ASTM D7112-05

(Test Method)Standard Test Method for Determining Stability and Compatibility of Heavy Fuel Oils and Crude Oils by Heavy Fuel Oil Stability Analyzer (Optical Detection)

Standard Test Method for Determining Stability and Compatibility of Heavy Fuel Oils and Crude Oils by Heavy Fuel Oil Stability Analyzer (Optical Detection)

SCOPE

1.1 This test method covers an automated procedure involving titration and optical detection of precipitated asphaltenes for determining the stability and compatibility parameters of refinery residual streams, residual fuel oils, and crude oils. Stability in this context is the ability to maintain asphaltenes in a peptized or dissolved state and not undergo flocculation or precipitation. Similarly, compatibility relates to the property of mixing two or more oils without precipitation or flocculation of asphaltenes.

1.2 This test method is applicable to residual products from atmospheric and vacuum distillation, from thermal, catalytic, and hydrocracking processes, to products typical of Specifications D 396, Grades No. 5L, 5H, and 6, and D 2880, Grades No. 3-GT and 4-GT, and to crude oils, providing these products contain 0.05 mass % or greater concentration of asphaltenes.

1.3 This test method is not relevant to oils that contain less than 0.05 % asphaltenes, and would be pointless to apply to unstable oils that already contain flocculated asphaltenes.

1.4 The values stated in SI units shall be considered standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

An American National Standard

Designation:D7112–05

Standard Test Method for

Determining Stability and Compatibility of Heavy Fuel Oils

and Crude Oils by Heavy Fuel Oil Stability Analyzer (Optical

Detection)

This standard is issued under the fixed designation D 7112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers an automated procedure involv-

D 4175 Terminology Relating to Petroleum, Petroleum

ing titration and optical detection of precipitated asphaltenes

Products, and Lubricants

for determining the stability and compatibility parameters of

D 4177 Practice for Automatic Sampling of Petroleum and

refinery residual streams, residual fuel oils, and crude oils.

Petroleum Products

Stability in this context is the ability to maintain asphaltenes in

D 6299 Practice for Applying Statistical Quality Assurance

a peptized or dissolved state and not undergo flocculation or

Techniques to Evaluate Analytical Measurement System

precipitation. Similarly, compatibility relates to the property of

Performance

mixingtwoormoreoilswithoutprecipitationorflocculationof

D 6560 Test Method for Determination of Asphaltenes

asphaltenes.

(Heptane Insolubles) in Crude Petroleum and Petroleum

1.2 This test method is applicable to residual products from

Products

atmospheric and vacuum distillation, from thermal, catalytic,

and hydrocracking processes, to products typical of Specifica-

3. Terminology

tions D 396, Grades No. 5L, 5H, and 6, and D 2880, Grades

3.1 Definitions:

No.3-GTand4-GT,andtocrudeoils,providingtheseproducts

3.1.1 For definitions of some terms used in this test method,

contain 0.05 mass % or greater concentration of asphaltenes.

such as crude oil, repeatability, reproducibility, and residual

1.3 This test method is not relevant to oils that contain less

fuel oil, refer to Terminology D 4175.

than 0.05 % asphaltenes, and would be pointless to apply to

3.1.2 asphaltenes, n—in petroleum technology, molecules

unstable oils that already contain flocculated asphaltenes.

of high molecular mass, high carbon/hydrogen ratio, and

1.4 The values stated in SI units shall be considered

containing hetero-atoms.

standard.

3.1.2.1 Discussion—Asphaltenes are generally found in

1.5 This standard does not purport to address all of the

crude oils and in heavy fuel oils containing residual fractions.

safety concerns, if any, associated with its use. It is the

Their presence is determined by their insolubility in alkanes

responsibility of the user of this standard to establish appro-

such as n-heptane and solubility in aromatics such as xylene.

priate safety and health practices and determine the applica-

3.1.3 compatibility, n—of crude oils and of heavy fuel oils,

bility of regulatory limitations prior to use.

the ability of two or more crude oils or fuel oils to be blended

2. Referenced Documents together within specified ratios without evidence of separation,

such as flocculation or separation of asphaltenes.

