ASTM A1037/A1037M-05(2012)

(Specification)Standard Specification for Steel Line Pipe, Black, Furnace-Butt-Welded (Withdrawn 2017)

Standard Specification for Steel Line Pipe, Black, Furnace-Butt-Welded (Withdrawn 2017)

SCOPE

1.1 This specification covers furnace-butt-welded, black, plain-end or threaded-end, steel pipe for use in the conveyance of fluids under pressure. Pipe in sizes NPS 1/2 to 4, inclusive, with nominal wall thickness 0.350 in. [8.9 mm] or less, as given in ASME B36.10M is included. Pipe having other dimensions, in this size range, may be furnished provided such pipe complies with all other requirements of this specification.

1.2 For plain-end pipe, it is intended that the pipe be capable of being circumferentially welded in the field when welding procedures in accordance with the requirements of the applicable pipeline construction code are used.

1.3 The values stated in either inch-pound units or in SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values in each system are not exact equivalents; therefore, each system is to be used independently of the other.

WITHDRAWN RATIONALE

This specification covered furnace-butt-welded, black, plain-end or threaded-end, steel pipe for use in the conveyance of fluids under pressure.

Formerly under the jurisdiction of Committee A01 on Steel, Stainless Steel and Related Alloys, this specification was withdrawn in September 2017. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A1037/A1037M −05 (Reapproved 2012)

Standard Specification for

Steel Line Pipe, Black, Furnace-Butt-Welded

This standard is issued under the fixed designation A1037/A1037M; the number immediately following the designation indicates the

year of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last

reapproval. A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 API Standards:

5LSpecification for Line Pipe

1.1 This specification covers furnace-butt-welded, black,

5BSpecification for Threading, Gauging, and Thread In-

plain-end or threaded-end, steel pipe for use in the conveyance

spection of Casing, Tubing, and Line Pipe Threads

of fluids under pressure. Pipe in sizes NPS ⁄2 to 4, inclusive,

with nominal wall thickness 0.350 in. [8.9 mm] or less, as

3. Terminology

given in ASME B36.10M is included. Pipe having other

3.1 Definitions—For terminology used in this specification,

dimensions,inthissizerange,maybefurnishedprovidedsuch

refer to Terminology A941.

pipe complies with all other requirements of this specification.

3.2 Definitions of Terms Specific to This Standard:

1.2 Forplain-endpipe,itisintendedthatthepipebecapable

3.2.1 furnace-butt-welded pipe, n—pipe produced in mul-

of being circumferentially welded in the field when welding

tiple lengths from coiled skelp and subsequently cut into

procedures in accordance with the requirements of the appli-

individual lengths, having its longitudinal butt joint forge

cable pipeline construction code are used.

welded by the mechanical pressure developed in rolling the

1.3 The values stated in either inch-pound units or in SI hot-formed skelp through a set of round pass welding rolls.

units are to be regarded separately as standard.Within the text,

3.2.2 lot, n—a quantity of pipe of the same ordered

the SI units are shown in brackets. The values in each system

diameter, heat, wall thickness, and grade as given in Table 1.

are not exact equivalents; therefore, each system is to be used

3.2.3 specified outside diameter (OD), n— the outside

independently of the other.

diameterspecifiedinthepurchaseorderortheoutsidediameter

listedinASMEB36.10Mforthenominalpipesizespecifiedin

2. Referenced Documents

the purchase order.

2.1 ASTM Standards:

4. General Requirements

A450/A450MSpecification for General Requirements for

Carbon and Low Alloy Steel Tubes 4.1 Pipe furnished under this specification shall conform to

A530/A530MSpecification for General Requirements for

the applicable requirements of Specification A530/A530M

Specialized Carbon and Alloy Steel Pipe unless otherwise provided herein.

A751Test Methods, Practices, and Terminology for Chemi-

5. Ordering Information

cal Analysis of Steel Products

A941TerminologyRelatingtoSteel,StainlessSteel,Related

5.1 It is the purchaser’s responsibility to specify in the

Alloys, and Ferroalloys

purchase order all information necessary to purchase the

neededmaterial.Examplesofsuchinformationinclude,butare

2.2 ASME Standard:

not limited to, the following:

ASME B36.10MWelded and SeamlessWrought Steel Pipe

5.1.1 Specification designation and year-date,

5.1.2 Quantity (feet or metres),

5.1.3 Grade (A or B),

This specification is under the jurisdiction ofASTM Committee A01 on Steel,

5.1.4 Size (either nominal (NPS) or outside diameter, and

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

wall thickness),

A01.09 on Carbon Steel Tubular Products.

