ASTM B8-11(2017)

(Specification)Standard Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

Standard Specification for Concentric-Lay-Stranded Copper Conductors, Hard, Medium-Hard, or Soft

ABSTRACT

This specification covers standard requirements for bare-concentric-lay stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core surrounded by one or more layers of helically laid wires. The conductors shall be classified as follows: Class AA, Class A, Class B, Class C, and Class D. Sizes, number of wires, and diameter of wires in the various classes of concentric-lay-stranded conductors shall conform to the prescribed requirements. Welds and brazes may be made in rods or in wires prior to final drawing. The completed conductor of varying classes shall conform to the minimum distance required between the joints. Diameters, areas, and mass of concentric-lay-stranded copper conductors shall conform to the prescribed requirements. Physical and electrical tests of conductors stranded of hard-drawn or medium-hard-drawn wires shall be conducted before but not after stranding. The approximate mass and electrical resistance may be determined using the required increments. The material shall also conform to the temperature corrections factor for conductor resistance.

SCOPE

1.1 This specification covers bare concentric-lay-stranded conductors made from round copper wires, either uncoated or coated with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core surrounded by one or more layers of helically laid wires.

Note 1: This specification also permits conductors for use as covered or insulated electrical conductors.

Note 2: Sealed conductors, that are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within the guidelines of this specification.

1.2 For the purposes of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

1.2.1 Class AA—For bare conductors usually used in overhead lines.

1.2.2 Class A—For conductors to be covered with weather-resistant (weather-proof), slow-burning materials, and for bare conductors where greater flexibility than is afforded by Class AA is required.

1.2.3 Class B—For conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and for the conductors indicated under Class A where greater flexibility is required.

1.2.4 Class C and Class D—For conductors where greater flexibility is required than is provided by Class B conductors.

1.3 The SI values for density are regarded as the standard. For all other properties, the inch-pound values are to be regarded as standard and the SI units may be approximate.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:B8 −11 (Reapproved 2017)

Standard Specification for

Concentric-Lay-Stranded Copper Conductors, Hard,

Medium-Hard, or Soft

This standard is issued under the fixed designation B8; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers bare concentric-lay-stranded 2.1 ASTM Standards:

conductors made from round copper wires, either uncoated or B1Specification for Hard-Drawn Copper Wire

coatedwithtin,lead,orleadalloyforgeneraluseforelectrical B2Specification for Medium-Hard-Drawn Copper Wire

purposes. These conductors shall be constructed with a central B3Specification for Soft or Annealed Copper Wire

core surrounded by one or more layers of helically laid wires. B33Specification for Tin-Coated Soft or Annealed Copper

Wire for Electrical Purposes

NOTE 1—This specification also permits conductors for use as covered

B172Specification for Rope-Lay-Stranded Copper Conduc-

or insulated electrical conductors.

torsHavingBunch-StrandedMembers,forElectricalCon-

NOTE 2—Sealed conductors, that are intended to prevent longitudinal

water propagation and are further covered/insulated, are also permitted

ductors

within the guidelines of this specification.

B173Specification for Rope-Lay-Stranded Copper Conduc-

1.2 For the purposes of this specification, conductors are tors Having Concentric-Stranded Members, for Electrical

classified as follows (Explanatory Note 1 and Note 2): Conductors

1.2.1 Class AA—For bare conductors usually used in over- B174Specification for Bunch-Stranded Copper Conductors

head lines. for Electrical Conductors

1.2.2 Class A—For conductors to be covered with weather- B189Specification for Lead-Coated and Lead-Alloy-Coated

resistant (weather-proof), slow-burning materials, and for bare Soft Copper Wire for Electrical Purposes

conductors where greater flexibility than is afforded by Class B193Test Method for Resistivity of Electrical Conductor

AA is required. Materials

1.2.3 Class B—For conductors to be insulated with various B246Specification for Tinned Hard-Drawn and Medium-

materials such as rubber, paper, varnished cloth, and so forth, Hard-Drawn Copper Wire for Electrical Purposes

and for the conductors indicated under Class A where greater B263Test Method for Determination of Cross-Sectional

flexibility is required. Area of Stranded Conductors

1.2.4 Class C and Class D—For conductors where greater B354Terminology Relating to Uninsulated Metallic Electri-

flexibility is required than is provided by Class B conductors. cal Conductors

B787/B787M Specification for 19 Wire Combination

1.3 The SI values for density are regarded as the standard.

Unilay-Stranded Copper Conductors for Subsequent Insu-

For all other properties, the inch-pound values are to be

lation

regarded as standard and the SI units may be approximate.

1.4 This international standard was developed in accor-

3. Ordering Information

dance with internationally recognized principles on standard-

3.1 Ordersformaterialunderthisspecificationshallinclude

ization established in the Decision on Principles for the

the following information:

Development of International Standards, Guides and Recom-

3.1.1 Quantity of each size and class,

mendations issued by the World Trade Organization Technical

3.1.2 Conductor size: circular-mil area orAWG (Section 6),

Barriers to Trade (TBT) Committee.

3.1.3 Class (see 1.2 and Table 1),

3.1.4 Temper (see 13.2),

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2017. Published April 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1915. Last previous edition approved in 2011 as B8–11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0008-11R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B8−11 (2017)

