ASTM C1367-06(2012)

(Test Method)Standard Test Method for Dead Load Resistance of a Sealant in Elevated Temperatures

Standard Test Method for Dead Load Resistance of a Sealant in Elevated Temperatures

SIGNIFICANCE AND USE

Sealants are generally subjected to stresses in end-use applications. This test method measures the heat resistance of sealants when subjected to dead load shear stresses while under heat.

SCOPE

1.1 This test method covers a laboratory procedure for determining the heat resistance of sealants. This test method is conducted under dead load in a shear mode. This test method was previously written to include only hot applied sealants.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are provided for information purposes only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.4 The subcommittee with jurisdiction of this standard is not aware of any similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1367 − 06 (Reapproved 2012)

Standard Test Method for

Dead Load Resistance of a Sealant in Elevated

Temperatures

This standard is issued under the fixed designation C1367; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions of Terms Specific to This Standard—

Definitions of the following terms used in this test method are

1.1 This test method covers a laboratory procedure for

found in Terminology C717, 4.2: applicator and specified

determining the heat resistance of sealants. This test method is

temperature.

conducted under dead load in a shear mode. This test method

was previously written to include only hot applied sealants.

4. Summary of Test Method

1.2 The values stated in SI units are to be regarded as the 4.1 The sealant is placed between glass and aluminum

substrates. The specimen conditioning time is recorded. The

standard. The values given in parentheses are provided for

information purposes only. specimen is heated in shear mode with a weight suspended

from the specimen. The weight applied and the time that it

1.3 This standard does not purport to address all of the

takes for the specimen to fail is recorded.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Sealants are generally subjected to stresses in end-use

bility of regulatory limitations prior to use.

applications. This test method measures the heat resistance of

1.4 The subcommittee with jurisdiction of this standard is

sealantswhensubjectedtodeadloadshearstresseswhileunder

not aware of any similar or equivalent ISO standard.

heat.

6. Apparatus

2. Referenced Documents

2 6.1 Sealant Applicator or Oven, capable of maintaining the

2.1 ASTM Standards:

sealant within 62.8°C (65°F) of the specified temperature.

B209 Specification for Aluminum and Aluminum-Alloy

Sheet and Plate 6.2 Substrates:

C717 Terminology of Building Seals and Sealants

6.2.1 Annealed glass that is 25.4 mm wide by 76.2 mm long

C1036 Specification for Flat Glass and 6.35 mm thick (1 in. by 3 in. by 0.25 in.). (See

C1375 Guide for Substrates Used in Testing Building Seals

Specification C1036.)

and Sealants 6.2.2 Aluminum alloy 5052-H32 that is 25.4 mm wide by

76.2 mm long and 0.508 mm thick (1 in. by 3 in. by 0.020 in.).

