ASTM D5179-02(2008)

(Test Method)Standard Test Method for Measuring Adhesion of Organic Coatings to Plastic Substrates by Direct Tensile Testing

Standard Test Method for Measuring Adhesion of Organic Coatings to Plastic Substrates by Direct Tensile Testing

SIGNIFICANCE AND USE

The pull-off strength (commonly referred to as adhesion) of a coating is an important performance property that has been used in specifications. This test method serves as a means for uniformly preparing and testing organic coatings on plastic substrates. Further information may be found in Appendix X1.

SCOPE

1.1 This test method covers the laboratory determination of organic coating adhesion to plastic substrates by mounting and removing an aluminum stud from the surface of the coating and measuring the force required to break the coating/substrate bond with a tensile tester.

1.2 This test method requires that the aluminum stud be adhered directly to the surface of a coated, cured panel (Fig. 1).

1.3 This test method is used to compare the adhesion of coatings to various plastic substrates, thus allowing for a quantitative comparison of various coating/substrate combinations.

1.4 Other tensile test methods are Test Method D 4541 and ISO 4624 (but are not technically equivalent).

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5179 − 02(Reapproved 2008)

Standard Test Method for

Measuring Adhesion of Organic Coatings to Plastic

Substrates by Direct Tensile Testing

This standard is issued under the fixed designation D5179; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 Other Standard:

ISO 4624 Paints and Varnishes—Pull-off test for adhesion

1.1 This test method covers the laboratory determination of

organic coating adhesion to plastic substrates by mounting and

3. Summary of Test Method

removinganaluminumstudfromthesurfaceofthecoatingand

3.1 An aluminum stud is bonded directly to a coated cured

measuring the force required to break the coating/substrate

panel. The adhesive is allowed to cure for2hat room

bond with a tensile tester.

temperature.The specimen is then subjected to test on a tensile

1.2 This test method requires that the aluminum stud be

tester equipped with an upper coupling adapter (Fig. 2), and a

adhereddirectlytothesurfaceofacoated,curedpanel(Fig.1).

restraining device (Fig. 3).

1.3 This test method is used to compare the adhesion of

3.2 If a coating is to fulfill its function of protecting or

coatings to various plastic substrates, thus allowing for a

decorating a substrate, it must adhere to it for the expected

quantitative comparison of various coating/substrate combina-

service life. Because the substrate and its surface preparation

tions.

(or lack of it) has a drastic effect on the adhesion of coatings,

a method of evaluation adhesion of a coating to different

1.4 Other tensile test methods are Test Method D4541 and

substrates or surface treatments, or of different coating to the

ISO 4624 (but are not technically equivalent).

same substrate and treatment, is of considerable usefulness in

1.5 The values stated in inch-pound units are to be regarded

the industry.

as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only

4. Significance and Use

and are not considered standard.

4.1 The pull-off strength (commonly referred to as adhe-

1.6 This standard does not purport to address all of the

sion)ofacoatingisanimportantperformancepropertythathas

safety concerns, if any, associated with its use. It is the

been used in specifications.This test method serves as a means

responsibility of the user of this standard to establish appro-

for uniformly preparing and testing organic coatings on plastic

priate safety and health practices and determine the applica-

substrates. FurtherinformationmaybefoundinAppendixX1.

bility of regulatory limitations prior to use.

5. Apparatus and Materials

2. Referenced Documents

5.1 Tensile Tester, commercially available.

2.1 ASTM Standards:

5.2 Aluminum Stud—The shape and dimensions of the stud

D4541 Test Method for Pull-Off Strength of Coatings Using

are shown in Fig. 1.

Portable Adhesion Testers

5.3 Upper Coupling Adaptor—The apparatus is shown in

3 1

Fig. 2. The adaptor is 3 ⁄4 in. (94 mm) long, 1 ⁄4 in. (31 mm)

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

This test method is under the jurisdiction of ASTM Committee D01 on Paint 4th Floor, New York, NY 10036, http://www.ansi.org.

and Related Coatings, Materials, andApplications and is the direct responsibility of Gray, K. N., Buckley, S. E., and Nelson, G. L., “Accessing Measurement

Subcommittee D01.23 on Physical Properties of Applied Paint Films. Standards for CoatingAdhesion to Plastics,” Modern Paint and Coatings Journal ,

Current edition approved July 1, 2008. Published July 2008. Originally approved Vol 75, No. 10, October 1985, p. 160.