2.1 ASTM Standards:

3.1.4 flocculation, n—of asphaltenes in crude oils or heavy

D 396 Specification for Fuel Oils

fuel oils, the aggregation of colloidally dispersed asphaltenes

D 2880 Specification for Gas Turbine Fuel Oils

into larger, visible masses that may or may not settle.

3.1.5 stability reserve, n—of crude oils, heavy fuel oils, and

residual streams containing asphaltenes, the property of an oil

This test method is under the jurisdiction of ASTM Committee D02 on

to maintain asphaltenes in a peptized (colloidally dispersed)

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

state and prevent their flocculation when stored or when

D02.14 on Stability and Cleanliness of Liquid Fuels.

Current edition approved April 1, 2005. Published April 2005.

blended with other oils.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.1.5.1 Discussion—An oil with a high stability reserve can

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be stored for a long period of time or blended with a range of

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. other oils without flocculation of asphaltenes.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7112–05

3.2 Definitions of Terms Specific to This Standard: indicates that an oil is more stable with respect to flocculation

of asphaltenes. P-value by this test method relates specifically

3.2.1 aromatic solvent equivalent (xylene equivalent), SE,

toxyleneand n-heptaneasthearomaticandparaffinicsolvents,

n—the lowest aromatic solvent (xylene) content, expressed as

a volume %, in a mixture containing aromatic and paraffinic respectively.

3.2.9 P , n—the P-value of an asphaltene, which is the

solvents (xylene and n-heptane) which, when mixed with oil,

a

will not result in flocculation of asphaltenes. See flocculation peptizability or ability of an asphaltene to remain colloidally

dispersed.

ratio.

3.2.10 P , n—the P-value of an oil matrix. See oil matrix.

3.2.1.1 Discussion—SE is defined as FR multiplied by

o

5/1

3.2.11 peptize, v—of an oil or cutter stock, to dissolve an

100 %, as shown in Eq 2.

asphaltene or to maintain an asphaltene in colloidal dispersion.

3.2.2 evaporation correction coeffıcient, n—the rate of

3.2.12 solubility blending number, S , n—a crude oil

evaporation of aromatic solvent (xylene) from the sample cup, BN

blending model parameter which can be used to determine if

measured in grams per hour.

blends of oils are incompatible or compatible. See insolubility

3.2.3 flocculation ratio (FR), n—the lowest aromatic sol-

number.

vent (xylene) concentration, expressed as a proportion of

3.2.12.1 Discussion—Solubility blending numbers for indi-

xylene to xylene plus n-heptane which, when mixed with an

vidual oils are determined and calculated from the density of

oil, will not result in flocculation of asphaltenes. See 15.1,Eq

the oil, aromatic solvent equivalent value, and volume of

1.

paraffinic solvent that can be added to 5 mL of oil without

3.2.4 FR , n—theflocculationratioatadilutionof5mLof

5/1

asphaltene precipitation. The equations are given under Calcu-

xylene and n-heptane solvent mixture to1gof oil.

lation of Results (see 15.2).

3.2.4.1 Discussion—The ratio 5 to 1 is used internally by a

3.2.13 step size, n—the volume in mL of each portion of

number of oil companies involved with the stability and

n-heptane added to the stock solution in the course of the test

compatibility of heavy fuel oils and crude oils. This ratio is

procedure.

chosen so that a P-value of six represents an FR of zero.

5/1

3.2.14 stock solution, n—asolutionofasampledissolvedin

3.2.5 insolubility number, I , n—a crude oil blending model

N

a specific amount of xylene.

parameter which can be used to determine if blends of oils are

3.3 Symbols:

compatible or incompatible. See solubility blending number.

FR = flocculation ratio

3.2.5.1 Discussion—Insolubilitynumbersforindividualoils

FR = flocculation ratio at a dilution of 5 mL solution

5/1

are determined and calculated from the density of the oil,

(xylene plus n-heptane) to1gofoil

aromatic solvent equivalent value and volume of paraffinic

FR = maximum flocculation ratio

max

solvent (n-heptane) that can be added to 5 mL of oil without

I = insolubility number

N

asphaltene precipitation. The equations are given under Calcu-

P = the P-value of an oil

lation of Results (see 15.2).

