ASTM B173-10

(Specification)Standard Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conductors

Standard Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conductors

ABSTRACT

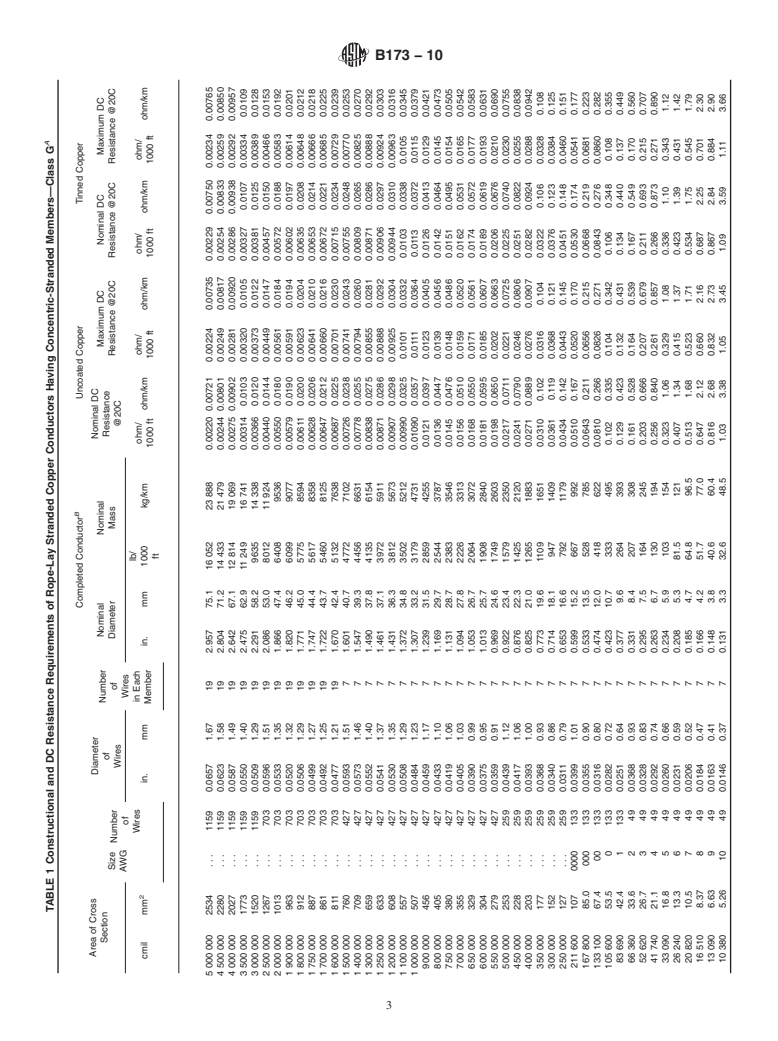

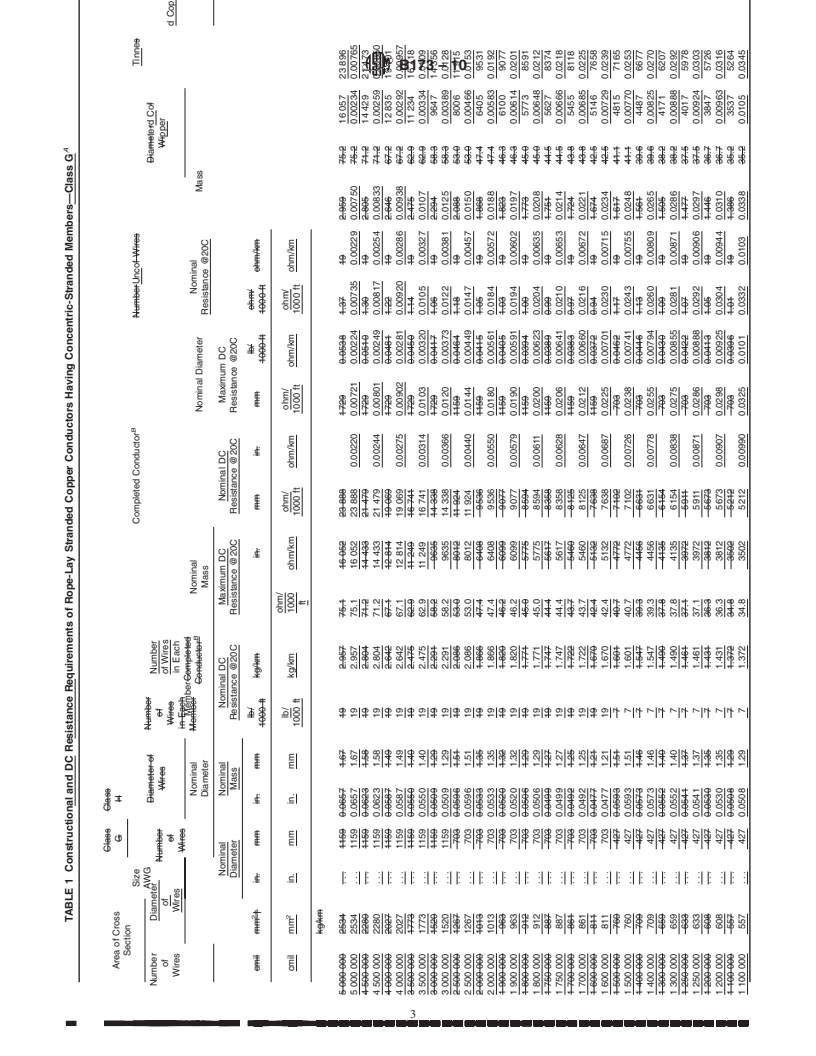

This specification covers bare rope-lay-stranded conductors having concentric-stranded members made from round copper wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors. Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective diameters and densities of uncoated wires. The rope-lay-stranded copper conductors under this specification are classified either as Class G or Class H. Requirements for joint construction (by soldering, brazing, or welding), lay length, and strand construction are detailed. Tests for the electrical properties of wires composing conductors made from soft or annealed copper wire, bare or coated, shall be made before stranding, while tests for the physical properties (such as elongation) may be made upon the wires before stranding or upon wires removed from the completed stranded conductors, but need not be made upon both. Elongation tests to determine compliance shall not be made on the conductor as a unit. If a tinning, lead-coating, or lead-alloy-coating test is required, it shall be made on the wires prior to stranding. The method of calculating mass, cross-sections and electrical resistance, and the prescribed density of copper to be taken for calculations are given.

SCOPE

1.1 This specification covers bare rope-lay-stranded conductors having concentric-stranded members made from round copper wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors (Explanatory Note 1 and Note 2).

1.2 Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective diameters and densities of uncoated wires.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. For conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B173 −10

StandardSpecification for

Rope-Lay-Stranded Copper Conductors Having Concentric-

1

Stranded Members, for Electrical Conductors