TABLE 1 Construction Requirements of Concentric-Lay-Stranded Copper Conductors

A

Area of Size, Class AA Class A Class B Class C Class D

Cross-Section, American

Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of

cmil Wire Gage

Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils

*5 000 000 . . . 169 172.0 217 151.8 271 135.8 271 135.8

4 500 000 . . . 169 163.2 217 144.0 271 128.9 271 128.9

4 000 000 . . . 169 153.8 217 135.8 271 121.5 271 121.5

3 500 000 . . . 127 166.0 169 143.9 217 127.0 271 113.6

*3 000 000 . . . 127 153.7 169 133.2 217 117.6 271 105.2

*2 500 000 . . . 91 165.7 127 140.3 169 121.6 217 107.3

*2 000 000 . . . 91 148.2 127 125.5 169 108.8 217 96.0

1 900 000 . . . 91 144.5 127 122.3 169 106.0 217 93.6

1 800 000 . . . 91 140.6 127 119.1 169 103.2 217 91.1

*1 750 000 . . . 91 138.7 127 117.4 169 101.8 217 89.8

1 700 000 . . . 91 136.7 127 115.7 169 100.3 217 88.5

1 600 000 . . . 91 132.6 127 112.2 169 97.3 217 85.9

*1 500 000 . . . 61 156.8 91 128.4 127 108.7 169 94.2

1 400 000 . . . 61 151.5 91 124.0 127 105.0 169 91.0

1 300 000 . . . 61 146.0 91 119.5 127 101.2 169 87.7

*1 250 000 . . . 61 143.1 91 117.2 127 99.2 169 86.0

1 200 000 . . . 61 140.3 91 114.8 127 97.2 169 84.3

1 100 000 . . . 61 134.3 91 109.9 127 93.1 169 80.7

*1 000 000 . 37 164.4 61 128.0 61 128.0 91 104.8 127 88.7

900 000 . 37 156.0 61 121.5 61 121.5 91 99.4 127 84.2

*800 000 . 37 147.0 61 114.5 61 114.5 91 93.8 127 79.4

*750 000 . 37 142.4 61 110.9 61 110.9 91 90.8 127 76.8

*700 000 . 37 137.5 61 107.1 61 107.1 91 87.7 127 74.2

650 000 . 37 132.5 61 103.2 61 103.2 91 84.5 127 71.5

*600 000 . 37 127.3 37 127.3 61 99.2 91 81.2 127 68.7

550 000 . 37 121.9 37 121.9 61 95.0 91 77.7 127 65.8

*500 000 . 19 162.2 37 116.2 37 116.2 61 90.5 91 74.1

450 000 . 19 153.9 37 110.3 37 110.3 61 85.9 91 70.3

*400 000 . 19 145.1 19 145.1 37 104.0 61 81.0 91 66.3

*350 000 . 12 170.8 19 135.7 37 97.3 61 75.7 91 62.0

*300 000 . 12 158.1 19 125.7 37 90.0 61 70.1 91 57.4

*250 000 . 12 144.3 19 114.7 37 82.2 61 64.0 91 52.4

*211 600 0000 7 173.9 7 173.9 19 105.5 37 75.6 61 58.9

*167 800 000 7 154.8 7 154.8 19 94.0 37 67.3 61 52.4

*133 100 00 7 137.9 7 137.9 19 83.7 37 60.0 61 46.7

*105 600 0 7 122.8 7 122.8 19 74.5 37 53.4 61 41.6

B

*83 690 1 3 167.0 7 109.3 19 66.4 37 47.6 61 37.0

B

*66 360 2 3 148.7 7 97.4 7 97.4 19 59.1 37 42.4

B

*52 620 3 3 132.5 7 86.7 7 86.7 19 52.6 37 37.7

B

*41 740 4 3 118.0 7 77.2 7 77.2 19 46.9 37 33.6

*33 090 5 . . . . 7 68.8 19 41.7 37 29.9

*26 240 6 . . . . 7 61.2 19 37.2 37 26.6

*20 820 7 . . . . 7 54.5 19 33.1 37 23.7

*16 510 8 . . . . 7 48.6 19 29.5 37 21.1

*13 090 9 . . . . 7 43.2 19 26.2 37 18.8

*10 380 10 . . . . 7 38.5 19 23.4 37 16.7

*6 530 12 . . . . 7 30.5 19 18.5 37 13.3

*4 110 14 . . . . 7 24.2 19 14.7 37 10.5

*2 580 16 . . . . 7 19.2 19 11.7 . .

*1 620 18 . . . . 7 15.2 19 9.2 . .

*1 020 20 . . . . 7 12.1 19 7.3 . .

*640 22 . . . . 7 9.6 19 5.8 . .

*404 24 . . . . 7 7.6 19 4.6 . .

* The sizes of conductors that have been marked with an asterisk provide for one or more schedules of preferred series, and are commonly used in the industry. The

sizes not marked are given simply as a matter of reference and it is suggested that their use be discouraged.

A

For unidirectional/unilay constructions the number of wires shown are minimum requirements.

B

Although Class AA conductors having three strands do not conform to the construction requirements of 1.1, they are listed in this table for convenience.