P = the P-value of an asphaltene

a

3.2.6 maximum flocculation ratio, FR , n—of asphaltenes

max

P = the P-value or peptizing power of an oil matrix

o

in residual fuel oils and crude oils, the minimum required

S = solubility blending number

BN

solvency power of a solvent mixture, expressed as a ratio by

SE = xylene equivalent, volume %

volume of aromatic solvent (xylene) to aromatic solvent plus

X = n-heptane consumption of undiluted oil, in mL/g of

min

paraffinic solvent (n-heptane) to keep the asphaltenes in an oil

oil

colloidally dispersed.

3.2.6.1 Discussion—FR is determined from a plot of

4. Summary of Test Method

max

flocculation ratios versus the oil concentration in solvent,

4.1 Stability and compatibility parameters are determined

extrapolated to infinite dilution of the sample at the y-axis

by titration and optical detection of precipitated asphaltenes.A

(where (1/X) = 0. See Eq 3).

stock solution is prepared and three different mixtures of the

3.2.7 oil matrix, n—that portion of a sample of heavy fuel

sample oil plus xylene are titrated with n-heptane to cause

oil or crude oil that surrounds and colloidally disperses the

precipitation of asphaltenes. The titrated mixture is continu-

asphaltenes.

ously circulated through an optical detector which detects

3.2.7.1 Discussion—For purposes of this test method, an oil

precipitatedasphaltenesbyback-scatteringofvisiblelight.The

sample is considered to be composed of an oil matrix (some-

amounts of oil, xylene, and n-heptane are used to calculate

times called an oil medium) and asphaltenes.

stability parameters: solvent equivalent, P-value, and FR .If

5/1

3.2.8 P-value, n—of refinery residual steams, residual fuel

the density of a crude oil sample is known, then the compat-

oils and crude oils, an indication of the stability or available

ibility parameters (S and I ) of the crude oil may also be

BN N

solvency power of an oil with respect to precipitation of

calculated.

asphaltenes.

5. Significance and Use

3.2.8.1 Discussion—Since the equation defining P-value is

P=(1+ X ),where X istheminimumvolumeofparaffinic 5.1 Automatic determination of stability parameters using a

min min

solvent, n-heptane, (in mL) needed to be added to1gofoilto light back-scattering technique improves accuracy and re-

result in flocculation of asphaltenes, the smallest P-value is 1, moves human errors. In manual testing, operators have to

which means the oil is unstable and can precipitate asphaltenes visually compare oil stains on pieces of filter paper to deter-

without addition of any paraffinic solvent. A higher P-value mine if asphaltenes have been precipitated.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7112–05