in 1991. Last previous edition approved in 2002 as D5179 – 02. DOI: 10.1520/ The sole source of supply of the wooden puritan applicators, in sizes 6 in. (150

D5179-02R08. mm)inlengthand0.007in.(2mm)indiameter,knowntothecommitteeatthistime

For referenced ASTM standards, visit the ASTM website, www.astm.org, or is Hardwood Products Co., Guilford, ME 04443. If you are aware of alternative

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM suppliers, please provide this information to ASTM International. Your comments

Standards volume information, refer to the standard’s Document Summary page on will receive careful consideration at a meeting of the responsible technical

the ASTM website. committee, which you may attend.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959. United States

D5179 − 02 (2008)

5.6 Adhesive, cyanoacrylate adhesive . Since cyanoacrylate

adhesives lose adhesive bond strength with time, do not use

previously opened containers or lots of adhesive known to be

old.

5.7 Two-Kilogram Weight, approximately 2 in. (50 mm) in

diameter and 5 in. (130 mm) in height.

6. Preparation and Conditioning of Specimen

6.1 Sanding Procedure—Sand the large face of stud with

80-grit sandpaper, making certain that the surface is uniformly

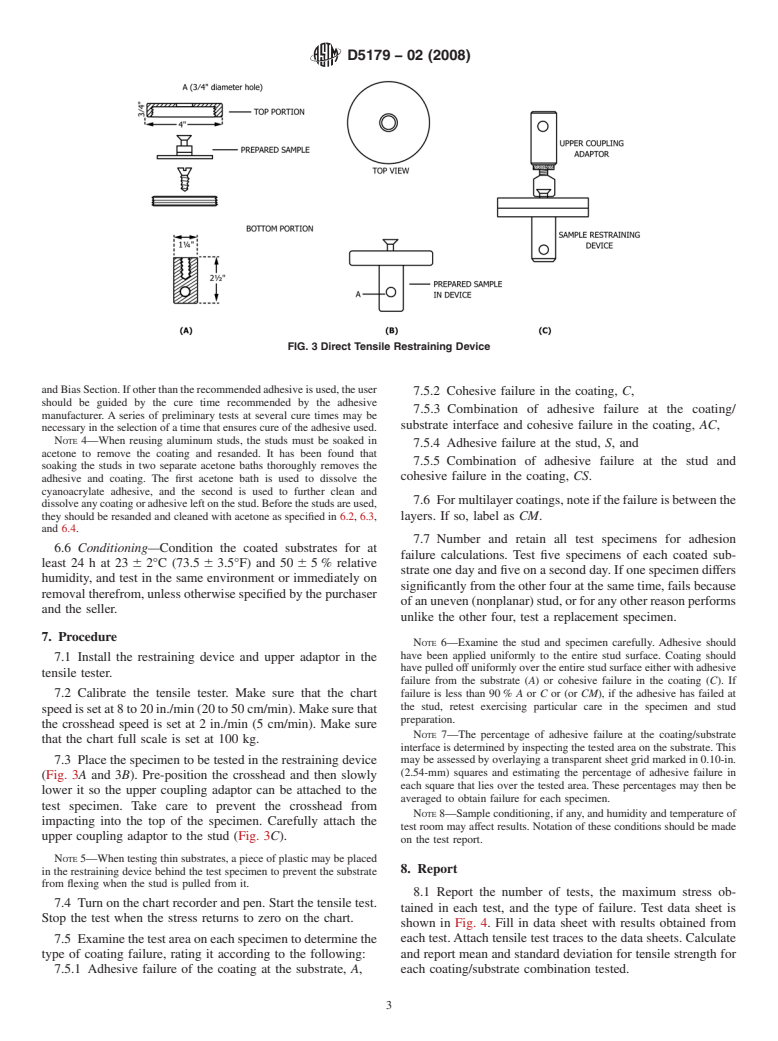

FIG. 1 Direct Tensile Model

roughened. When sanding studs, sand straight up and down;

rotate stud one quarter of a turn and continue sanding. Make

certain the surface of the stud is flat but rough. While sanding,

keepthestudfaceparalleltothesandpaper.Nonplanarsurfaces

cannot be used in testing because they lead to nonuniform

bonding of the stud to the coated surface. Only flat (planar)

studs should be used in testing. Planarity may be assessed by

placing a stud on a flat surface and checking to see if the stud

wobbles. Careful preparation of studs is essential for good

adhesive adhesion.

