ASTM B778-97

(Specification)Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors (AAC/TW)

Standard Specification for Shaped Wire Compact Concentric-Lay-Stranded Aluminum Conductors (AAC/TW)

SCOPE

1.1 This specification covers shaped wire compact concentric-lay-stranded aluminum conductor (AAC/TW) and its component wires for use as overhead electrical conductors (Explanatory Notes 1 and 2).

1.2 The values stated in inch-pound units are to be regarded as the standard with the exception of temperature and resistivity. The SI equivalents of inch-pound units may be approximate. Note 1-AAC/TW is designed to increase the aluminum area for a given diameter of conductor by the use of trapezoidally shaped wires (TW). The conductors consist of a central core of one round aluminum wire or a seven-strand compact round core surrounded by two or more layers of trapezoidal aluminum 1350-H19 wires. For the purposes of this specification, the sizes listed are tabulated on the basis of the finished conductor having an area equal to that of specific sizes of standard AAC (Table 1) or in fixed diameter increments (Table 2) so as to facilitate conductor selection. Note 2-The aluminum and temper designations conform to ANSI Standard H35.1. Aluminum 1350 corresponds to Unified Numbering System (UNS) A91350 in accordance with Practice E527.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 778 – 97

Standard Specification for

Shaped Wire Compact Concentric-Lay-Stranded Aluminum

Conductors (AAC/TW)

This standard is issued under the fixed designation B 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

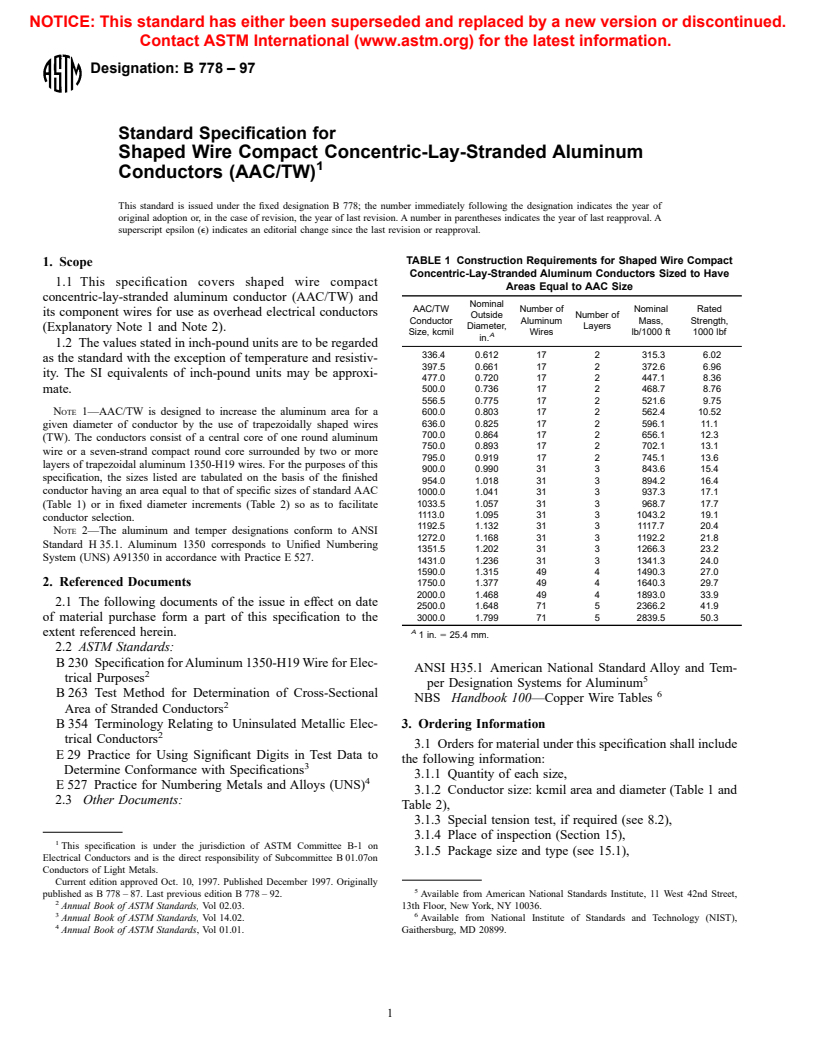

TABLE 1 Construction Requirements for Shaped Wire Compact

1. Scope

Concentric-Lay-Stranded Aluminum Conductors Sized to Have

1.1 This specification covers shaped wire compact

Areas Equal to AAC Size

concentric-lay-stranded aluminum conductor (AAC/TW) and

Nominal

AAC/TW Number of Nominal Rated

its component wires for use as overhead electrical conductors

Outside Number of

Conductor Aluminum Mass, Strength,

Diameter, Layers

(Explanatory Note 1 and Note 2).

