where:

a = absorbance of sample solution, and

PLUTONIUM BY AMPEROMETRIC TITRATION

b = average absorbance of duplicate calibration blanks.

WITH IRON(II)

(This test method was discontinued in 1992 and replaced by

THORIUM BY THORIN SPECTROPHOTOMETRIC

Test Method C1206)

TEST METHOD

PLUTONIUM BY CERIC SULFATE TITRATION TEST

11. Scope

METHOD

(This test method is replaced by Test Method C1235.)

11.1 This test method covers the determination of thorium

intherangefrom10to150µg/gofplutoniuminnuclear-grade

TEST METHOD FOR PLUTONIUM ASSAY BY

plutonium metal.

PLUTONIUM(III) DIODE ARRAY

SPECTROPHOTOMETRY

12. Summary of Test Method

(With appropriate sample preparation, the measurement

described in Test Method C1307 may be used for plutonium

12.1 To an acid solution of plutonium metal, lanthanum is

determination.)

added as a carrier and is precipitated along with thorium as

insolublefluoride,whiletheplutoniumremainsinsolutionand

URANIUM BY ARSENAZO I

isdecantedaftercentrifugationofthesample.Thethoriumand

SPECTROPHOTOMETRIC TEST METHOD

lanthanumfluorideprecipitatesaredissolvedinperchloricacid

andtheabsorbanceofthethorium-Thorincomplexismeasured

8. Scope

at a wavelength of 545 nm versus a reference solution. The

8.1 Thistestmethodcoversthedeterminationofuraniumin

molar absorptivity of the colored complex is of 15 600 for

the range from 300 to 3000 µg/g of plutonium.

thorium concentration in the range from 5 to 70 µg Th/10 mL

of solution.

9. Summary of Test Method

13. Procedure

9.1 Plutonium metal dissolved in 6 N HCl is reduced to

Pu(III) with hydroxylamine hydrochloride. The uranium and

13.1 Transfer an aliquot of solution of plutonium metal,

plutonium are separated by anion exchange; then the uranium

prepared in accordance with Sections 6 and 7 of these test

is determined by measuring the absorbance of the U(VI)-

methods, that contains from 10 to 70 µg of thorium and no

Arsenazo I complex in a 1-cm cell at a wavelength of 600 nm

greater than 500 mg of plutonium, into a 20-mL beaker.

versus a reagent blank.

13.2 Determine the thorium concentration in accordance

10. Procedure with the appropriate sections of Test Methods C759.

10.1 Transfer an aliquot of sample solution, prepared in

NOTE 2—Since the starting sample is plutonium metal the following

accordance with Practice C1168, that contains approximately equation for calculating the thorium concentration must be substituted for

the equation given in 49.3 of Test Methods C759:

70 mg of plutonium, to a 50-mLbeaker and add 1 mLof nitric

acid (sp gr 1.42) and heat to boiling. Proceed with the

Th, µg/g ofPu 5 Y 2 B D/AW (2)

~ !

determination of uranium in accordance with the appropriate

where:

sections of Test Methods C759.

A, B = constants in the linear calibration equation,

NOTE 1—Since the sample starts as plutonium metal and is then

W = sample weight, g,

dissolved in acid and diluted to volume and an aliquot of this solution

D = dilution factor= V/E

taken for the uranium determination, the following equation for calculat-

C758 − 04 (2010)

where: 19. Apparatus

V = volume to which dissolved plutonium metal is diluted,

19.1 Spectrophotometer, visible range.

mL, and

19.2 Extraction Bottles, glass-stopped, 125-mL volume.

E = volume of aliquot of V taken for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.