6.2 Cleaning Procedure—Place sanded studs in a large

beaker. Pour technical grade acetone over the studs and swirl

the beaker to completely wash the studs. Pour out acetone and

repeatthecleaningprocedure.Soakthestudforatleast15min,

pour out the acetone, and allow the studs to dry.

6.3 Place washed and dried studs and beaker in an oven at

120°C and allow to heat for 1 h. Remove the beaker and studs

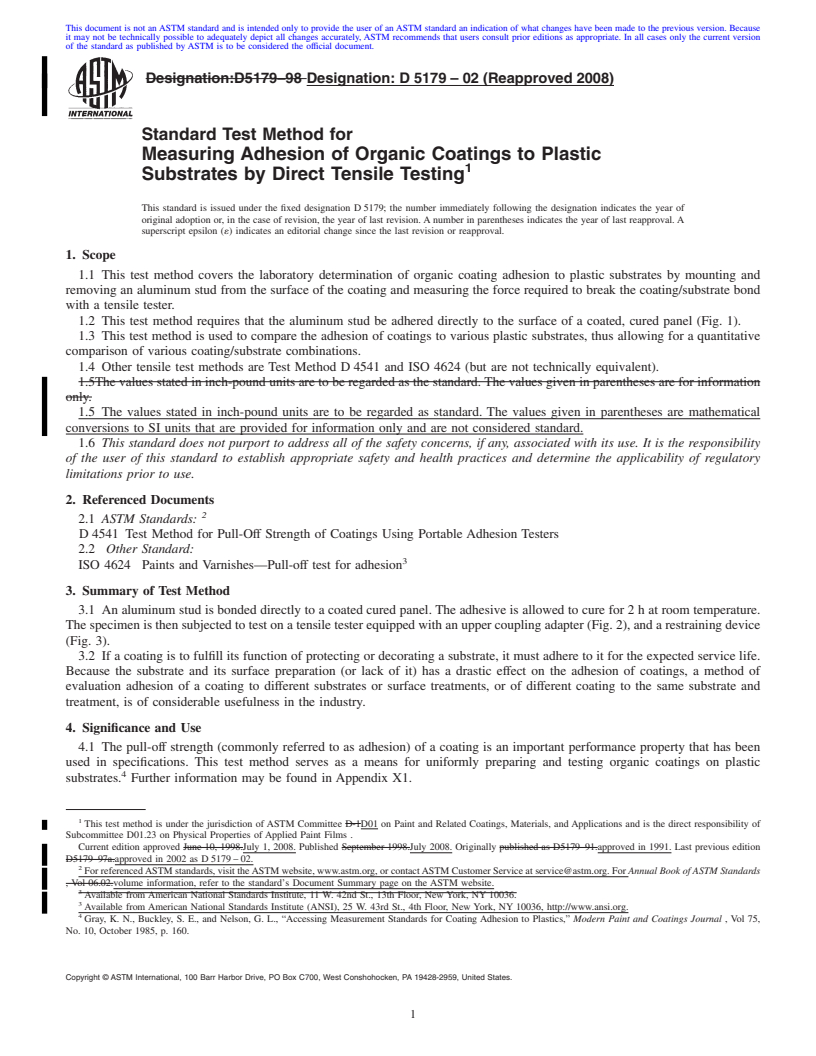

FIG. 2 Upper Coupling Adaptor

from the oven and allow to cool. DO NOTTOUCH FACE OF

STUDS.

6.4 Spread four drops of cyanoacrylate adhesive on the

in diameter at the top, and 1 in. (25 mm) in diameter at the

bottom. The hole, indicated by “B,” is used to attach the large face of an aluminum stud. Next, quickly press the stud

onto the coated test substrate. Place a 2-kg weight on the stud

adaptor to the tensile tester load cell. The hole has a ⁄2-in.

(13-mm) diameter. The machined opening indicated by “A,” is to ensure good contact between the stud, adhesive, and surface

of the coating. Clean the excess adhesive from the edge of the

to receive the head of the aluminum stud.