Size, kcmil Wires lb/1000 ft 1000 lbf

A

in.

1.2 The values stated in inch-pound units are to be regarded

336.4 0.612 17 2 315.3 6.02

as the standard with the exception of temperature and resistiv-

397.5 0.661 17 2 372.6 6.96

ity. The SI equivalents of inch-pound units may be approxi-

477.0 0.720 17 2 447.1 8.36

mate. 500.0 0.736 17 2 468.7 8.76

556.5 0.775 17 2 521.6 9.75

NOTE 1—AAC/TW is designed to increase the aluminum area for a

600.0 0.803 17 2 562.4 10.52

636.0 0.825 17 2 596.1 11.1

given diameter of conductor by the use of trapezoidally shaped wires

700.0 0.864 17 2 656.1 12.3

(TW). The conductors consist of a central core of one round aluminum

750.0 0.893 17 2 702.1 13.1

wire or a seven-strand compact round core surrounded by two or more

795.0 0.919 17 2 745.1 13.6

layers of trapezoidal aluminum 1350-H19 wires. For the purposes of this

900.0 0.990 31 3 843.6 15.4

specification, the sizes listed are tabulated on the basis of the finished

954.0 1.018 31 3 894.2 16.4

conductor having an area equal to that of specific sizes of standard AAC

1000.0 1.041 31 3 937.3 17.1

1033.5 1.057 31 3 968.7 17.7

(Table 1) or in fixed diameter increments (Table 2) so as to facilitate

1113.0 1.095 31 3 1043.2 19.1

conductor selection.

1192.5 1.132 31 3 1117.7 20.4

NOTE 2—The aluminum and temper designations conform to ANSI

1272.0 1.168 31 3 1192.2 21.8

Standard H 35.1. Aluminum 1350 corresponds to Unified Numbering

1351.5 1.202 31 3 1266.3 23.2

System (UNS) A91350 in accordance with Practice E 527.

1431.0 1.236 31 3 1341.3 24.0

1590.0 1.315 49 4 1490.3 27.0

2. Referenced Documents 1750.0 1.377 49 4 1640.3 29.7

2000.0 1.468 49 4 1893.0 33.9

2.1 The following documents of the issue in effect on date

2500.0 1.648 71 5 2366.2 41.9

of material purchase form a part of this specification to the 3000.0 1.799 71 5 2839.5 50.3

A

extent referenced herein.

1 in. 5 25.4 mm.

2.2 ASTM Standards:

B 230 Specification for Aluminum 1350-H19 Wire for Elec-

ANSI H35.1 American National Standard Alloy and Tem-

trical Purposes 5

per Designation Systems for Aluminum

B 263 Test Method for Determination of Cross-Sectional

NBS Handbook 100—Copper Wire Tables

Area of Stranded Conductors

B 354 Terminology Relating to Uninsulated Metallic Elec-

3. Ordering Information

trical Conductors

3.1 Orders for material under this specification shall include

E 29 Practice for Using Significant Digits in Test Data to

the following information:

Determine Conformance with Specifications

3.1.1 Quantity of each size,

E 527 Practice for Numbering Metals and Alloys (UNS)

3.1.2 Conductor size: kcmil area and diameter (Table 1 and

2.3 Other Documents:

Table 2),

3.1.3 Special tension test, if required (see 8.2),

3.1.4 Place of inspection (Section 15),

This specification is under the jurisdiction of ASTM Committee B-1 on

3.1.5 Package size and type (see 15.1),

Electrical Conductors and is the direct responsibility of Subcommittee B 01.07on

Conductors of Light Metals.