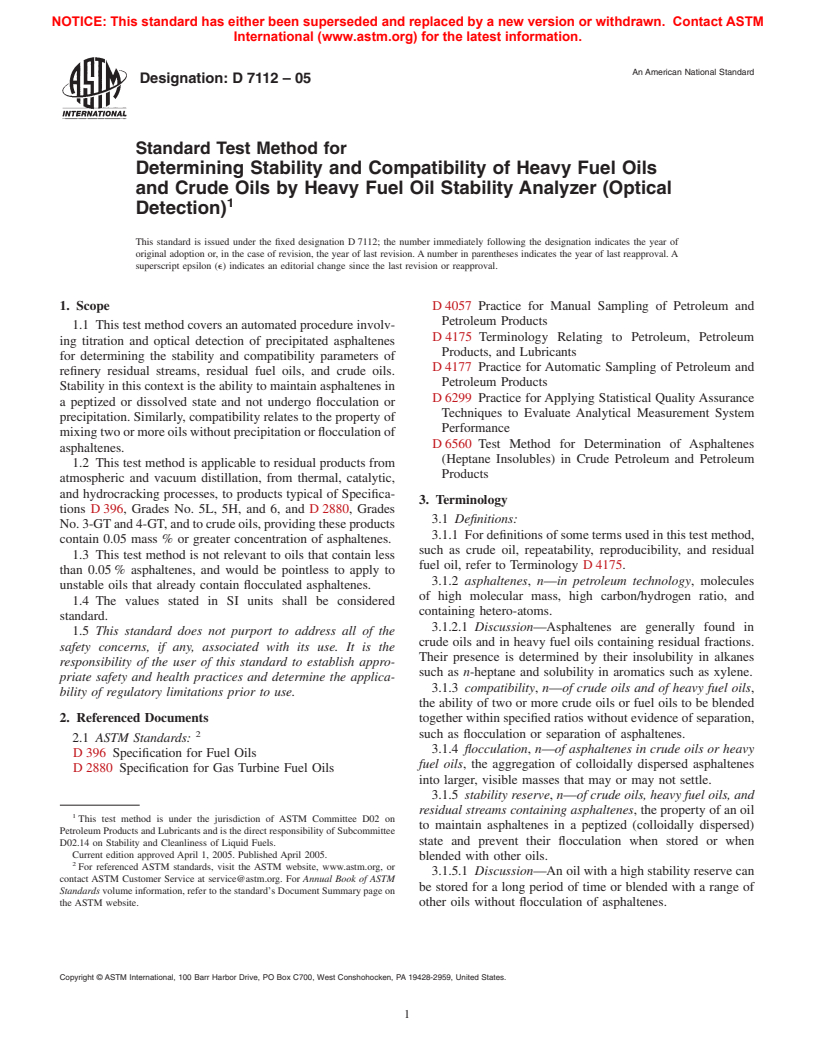

FIG. 1 Schematic Diagram of PORLA Heavy and Crude Oil Stability and Compatibility Analyzer

5.2 Refinery thermal and hydrocracking processes can be 6.2 Solid particles, such as coke or wax particles, mud,

run closer to their severity limits if stability parameters can be sand, or catalyst fines, in the oil will not affect the optical

calculated more accurately. This gives increased yield and detector or interfere with the results.

profitability.

7. Apparatus

5.3 Results from the test method could be used to set a

7.1 PORLA Heavy and Crude Oil Stability and Compatibil-

standard specification for stability parameters for fuel oils.

,

3 4

ity Analyzer —See Fig. 1.

5.4 The compatibility parameters of crude oils can be used

7.1.1 Aportion of the apparatus is shown diagrammatically

in crude oil blending in refineries to determine, in advance,

in Fig. 1 and is comprised of the following parts:

whichcrudeoilblendswillbecompatibleandthuscanbeused

7.1.1.1 Sample Cup, light weight, inert cups designed to fit

to minimize plugging problems, unit shut downs, and mainte-

the sample carousel, with a smooth, flat bottom, volume

nance costs. Determination of crude oil compatibility param-

approximately 100 mL. Typically, aluminum cups have been

eters also enables refineries to select crude oil mixtures more

used.

economically.

7.1.1.2 Sample Carousel, typically a four-position sample

5.5 Thistestmethodcanmeasurestabilityandcompatibility

cup holder delivering the sample cups sequentially to the

parameters, and determine stability reserve on different blends

measurement position.

for particular applications to optimize the blending, storage,

and use of heavy fuel oils

The PORLA Heavy and Crude Oil Stability and Compatibility Analyzer is

NOTE 1—Users of this test method would normally use stability and

covered by Euro patent EP 0737309 and U.S. patent US5715046. Interested parties

compatibility parameters to determine stability reserve of residual prod-

are invited to submit information regarding the identification of an alternative(s) to

ucts, fuel blends and crude oils. However, the interpretation of stability,

this patented item to the ASTM International Headquarters. Your comments will

stability reserve and compatibility is heavily ‘use dependent,’ and is

receive careful consideration at a meeting of the responsible technical committee,

beyond the scope of this test method.

which you may attend.