stud with a wooden applicator. Carefully remove the weight

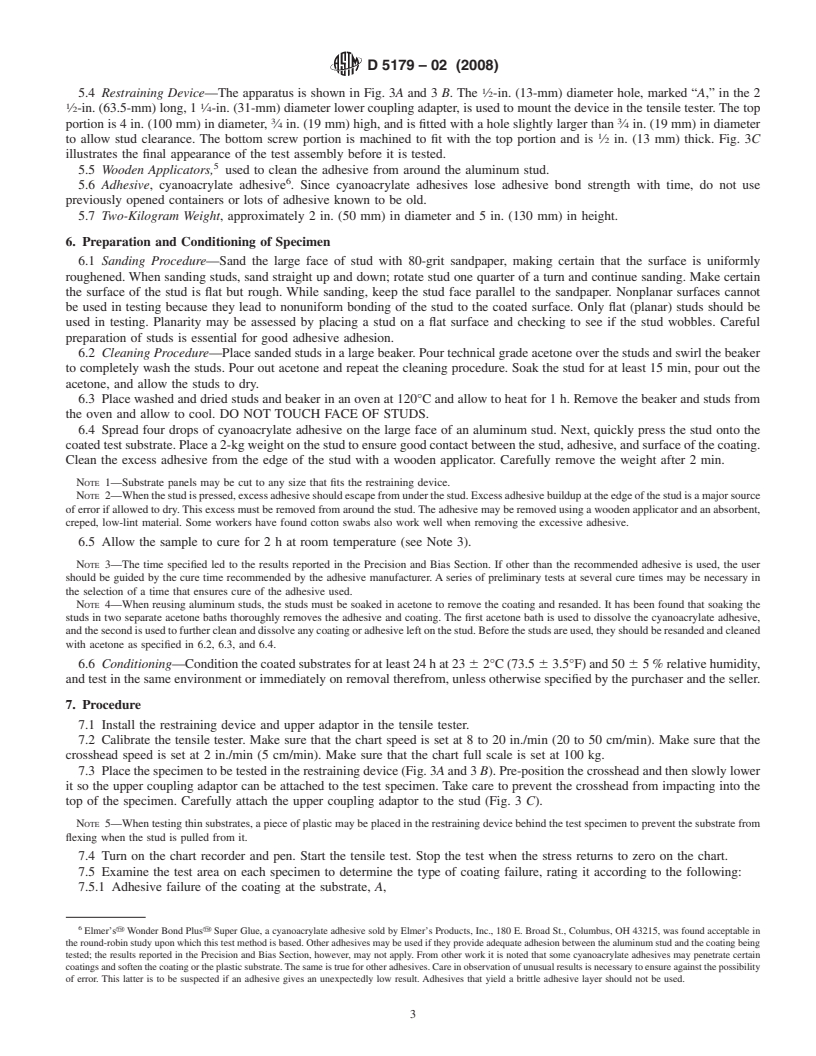

5.4 Restraining Device—The apparatus is shown in Fig. 3A

after 2 min.

and 3 B. The ⁄2-in. (13-mm) diameter hole, marked “A,” in the

1 1

2 ⁄2-in. (63.5-mm) long, 1 ⁄4-in. (31-mm) diameter lower

NOTE1—Substratepanelsmaybecuttoanysizethatfitstherestraining

device.

coupling adapter, is used to mount the device in the tensile

3 NOTE 2—When the stud is pressed, excess adhesive should escape from

tester. The top portion is 4 in. (100 mm) in diameter, ⁄4 in. (19

under the stud. Excess adhesive buildup at the edge of the stud is a major

mm)high,andisfittedwithaholeslightlylargerthan ⁄4in.(19

source of error if allowed to dry. This excess must be removed from

mm) in diameter to allow stud clearance. The bottom screw

around the stud.The adhesive may be removed using a wooden applicator

portion is machined to fit with the top portion and is ⁄2 in. (13

and an absorbent, creped, low-lint material. Some workers have found

cotton swabs also work well when removing the excessive adhesive.

mm) thick. Fig. 3C illustrates the final appearance of the test

assembly before it is tested.

6.5 Allow the sample to cure for2hat room temperature

(see Note 3).

5.5 Wooden Applicators, used to clean the adhesive from

around the aluminum stud.

NOTE 3—The time specified led to the results reported in the Precision

Elmer’s™ Wonder Bond Plus™ Super Glue, a cyanoacrylate adhesive sold by

Elmer’s Products, Inc., 180 E. Broad St., Columbus, OH 43215, was found

acceptable in the round-robin study upon which this test method is based. Other

adhesives may be used if they provide adequate adhesion between the aluminum

stud and the coating being tested; the results reported in the Precision and Bias

Section, however, may not apply. From other work it is noted that some

cyanoacrylateadhesivesmaypenetratecertaincoatingsandsoftenthecoatingorthe

plastic substrate. The same is true for other adhesives. Care in observation of

unusual results is necessary to ensure against the possibility of error. This latter is

tobesuspectedifanadhesivegivesanunexpectedlylowresult.Adhesivesthatyield

a brittle adhesive layer should not be used.