Current edition approved Oct. 10, 1997. Published December 1997. Originally

published as B 778 – 87. Last previous edition B 778 – 92. Available from American National Standards Institute, 11 West 42nd Street,

Annual Book of ASTM Standards, Vol 02.03. 13th Floor, New York, NY 10036.

3 6

Annual Book of ASTM Standards, Vol 14.02. Available from National Institute of Standards and Technology (NIST),

Annual Book of ASTM Standards, Vol 01.01. Gaithersburg, MD 20899.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 778

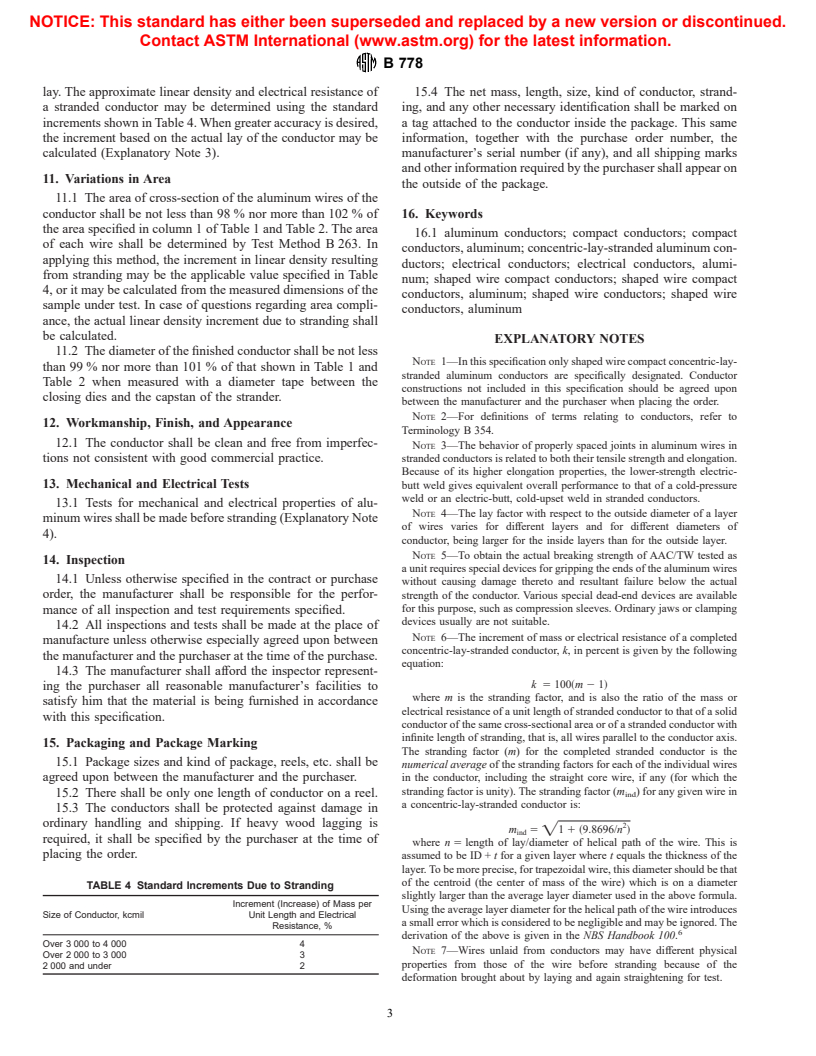

TABLE 2 Construction Requirements for Shaped Wire Compact

6.4 The direction of lay of the outside layer of aluminum

Concentric-Lay-Stranded Aluminum Conductors, in

wires shall be right-hand.

Fixed-Diameter Increments

6.5 The direction of lay of the aluminum wires shall be

Nominal

AAC/TW Number of Nominal Rated reversed in successive layers.

Outside Number of

Conductor Aluminum Mass, Strength,

6.6 For the purpose of this specification the lay factor is the

Diameter, Layers

Size, kcmil Wires lb/1000 ft 1000 lbf

in.

length of lay of a given layer divided by its outside diameter.