3.1.5 Whether coated or uncoated; if coated, designate type 3.1.11 Place of inspection (see Section 14).

of coating (see 13.1 and 13.2),

3.1.6 Details of special-purpose lays, if required (see 5.4),

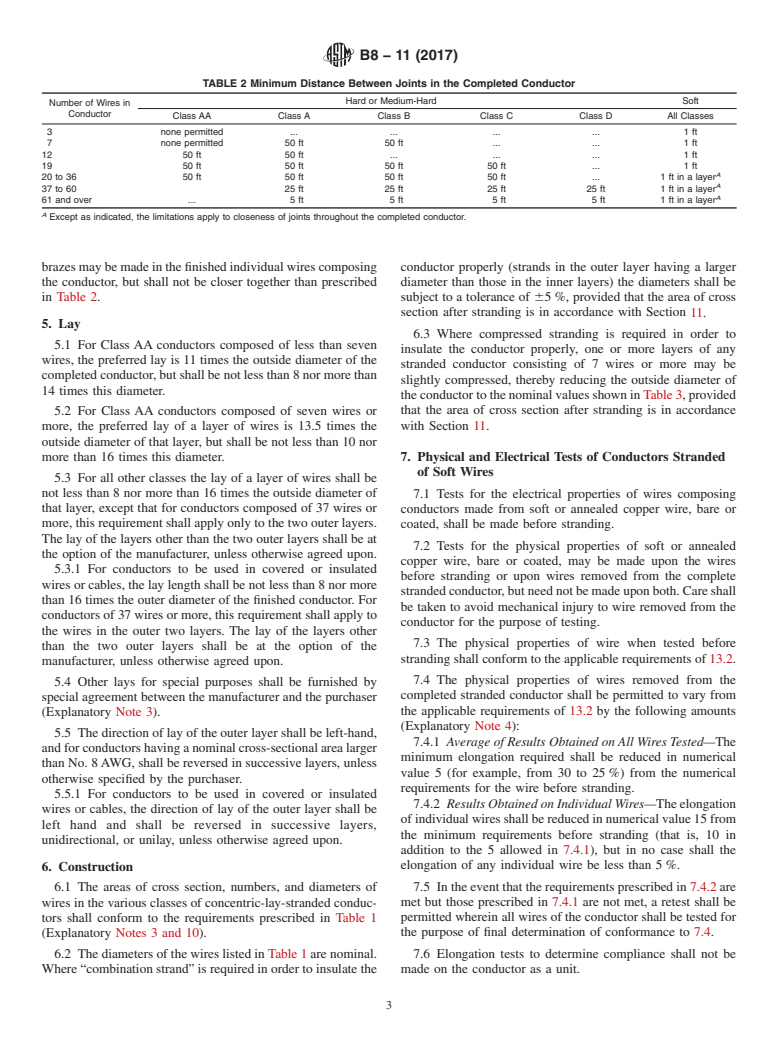

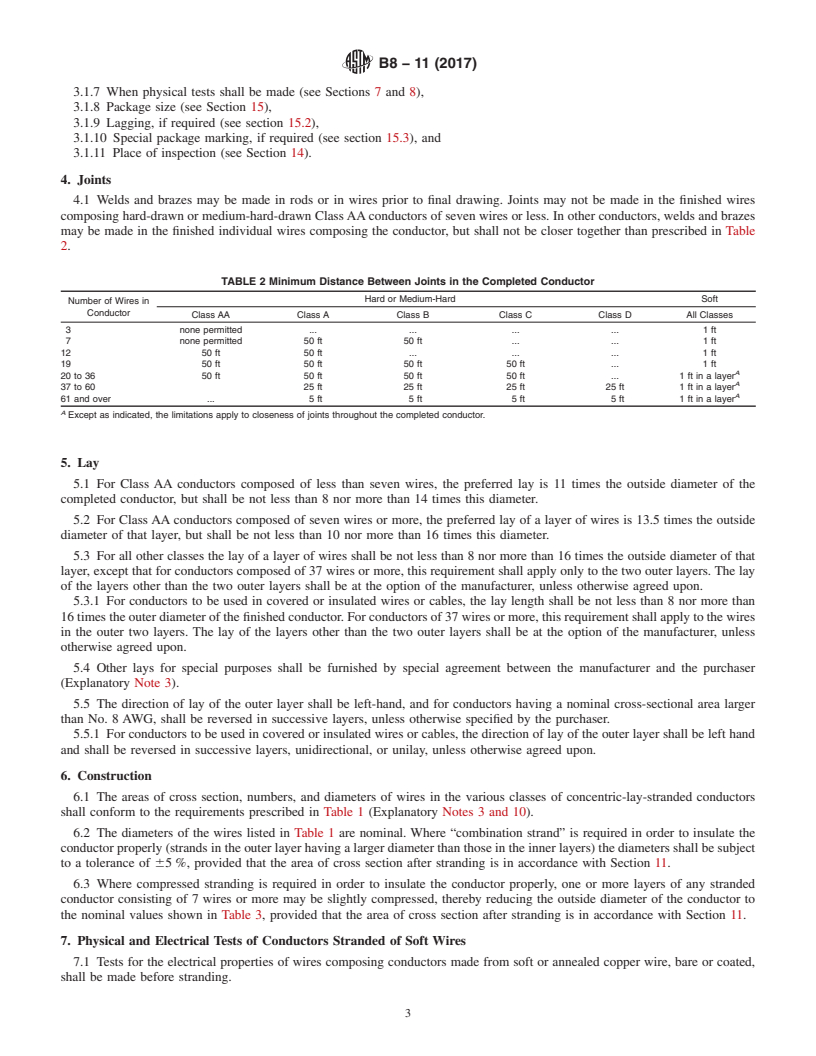

4. Joints

3.1.7 Whenphysicaltestsshallbemade(seeSections7and

4.1 Welds and brazes may be made in rods or in wires prior

8),

to final drawing. Joints may not be made in the finished wires

3.1.8 Package size (see Section 15),

composing hard-drawn or medium-hard-drawn ClassAAcon-

3.1.9 Lagging, if required (see section 15.2),

ductors of seven wires or less. In other conductors, welds and

3.1.10 Special package marking, if required (see section

15.3), and

B8−11 (2017)

TABLE 2 Minimum Distance Between Joints in the Completed Conductor

Hard or Medium-Hard Soft

Number of Wires in

Conductor

Class AA Class A Class B Class C Class D All Classes

3 none permitted . . . . 1 ft

7 none permitted 50 ft 50 ft . . 1 ft

12 50 ft 50 ft . . . 1 ft

19 50 ft 50 ft 50 ft 50 ft . 1 ft

A

20 to 36 50 ft 50 ft 50 ft 50 ft . 1 ft in a layer

A

37 to 60 25 ft 25 ft 25 ft 25 ft 1 ft in a layer

A

61 and over . 5 ft 5 ft 5 ft 5 ft 1 ft in a layer

A

Except as indicated, the limitations apply to closeness of joints throughout the completed conductor.

brazesmaybemadeinthefinishedindividualwirescomposing conductor properly (strands in the outer layer having a larger

the conductor, but shall not be closer together than prescribed diameter than those in the inner layers) the diameters shall be

in Table 2. subject to a tolerance of 65%, provided that the area of cross

section after stranding is in accordance with Section 11.

5. Lay

6.3 Where compressed stranding is required in order to

5.1 For Class AA conductors composed of less than seven

insulate the conductor properly, one or more layers of any

wires, the preferred lay is 11 times the outside diameter of the

stranded conductor consisting of 7 wires or more may be

completedconductor,butshallbenotlessthan8normorethan

slightly compressed, thereby reducing the outside diameter of

14 times this diameter.

theconductortothenominalvaluesshowninTable3,provided

5.2 For Class AA conductors composed of seven wires or that the area of cross section after stranding is in accordance

with Section 11.

more, the preferred lay of a layer of wires is 13.5 times the

outside diameter of that layer, but shall be not less than 10 nor

more than 16 times this diameter. 7. Physical and Electrical Tests of Conductors Stranded

of Soft Wires

5.3 For all other classes the lay of a layer of wires shall be

not less than 8 nor more than 16 times the outside diameter of 7.1 Tests for the electrical properties of wires composing

that layer, except that for conductors composed of 37 wires or

conductors made from soft or annealed copper wire, bare or

more,thisrequirementshallapplyonlytothetwoouterlayers. coated, shall be made before stranding.

The lay of the layers other than the two outer layers shall be at

7.2 Tests for the physical properties of soft or annealed

the option of the manufacturer, unless otherwise agreed upon.

copper wire, bare or coated, may be made upon the wires

5.3.1 For conductors to be used in covered or insulated

before stranding or upon wires removed from the complete

wiresorcables,thelaylengthshallbenotlessthan8normore

strandedconductor,butneednotbemadeuponboth.Careshall

than 16 times the outer diameter of the finished conductor. For

be taken to avoid mechanical injury to wire removed from the

conductorsof37wiresormore,thisrequirementshallapplyto

conductor for the purpose of testing.

the wires in the outer two layers. The lay of the layers other

7.3 The physical properties of wire when tested before

than the two outer layers shall be at the option of the

strandingshallconformtotheapplicablerequirementsof13.2.

manufacturer, unless otherwise agreed upon.

7.4 The physical properties of wires removed from the

5.4 Other lays for special purposes shall be furnished by

completed stranded conductor shall be permitted to vary from

special agreement between the manufacturer and the purchaser

the applicable requirements of 13.2 by the following amounts

(Explanatory Note 3).

(Explanatory Note 4):

5.5 Thedirectionoflayoftheouterlayershallbeleft-hand,

7.4.1 AverageofResultsObtainedonAllWiresTested—The

andforconductorshavinganominalcross-sectionalarealarger

minimum elongation required shall be reduced in numerical

than No. 8AWG, shall be reversed in successive layers, unless

value 5 (for example, from 30 to 25%) from the numerical

otherwise specified by the purchaser.

requirements for the wire before stranding.