D5179 − 02 (2008)

FIG. 3 Direct Tensile Restraining Device

andBiasSection.Ifotherthantherecommendedadhesiveisused,theuser

7.5.2 Cohesive failure in the coating, C,

should be guided by the cure time recommended by the adhesive

7.5.3 Combination of adhesive failure at the coating/

manufacturer. A series of preliminary tests at several cure times may be

substrate interface and cohesive failure in the coating, AC,

necessary in the selection of a time that ensures cure of the adhesive used.

NOTE 4—When reusing aluminum studs, the studs must be soaked in

7.5.4 Adhesive failure at the stud, S, and

acetone to remove the coating and resanded. It has been found that

7.5.5 Combination of adhesive failure at the stud and

soaking the studs in two separate acetone baths thoroughly removes the

cohesive failure in the coating, CS.

adhesive and coating. The first acetone bath is used to dissolve the

cyanoacrylate adhesive, and the second is used to further clean and

7.6 Formultilayercoatings,noteifthefailureisbetweenthe

dissolveanycoatingoradhesiveleftonthestud.Beforethestudsareused,

they should be resanded and cleaned with acetone as specified in 6.2, 6.3, layers. If so, label as CM.

and 6.4.

7.7 Number and retain all test specimens for adhesion

6.6 Conditioning—Condition the coated substrates for at

failure calculations. Test five specimens of each coated sub-

least 24 h at 23 6 2°C (73.5 6 3.5°F) and 50 6 5 % relative

strate one day and five on a second day. If one specimen differs

humidity, and test in the same environment or immediately on

significantly from the other four at the same time, fails because

removaltherefrom,unlessotherwisespecifiedbythepurchaser

ofanuneven(nonplanar)stud,orforanyotherreasonperforms

and the seller.

unlike the other four, test a replacement specimen.

7. Procedure

NOTE 6—Examine the stud and specimen carefully. Adhesive should

have been applied uniformly to the entire stud surface. Coating should

7.1 Install the restraining device and upper adaptor in the

have pulled off uniformly over the entire stud surface either with adhesive

tensile tester.

failure from the substrate (A) or cohesive failure in the coating (C). If

7.2 Calibrate the tensile tester. Make sure that the chart failure is less than 90 % A or C or (or CM), if the adhesive has failed at

the stud, retest exercising particular care in the specimen and stud

speedissetat8to20in./min(20to50cm/min).Makesurethat

preparation.

the crosshead speed is set at 2 in./min (5 cm/min). Make sure

NOTE 7—The percentage of adhesive failure at the coating/substrate

that the chart full scale is set at 100 kg.

interface is determined by inspecting the tested area on the substrate. This

7.3 Place the specimen to be tested in the restraining device may be assessed by overlaying a transparent sheet grid marked in 0.10-in.

(2.54-mm) squares and estimating the percentage of adhesive failure in

(Fig. 3A and 3B). Pre-position the crosshead and then slowly

each square that lies over the tested area. These percentages may then be

lower it so the upper coupling adaptor can be attached to the

averaged to obtain failure for each specimen.

test specimen. Take care to prevent the crosshead from

NOTE 8—Sample conditioning, if any, and humidity and temperature of

impacting into the top of the specimen. Carefully attach the

test room may affect results. Notation of these conditions should be made

upper coupling adaptor to the stud (Fig. 3C).

on the test report.

NOTE 5—When testing thin substrates, a piece of plastic may be placed

8. Report

in the restraining device behind the test specimen to prevent the substrate

from flexing when the stud is pulled from it.

8.1 Report the number of tests, the maximum stress ob-

7.4 Turn on the chart recorder and pen. Start the tensile test.

tained in each test, and the type of failure. Test data sheet is

Stop the test when the stress returns to zero on the chart.

shown in Fig. 4. Fill in data sheet with results obtained from

7.5 Examinethetestareaoneachspecimentodeterminethe each test.Attach tensile test traces to the data sheets. Calculate

type of coating failure, rating it according to the following: and report mean and standard deviation for tensile strength for

7.5.1 Adhesive failure of the coating at the substrate, A, each coating/substrate combination tested.

D5179 − 02 (2008)

FIG. 4 Coating Adhesion Testing by Direct Tensile Methods

9. Precision and Bias 2 and Table 3.

9.1 The precision and bias are primarily dependent upon the

9.3 Bias—No information can be provided on the bias of

accuracy of the force measurements, the alignment of the

this test method for measuring adhesion because no material

device, the care exercised in stud and specimen preparation,

having an accepted reference value is available.

and the care in testing.