3. Terminology (See Specification B209.)

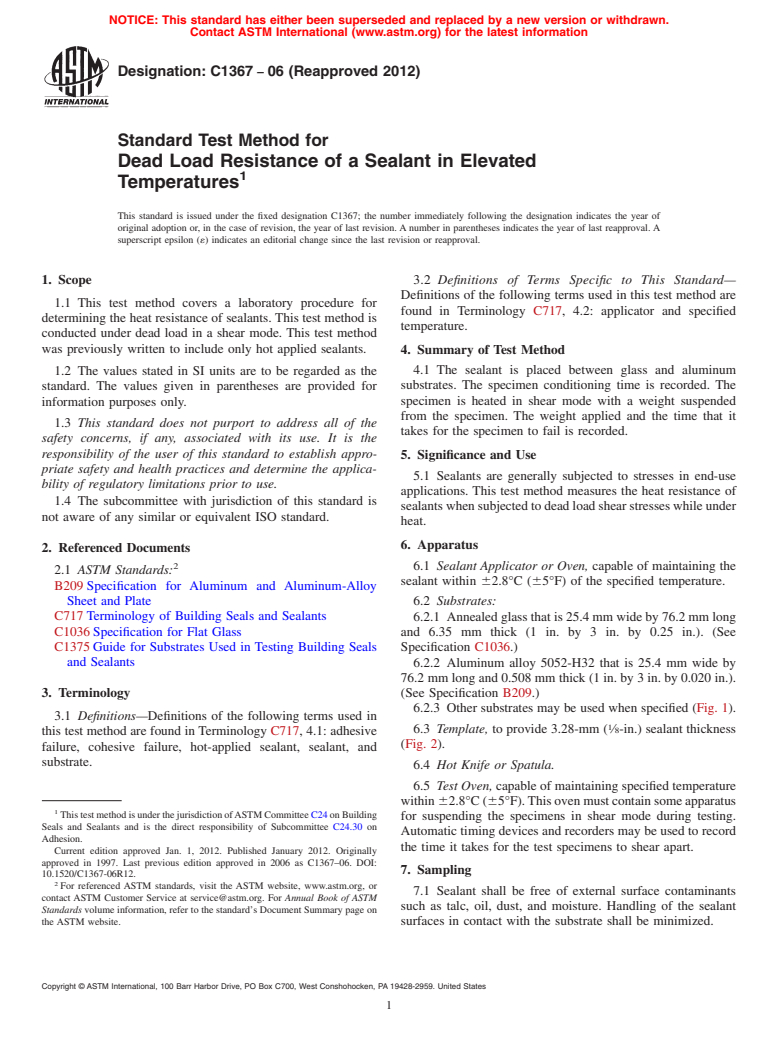

6.2.3 Other substrates may be used when specified (Fig. 1).

3.1 Definitions—Definitions of the following terms used in

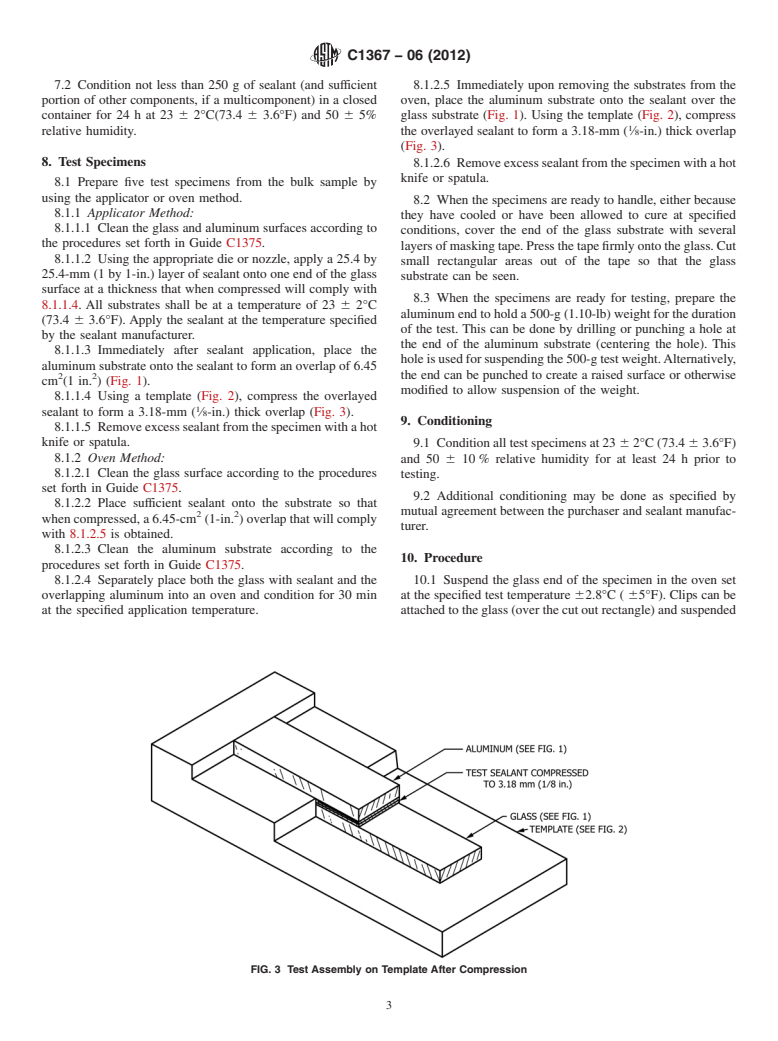

6.3 Template, to provide 3.28-mm ( ⁄8-in.) sealant thickness

this test method are found in Terminology C717, 4.1: adhesive

(Fig. 2).

failure, cohesive failure, hot-applied sealant, sealant, and

substrate.

6.4 Hot Knife or Spatula.

6.5 Test Oven, capable of maintaining specified temperature

within 62.8°C(65°F).Thisovenmustcontainsomeapparatus

ThistestmethodisunderthejurisdictionofASTMCommitteeC24onBuilding

for suspending the specimens in shear mode during testing.

Seals and Sealants and is the direct responsibility of Subcommittee C24.30 on

Automatic timing devices and recorders may be used to record

Adhesion.

the time it takes for the test specimens to shear apart.

Current edition approved Jan. 1, 2012. Published January 2012. Originally

approved in 1997. Last previous edition approved in 2006 as C1367–06. DOI:

7. Sampling

10.1520/C1367-06R12.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Sealant shall be free of external surface contaminants

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

such as talc, oil, dust, and moisture. Handling of the sealant

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. surfaces in contact with the substrate shall be minimized.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1367 − 06 (2012)

FIG. 1 Assembly of Test Sealant on Substrates

NOTE 1—The template shall be made of a material of low thermal

conductivity, such as wood or fiberglass.

FIG. 2 Template

C1367 − 06 (2012)

7.2 Condition not less than 250 g of sealant (and sufficient 8.1.2.5 Immediately upon removing the substrates from the

portion of other components, if a multicomponent) in a closed oven, place the aluminum substrate onto the sealant over the

container for 24 h at 23 6 2°C(73.4 6 3.6°F) and 50 6 5% glass substrate (Fig. 1). Using the template (Fig. 2), compress

relative humidity. the overlayed sealant to form a 3.18-mm ( ⁄8-in.) thick overlap

(Fig. 3).

8. Test Specimens

8.1.2.6 Removeexcesssealantfromthespecimenwithahot

knife or spatula.

8.1 Prepare five test specimens from the bulk sample by

using the applicator or oven method.

8.2 When the specimens are ready to handle, either because

8.1.1 Applicator Method:

they have cooled or have been allowed to cure at specified

8.1.1.1 Clean the glass and aluminum surfaces according to

conditions, cover the end of the glass substrate with several

the procedures set forth in Guide C1375.

layersofmaskingtape.Pressthetapefirmlyontotheglass.Cut

8.1.1.2 Using the appropriate die or nozzle, apply a 25.4 by

small rectangular areas out of the tape so that the glass

25.4-mm (1 by 1-in.) layer of sealant onto one end of the glass

substrate can be seen.

surface at a thickness that when compressed will comply with

8.3 When the specimens are ready for testing, pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.