5.5.1 For conductors to be used in covered or insulated

7.4.2 ResultsObtainedonIndividualWires—Theelongation

wires or cables, the direction of lay of the outer layer shall be

ofindividualwiresshallbereducedinnumericalvalue15from

left hand and shall be reversed in successive layers,

the minimum requirements before stranding (that is, 10 in

unidirectional, or unilay, unless otherwise agreed upon.

addition to the 5 allowed in 7.4.1), but in no case shall the

elongation of any individual wire be less than 5%.

6. Construction

7.5 Intheeventthattherequirementsprescribedin7.4.2are

6.1 The areas of cross section, numbers, and diameters of

wires in the various classes of concentric-lay-stranded conduc- met but those prescribed in 7.4.1 are not met, a retest shall be

permitted wherein all wires of the conductor shall be tested for

tors shall conform to the requirements prescribed in Table 1

the purpose of final determination of conformance to 7.4.

(Explanatory Notes 3 and 10).

6.2 ThediametersofthewireslistedinTable1arenominal. 7.6 Elongation tests to determine compliance shall not be

Where“combinationstrand”isrequiredinordertoinsulatethe made on the conductor as a unit.

B8−11 (2017)

TABLE 3 Diameters, Areas, and Mass of Concentric-Lay-Stranded Copper Conductors (Explanatory Note 8)

A

Nominal Conductor Diameter, in.

dc Resistance at

Size of Conductor, Mass

B

20°C

Concentric Strand

Reverse

Concentric

Unilay

Area, in.

Com-

Com-

C

cmil or AWG numbers mm Class AA Class A Class B pressed lbs/1000 ft kg/km Ω/1000 ft Ω/km

pressed

Class B Diameter,

in.

Diameter,

in.

*5 000 000 cmil 2530 . 2.580 2.581 . .

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B8 − 11 (Reapproved 2017)

Standard Specification for

Concentric-Lay-Stranded Copper Conductors, Hard,

Medium-Hard, or Soft

This standard is issued under the fixed designation B8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

1.1 This specification covers bare concentric-lay-stranded 2.1 ASTM Standards:

conductors made from round copper wires, either uncoated or B1 Specification for Hard-Drawn Copper Wire

coated with tin, lead, or lead alloy for general use for electrical B2 Specification for Medium-Hard-Drawn Copper Wire

purposes. These conductors shall be constructed with a central B3 Specification for Soft or Annealed Copper Wire

core surrounded by one or more layers of helically laid wires. B33 Specification for Tin-Coated Soft or Annealed Copper

Wire for Electrical Purposes

NOTE 1—This specification also permits conductors for use as covered

B172 Specification for Rope-Lay-Stranded Copper Conduc-

or insulated electrical conductors.

tors Having Bunch-Stranded Members, for Electrical Con-

NOTE 2—Sealed conductors, that are intended to prevent longitudinal

water propagation and are further covered/insulated, are also permitted

ductors

within the guidelines of this specification.

B173 Specification for Rope-Lay-Stranded Copper Conduc-

1.2 For the purposes of this specification, conductors are tors Having Concentric-Stranded Members, for Electrical

classified as follows (Explanatory Note 1 and Note 2): Conductors

1.2.1 Class AA—For bare conductors usually used in over- B174 Specification for Bunch-Stranded Copper Conductors

head lines. for Electrical Conductors

1.2.2 Class A—For conductors to be covered with weather- B189 Specification for Lead-Coated and Lead-Alloy-Coated

resistant (weather-proof), slow-burning materials, and for bare Soft Copper Wire for Electrical Purposes

conductors where greater flexibility than is afforded by Class B193 Test Method for Resistivity of Electrical Conductor

AA is required. Materials

1.2.3 Class B—For conductors to be insulated with various B246 Specification for Tinned Hard-Drawn and Medium-

materials such as rubber, paper, varnished cloth, and so forth, Hard-Drawn Copper Wire for Electrical Purposes

and for the conductors indicated under Class A where greater B263 Test Method for Determination of Cross-Sectional

flexibility is required. Area of Stranded Conductors

1.2.4 Class C and Class D—For conductors where greater B354 Terminology Relating to Uninsulated Metallic Electri-

flexibility is required than is provided by Class B conductors. cal Conductors

B787/B787M Specification for 19 Wire Combination

1.3 The SI values for density are regarded as the standard.

Unilay-Stranded Copper Conductors for Subsequent Insu-

For all other properties, the inch-pound values are to be

lation

regarded as standard and the SI units may be approximate.

1.4 This international standard was developed in accor-

3. Ordering Information

dance with internationally recognized principles on standard-

3.1 Orders for material under this specification shall include

ization established in the Decision on Principles for the

the following information:

Development of International Standards, Guides and Recom-

3.1.1 Quantity of each size and class,

mendations issued by the World Trade Organization Technical

3.1.2 Conductor size: circular-mil area or AWG (Section 6),

Barriers to Trade (TBT) Committee.

3.1.3 Class (see 1.2 and Table 1),

3.1.4 Temper (see 13.2),

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on

Conductors of Copper and Copper Alloys. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2017. Published April 2017. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1915. Last previous edition approved in 2011 as B8 – 11. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/B0008-11R17. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B8 − 11 (2017)