9.2 A round robin involving five different types of coatings

10. Keywords

and seven different plastic substrates, and ten different labora-

10.1 adhesion; bond strength; cyanoacrylate adhesive; plas-

tories yielded interlaboratory reproducibility data as shown in

tic substrate; pull-off strength; pull testing; tensile tester

Table 1. Within laboratory repeatability data is shown in Table

Acomplete report with additional data is available. See Nelson, G. L., “Testing

of EMI/RFI Coating Adhesion to Plastics by a Tensile Test Method,” Final Report

for Computer and Business Manufacturers Association and Society of the Plastics

Industry, University of Southern Mississippi, June, 1989.

TABLE 1 Overall Test Reproducibility

NOTE 1—This data was generated with lesser cautionary language than

found in Not

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D5179–98 Designation:D5179–02(Reapproved2008)

Standard Test Method for

Measuring Adhesion of Organic Coatings to Plastic

Substrates by Direct Tensile Testing

This standard is issued under the fixed designation D 5179; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the laboratory determination of organic coating adhesion to plastic substrates by mounting and

removing an aluminum stud from the surface of the coating and measuring the force required to break the coating/substrate bond

with a tensile tester.

1.2 This test method requires that the aluminum stud be adhered directly to the surface of a coated, cured panel (Fig. 1).

1.3 This test method is used to compare the adhesion of coatings to various plastic substrates, thus allowing for a quantitative

comparison of various coating/substrate combinations.

1.4 Other tensile test methods are Test Method D 4541 and ISO 4624 (but are not technically equivalent).

1.5The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

only.

1.5 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 4541 Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers

2.2 Other Standard:

ISO 4624 Paints and Varnishes—Pull-off test for adhesion

3. Summary of Test Method

3.1 An aluminum stud is bonded directly to a coated cured panel. The adhesive is allowed to cure for2hat room temperature.

The specimen is then subjected to test on a tensile tester equipped with an upper coupling adapter (Fig. 2), and a restraining device

(Fig. 3).

3.2 If a coating is to fulfill its function of protecting or decorating a substrate, it must adhere to it for the expected service life.

Because the substrate and its surface preparation (or lack of it) has a drastic effect on the adhesion of coatings, a method of

evaluation adhesion of a coating to different substrates or surface treatments, or of different coating to the same substrate and

treatment, is of considerable usefulness in the industry.

4. Significance and Use

4.1 The pull-off strength (commonly referred to as adhesion) of a coating is an important performance property that has been

used in specifications. This test method serves as a means for uniformly preparing and testing organic coatings on plastic

substrates. Further information may be found in Appendix X1.

This test method is under the jurisdiction of ASTM Committee D-1D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.23 on Physical Properties of Applied Paint Films .

Current edition approved June 10, 1998.July 1, 2008. Published September 1998.July 2008. Originally published as D5179–91.approved in 1991. Last previous edition

D5179–97a.approved in 2002 as D 5179 – 02.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 06.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute, 11 W. 42nd St., 13th Floor, New York, NY 10036.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Gray, K. N., Buckley, S. E., and Nelson, G. L., “Accessing Measurement Standards for Coating Adhesion to Plastics,” Modern Paint and Coatings Journal , Vol 75,

No. 10, October 1985, p. 160.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D5179–02 (2008)

FIG. 1 Direct Tensile Model

FIG. 2 Upper Coupling Adaptor

FIG. 3 Direct Tensile Restraining Device

5. Apparatus and Materials

5.1 Tensile Tester, commercially available.

5.2 Aluminum Stud—The shape and dimensions of the stud are shown in Fig. 1.

3 1

5.3 Upper Coupling Adaptor—The apparatus is shown in Fig. 2. The adaptor is 3 ⁄4 in. (94 mm) long, 1 ⁄4 in. (31 mm) in

diameter at the top, and 1 in. (25 mm) in diameter at the bottom. The hole, indicated by “B,” is used to attach the adaptor to the

tensile tester load cell. The hole has a ⁄2-in. (13-mm) diameter. The machined opening indicated by “A,” is to receive the head of

the aluminum stud.