322.5 0.60 17 2 302.3 5.88

7. Construction

384.5 0.65 17 2 360.4 6.74

449.4 0.70 17 2 421.2 7.88

7.1 The nominal aluminum cross-sectional area, the outside

521.7 0.75 17 2 489.0 9.14

diameter, the nominal number of aluminum wires, the number

595.8 0.80 17 2 558.4 10.44

678.2 0.85 17 2 635.7 11.88

of layers, the linear density, and the rated strength, of the

761.5 0.90 17 2 713.7 13.07

shaped wire compact concentric-lay-stranded aluminum con-

854.2 0.95 17 2 800.6 14.86

918.8 1.00 31 3 861.2 15.76 ductors, shall be as shown in Table 1 and Table 2.

1020.0 1.05 31 3 956.0 17.50

NOTE 3—Exception to 7.1. Because the final design of a shaped wire

1123.1 1.10 31 3 1052.7 19.26

1234.2 1.15 31 3 1156.8 21.17 compact conductor is contingent on several factors such as layer diameter,

1346.8 1.20 31 3 1262.3 23.10

wire width and thickness, and the like, the actual configuration of a given

1467.9 1.25 31 3 1375.9 24.65

size may vary between manufacturers. This might result in a slight

1583.2 1.30 34 3 1483.9 26.59

variation in the number of wires and number of layers, from that shown in

1682.7 1.35 49 4 1577.5 28.55

Table 1 and Table 2, and also in the dimensions of the individual wires.

1812.7 1.40 49 4 1699.0 30.74

1954.3 1.45 49 4 1832.1 33.16

8. Rated Strength of Conductor

2093.6 1.50 49 4 1981.6 35.51

2245.4 1.55 49 4 2125.7 37.30

8.1 The rated strength of a conductor, as shown in Table 1

2388.1 1.60 52 4 2260.3 39.67

2514.8 1.65 71 5 2379.5 42.17 and Table 2, shall be taken as the percentage, indicated in Table

2667.2 1.70 71 5 2524.5 44.74

3, in accordance with the number of aluminum layers, of the

2844.5 1.75 71 5 2692.2 47.70

sum of the wire strengths calculated from the specified

3006.2 1.80 71 5 2873.0 50.43

diameter of the round wires having the same area as the

trapezoidal wires used in the manufacture of the conductor, and

the appropriate minimum average tensile strength given in

3.1.6 Special package markings, if required (Section 15),

Specification B 230.

and

8.1.1 The rated strengths of conductors calculated in accor-

3.1.7 Heavy wood lagging, if required (see 15.3).

dance with 8.1 and 8.3 are listed in Table 1 and Table 2.

4. Requirement for Wires 8.2 Tests to confirm that the rated strength of the conductor

is met are not required by this specification, but shall be made

4.1 Before stranding, the trapezoidal aluminum wires shall

if agreed upon between the manufacturer and the purchaser at

conform to the requirements of Specification B 230 except for

the time of placing an order. When tested, the breaking strength

shape and diameter tolerance. The tensile strength and elonga-

of the conductor shall be not less than the rated strength if

tion requirements of trapezoidal wires shall be the same as for

failure occurs in the free length at least 1 in. (25 mm) beyond

round wires of equal area. The area tolerances shall be such

the end of either gripping device, or shall be not less than 95 %

that the finished conductor conforms to Section 11.

of the rated strength if failure occurs inside or within 1 in. of

5. Joints

the end of either gripping device (Explanatory Note 2).

8.3 Rated strength and breaking strength values shall be

5.1 Electric-butt welds, electric-butt cold-upset welds, or

rounded to three significant figures in the final value only, in

cold-pressure welds may be made in the individual aluminum

accordance with Practice E 29.

wires during the stranding process. No weld shall occur within

50 ft (15 m) of any other weld in the completed conductor

9. Density

(Explanatory Note 3).

9.1 For the purpose of calculating mass per unit length,

6. Lay cross-sections, and the like, the density of aluminum 1350 shall

3 3

be taken as 0.0975 lb/in. (2705 kg/m ) at 20°C.

6.1 The preferred lay of the outside layer of aluminum wires

of shaped wire aluminum conductors, having multiple layers of

10. Mass and Electrical Resistance

aluminum wires is 11 times the outside diameter of the

10.1 The mass per unit length and electrical resistance of a

conductor but the lay shall not be less than 10 nor more tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.