TABLE 1 Construction Requirements of Concentric-Lay-Stranded Copper Conductors

A

Area of Size, Class AA Class A Class B Class C Class D

Cross-Section, American

Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of

cmil Wire Gage

Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils

*5 000 000 . . . 169 172.0 217 151.8 271 135.8 271 135.8

4 500 000 . . . 169 163.2 217 144.0 271 128.9 271 128.9

4 000 000 . . . 169 153.8 217 135.8 271 121.5 271 121.5

3 500 000 . . . 127 166.0 169 143.9 217 127.0 271 113.6

*3 000 000 . . . 127 153.7 169 133.2 217 117.6 271 105.2

*2 500 000 . . . 91 165.7 127 140.3 169 121.6 217 107.3

*2 000 000 . . . 91 148.2 127 125.5 169 108.8 217 96.0

1 900 000 . . . 91 144.5 127 122.3 169 106.0 217 93.6

1 800 000 . . . 91 140.6 127 119.1 169 103.2 217 91.1

*1 750 000 . . . 91 138.7 127 117.4 169 101.8 217 89.8

1 700 000 . . . 91 136.7 127 115.7 169 100.3 217 88.5

1 600 000 . . . 91 132.6 127 112.2 169 97.3 217 85.9

*1 500 000 . . . 61 156.8 91 128.4 127 108.7 169 94.2

1 400 000 . . . 61 151.5 91 124.0 127 105.0 169 91.0

1 300 000 . . . 61 146.0 91 119.5 127 101.2 169 87.7

*1 250 000 . . . 61 143.1 91 117.2 127 99.2 169 86.0

1 200 000 . . . 61 140.3 91 114.8 127 97.2 169 84.3

1 100 000 . . . 61 134.3 91 109.9 127 93.1 169 80.7

*1 000 000 . 37 164.4 61 128.0 61 128.0 91 104.8 127 88.7

900 000 . 37 156.0 61 121.5 61 121.5 91 99.4 127 84.2

*800 000 . 37 147.0 61 114.5 61 114.5 91 93.8 127 79.4

*750 000 . 37 142.4 61 110.9 61 110.9 91 90.8 127 76.8

*700 000 . 37 137.5 61 107.1 61 107.1 91 87.7 127 74.2

650 000 . 37 132.5 61 103.2 61 103.2 91 84.5 127 71.5

*600 000 . 37 127.3 37 127.3 61 99.2 91 81.2 127 68.7

550 000 . 37 121.9 37 121.9 61 95.0 91 77.7 127 65.8

*500 000 . 19 162.2 37 116.2 37 116.2 61 90.5 91 74.1

450 000 . 19 153.9 37 110.3 37 110.3 61 85.9 91 70.3

*400 000 . 19 145.1 19 145.1 37 104.0 61 81.0 91 66.3

*350 000 . 12 170.8 19 135.7 37 97.3 61 75.7 91 62.0

*300 000 . 12 158.1 19 125.7 37 90.0 61 70.1 91 57.4

*250 000 . 12 144.3 19 114.7 37 82.2 61 64.0 91 52.4

*211 600 0000 7 173.9 7 173.9 19 105.5 37 75.6 61 58.9

*167 800 000 7 154.8 7 154.8 19 94.0 37 67.3 61 52.4

*133 100 00 7 137.9 7 137.9 19 83.7 37 60.0 61 46.7

*105 600 0 7 122.8 7 122.8 19 74.5 37 53.4 61 41.6

B

*83 690 1 3 167.0 7 109.3 19 66.4 37 47.6 61 37.0

B

*66 360 2 3 148.7 7 97.4 7 97.4 19 59.1 37 42.4

B

*52 620 3 3 132.5 7 86.7 7 86.7 19 52.6 37 37.7

B

*41 740 4 3 118.0 7 77.2 7 77.2 19 46.9 37 33.6

*33 090 5 . . . . 7 68.8 19 41.7 37 29.9

*26 240 6 . . . . 7 61.2 19 37.2 37 26.6

*20 820 7 . . . . 7 54.5 19 33.1 37 23.7

*16 510 8 . . . . 7 48.6 19 29.5 37 21.1

*13 090 9 . . . . 7 43.2 19 26.2 37 18.8

*10 380 10 . . . . 7 38.5 19 23.4 37 16.7

*6 530 12 . . . . 7 30.5 19 18.5 37 13.3

*4 110 14 . . . . 7 24.2 19 14.7 37 10.5

*2 580 16 . . . . 7 19.2 19 11.7 . .

*1 620 18 . . . . 7 15.2 19 9.2 . .

*1 020 20 . . . . 7 12.1 19 7.3 . .

*640 22 . . . . 7 9.6 19 5.8 . .

*404 24 . . . . 7 7.6 19 4.6 . .

* The sizes of conductors that have been marked with an asterisk provide for one or more schedules of preferred series, and are commonly used in the industry. The

sizes not marked are given simply as a matter of reference and it is suggested that their use be discouraged.

A

For unidirectional/unilay constructions the number of wires shown are minimum requirements.

B

Although Class AA conductors having three strands do not conform to the construction requirements of 1.1, they are listed in this table for convenience.

3.1.5 Whether coated or uncoated; if coated, designate type 3.1.11 Place of inspection (see Section 14).

of coating (see 13.1 and 13.2),

3.1.6 Details of special-purpose lays, if required (see 5.4),

4. Joints

3.1.7 When physical tests shall be made (see Sections 7 and

4.1 Welds and brazes may be made in rods or in wires prior

8),

to final drawing. Joints may not be made in the finished wires

3.1.8 Package size (see Section 15),

composing hard-drawn or medium-hard-drawn Class AA con-

3.1.9 Lagging, if required (see section 15.2),

ductors of seven wires or less. In other conductors, welds and

3.1.10 Special package marking, if required (see section

15.3), and

B8 − 11 (2017)

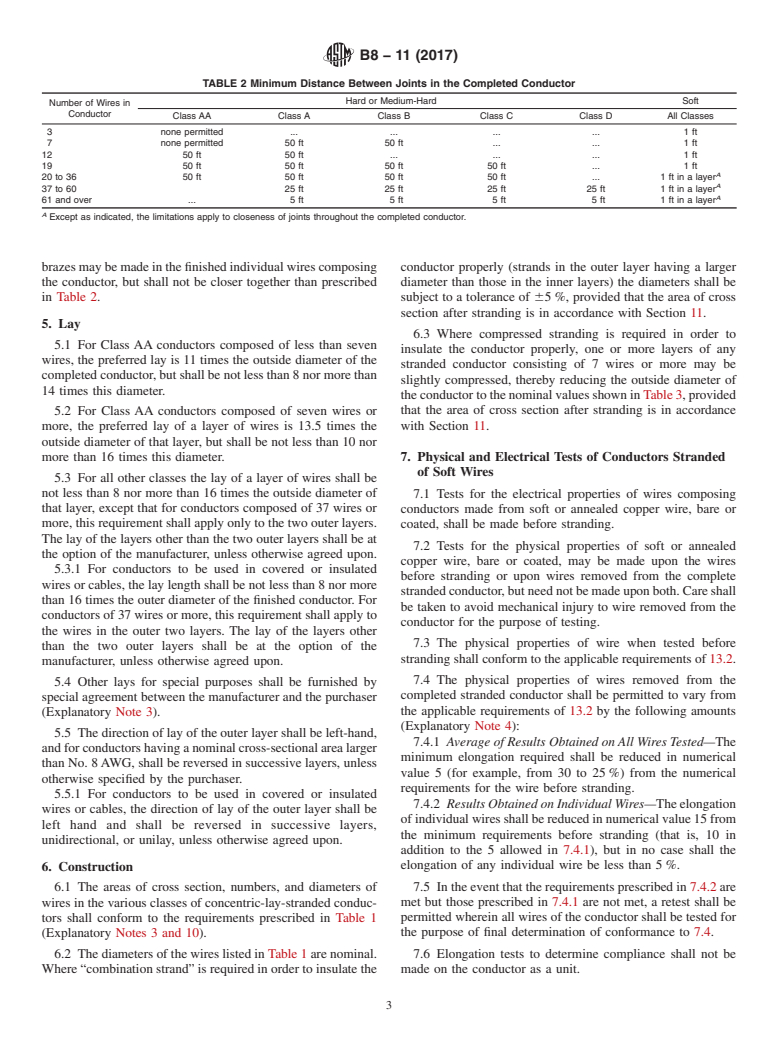

TABLE 2 Minimum Distance Between Joints in the Completed Conductor

Hard or Medium-Hard Soft

Number of Wires in

Conductor

Class AA Class A Class B Class C Class D All Classes

3 none permitted . . . . 1 ft

7 none permitted 50 ft 50 ft . . 1 ft

12 50 ft 50 ft . . . 1 ft

19 50 ft 50 ft 50 ft 50 ft . 1 ft

A

20 to 36 50 ft 50 ft 50 ft 50 ft . 1 ft in a layer

A

37 to 60 25 ft 25 ft 25 ft 25 ft 1 ft in a layer

A

61 and over . 5 ft 5 ft 5 ft 5 ft 1 ft in a layer

A

Except as indicated, the limitations apply to closeness of joints throughout the completed conductor.