The sole source of supply of the wooden puritan applicators, in sizes 6 in. (150 mm) in length and 0.007 in. (2 mm) in diameter, known to the committee at this time

is Hardwood Products Co., Guilford, ME 04443. If you are aware of alternative suppliers, please provide this information to ASTM Headquarters.International. Your

comments will receive careful consideration at a meeting of the responsible technical committee, which you may attend.

D5179–02 (2008)

5.4 Restraining Device—The apparatus is shown in Fig. 3A and 3 B. The ⁄2-in. (13-mm) diameter hole, marked “A,” in the 2

1 1

⁄2-in. (63.5-mm) long, 1 ⁄4-in. (31-mm) diameter lower coupling adapter, is used to mount the device in the tensile tester. The top

3 3

portion is 4 in. (100 mm) in diameter, ⁄4 in. (19 mm) high, and is fitted with a hole slightly larger than ⁄4 in. (19 mm) in diameter

to allow stud clearance. The bottom screw portion is machined to fit with the top portion and is ⁄2 in. (13 mm) thick. Fig. 3C

illustrates the final appearance of the test assembly before it is tested.

5.5 Wooden Applicators, used to clean the adhesive from around the aluminum stud.

5.6 Adhesive, cyanoacrylate adhesive . Since cyanoacrylate adhesives lose adhesive bond strength with time, do not use

previously opened containers or lots of adhesive known to be old.

5.7 Two-Kilogram Weight, approximately 2 in. (50 mm) in diameter and 5 in. (130 mm) in height.

6. Preparation and Conditioning of Specimen

6.1 Sanding Procedure—Sand the large face of stud with 80-grit sandpaper, making certain that the surface is uniformly

roughened. When sanding studs, sand straight up and down; rotate stud one quarter of a turn and continue sanding. Make certain

the surface of the stud is flat but rough. While sanding, keep the stud face parallel to the sandpaper. Nonplanar surfaces cannot

be used in testing because they lead to nonuniform bonding of the stud to the coated surface. Only flat (planar) studs should be

used in testing. Planarity may be assessed by placing a stud on a flat surface and checking to see if the stud wobbles. Careful

preparation of studs is essential for good adhesive adhesion.

6.2 CleaningProcedure—Place sanded studs in a large beaker. Pour technical grade acetone over the studs and swirl the beaker

to completely wash the studs. Pour out acetone and repeat the cleaning procedure. Soak the stud for at least 15 min, pour out the

acetone, and allow the studs to dry.

6.3 Place washed and dried studs and beaker in an oven at 120°C and allow to heat for 1 h. Remove the beaker and studs from

the oven and allow to cool. DO NOT TOUCH FACE OF STUDS.

6.4 Spread four drops of cyanoacrylate adhesive on the large face of an aluminum stud. Next, quickly press the stud onto the

coated test substrate. Place a 2-kg weight on the stud to ensure good contact between the stud, adhesive, and surface of the coating.

Clean the excess adhesive from the edge of the stud with a wooden applicator. Carefully remove the weight after 2 min.

NOTE 1—Substrate panels may be cut to any size that fits the restraining device.

NOTE 2—Whenthestudispressed,excessadhesiveshouldescapefromunderthestud.Excessadhesivebuildupattheedgeofthestudisamajorsource

of error if allowed to dry.This excess must be removed from around the stud.The adhesive may be removed using a wooden applicator and an absorbent,

creped, low-lint material. Some workers have found cotton swabs also work well when removing the excessive adhesive.

6.5 Allow the sample to cure for2hat room temperature (see Note 3).

NOTE 3—The time specified led to the results reported in the Precision and Bias Section. If other than the recommended adhesive is used, the user

should be guided by the cure time recommended by the adhesive manufacturer. A series of preliminary tests at several cure times may be necessary in

the selection of a time that ensures cure of the adhesive used.

NOTE 4—When reusing aluminum studs, the studs must be soaked in acetone to remove the coating and resanded. It has been found that soaking the

studs in two separate acetone baths thoroughly removes the adhesive and coating. The first acetone bath is used to dissolve the cyanoacrylate adhesive,

andthesecondisusedtofurthercleananddissolveanycoatingoradhesiveleftonthestud.Beforethestudsareused,theyshouldberesandedandcleaned

with acetone as specified in 6.2, 6.3, and 6.4.