The sole source of supply of the PORLA Heavy and Crude Oil Stability and

6. Interferences

CompatibilityAnalyzerknowntothecommitteeatthistimeisFinnishMeasurement

Systems Limited, Outilantie 3, Fin-83750 Sotkuma, Finland. If you are aware of

6.1 Free water present in the oil can cause difficulties with

alternative suppliers, please provide this information to ASTM International

the optical detector and should be removed by centrifuging

Headquarters.Your comments will receive careful consideration at a meeting of the

prior to testing. responsible technical committee, which you may attend.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

D7112–05

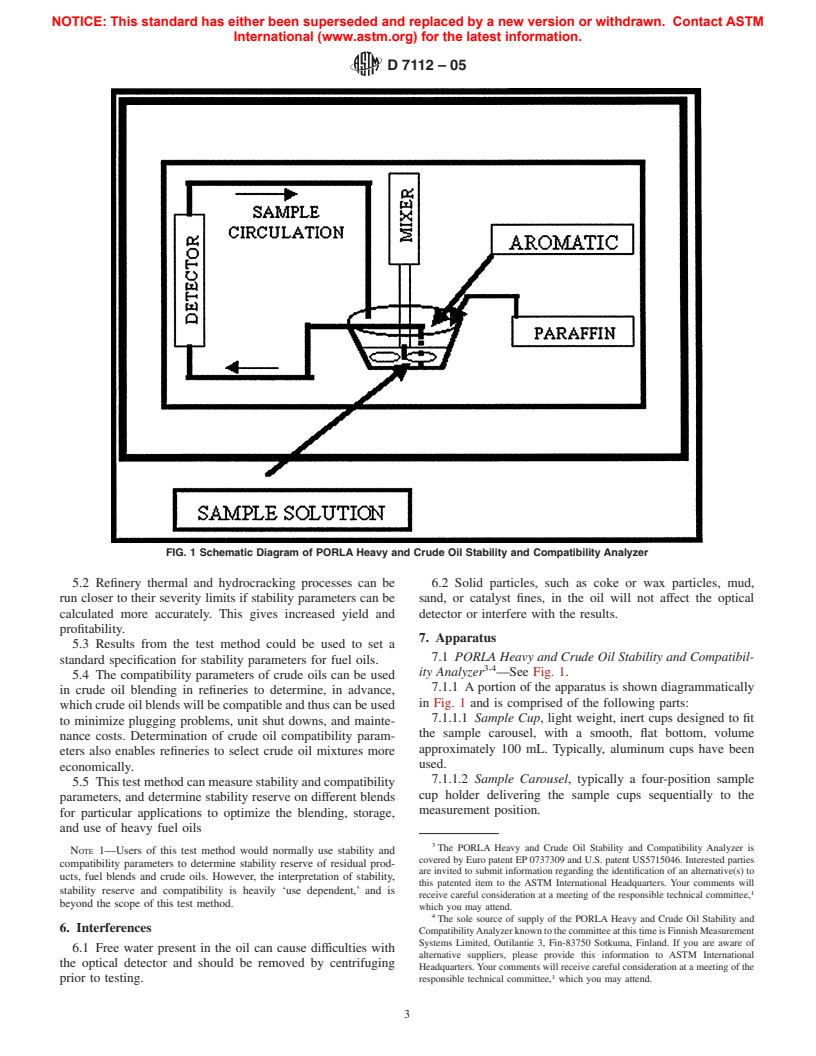

FIG. 2 Schematic Diagram of PORLA Heavy and Crude Oil Stability and Compatibility Analyzer Detector

7.1.1.3 Mixer Lift System, vertically moving lift system, 7.1.2 Computer, controls the measurement and calibration

forming a seal with the sample cup in the measurement programs and is an interface between the operator and the

position and incorporating a mechanical stirrer which starts to analyzer.

rotate when the seal is made. It also incorporates delivery lines 7.1.3 PORLA Step Measurement Screen, computer display,

for n-heptane and xylene addition, the circulation line for allowingdataaboutthesampleandoperatortobeinputaswell

passing the sample through the detector and the exhaust line, as showin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.