brazes may be made in the finished individual wires composing conductor properly (strands in the outer layer having a larger

the conductor, but shall not be closer together than prescribed diameter than those in the inner layers) the diameters shall be

in Table 2. subject to a tolerance of 65 %, provided that the area of cross

section after stranding is in accordance with Section 11.

5. Lay

6.3 Where compressed stranding is required in order to

5.1 For Class AA conductors composed of less than seven

insulate the conductor properly, one or more layers of any

wires, the preferred lay is 11 times the outside diameter of the

stranded conductor consisting of 7 wires or more may be

completed conductor, but shall be not less than 8 nor more than

slightly compressed, thereby reducing the outside diameter of

14 times this diameter.

the conductor to the nominal values shown in Table 3, provided

that the area of cross section after stranding is in accordance

5.2 For Class AA conductors composed of seven wires or

more, the preferred lay of a layer of wires is 13.5 times the with Section 11.

outside diameter of that layer, but shall be not less than 10 nor

more than 16 times this diameter. 7. Physical and Electrical Tests of Conductors Stranded

of Soft Wires

5.3 For all other classes the lay of a layer of wires shall be

not less than 8 nor more than 16 times the outside diameter of

7.1 Tests for the electrical properties of wires composing

that layer, except that for conductors composed of 37 wires or conductors made from soft or annealed copper wire, bare or

more, this requirement shall apply only to the two outer layers.

coated, shall be made before stranding.

The lay of the layers other than the two outer layers shall be at

7.2 Tests for the physical properties of soft or annealed

the option of the manufacturer, unless otherwise agreed upon.

copper wire, bare or coated, may be made upon the wires

5.3.1 For conductors to be used in covered or insulated

before stranding or upon wires removed from the complete

wires or cables, the lay length shall be not less than 8 nor more

stranded conductor, but need not be made upon both. Care shall

than 16 times the outer diameter of the finished conductor. For

be taken to avoid mechanical injury to wire removed from the

conductors of 37 wires or more, this requirement shall apply to

conductor for the purpose of testing.

the wires in the outer two layers. The lay of the layers other

7.3 The physical properties of wire when tested before

than the two outer layers shall be at the option of the

stranding shall conform to the applicable requirements of 13.2.

manufacturer, unless otherwise agreed upon.

7.4 The physical properties of wires removed from the

5.4 Other lays for special purposes shall be furnished by

completed stranded conductor shall be permitted to vary from

special agreement between the manufacturer and the purchaser

the applicable requirements of 13.2 by the following amounts

(Explanatory Note 3).

(Explanatory Note 4):

5.5 The direction of lay of the outer layer shall be left-hand,

7.4.1 Average of Results Obtained on All Wires Tested—The

and for conductors having a nominal cross-sectional area larger

minimum elongation required shall be reduced in numerical

than No. 8 AWG, shall be reversed in successive layers, unless

value 5 (for example, from 30 to 25 %) from the numerical

otherwise specified by the purchaser.

requirements for the wire before stranding.

5.5.1 For conductors to be used in covered or insulated

7.4.2 Results Obtained on Individual Wires—The elongation

wires or cables, the direction of lay of the outer layer shall be

of individual wires shall be reduced in numerical value 15 from

left hand and shall be reversed in successive layers,

the minimum requirements before stranding (that is, 10 in

unidirectional, or unilay, unless otherwise agreed upon.

addition to the 5 allowed in 7.4.1), but in no case shall the

elongation of any individual wire be less than 5 %.

6. Construction

6.1 The areas of cross section, numbers, and diameters of 7.5 In the event that the requirements prescribed in 7.4.2 are

met but those prescribed in 7.4.1 are not met, a retest shall be

wires in the various classes of concentric-lay-stranded conduc-

tors shall conform to the requirements prescribed in Table 1 permitted wherein all wires of the conductor shall be tested for

the purpose of final determination of conformance to 7.4.

(Explanatory Notes 3 and 10).

6.2 The diameters of the wires listed in Table 1 are nominal. 7.6 Elongation tests to determine compliance shall not be

Where “combination strand” is required in order to insulate the made on the conductor as a unit.

B8 − 11 (2017)

TABLE 3 Diameters, Areas, and Mass of Concentric-Lay-Stranded Copper Conductors (Explanatory Note 8)

A

Nominal Conductor Diameter, in.

dc Resistance at

Size of Conductor, Mass

B

20°C

Concentric Strand

Reverse

Concentric

Unilay

Area, in.

Com-

Com-

C

cmil or AWG numbers mm Class AA Class A Class B pressed lbs/1000 ft kg/km

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B8 − 11 B8 − 11 (Reapproved 2017)

Standard Specification for

Concentric-Lay-Stranded Copper Conductors, Hard,

Medium-Hard, or Soft

This standard is issued under the fixed designation B8; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope

1.1 This specification covers bare concentric-lay-stranded conductors made from round copper wires, either uncoated or coated

with tin, lead, or lead alloy for general use for electrical purposes. These conductors shall be constructed with a central core

surrounded by one or more layers of helically laid wires.

NOTE 1—This specification also permits conductors for use as covered or insulated electrical conductors.

NOTE 2—Sealed conductors, that are intended to prevent longitudinal water propagation and are further covered/insulated, are also permitted within

the guidelines of this specification.

1.2 For the purposes of this specification, conductors are classified as follows (Explanatory Note 1 and Note 2):

1.2.1 Class AA—For bare conductors usually used in overhead lines.

1.2.2 Class A—For conductors to be covered with weather-resistant (weather-proof), slow-burning materials, and for bare

conductors where greater flexibility than is afforded by Class AA is required.

1.2.3 Class B—For conductors to be insulated with various materials such as rubber, paper, varnished cloth, and so forth, and

for the conductors indicated under Class A where greater flexibility is required.