6.6 Conditioning—Conditionthecoatedsubstratesforatleast24hat23 6 2°C(73.5 6 3.5°F)and50 6 5 %relativehumidity,

and test in the same environment or immediately on removal therefrom, unless otherwise specified by the purchaser and the seller.

7. Procedure

7.1 Install the restraining device and upper adaptor in the tensile tester.

7.2 Calibrate the tensile tester. Make sure that the chart speed is set at 8 to 20 in./min (20 to 50 cm/min). Make sure that the

crosshead speed is set at 2 in./min (5 cm/min). Make sure that the chart full scale is set at 100 kg.

7.3 Place the specimen to be tested in the restraining device (Fig. 3Aand 3B). Pre-position the crosshead and then slowly lower

it so the upper coupling adaptor can be attached to the test specimen. Take care to prevent the crosshead from impacting into the

top of the specimen. Carefully attach the upper coupling adaptor to the stud (Fig. 3 C).

NOTE 5—When testing thin substrates, a piece of plastic may be placed in the restraining device behind the test specimen to prevent the substrate from

flexing when the stud is pulled from it.

7.4 Turn on the chart recorder and pen. Start the tensile test. Stop the test when the stress returns to zero on the chart.

7.5 Examine the test area on each specimen to determine the type of coating failure, rating it according to the following:

7.5.1 Adhesive failure of the coating at the substrate, A,

Elmer’sy Wonder Bond Plusy Super Glue, a cyanoacrylate adhesive sold by Elmer’s Products, Inc., 180 E. Broad St., Columbus, OH 43215, was found acceptable in

the round-robin study upon which this test method is based. Other adhesives may be used if they provide adequate adhesion between the aluminum stud and the coating being

tested; the results reported in the Precision and Bias Section, however, may not apply. From other work it is noted that some cyanoacrylate adhesives may penetrate certain

coatingsandsoftenthecoatingortheplasticsubstrate.Thesameistrueforotheradhesives.Careinobservationofunusualresultsisnecessarytoensureagainstthepossibility

of error. This latter is to be suspected if an adhesive gives an unexpectedly low result. Adhesives that yield a brittle adhesive layer should not be used.

D5179–02 (2008)

7.5.2 Cohesive failure in the coating, C,

7.5.3 Combination of adhesive failure at the coating/substrate interface and cohesive failure in the coating, AC,

7.5.4 Adhesive failure at the stud, S, and

7.5.5 Combination of adhesive failure at the stud and cohesive failure in the coating, CS.

7.6 For multilayer coatings, note if the failure is between the layers. If so, label as CM.

7.7 Number and retain all test specimens for adhesion failure calculations.Test five specimens of each coated substrate one day

and five on a second day. If one specimen differs significantly from the other four at the same time, fails because of an uneven

(nonplanar) stud, or for any other reason performs unlike the other four, test a replacement specimen.

NOTE 6—Examinethestudandspecimencarefully.Adhesiveshouldhavebeenapplieduniformlytotheentirestudsurface.Coatingshouldhavepulled

off uniformly over the entire stud surface either with adhesive failure from the substrate (A) or cohesive failure in the coating ( C). If failure is less than

90 % A or C or (or CM), if the adhesive has failed at the stud, retest exercising particular care in the specimen and stud preparation.

NOTE 7—The percentage of adhesive failure at the coating/substrate interface is determined by inspecting the tested area on the substrate. This may

be assessed by overlaying a transparent sheet grid marked in 0.10-in. (2.54-mm) squares and estimating the percentage of adhesive failure in each square

that lies over the tested area. These percentages may then be averaged to obtain failure for each specimen.

NOTE 8—Sample conditioning, if any, and humidity and temperature of test room may affect results. Notation of these conditions should be made on

the test report.

8. Report

8.1 Report the number of tests, the maximum stress obtained in each test, and the type of failure. Test data sheet is shown in

Fig. 4. Fill in data sheet with results obtained from each test.Attach tensile test traces to the data sheets. Calculate and report mean

and standard deviation for tensile strength for each coating/substrate combination tested.

9. Precision and Bias

9.1 The precision and bias are primarily dependent upon the accuracy of the force measurements, the alignment of the device,

the care exercised in stud and specimen preparation, and the care in testing.

9.2 Around robin involving five different types of coatings and seven different plastic substrates, and ten different laboratories

yielded interlaboratory reproducibility data as shown inTable 1.Within laboratory repeatability data is shown inTable 2 andTable

3.

9.3 Bias—No information can be provided on the bias of this test method for measuring adhesion because no material having

an

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.