Current edition approved March 1, 2012. Published November 2012. Originally

5.1.5 Length,

approved in 2005. Last previous edition approved in 2005 as A1037/A1037M–05.

5.1.6 End finish (plain-end, special plain-end, or threaded-

DOI: 10.1520/A1037_A1037M-05R12.

end, see 15.1),

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.1.7 End use of the pipe,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from American Society of Mechanical Engineers (ASME), ASME Available from The American Petroleum Institute (API), 1220 L. St., NW,

International Headquarters, Three Park Ave., New York, NY 10016-5990. Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A1037/A1037M−05 (2012)

TABLE 1 Lot Size and Sample Size for Mechanical Testing

where:

Size Sample

e = minimum elongation in percent, rounded to the nearest

Lot Size

Designation Size

percent,

C = constant = 625000 [1940],

NPS 2 through 50 tons [45 Mg] or 500 lengths, 1

A = cross-sectional area of the tensile test specimen in

NPS 4 or fraction thereof

2 2

in. [mm ], based upon the specified outside diameter

or the nominal specimen width and the specified wall

2 2

thickness, rounded to the nearest 0.01 in. [1 mm ]. If

the area thus calculated is greater than 0.75 in. [485

5.1.8 Special requirements, and 2 2

mm ], the value of 0.75 in. [485 mm ] shall be used,

5.1.9 Bar coding (see 18.3).

and

U = specified minimum tensile strength, psi [MPa].

6. Materials and Manufacture

9. Flattening Test

6.1 Thesteelshallbemadebyoneormoreofthefollowing

processes: basic-oxygen, electric-furnace, or open-hearth. 9.1 Atestspecimenatleast4in.[100mm]inlengthshallbe

flattened cold between parallel plates in three steps, with the

6.2 The pipe shall be made by the furnace-butt-welding

weldlocatedeither0°or90°fromthelineofdirectionofforce,

process.

as required in 9.2.1. Except as allowed by 9.3, during the first

step, which is a test for ductility of the weld, no cracks or

7. Chemical Composition

breaks on the inside, outside, or end surfaces at the weld shall

7.1 Thesteelshallcontain,byheatandproductanalyses,no

be present before the distance between the plates is less than

more than 0.25% carbon, 1.20% manganese, 0.045% sulfur,

two thirds of the specified diameter of the pipe. As a second

and 0.045% phosphorus.

step, the flattening shall be continued as a test for ductility

away from the weld. During the second step, no cracks or

7.2 As a minimum, the required analysis shall contain the

following elements: carbon, manganese, phosphorus, sulfur, breaks on the inside, outside, or end surfaces away from the

weld, shall be present before the distance between the plates is

chromium, columbium, copper, molybdenum, nickel, silicon,

and vanadium. less than one third of the specified outside diameter of the pipe

but is not less than five times the wall thickness of the pipe.

7.3 Product analyses shall be made on at least two samples

During the third step, which is a test for soundness, the

from each heat of steel.

flattening shall be continued until the test specimen breaks or

7.4 All analyses shall be in accordance with Test Methods,

the opposite walls of the test specimen meet. Evidence of

Practices, and Terminology A751.

laminated or unsound material or of incomplete weld that is

revealed by the flattening test shall be cause for rejection.

7.5 Ifoneorbothoftheproductanalysesrepresentingaheat

failstoconformtothespecifiedrequirements,theheatshallbe

9.2 The flattening test specified in 9.1 shall be made as

rejected, or analyses shall be made on double the original

follows:

numberoftestsamplesthatfailed,eachofwhichshallconform

9.2.1 Test specimens taken from the front end of the first

to the specified requirements.

pipe intended to be supplied from each coil and the back end

of the last pipe intended to be supplied from each coil shall be

8. Tensile Requirements

flattenedwiththeweldlocatedat90°fromthelineofdirection

8.1 The material shall conform to the requirements for of force.

9.2.2 Test specimens taken from pipe at any two locations

tensile properties given in Table 2 and in 8.4.

intermediate to the front end of the first pipe and the back end

8.2 The yield strength corresponding to a total extension

of the last pipe intended to be supplied from each coil shall be

under load of 0.5% of the gage length shall be determined.

flattened with the weld located at 0° from the line of direction

8.3 Longitudinal tests shall be performed for all pipe. Such

of force.