1.2.4 Class C and Class D—For conductors where greater flexibility is required than is provided by Class B conductors.

1.3 The SI values for density are regarded as the standard. For all other properties, the inch-pound values are to be regarded

as standard and the SI units may be approximate.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

B1 Specification for Hard-Drawn Copper Wire

B2 Specification for Medium-Hard-Drawn Copper Wire

B3 Specification for Soft or Annealed Copper Wire

B33 Specification for Tin-Coated Soft or Annealed Copper Wire for Electrical Purposes

B172 Specification for Rope-Lay-Stranded Copper Conductors Having Bunch-Stranded Members, for Electrical Conductors

B173 Specification for Rope-Lay-Stranded Copper Conductors Having Concentric-Stranded Members, for Electrical Conduc-

tors

B174 Specification for Bunch-Stranded Copper Conductors for Electrical Conductors

B189 Specification for Lead-Coated and Lead-Alloy-Coated Soft Copper Wire for Electrical Purposes

B193 Test Method for Resistivity of Electrical Conductor Materials

B246 Specification for Tinned Hard-Drawn and Medium-Hard-Drawn Copper Wire for Electrical Purposes

B263 Test Method for Determination of Cross-Sectional Area of Stranded Conductors

B354 Terminology Relating to Uninsulated Metallic Electrical Conductors

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.04 on Conductors

of Copper and Copper Alloys.

Current edition approved April 1, 2011April 1, 2017. Published May 2011April 2017. Originally approved in 1915. Last previous edition approved in 20042011 as

B8 – 04.B8 – 11. DOI: 10.1520/B0008-11.10.1520/B0008-11R17.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B8 − 11 (2017)

B787/B787M Specification for 19 Wire Combination Unilay-Stranded Copper Conductors for Subsequent Insulation

3. Ordering Information

3.1 Orders for material under this specification shall include the following information:

3.1.1 Quantity of each size and class,

3.1.2 Conductor size: circular-mil area or AWG (Section 6),

3.1.3 Class (see 1.2 and Table 1),

3.1.4 Temper (see 13.2),

3.1.5 Whether coated or uncoated; if coated, designate type of coating (see 13.1 and 13.2),

3.1.6 Details of special-purpose lays, if required (see 5.4),

TABLE 1 Construction Requirements of Concentric-Lay-Stranded Copper Conductors

A

Area of Size, Class AA Class A Class B Class C Class D

Cross-Section, American

Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of Number of Diameter of

cmil Wire Gage

Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils Wires Wires, mils

*5 000 000 . . . 169 172.0 217 151.8 271 135.8 271 135.8

4 500 000 . . . 169 163.2 217 144.0 271 128.9 271 128.9

4 000 000 . . . 169 153.8 217 135.8 271 121.5 271 121.5

3 500 000 . . . 127 166.0 169 143.9 217 127.0 271 113.6

*3 000 000 . . . 127 153.7 169 133.2 217 117.6 271 105.2

*2 500 000 . . . 91 165.7 127 140.3 169 121.6 217 107.3

*2 000 000 . . . 91 148.2 127 125.5 169 108.8 217 96.0

1 900 000 . . . 91 144.5 127 122.3 169 106.0 217 93.6

1 800 000 . . . 91 140.6 127 119.1 169 103.2 217 91.1

*1 750 000 . . . 91 138.7 127 117.4 169 101.8 217 89.8

1 700 000 . . . 91 136.7 127 115.7 169 100.3 217 88.5

1 600 000 . . . 91 132.6 127 112.2 169 97.3 217 85.9

*1 500 000 . . . 61 156.8 91 128.4 127 108.7 169 94.2

1 400 000 . . . 61 151.5 91 124.0 127 105.0 169 91.0

1 300 000 . . . 61 146.0 91 119.5 127 101.2 169 87.7

*1 250 000 . . . 61 143.1 91 117.2 127 99.2 169 86.0

1 200 000 . . . 61 140.3 91 114.8 127 97.2 169 84.3

1 100 000 . . . 61 134.3 91 109.9 127 93.1 169 80.7

*1 000 000 . 37 164.4 61 128.0 61 128.0 91 104.8 127 88.7

900 000 . 37 156.0 61 121.5 61 121.5 91 99.4 127 84.2

*800 000 . 37 147.0 61 114.5 61 114.5 91 93.8 127 79.4

*750 000 . 37 142.4 61 110.9 61 110.9 91 90.8 127 76.8

*700 000 . 37 137.5 61 107.1 61 107.1 91 87.7 127 74.2

650 000 . 37 132.5 61 103.2 61 103.2 91 84.5 127 71.5

*600 000 . 37 127.3 37 127.3 61 99.2 91 81.2 127 68.7

550 000 . 37 121.9 37 121.9 61 95.0 91 77.7 127 65.8

*500 000 . 19 162.2 37 116.2 37 116.2 61 90.5 91 74.1

450 000 . 19 153.9 37 110.3 37 110.3 61 85.9 91 70.3

*400 000 . 19 145.1 19 145.1 37 104.0 61 81.0 91 66.3

*350 000 . 12 170.8 19 135.7 37 97.3 61 75.7 91 62.0

*300 000 . 12 158.1 19 125.7 37 90.0 61 70.1 91 57.4

*250 000 . 12 144.3 19 114.7 37 82.2 61 64.0 91 52.4

*211 600 0000 7 173.9 7 173.9 19 105.5 37 75.6 61 58.9

*167 800 000 7 154.8 7 154.8 19 94.0 37 67.3 61 52.4

*133 100 00 7 137.9 7 137.9 19 83.7 37 60.0 61 46.7

*105 600 0 7 122.8 7 122.8 19 74.5 37 53.4 61 41.6

B

*83 690 1 3 167.0 7 109.3 19 66.4 37 47.6 61 37.0

B

*66 360 2 3 148.7 7 97.4 7 97.4 19 59.1 37 42.4

B

*52 620 3 3 132.5 7 86.7 7 86.7 19 52.6 37 37.7

B

*41 740 4 3 118.0 7 77.2 7 77.2 19 46.9 37 33.6

*33 090 5 . . . . 7 68.8 19 41.7 37 29.9

*26 240 6 . . . . 7 61.2 19 37.2 37 26.6

*20 820 7 . . . . 7 54.5 19 33.1 37 23.7

*16 510 8 . . . . 7 48.6 19 29.5 37 21.1

*13 090 9 . . . . 7 43.2 19 26.2 37 18.8

*10 380 10 . . . . 7 38.5 19 23.4 37 16.7

*6 530 12 . . . . 7 30.5 19 18.5 37 13.3

*4 110 14 . . . . 7 24.2 19 14.7 37 10.5

*2 580 16 . . . . 7 19.2 19 11.7 . .

*1 620 18 . . . . 7 15.2 19 9.2 . .

*1 020 20 . . . . 7 12.1 19 7.3 . .

*640 22 . . . . 7 9.6 19 5.8 . .