This standard is issued under the fixed designation B173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conduc-

1.1 This specification covers bare rope-lay-stranded con-

torsHavingBunch-StrandedMembers,forElectricalCon-

ductors having concentric-stranded members made from round

ductors

copper wires, either uncoated or coated with tin, lead, or

B189 Specification for Lead-Coated and Lead-Alloy-Coated

lead-alloy for use as electrical conductors (Explanatory Note 1

Soft Copper Wire for Electrical Purposes

and Note 2).

B193 Test Method for Resistivity of Electrical Conductor

1.2 Coated wires shall include only those wires with fin-

Materials

ished diameters and densities substantially equal to the respec-

B263 Test Method for Determination of Cross-Sectional

tive diameters and densities of uncoated wires.

Area of Stranded Conductors

1.3 The values stated in inch-pound or SI units are to be B354 Terminology Relating to Uninsulated Metallic Electri-

cal Conductors

regarded separately as standard. Each system shall be used

independently of the other. Combining values from the two 2.3 American National Standard:

3

systems may result in nonconformance with the specification. ANSI C42.35 Definitions of Electrical Terms

For conductor sizes designated byAWG or kcmil, the require-

3. Classification

ments in SI units have been numerically converted from

corresponding values, stated or derived, in inch-pound units.

3.1 For the purpose of this specification rope-lay-stranded

For conductor sizes designated by SI units only, the require-

conductors having concentric-stranded members are classified

ments are stated or derived in SI units.

as follows:

1.3.1 For density, resistivity, and temperature, the values

3.1.1 Class G—Conductors consisting of 7 to 61 rope-lay-

stated in SI units are to be regarded as standard.

stranded members, each of which consists of 7 to 19

concentric-stranded wires, with total conductor sizes ranging

2 2

2. Referenced Documents

from No. 14AWG (2.08 mm ) to 5 000 000 cmil (2534 mm ).