tests shall be either strip specimens taken 90° from the weld or

9.3 When low D-to-t ratio pipe is tested, because the strain

full section specimens, at the option of the manufacturer.

imposed due to geometry is unreasonably high on the inside

8.4 The minimum elongation in 2 in. [50 mm] for each

surface at the six and twelve o’clock locations, cracks at these

grade shall be that determined by the following equation:

locations shall not be cause for rejection if the D-to-t ratio is

0.2 0.9

less than 10.

e 5 CA /U (1)

10. Hydrostatic Test

10.1 Each length of pipe shall be subjected to the hydro-

TABLE 2 Tensile Requirements

static test without leakage through the weld seam or the pipe

Yield Strength, min Tensile Strength, min

body.

Grade

psi MPa psi MPa

10.2 Each length of pipe NPS 2 or larger shall be tested, by

A 30 000 205 48 000 330

the manufacturer, to a minimum hydrostatic pressure calcu-

B 35 000 240 60 000 415

lated from the following relationship:

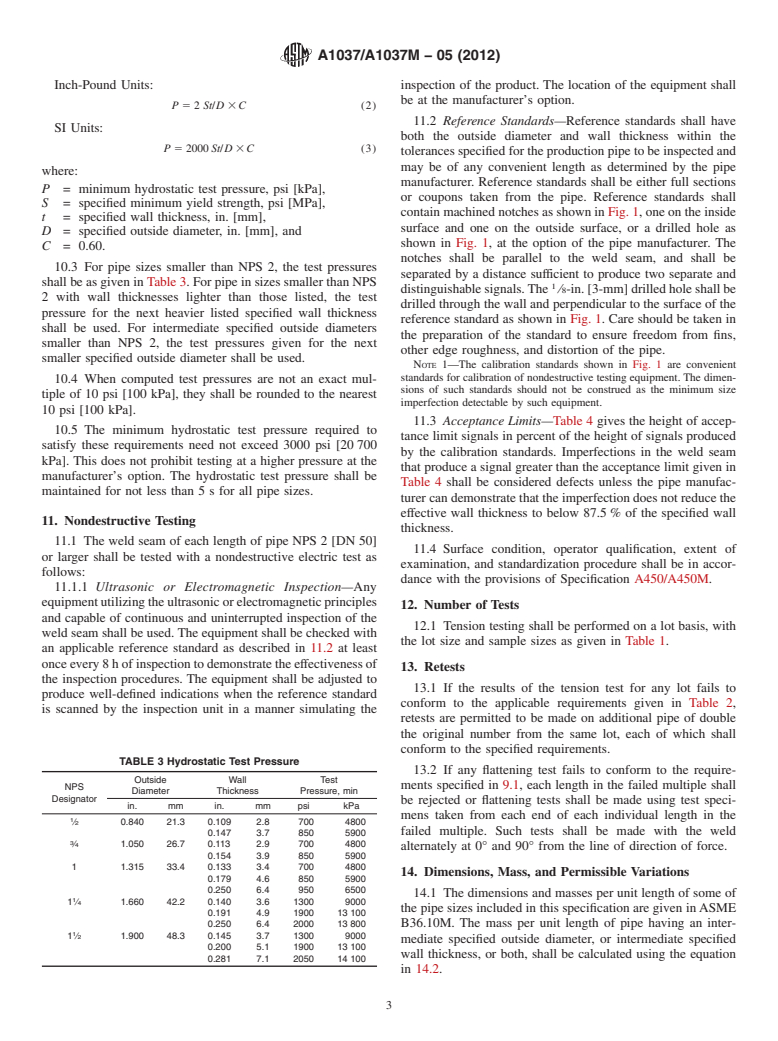

A1037/A1037M−05 (2012)

Inch-Pound Units: inspection of the product. The location of the equipment shall

be at the manufacturer’s option.

P 5 2 St/D 3C (2)

11.2 Reference Standards—Reference standards shall have

SI Units:

both the outside diameter and wall thickness within the

P 5 2000 St/D 3C (3)

tolerancesspecifiedfortheproductionpipetobeinspectedand

may be of any convenient length as determined by the pipe

where:

manufacturer. Reference standards shall be either full sections

P = minimum hydrostatic test pressure, psi [kPa],

or coupons taken from the pipe. Reference standards shall

S = specified minimum yield strength, psi [MPa],

containmachinednotchesasshowninFig.1,oneontheinside

t = specified wall thickness, in. [mm],

surface and one on the outside surface, or a dr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.