*404 24 . . . . 7 7.6 19 4.6 . .

* The sizes of conductors that have been marked with an asterisk provide for one or more schedules of preferred series, and are commonly used in the industry. The

sizes not marked are given simply as a matter of reference and it is suggested that their use be discouraged.

A

For unidirectional/unilay constructions the number of wires shown are minimum requirements.

B

Although Class AA conductors having three strands do not conform to the construction requirements of 1.1, they are listed in this table for convenience.

B8 − 11 (2017)

3.1.7 When physical tests shall be made (see Sections 7 and 8),

3.1.8 Package size (see Section 15),

3.1.9 Lagging, if required (see section 15.2),

3.1.10 Special package marking, if required (see section 15.3), and

3.1.11 Place of inspection (see Section 14).

4. Joints

4.1 Welds and brazes may be made in rods or in wires prior to final drawing. Joints may not be made in the finished wires

composing hard-drawn or medium-hard-drawn Class AA conductors of seven wires or less. In other conductors, welds and brazes

may be made in the finished individual wires composing the conductor, but shall not be closer together than prescribed in Table

2.

TABLE 2 Minimum Distance Between Joints in the Completed Conductor

Hard or Medium-Hard Soft

Number of Wires in

Conductor

Class AA Class A Class B Class C Class D All Classes

3 none permitted . . . . 1 ft

7 none permitted 50 ft 50 ft . . 1 ft

12 50 ft 50 ft . . . 1 ft

19 50 ft 50 ft 50 ft 50 ft . 1 ft

A

20 to 36 50 ft 50 ft 50 ft 50 ft . 1 ft in a layer

A

37 to 60 25 ft 25 ft 25 ft 25 ft 1 ft in a layer

A

61 and over . 5 ft 5 ft 5 ft 5 ft 1 ft in a layer

A

Except as indicated, the limitations apply to closeness of joints throughout the completed conductor.

5. Lay

5.1 For Class AA conductors composed of less than seven wires, the preferred lay is 11 times the outside diameter of the

completed conductor, but shall be not less than 8 nor more than 14 times this diameter.

5.2 For Class AA conductors composed of seven wires or more, the preferred lay of a layer of wires is 13.5 times the outside

diameter of that layer, but shall be not less than 10 nor more than 16 times this diameter.

5.3 For all other classes the lay of a layer of wires shall be not less than 8 nor more than 16 times the outside diameter of that

layer, except that for conductors composed of 37 wires or more, this requirement shall apply only to the two outer layers. The lay

of the layers other than the two outer layers shall be at the option of the manufacturer, unless otherwise agreed upon.

5.3.1 For conductors to be used in covered or insulated wires or cables, the lay length shall be not less than 8 nor more than

16 times the outer diameter of the finished conductor. For conductors of 37 wires or more, this requirement shall apply to the wires

in the outer two layers. The lay of the layers other than the two outer layers shall be at the option of the manufacturer, unless

otherwise agreed upon.

5.4 Other lays for special purposes shall be furnished by special agreement between the manufacturer and the purchaser

(Explanatory Note 3).

5.5 The direction of lay of the outer layer shall be left-hand, and for conductors having a nominal cross-sectional area larger

than No. 8 AWG, shall be reversed in successive layers, unless otherwise specified by the purchaser.

5.5.1 For conductors to be used in covered or insulated wires or cables, the direction of lay of the outer layer shall be left hand

and shall be reversed in successive layers, unidirectional, or unilay, unless otherwise agreed upon.

6. Construction

6.1 The areas of cross section, numbers, and diameters of wires in the various classes of concentric-lay-stranded conductors

shall conform to the requirements prescribed in Table 1 (Explanatory Notes 3 and 10).

6.2 The diameters of the wires listed in Table 1 are nominal. Where “combination strand” is required in order to insulate the

conductor properly (strands in the outer layer having a larger diameter than those in the inner layers) the diameters shall be subject

to a tolerance of 65 %, provided that the area of cross section after stranding is in accordance with Section 11.

6.3 Where compressed stranding is required in order to insulate the conductor properly, one or more layers of any stranded

conductor consisting of 7 wires or more may be slightly compressed, thereby reducing the outside diameter of the conductor to

the nominal values shown in Table 3, provided that the area of cross section after stranding is in accordance with Section 11.

7. Physical and Electrical Tests of Conductors Stranded of Soft Wires

7.1 Tests for the electrical properties of wires composing conductors made from soft or annealed copper wire, bare or coated,

shall be made before stranding.

B8 − 11 (2017)

TABLE 3 Diameters, Areas, and Mass of Concentric-Lay-Stranded Copper Conductors (Explanatory Note 8)

A

Nominal Conductor Diameter, in.

dc Resistance at

Size of Conductor, Mass

B

20°C

Concentric Strand

Reverse

Concentric

Unilay

Area, in.

Com-

Com-

C

cmil or AWG numbers mm Class AA Class A Class B pressed lbs/1000 ft kg/km Ω/1000 ft Ω/km

pressed

Class B Diameter,

in.

Diameter,

in.

*5 000 000 cmil 2530 . 2.580 2.581 . . 3.927 15 890 23 649 0.00218 0.00715

4 500 000 cmil 2280 . 2.448 2.448 . . 3.534 14 300 21 283 0.00242 0.00794

4 000 000 cmil 2030 . 2.307 2.309 . . 3.142 12 590 18 738 0.00270 0.00886

3 500 000 cmil 1770 . 2.158 2.159 . . 2.749 11 020 16 401 0.00308 0.0101

*3 000 000 cmil 1520 . 1.998 1.998 . . 2.356 9 353 13 920 0.00356 0.0117

*2 500 000 cmil 1270 . 1.823 1.824 . . 1.963 7 794 11 600 0.00427 0.0140

*2 000 000 cmil 1010 . 1.630 1.632 1.583 1.533 1.571 6 175 9 190 0.00529 0.0174

1 900 000 cmil 963 . 1.590 1.590 1.542 1.494 1.492 5 866 8 730 0.00557 0.0183

1 800 000 cmil 912 . 1.547 1.548 1.502 1.454 1.414 5 558 8 272 0.00588 0.0193

*1 750 000 cmil 887 . 1.526 1.526 1.480 1.434 1.374 5 403 8 041 0.00604 0.0198

1 700 000 cmil 861 . 1.504 1.504 1.459 1.413 1.335 5 249 7 812 0.00622 0.0204

1 600 000 cmil 801 . 1.459 1.459 1.415 1.371 1.257 4 940 7 352 0.00661 0.0217

*1 500 000 cmil 760 . 1.411 1.412 1.370 1.327 1.178 4 631 6 892 0.00705 0.0231

1 400 000 cmil 709 . 1.364 1.364 1.323 1.282 1.100 4 323 6 435 0.00756 0.0248

1 300 000 cmil 659 . 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.