(Typical use is for rubber-sheathed conductor, apparatus

2.1 The following documents of the issue in effect at the

conductor, portable conductor, and similar applications.)

time of reference form a part of this specification to the extent

3.1.2 Class H—Conductors consisting of 19 to 91 rope-lay-

referenced herein:

stranded members, each of which consists of 7 to 19

2

2.2 ASTM Standards:

concentric-stranded wires, with total conductor sizes ranging

B3 Specification for Soft or Annealed Copper Wire

2 2

from No. 9 AWG (6.63 mm ) to 5 000 000 cmil (2534 mm ).

B8 Specification for Concentric-Lay-Stranded Copper

Class K construction produces a conductor with greater flex-

Conductors, Hard, Medium-Hard, or Soft

ibility than class G. (Typical use is for rubber-sheathed cord

B33 Specification for Tin-Coated Soft or Annealed Copper

and applications where flexibility is required such as on

take-up reels over sheaves and extra-flexible apparatus con-

ductor.)

1

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

4. Ordering Information

Conductors of Copper and Copper Alloys.

Current edition approved April 1, 2010. Published May 2010. Originally

4.1 Orders for material under this specification shall include

approvedin1942toreplaceportionsofB158 – 41 T.Lastpreviouseditionapproved

ε1

the following information:

in 2007 as B173 – 01a (2007) . DOI: 10.1520/B0173-10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B173−10

4.1.1 Quantity of each size and class; 8.2 Tests for the physical properties of soft or annealed

4.1.2 Conductor size: circular-mil area orAWG (Section 7); copper wire, bare or coated, may be made upon the wires

4.1.3 Class (Sec

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:B173–01a (Reapproved 2007) Designation: B173 – 10

Standard Specification for

Rope-Lay-Stranded Copper Conductors Having Concentric-

1

Stranded Members, for Electrical Conductors

This standard is issued under the fixed designation B173; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1

´ NOTE—Table1 was editorially corrected in March 2007.

1. Scope

1.1 This specification covers bare rope-lay-stranded conductors having concentric-stranded members made from round copper

wires, either uncoated or coated with tin, lead, or lead-alloy for use as electrical conductors (Explanatory Note 1 and Note 2).

1.2 Coated wires shall include only those wires with finished diameters and densities substantially equal to the respective

diameters and densities of uncoated wires.

1.3 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used

independently of the other. Combining values from the two systems may result in nonconformance with the specification. For

conductor sizes designated by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding

values, stated or derived, in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or

derived in SI units.

1.3.1 For density, resistivity, and temperature, the values stated in SI units are to be regarded as standard.

2. Referenced Documents

2.1 The following documents of the issue in effect at the time of reference form a part of this specification to the extent

referenced herein:

2

2.2 ASTM Standards:

B3 Specification for Soft or Annealed Copper Wire

B8 Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

2.3 American National Standard:

3

ANSI C42.35 Definitions of Electrical Terms

3. Classification

3.1 For the purpose of this specification rope-lay-stranded conductors having concentric-stranded members are classified as

follows:

3.1.1 Class G—Conductors consisting of 7 to 61 rope-lay-stranded members, each of which consists of 7 to 19 concentric-

2 2

stranded wires, with total conductor sizes ranging from No. 14AWG (2.08 mm ) to 5 000 000 cmil (2534 mm ). (Typical use is

for rubber-sheathed conductor, apparatus conductor, portable conductor, and similar applications.)

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved March 15, 2007. Published April 2007. Originally approved in 1942 to replace portions of B158–41T. Last previous edition approved in 2001

as B173–01a. DOI: 10.1520/B0173-01AR07E01.

Current edition approvedApril 1, 2010. Published May 2010. Originally approved in 1942 to replace portions of B158 – 41 T. Last previous edition approved in 2007 as

´1

B173 – 01a (2007) . DOI: 10.1520/B0173-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B173 – 10

3.1.2 Class H—Conductors consisting of 19 to 91 rope-lay-stranded members, each of which consists of 7 to 19

2 2

concentric-stranded wires, with total conductor sizes ranging from No. 9AWG (6.63 mm ) to 5 000 000 cmil (2534 mm ). Class

K co

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.